Subsoil compaction caused by machinery traffic on a Swedish Eutric Cambisol at different soil water...

-

Upload

ranjeetkumar22 -

Category

Documents

-

view

32 -

download

3

Transcript of Subsoil compaction caused by machinery traffic on a Swedish Eutric Cambisol at different soil water...

Soil & Tillage Research 73 (2003) 107–118

Subsoil compaction caused by machinery traffic on a SwedishEutric Cambisol at different soil water contents

A. Trautner∗, J. ArvidssonDepartment of Soil Sciences, Swedish University of Agricultural Sciences, Box 7014, SE 75007 Uppsala, Sweden

Abstract

Field traffic may reduce the amount of air-filled pores and cavities in the soil thus affecting a large range of physical soilproperties and processes, such as infiltration, soil water flow and water retention. Furthermore, soil compaction may increasethe mechanical strength of the soil and thereby impede root growth.

The objective of this research was to test the hypotheses that: (1) the degree of soil displacement during field traffic dependslargely on the soil water content, and (2) the depth to which the soil is displaced during field traffic can be predicted onthe basis of the soil precompression stress and calculated soil stresses. In 1999, field measurements were carried out on aSwedish swelling/shrinking clay loam of stresses and vertical soil displacement during traffic with wheel loads of 2, 3, 5 and7 Mg at soil water contents of between 11 and 35% (w/w). This was combined with determinations of soil precompressionstress at the time of the traffic and predictions of the soil compaction with the soil compaction model SOCOMO. Vertical soildisplacement increased with increased axle load. In May, the soil precompression stress was approximately 100 kPa at 0.3,0.5 and 0.7 m depth. In August and September, the soil precompression stress at 0.3, 0.5 and 0.7 m depth was 550–1245 kPa.However, when traffic with a wheel load of 7 Mg was applied, the soil displacements at 0.5 m depth were several times largerin August and September than in May, and even more at 0.7 m depth. An implication of the results is that the precompressionstress does not always provide a good indication of the risk for subsoil compaction. A practical consequence is that subsoilcompaction in some soils may occur even when the soil is very dry. The SOCOMO model predicted the soil displacementrelatively well when the soil precompression stress was low. However, for all other wheeling treatments, the model failed topredict that any soil compaction would occur, even at high axle loads.

The measured soil stresses were generally higher than the stresses calculated with the SOCOMO model. Neither theapplication of a parabolic surface load distribution nor an increased concentration factor could account for this difference.This was probably because the stress distribution in a very dry and strongly structured soil is different from the stressdistribution in more homogeneous soils.© 2003 Elsevier B.V. All rights reserved.

Keywords:Subsoil compaction; Soil stress; Precompression stress; Water content; Traffic treatment; Compaction model; Eutric Cambisol;Sweden

∗ Corresponding author. Present address: Frodesvej 6, 2880Bagsværd, Denmark.E-mail address:[email protected] (A. Trautner).

1. Introduction

Field traffic using vehicles with high axle loads islikely to compact the soil below the plough layer.Compaction of the subsoil should be avoided since soilproductivity is at risk of being reduced, and becausethe effects are very persistent, perhaps even permanent

0167-1987/$ – see front matter © 2003 Elsevier B.V. All rights reserved.doi:10.1016/S0167-1987(03)00104-1

108 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

(Håkansson and Reeder, 1994). Mechanical looseningto improve the structure of the subsoil is expensive andhas often proved unsuccessful, and in some cases theeffect can even be negative (Håkansson and Reeder,1994).

