Submerged Combustion Melting The Next Generation Melting System David Rue Gas Technology Institute...

-

Upload

melvin-pierpoint -

Category

Documents

-

view

234 -

download

5

Transcript of Submerged Combustion Melting The Next Generation Melting System David Rue Gas Technology Institute...

Submerged Combustion Melting The Next Generation Melting System

David Rue

Gas Technology Institute

66th Glass Problems Conference

U. Of Illinois, Champaign, IL

Oct. 26, 2005

DODOEE

SM

Submerged Combustion Melting Principle

• Air-fuel or oxygen-fuel mixture is fired directly into a pool of hot melt– intense combustion

– direct contact heat transfer - combustion products bubble through the melt

• reduced NOx formation

• reduced CO and unburned hydrocarbon emissions

– High rate of heat transfer and rapid mass transfer

• High thermal efficiency

• Reduced melter size

Submerged Combustion Melting Features

• Melting and mixing in a single device– No external device needs to contact the melt– Short residence time from forced convective heating and mixing

• Melter is simple, robust, and reliable– Small size – low capital cost– SCM is easily started and stopped in a few hours– No hot repair work required

• Compatible with other segmented melting process steps– Charging– Conditioning– heat recovery

GTI and GI SCM History• Gas Institute (Ukraine) developed SCM for mixed nuclear waste

vitrification and industrial melting – not deployed• Process simplified and commercial, air-fired units operating

more than 10 years for other applications– two 3-ton/h rockwool SCM units in Kiev, Ukraine– three 3-ton/h rockwool SCM units in Byarosa, Belarus– One SCM cement aggregate unit in Noril’sk Russia

• GTI licensed SCM for applications outside former Soviet Union• GTI has patents and background IP in melting, submerged

firing, and heat recovery• 500-lb/h SCM unit fabricated and operated at GTI

– Multiple melts including basalt and sodium silicate– First use of oxy-gas burners

SCM 3 ton/h Mineral Wool

SCM in Belarus

Loading Feed Hopper

SCM Furnace

SCM Interior

From Melt to Mineral Wool

Molten Slag Channel

4 Wheel Fiber Spinner

Blow Chamber

Product Fiber Mat

SCM Advantages

• Energy savings >20% vs. oxy-gas melters• >55% capital cost reduction

– Compact with very little refractory – 80% refractory reduction

– Melt area is 15% of tank melter area (0.6 ft2/ton/day)

• Reduced emissions– NOx >50% below oxy-gas melters– CO and unburned hydrocarbons

reduced >20%• Rapid switching of melt composition• Short residence time - rapid heat transfer• Reliable, proven melting technology• Feed flexibility lowers batch and feeder

cost• Mates with conditioning and heat

recovery steps• Excellent redox and color control

STACK

RECUPERATOR

SEPARATIONZONE

FEEDER

MELT BATH

BURNERS

MELTREMOVAL

Approaches to Glass Melting

• Single tank– Compromise simple and reliable, but non-optimized

approach

– Holding furnaces, fining, and conditioning are needed after the melter for many glass products

• Staged or ‘segmented’– Melting, mixing, refining, conditioning, heat recovery,

etc. are optimized as needed for the glass product

– highly flexible with many potential process advantages

– Requires eloquent design for reliability and to avoid over-complexity and high capital cost

NGMS Project Underway at GTI

• Demonstrate melting and homogenization stage of low capital cost, energy efficient NGMS process for all industrially produced glass

• Sponsors – DOE– NYSERDA– Gas industry

• Consortium actively supporting development and commercialization of SCM fro NGMS– Corning Incorporated - PPG Industries, Inc.– Johns Manville - Schott North

America– Owens Corning

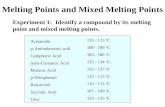

Batch-Scale SCM at GTI

Lab-Scale SCM• Industry batch melted to glass• Full glass range melted

– Low-temp. soda-lime glass– High-temp ‘hard’ LCD glass– Borosilicate glass– Scrap reinforcing fiberglass

• Batch feed• Continuous discharge• Evaluation of glass product

before pilot SCM fabrication• Components scaled for 0.5-1.0

ton/h pilot SCM• Product glass is fully melted and

homogeneous

Special Tap Designed for Glass Melts

Soda-Lime Glass

Scrap Fiberglass – Melt Sampling

Pilot-Scale SCM Unit• Objective – continuous feed and discharge – made easier with

– Larger capacity melter (0.5-1.0 ton/h)\– Demonstrated platinum discharge tap

• Most components are in place and tested– Melter, burners, cooling water chiller needed– Added instrumentation into data acquisition system

• Multiple burners spaced to create– Uniform temperature profile– Desired mixing and residence time distributions– Elimination of poor mixing zones in corners and along walls

• Flexibility built into the unit– Changeable burner patterns– Provisions for two or more discharge locations– Provisions for two feed locations

Glass Quality Varies Dramatically

Glass Market Seeds/Oz Relative Seed Quality

LCD Display 10x better than TV panel glass

TV Panel 10x better than float glass

Float/Flat 1,000 - 10,000x better than container glass

Textile Fiber 100x better than container glass

Tableware < 2 10x better than container glass

Lighting Glass ~ 25

2x better than container glass

Container 10-20 10x better than funnel glass

TV Funnel~ 200

2x better than wool insulation fiberglass

Insulation Fiber ~ 400

Acceptable Bubble Count• Lower-cost glass making must have BOTH

– High intensity melting

– Rapid refining

• Quality varies over 5 orders of magnitude

• SCM alone –

– Makes fully melted homogeneous glass

– Only makes lowest quality glass

• SCM works well with all external refining methods

NGMS (SCM AND Rapid Refining)• If refining is slow, the capital cost benefits of low-cost, high-

intensity melting are lost

• Potential refining approaches include

Sonic Lab-scale tested Potentially low cost and very rapid, easily installed

Helium (inert gas)

Entering commercial trials

Helium cost is acceptable, not usable on all glasses

Thin film Limited commercial use

Particularly good SCM match, bubbles are large and no CO2

Reduced pressure

Limited commercial use

Requires good control, hardware is expensive

centrifugal Pilot-scale tested Complex hardware, potentially very rapid

Toward Commercialization• Already completed

– SCM concept – Pilot-scale oncept validation, including combustion system– Initial commercial use for low-quality products (mineral wool,

aggregate)• Current activities – through 2006

– Lab-scale melting of full range of industrial glass and fiberglass scrap

– Batch feed and continuous discharge using oxy-gas burners– CFD and physical modeling of SCM– Design, fabrication, and operation of continuous 0.5-1.0 ton/h

pilot-scale SCM– Preparations for first industrial demo-scale SCM– Design, construction of first commercial SCM making

abrasives from steel industry waste and cullet (northern IN)

Next Steps• 2006-2008

– Plan first glass industry plant demo-scale 1-4 ton/h SCM– Fiberglass or scrap fiberglass – Test unit not replacing existing melter– Rapid conditioning work to develop NGMS for all industrial

glass compositions• 2009+

– Demo-scale SCM and NGMS units in consortium member plants

– Initial replacement of current melters with NGMS • 2012+

– Fully developed and commercially demonstrated NGMS using SCM

– Licensing of NGMS to non-consortium member glass companies

Commercialization Pathway

• Expected order of market entry – Scrap fiberglass– Fiberglass– Specialty glass (pressed and blown)– Specialty glass (optical fiber, LCD, etc.)– Container glass– Flat glass

• Consortium agreement lays out company access priority to the NGMS technology– Consortium member companies– GMIC member companies– Non-GMIC glass companies