Subsea Micropiles overview(5 Dec 2018) short...

Transcript of Subsea Micropiles overview(5 Dec 2018) short...

Derek Robertson

5 December 2018

SUBSEA MICROPILES PROPRIETARY1

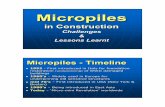

History• First use dates back to the early 1950’s in Italy, where new methods of

underpinning for existing structures were needed to restore structures and monuments damaged during World War II.

• Dr. Fernando Lizzi is commonly recognized as the inventor of micropiles in the form of the tree root pile or "palo-radice".

• Rapid growth in the specification and use of micropiles in the United States since the mid 1980’s to early 1990’s partly as a result of Federal Highway Administration research efforts.

• Micropiles currently are now widely specified and used in all terrestial construction sectors worldwide.

SUBSEA MICROPILES PROPRIETARY 2

Micropiles

Lockheed Martin IP• Under its Ocean Thermal Energy Conversion program,

Lockheed Martin developed IP for the adaptation of terrestrial micropiles to the marine environment, using remote seabed drilling and grouting systems.

• Since 2008, research and development has been carried out to advance designs and key operational concepts to include testing of optimal grout formulations and injection systems.

• U.S. Patent No. 9,051,030

q “Undersea Anchoring System and Method”

q Co-inventors John E. Halkyard and Jonathan B. Machin

• Subsea Micropiles Limited secures exclusive worldwide license to Lockheed Martin IP (Jan 2018)

SUBSEA MICROPILES PROPRIETARY4

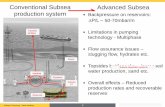

Why offshore now?• Advent of robotic underwater drilling systems

• Need to substantially reduce cost basis of offshore foundations and structures

• More challenging subsea environment

• Advanced marine structures need compliant anchor/stabilization solutions

• Increased demand to minimize environmental impacts

• Improve safety with increased automation/ROV’s

Recent development of remote seabed

drills is an enabling technology

Rock dumping - Micropile solutions are cost effective alternative for pipeline stabilization

Operators are keen to remove human intervention from subsea operations

SUBSEA MICROPILES PROPRIETARY5

Value proposition• Dramatically reduce the cost of foundation

and anchor solutions (~50%)

• Require, smaller, less expensive and more available installation vessels

• Proven track record (onshore) of good performance in a wide range of soil and rock conditions

• Other benefits not captured in example:q Avoid mobilization costs and project delays with larger

construction vessels

q Avoid pile refusals

q Cost effective mid-life intervention option

q Operate in wider range of weather states

q Reduced environmental impact

Heavy crane vessel Drill w/small support vessel

Vs.

SUBSEA MICROPILES PROPRIETARY6

Variables Single Suction Anchor Micropile Array

Anchor sizeSingle suction pile-

Diameter 3mLength 7m

4 templates – connected micropiles. Diameter 0.15m, Length 10m

Material cost estimate $150,000 $75,000

Installation spreadCrane vessel

@$150k per dayROVSV + Seabed drill

@ $75k per day

Installation duration 48 hours 48 hours

Total cost $450,000 $225,000

Example of a pipeline hold-back anchor w/required capacity 100 Te

Technical ViabilityConcept Integrates Existing Technologies for Support Craft & Drilling

SUBSEA MICROPILES PROPRIETARY

ßSeabed Remote Drill Technology is a Commercially Available Technology(TRL 9).

ROVdrill from Perry Slingsby Systems à 0.13 m OD x 20 m

Commercial àAvailable Ischebeck

Anchor (TRL 9)

Two modifications to COTS Drilled Anchor Pile Installation Required:

1. Pile injection pressures must be locally monitored and controlled at the seabed to eliminate the risk of fracturing the rock substrate, reducing the anchor piles holding capacity.

2. A grout quality surveillance system, possibly operating in real time, will also need to be modified in order to validate that the piles are properly grouted over their full length.

Neither modification represents a technical or financial risk to the grout delivery operation.

q Some development and validation testing of the grout process will be required, synergistic activity with the 2011 DoE research program.

Finite Element Analysis Can be Used to Tune Bit Installation Angles to Maximize Anchoring Performance.

Performance of MicropilesDesign Considerations

q Micropiles have an extensive track record (onshore) of good performance in the full range of soil and rock conditions, including soft to stiff clays, sands and gravels. Few standards apply and proprietary designs are used.

q Vertical load capacity can be verified if required if required by proof load testing

q Horizontal loads are mobilized by conventional passive resistance and micropiles can be included as appropriate to optimize load resistance

q Horizontal load capacity can be enhanced by pre-tensioning which stiffens the foundation significantly

q In some conditions performance monitoring may be required e.g. to monitor pre-stresses.

SUBSEA MICROPILES PROPRIETARY 8