Söhne (1958)calculated the pressure distributionunder wheels by a process based on the semi-empiricalformulas ofFrölich (1934)and concluded: “The pres-sure in the upper soil layer is determined by the spe-cific pressure at the surface. . . The pressure in thedeeper soil layers is determined by the amount ofthe load”. This is supported by experimental results.Lebert et al. (1989)found that vertical stresses couldbe reduced in the topsoil by using larger wheels, butin the subsoil the reduction was less significant.Yanget al. (1991)applied a load of 208 kg on a singlewheel and 467 kg using dual wheels, thus maintainingthe same surface pressure. The soil was compactedto a depth of 35 cm beneath the dual wheel with thelarger wheel load and to 25 cm depth beneath thesingle wheel with the lower wheel load. In field ex-periments using axle loads exceeding 8 Mg,Danfors(1994)reduced the compaction of moist clay soils inthe 0.3–0.4 m layer by reducing the inflation pressurefrom 150 to 50 kPa, but not at greater depth.

In Sweden, a general recommendation to limit theload to 6 Mg per axle has been given to farmers since1974 (Håkansson and Danfors, 1981). Van den Akker(1994)suggests recommending limits for permissiblewheel loads and tire inflation pressures depending onthe mechanical properties of the subsoil.

In 1999, a project was started in Sweden to developlocal recommendations for farmers regarding the max-imum permissible combinations of axle load and tireinflation pressure on different soils at different timesof the year. Within that project, measurements of ver-tical stress and soil displacement during traffic at dif-ferent soil water contents were made using a tech-nique developed byArvidsson and Andersson (1997).

Table 1Particle size distribution, organic matter content and dry bulk density content at the experimental site, Ultuna (the bulk density wasmeasured on 11 June 1999)

Depth (mm) <0.002 mm (g kg−1) 0.002–0.006 mm (g kg−1) >0.06 mm (g kg−1) Organic matter (g kg−1) Bulk density (Mg m−3)

100 400 397 184 20300 533 386 79 2 1.60500 454 469 78 0 1.46700 435 442 122 0 1.46

In 1999, measurements of stresses and vertical soildisplacement during field traffic were combined withdeterminations of soil precompression stress of soilcores sampled at the time of the traffic and predic-tions of the soil compaction with the analytical soilcompaction model SOCOMO (Van den Akker, 1988).The objective was to test the hypotheses that: (1) thedegree of soil compaction during field traffic dependslargely on the soil water content, and (2) the depth towhich the soil is compacted during wheeling can bepredicted on the basis of soil mechanical propertiesand calculation of soil stresses.

In the present paper, the main results obtained in1999 are summarized.

2. Materials and methods

2.1. Experimental site

The experimental site was established at Ultuna(59◦49′N, 17◦39′E) near Uppsala, Sweden. The soilwas a swelling/shrinking clay loam (40% clay in100 mm depth) classified as a Eutric Cambisol, withparticle size distribution and bulk density as shown inTable 1.

The experimental site was ploughed in the autumnof 1998. After harrowing at the beginning of May1999, wheat (Triticum spp.) was sown. Measurementsof wheeling effects were carried out at actual soil watercontent on 11 May, 8 June, 15 July, 14 August, 10September, 27 October and 1 December.

Weather data (Table 2) were obtained from the me-teorological station at Ultuna, about 1 km from the site.

2.2. Traffic experiment

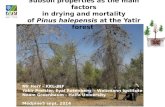

A tractor-towed trailer was constructed to applytraffic with controlled axle loads (Fig. 1). It could be

A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118 109

Table 2Monthly precipitation at the meteorological station at Ultuna, in1999 and for 1961–1990

1999 (mm) Mean of 1961–1990 (mm)

April 82.9 29.3May 15.4 32.8June 32.6 45.9July 11.9 70.5August 32.8 66.4September 68.4 57.0October 25.6 49.6November 9.2 50.6

loaded from 2 up to 7 Mg on the right wheel, which ranoutside the rut created by the tractor wheels. This wasdone to avoid compacting the soil before the passage ofthe trailer wheel. The trailer was equipped with Trelle-borg TWIN 700-26.5 tires. On each wheeling treat-ment, wheel loads of 2, 3, 5 and 7 Mg were applied.Each wheel load was applied on soil not disturbed byprevious traffic treatments. The inflation pressure was140 kPa with wheel loads of 2, 3 and 5 Mg and 240 kPawith 7 Mg wheel load.

The contact area on a hard surface was measured byparking the wheel on cloth and spraying paint around

Fig. 1. The tractor-towed trailer used for applying traffic with controlled axle loads. It could be loaded from 2 up to 7 Mg on the rightwheel, running outside the rut created by the tractor wheels. The markers in the soil in front of the trailer wheel indicated the position ofthe measuring equipment installed laterally from a pit (at the far left) into the soil.

Fig. 2. Displacement sensor with a pressure cell attached on top. A1095 mm long steel rod is attached to the head. The probe isinstalled horizontally into the soil and registers soil vertical stressand movement simultaneously.

the tire. The contact area was thereafter cut out of thecloth, and transferred to paper that was then weighedto calculate the area.

2.3. Soil displacement and stress measurements

Soil vertical displacement during wheeling wasmeasured as described byArvidsson and Andersson(1997). The technique is based on the principle thatthe pressure of a liquid column is proportional to itsheight. The probe contains a Plexiglas body (length70 mm, width 35 mm, height 36 mm) filled withsilicone-oil (Fig. 2). The oil is connected through ahose to a pressure transducer. Vertical movement of

110 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

the cylinder changes the height of the oil-column andthe output signal of the pressure transducer. The trans-ducer can measure a displacement of 102 mm with arepeatability of 0.1 mm (Arvidsson and Andersson,1997). A load cell was mounted on top of the probecylinder to measure the normal vertical soil stressduring wheeling. The probe-head was attached to a1095 mm long steel rod. Each probe was installedinto the soil through a borehole approximately 1 mlong with a radius of 60 mm. The hole was drilledhorizontally from a dug pit, and a steel tube with thesame diameter as the hole was inserted to stabilizethe hole. At the end of the hole, a square reamer(35 mm×35 mm) removed 100 mm of soil so that thecylinder would be firmly embedded in soil relativelyundisturbed by the installation procedure. Before eachwheeling treatment, probes were installed at 0.3, 0.5and 0.7 m depth under the centerline of the wheel rut(Fig. 1).

2.4. Soil water content and precompression stress

For each wheeling treatment, the gravimetric soilwater content was determined to 1 m depth by sam-pling soil at intervals of 0.1 m. The soil plastic limit(PL) was determined according to theBritish Standard1377 (1975)with five replicates per depth.

At 0.3, 0.5 and 0.7 m depth, two undisturbed soilcores (25 mm in height, 72 mm in diameter) were sam-pled per depth for determination of the soil precom-pression stress at the time of each wheeling. Uniaxialloading of the soil cores was carried out at the actualsoil water content, in most cases in an oedometer de-scribed byEriksson (1974). Stresses of 12.5, 25, 50,100, 150, 200, 400 and 800 were applied sequentially,each for 30 min after which the strain was determined.The soil cores sampled on 10 September were testedin a “Universal-Prüfpresse” UP 100. Stresses of 13,50, 75, 100, 150, 200, 400, 800, 1000, 1600, 3200 and4800 kPa were applied sequentially. Each stress wasapplied for 30 min before the amount of strain was de-termined. The precompression stress was determinedaccording toCasagrande (1936).

2.5. Soil compaction modeling

The analytic soil compaction model SOCOMO (Vanden Akker, 1988) was used to predict the depth to

which soil compaction would occur. The model isbased on the theory of J.V. Boussinesq, described bySöhne (1958). With SOCOMO, the major and minorprincipal soil stresses were calculated for each wheelload and contact area for a uniformly distributed sur-face load and a parabolic surface load (Fig. 3). Thepower for the parabolic in the driving direction and inthe cross-section was set to 2 and 3, respectively, andthe ratio of the maximum stress under the sides of thetire footprint to the maximum stress of the center ofthe tire footprint was 0.8 (Van den Akker, 1994). Con-centration factors of 4 and 6 were used for hard andsoft soil, respectively (Koolen and Kuipers, 1983).

The failure criterion used by SOCOMO to predictto which depth the soil would be compacted was thatthe calculated major stress was higher than the pre-compression stress of the soil.

3. Results

3.1. Soil water content

The whole experimental period except Septemberhad considerably less precipitation than normal, withmonthly rainfall of between 17 and 71% of the 30-yearaverage. The precipitation in April 1999 (82.9 mm)was well above 30-year average (29.3 mm). There-fore, during the wheeling treatment on 11 May, thesoil water content was near field capacity, except inthe surface layer, and was the highest recorded for theseven wheeling treatments. It was nearly the same asthe PL of the soil (Fig. 4). During the summer, theprecipitation was well below the 30-year average andthe soil water content decreased. In the autumn, espe-cially after a rainy September where the precipitationwas 120% of the 30-year average, the soil water con-tent increased but did not reach the same level as onthe first wheeling treatment on 11 May.

3.2. Soil precompression stress

The soil precompression stress was greatly influ-enced by the soil water content. On the first wheelingoccasion in May, when soil was near field capacity, thesoil precompression stress was approximately 100 kPaat 0.3, 0.5 and 0.7 m depth. The precompressionstress increased during the summer, and decreased

A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118 111

Fig. 3. A parabolic surface load distribution calculated with the SOCOMO model for a wheel load of 7 Mg. The power for the parabolic inthe driving direction and cross-section was 2 and 3, respectively, and the ratio of the maximum stress under the sides of the tire footprintto the maximum stress of the center of the tire footprint 0.8.

Fig. 4. Soil water content for seven wheeling treatments during 1999. In addition, the soil PL is shown. 1= 11 May; 2 = 8 June;3 = 15 July; 4= 14 August; 5= 10 September; 6= 27 October; 7= 1 December.

112 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

Fig. 5. An example of the relationship obtained between bulk density and applied uniaxial stress. This sample was from the 0.7 m depthon 10 September 1999.

after September. In August, the precompression stresswas above 580 kPa at all depths, while in Septem-ber, the precompression stress at 0.7 m depth wasnearly 1000 kPa and at 0.3 m depth, 1245 kPa.Fig. 5shows an example of the relationship between bulkdensity and the applied stress. The soil sample wastaken at 0.7 m depth, and the precompression stressdetermined to approximately 1200 kPa.

3.3. Contact area

The average ground contact stress was calculatedfrom the axle load and the measured contact area ona hard surface (Table 3). For all loads, the calculatedaverage ground contact stress was close to the inflationpressure.

Table 3The measured contact area on a hard surface by different axle loadsof the trailer used in the experiments, and the calculated averagecontact area stress (the tire was a Trelleborg TWIN 700-26.5)

Axle load(Mg)

Inflationpressure (kPa)

Contactarea (m2)

Average groundcontact stress (kPa)

4 140 0.156 1286 140 0.197 1528 140 0.293 137

10 140 0.343 14614 240 0.285 246

The contact area in the field did not differ muchfrom the contact area measured on hard surface be-cause the ruts after each traffic treatment were small(Fig. 1).

3.4. Normal vertical soil stress

Two criterions were used to filter the measured nor-mal vertical stresses. Data was disregarded if (1) thenormal vertical stress was null, or (2) the normal ver-tical stress was lower than the stress measured in thehorizontal soil layer below. In this experiment, ap-proximately 30% of the stress measurements had tobe disregarded after each traffic treatment.

Fig. 6 shows the normal vertical stresses below atire load of 7 Mg measured at 0.3, 0.5 and 0.7 m depthduring seven traffic treatments. The tendency was forthe normal vertical stress to be the largest when thesoil was dry. At 0.3 m depth, the normal vertical stressmeasured in July and September were above 600 kPa,while in May, June, October and December it was ap-proximately 400 kPa.Fig. 6 also presents the normalvertical soil stresses below a uniformly distributed sur-face load (Table 3) and a parabolic surface load distri-bution (Fig. 3) calculated with the SOCOMO model.Concentration factors of 4 and 6 were applied for bothsurface load distributions. The highest calculated soil

A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118 113

Fig. 6. Normal vertical soil stresses measured at 0.3, 0.5 and 0.7 m depth in seven wheeling treatments during 1999. The wheel load was7 Mg. Calculations by SOCOMO of the normal vertical soil stresses below a uniformly distributed load and a parabolic stress distributionmodel using two concentration factors,ν = 4 and 6, are shown.

stress was found when a parabolic surface load distri-bution and a concentration factor of 6 were assumed(258, 167 and 112 kPa at 0.3, 0.5 and 0.7 m depth, re-spectively), but the measured soil stresses were muchhigher, especially at 0.3 m depth where the measuredsoil stresses ranged from 390 to 650 kPa.

The measured normal vertical soil stress was in gen-eral high (Fig. 7). It varied considerably, but generallyincreased with the axle load. Even when a parabolicsurface load distribution and a concentration factorof 6 were applied, calculations of the vertical normalstresses by the SOCOMO model were generally low

compared to the measured stresses, especially at 0.3 mdepth.

3.5. Soil vertical displacement

The soil vertical displacements measured duringtraffic with four different axle loads on seven treat-ments are presented along with the soil precompres-sion stress and soil water content inTable 4. Thevertical soil displacement during field traffic withwheel loads of 2, 3, 5 and 7 Mg increased with thewheel load. In all treatments, axle loads of 2, 3, 5 and

114 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

Fig. 7. The soil stress at 0.3, 0.5 and 0.7 m depth below wheel loads of 2, 3, 5 and 7 Mg, recorded at seven wheeling treatments: 1= 11May; 2 = 8 June; 3= 15 July; 4= 14 August; 5= 10 September; 6= 27 October; 7= 1 December. The soil stresses calculated bySOCOMO are also presented.

A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118 115

Table 4Water content, precompression stress and vertical soil displacement at seven traffic treatments, Ultuna, Sweden in 1999

Date Depth(m)

Water content(%, w/w)

Precompressionstress (kPa)

Vertical soil displacement (mm)

2 Mg wheelload

3 Mg wheelload

5 Mg wheelload

7 Mg wheelload

11 May 1999 0.30 23 105 −0.9 −1.5 −1.2 −7.00.50 25 97 0.0 −0.1 −0.5 −0.40.70 29 97 0.0 0.0 −0.2 0.0

8 June 1999 0.30 20 183 −0.4 −0.7a −1.5a −2.70.50 21 136 0.0 −0.2a −0.1a −0.60.70 25 178 0.0 −0.1a −0.0a −0.2

15 July 1999 0.30 18 331 −0.2 –b – −2.10.50 19 263 −0.1 −0.2 −0.5 −0.60.70 19 232 0.0 −0.1 −0.3 −0.3

14 August 1999 0.30 14 610 −0.2 −0.2 −0.5 −3.20.50 18 653 −0.1 −0.2 −0.5 −1.00.70 20 582 −0.1 0.0 −0.2 −0.7

10 September 1999 0.30 19 1245 – −0.3 −1.1 −2.00.50 18 550 −0.1 – −0.5 −1.90.70 19 944 0.0 – −0.2 −0.7

27 October 1999 0.30 22 200 −0.4 −1.2 −1.8 −3.20.50 20 355 −0.1 −0.1 −0.5 −0.80.70 22 299 0.0 0.0 −0.2 −0.5

1 December 1999 0.30 21 126 −0.1 −1.1a −2.8a −3.4a

0.50 22 89 −0.1 −0.9a −0.6a −0.8a

0.70 28 316 0.0 −0.1a −0.0a −0.4a

a Average of two measurements.b Missing value.

7 Mg caused vertical soil displacement (0.1–7.0 mm)at 0.3 m depth, and, apart from the treatments on 8May and 11 June, also at 0.5 m depth (0.1–1.9 mm).The vertical soil displacement tended to be thelargest when the soil was dry and rigid. For exam-ple, in August and September the soil displacementat 0.7 m depth was 1.0 and 1.9 mm, respectively,whereas in May and June it was 0 and 0.2 mm,respectively.

3.6. Predicting the soil compaction

The model calculation showed that on 11 May, withwheel loads of 2, 3, 5 and 7 Mg, the soil stress ex-ceeded the soil strength at 0.3, 0.4, 0.5 and 0.8 m depth,respectively. This corresponded relatively well withthe measured soil displacement. However, on all otherwheeling treatments, the model failed to predict thatthe soil would be compacted by the wheeling, even at

high axle loads. The failure criterion used was that thecalculated major stress was higher than the precom-pression stress of the soil.

4. Discussion

4.1. Soil precompression strength

The precompression stress reflected the soil watercontent and the precipitation data well. After the deter-mination of the soil precompression stress on 14 Au-gust, it became apparent that if the soil got any drierthan the 14% water content (w/w) recorded at thattime, the stress range used would be too limited fora determination of the virgin compression line, whichis necessary for the determination of the soil precom-pression stress. Therefore, on 10 September the stressrange was increased to 4800 kPa. Even so, the virgin

116 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

compression line was derived from only a few points,since the soil precompression stress was higher than1000 kPa (Fig. 5).

The soil displacement clearly increased with thewheel load in all treatments. It was found that rel-atively low wheel loads could cause vertical soildisplacement at large depths, even when the soil wasdry and the soil precompression stress well above500 kPa; all wheeling treatments with wheel loadsof 3 Mg resulted in soil displacement at 0.5 m depth,and in 50% of the all measurements even to a depthof 0.7 m. This was in contradiction to an earlier ex-periment (Arvidsson and Trautner, 1998), where aftersimilar field measurements on a sandy clay loam itwas concluded that, “the soil moisture content wasthe most decisive factor for the soil deformation”.It this experiment, the soil displacement tended tobe larger when the soil precompression stress washigh. The explanation for this is likely to be foundin the swelling/shrinking properties of the soil. In thetopsoil, large solid clods with 2–5 cm wide cracks inbetween were formed as the soil dried out. Clods upto 0.4 m in diameter were observed. In the subsoil themost obvious crack system was some vertical cracksthat were several mm wide and relatively periodicallydistributed, approximately 1 m−2. Furthermore, asthe soil dried out, the soil aggregates became moreand more pronounced, and fine cracks were formedbetween the aggregates. The displacement measuredin dry soil with high precompression stress was prob-ably a result of soil aggregates or clods being pushedtogether by closing cracks, whereas the aggregatesor clods remained intact. Hence, the high precom-pression stress reflected the intra-aggregate strength,but not the ability of the soil to resist compactionbecause of the considerable lower inter-aggregatestrength.

For most wheeling treatments, the SOCOMO modelpredicted that no soil compaction would occur. Themain reason for this was the failure criterion used bythe model that the calculated major stress should behigher than the soil precompression stress before thesoil would compact. An implication of the results isthat the precompression stress does not always providea good indication of the risk for subsoil compaction.A practical consequence is that subsoil compactionin some soils may occur even when the soil is verydry.

4.2. Stress distribution in a structured soil

For all wheel loads applied in the treatments, thecalculated average ground pressure was close to theinflation pressure. Since the depth of the ruts from thetraffic treatments were very small, the contact area inthe field was considered to be close to the contact areathat was measured on concrete. The measured verticalnormal stresses were in general high. At 0.3 m depthit was often much larger than the calculated averageground pressure (Fig. 7). For example, with a wheelload of 7 Mg, the measured soil stresses ranged from390 to 650 kPa while the calculated average groundcontact stress were 246 kPa. The maximum groundpressure may well exceed the calculated averageground pressure;Burt et al. (1992)found that the max-imum ground pressure under a lug was sometimes ashigh as four times the calculated average ground pres-sure. However, it is unclear if the high soil stressesmeasured were caused by uneven stress distributionunder the wheel, since this effect is often thought to belimited to the topsoil (Håkansson and Reeder, 1994).A second possible explanation might be that the pres-sure sensors overestimated the soil stresses:Horn andLebert (1994)reported that pressure sensors mightoverestimate soil stresses if the pressure sensor weremore rigid than the soil. However, it is unlikely thatthis can account for the large differences between thecalculated average ground pressure and the measuredvertical soil stress;Arvidsson and Trautner (1998)used pressure sensors to measure soil stresses undera self-propelled, six-row sugar beet harvester, andfound that the vertical soil stress at 0.3 m depth wasrelatively close to the inflation pressure even when thesoil precompression stress was low (50–100 kPa). Amore likely explanation for the high stresses measuredis that the stress distribution in a very dry and stronglystructured soil is different from the stress distribu-tion in more homogeneous soils. For example, it ispossible that vertical cracks can reduce or inhibit hor-izontal distribution of the stress. Thus, the stress maybe concentrated around the load axis and propagatedeep into the soil. After a personal communicationfrom J. Van den Akker,Håkansson and Reeder (1994)speculated “the occurrence of deep vertical cracksin dry swelling/shrinking soils leads to the trans-mission of stresses into deep subsoil layers withoutattenuation”.

A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118 117

4.3. Model predictions

The SOCOMO model generally underestimated thenormal vertical soil stress, especially at 0.3 m depth(Fig. 7). Neither the application of a parabolic surfaceload distribution nor an increased concentration factorcould account for the differences between the mea-sured and the calculated normal vertical stress (Fig. 6).

Approximately 30% of the stress measurements hadto be disregarded because the peak values were eithernull or lower than the measured stress recorded bythe pressure sensor below. In comparison, only 5% ofthe soil displacement measurements had to be disre-garded. The explanation for this difference is that thepressure sensors require a far better soil contact thanthe displacement sensors. In the authors’ experience,the pressure sensors are highly influenced by the struc-ture, heterogeneity and strength of the soil in contactwith or close to the pressure sensor.

The SOCOMO model is based on the Boussinesqstress distribution theory described bySöhne (1958).The assumptions for the Boussinesq stress distributiontheory are, for example, that the soil medium is homo-geneous, isotropic and weightless. Obviously, this isnot characterizing for natural soils. Nevertheless, theSOCOMO model has been reported to be efficient inestimating risks of subsoil compaction for some soiltypes and water conditions (Arvidsson et al., 2001), itis easy to use and only requires the input of relativelysimple soil mechanical properties. Hence, it might bea useful tool under some circumstances, which needsto be determined by field experiments.

5. Conclusions and implications forfurther studies

The vertical soil displacement increased with theaxle load. This effect was pronounced throughout alltraffic treatments. This research showed that the soilprecompression stress does not always provide a goodindication of the risk for subsoil compaction. It wasfound that subsoil compaction might occur in somesoils even when the soil is very dry.

The measured vertical normal stresses were in gen-eral high, at 0.3 m depth it was often much larger thanthe calculated average ground pressure, and the mea-sures soil stresses were also generally higher than the

stresses calculated with the SOCOMO model. Neitherthe application of a parabolic surface load distribu-tion nor a concentration factor could account for thisdifference. This was probably because the stress dis-tribution in a very dry and strongly structured soil isdifferent from the stress distribution in more homoge-neous soils.

More field experiments are needed in order to char-acterize the soil compaction event and the distributionof stresses as affected by soil type, soil structure andwater conditions.

In the author’s view, there is a strong need for fieldexperiments in order to characterize the soil com-paction event and the distribution of stresses as af-fected by soil type, soil structure and water conditions.For example, specific attention must be paid to the ef-fect of the physical properties of the topsoil on thestress distribution in the subsoil.

Acknowledgements

The authors wish to thank Dr. Markus Berli, theSwiss Federal Institute of Technology, for his mea-surements of the soil precompression stress. The au-thors would also like to thank Professor Emeritus Dr.Inge Håkansson for his help, helpful comments andencouragement. We are also grateful to E. Puymoyenfor hard labour beyond the call of duty in the pits dur-ing those very hot and dry months, and to U. Svantes-son, J. Löfkvist and B. Mårtensson for all their help.

References

Arvidsson, J., Andersson, S., 1997. Determination of soildisplacement by measuring the pressure of a column of liquid.In: Proceedings of the 14th ISTRO Conference, Pulawy, Poland,pp. 47–50.

Arvidsson, J., Trautner, A., 1998. Subsoil displacement duringsugar beet harvest at different soil water contents. In:Proceedings of the First Workshop of the Concerted Actionon Subsoil Compaction, Wageningen, The Netherlands, May28–30, 1998, pp. 50–55.

Arvidsson, J., Trautner, A., Van den Akker, J.J.H., Schjønning, P.,2001. Subsoil compaction caused by heavy sugar beet harvestersin southern Sweden. II. Soil displacement during wheeling andmodel computations of compaction. Soil Till. Res. 29, 195–204.

British Standard 1377, 1975. Methods of Testing Soils for CivilEngineering Purposes. British Standards Institute, London, 134pp.

118 A. Trautner, J. Arvidsson / Soil & Tillage Research 73 (2003) 107–118

Burt, E.C., Wood, R.K., Bailey, A.C., 1992. Some comparison ofaverage to peak soil-contact pressures. Trans. Am. Soc. Agric.Eng. 35, 401–404.

Casagrande, A., 1936. The determination of pre-consolidationload and its practical significance. In: Proceedings of theInternational Conference on Soil Mechanics and FoundationEngineering, vol. III, Harvard University, Cambridge, MA, July22–26, 1936, pp. 60–64.

Danfors, B., 1994. Changes in the subsoil porosity caused byheavy vehicles. Soil Till. Res. 29, 135–144.

Eriksson, J., 1974. Markpackning och rotmiljö (Soil compactionand root environment). Report 126. Division of AgriculturalHydrotechnics, Department of Soil Sciences, SwedishUniversity of Agricultural Science, Uppsala, Sweden.

Frölich, O.K., 1934. Drückverteilung im Baugrunde, Wien.Håkansson, I., Danfors, B., 1981. Effects of heavy traffic on soil

conditions and crop growth. In: Proceedings of the SeventhInternational Conference of the International Society forTerrain-vehicle Systems, Calgary, Alta., Canada, pp. 239–253.

Håkansson, I., Reeder, R.C., 1994. Subsoil compaction by vehicleswith high axle load-extent, persistence and crop response. SoilTill. Res. 29, 277–304.

Horn, R., Lebert, M., 1994. Soil compaction and compressibility.In: Soane, B.D., Van Ouwerkerk, C. (Eds.), Soil Compactionin Crop Production. Elsevier, Amsterdam, pp. 45–69.

Koolen, A.J., Kuipers, H., 1983. Agricultural Soil Mechanics.Springer/Verlag, Berlin/Heidelberg, 241 pp.

Lebert, M., Burger, N., Horn, R., 1989. Effects of dynamic andstatic loading on compaction of structured soils. NATO Adv.Sci. Inst. Ser. E: Appl. Sci. 172, 73–80.

Söhne, W., 1958. Fundamentals of pressure distribution andsoil compaction under tractor tires. Agric. Eng. 39, 276–281,290.

Van den Akker, J.J.H., 1988. Model computations of subsoil stressdistribution and compaction due to field traffic. In: Proceedingsof the 11th International Conference of ISTRO, Edinburgh, UK,pp. 403–408.

Van den Akker, J.J.H., 1994. Prevention of subsoil compaction bytuning the wheel load to the bearing capacity of the subsoil. In:Proceedings of the 13th International Conference of ISTRO,Aalborg, Denmark, pp. 537–542.

Yang, Y., Yu, Q., Yu, G., Liu, R., 1991. Subsoil compaction dueto total load on tractor wheel. Paper No. 911060. An ASAEMeeting Presentation.