Study on Membrane Characteristics of Alginate Chitosan Micro Capsule With Cell Growth 2011 Journal...

Transcript of Study on Membrane Characteristics of Alginate Chitosan Micro Capsule With Cell Growth 2011 Journal...

Sw

Wa

b

a

ARRAA

KAMMA

1

epctcsIt[

lcscnp

f

0d

Journal of Membrane Science 377 (2011) 214– 220

Contents lists available at ScienceDirect

Journal of Membrane Science

j ourna l ho me pag e: www.elsev ier .com/ locate /memsci

tudy on membrane characteristics of alginate–chitosan microcapsuleith cell growth

eiting Yua, Huiyi Songa, Guoshuang Zhenga, Xiudong Liub,∗, Ying Zhanga, Xiaojun Maa,∗

Laboratory of Biomedical Materials Engineering, Dalian Institute of Chemical Physics(DICP), Chinese Academy of Sciences(CAS), Dalian 116023, PR ChinaCollege of Environment and Chemical Engineering, Dalian University, Dalian Economic Technological Development Zone, Dalian 116622, PR China

r t i c l e i n f o

rticle history:eceived 7 March 2011eceived in revised form 17 April 2011ccepted 26 April 2011vailable online 5 May 2011

ey words:lginate–chitosan microcapsuleembrane characteristics

a b s t r a c t

Alginate–chitosan (AC) microcapsule with polyelectrolyte complex (PEC) membrane has been attrac-tive in biotechnological area such as cell immobilization fermentation. The PEC membrane has beenknown important to control microcapsule performance, but the knowledge was mainly obtained withempty or drug-loaded microcapsules. In this paper, the emphasis was to explore the influence of cellgrowth on PEC membrane characteristics, that is, to study the membrane characteristics in dynamicprocess. AC microcapsule entrapping yeast cells (Saccharomyces cerevisiae BY4741) was used as model,and the PEC membrane characteristics including membrane thickness, swelling behavior, permeabil-ity, and component were studied during cell culture process. It was found that both the membrane

icroencapsulated cell culturepparent membrane

thickness and volume swelling degree of AC microcapsule increased, however, membrane permeabil-ity decreased with the growth of entrapped yeast cells. Fluorescence-labeling studies suggested theconcentrated alginate layer squeezed by the proliferated cells and macromolecular metabolites layersecreted by proliferated cells contributed to above increment. The former PEC membrane, togetherwith the new layers, constituted the ‘apparent membrane’, which increased the diffusion resistance of

substances.. Introduction

Microencapsulation is a kind of membrane technology, whichncloses chemicals, drugs, enzymes or cells within a semi-ermeable membrane to protect the bioactivity or to realizeontrolled release or to produce substances of value [1,2]. Amonghe reported microcapsule systems, alginate–chitosan (AC) micro-apsule has been arousing interest due to the inherent propertiesuch as biocompatibility, nontoxicity, and biodegradability [3–5].t has been widely reported in the studies on drug delivery sys-ems [6,7], enzyme immobilization [8], cell immobilization culture9–12], and cell transplantation [13–16].

Alginate is an anionic linear polysaccharide containing 1,4-inked d-mannuronic acid and l-guluronic acid residues [17], whichan form hydrogels in the presence of some multivalent metal ions

uch as calcium ion. Chitosan, the only naturally cationic polysac-haride [18], can diffuse into three-dimensional (3D) alginate geletwork. Under simultaneous electrostatic interaction betweenrotonated amino groups of chitosan and carboxyl groups of algi-∗ Corresponding authors. Tel.: +86 411 84379139/87402448;ax: +86 411 84379096.

E-mail addresses: [email protected] (X. Liu), [email protected] (X. Ma).

376-7388/$ – see front matter © 2011 Elsevier B.V. All rights reserved.oi:10.1016/j.memsci.2011.04.053

© 2011 Elsevier B.V. All rights reserved.

nate [19], polyelectrolyte complex (PEC) microcapsule membraneis formed [20].

The PEC membrane has been demonstrated to play an impor-tant role in controlling the performance of AC microcapsules inbiomedical applications. So far, it has been found that many param-eters such as molecular weight (Mw), chain flexibility, and chargedensity of both polysaccharides have affected the membrane struc-ture, mechanical strength, substance permeaselectivity. However,the above understanding mainly results from the researches basedon empty [19,21–25] or drugs-loaded AC microcapsules [26–28],which only provide the static characteristics of membrane. WhenAC microcapsules are used into immobilized cell culture and fer-mentation, the growth and metabolism process of entrapped cellswere thought to have effect on the structure and characteristicsof PEC membrane, which will in return affect the cell growth andmetabolism.

Therefore, the PEC membrane characteristics of AC micro-capsules with cell growth were concerned with the purpose ofobtaining the dynamic membrane characteristics in this paper.Yeast cell (Saccharomyces cerevisiae BY4741) was used as model,calcium alginate gel (CAG) beads entrapped cells were produced

firstly, followed the complex reaction with chitosan to form thePEC microcapsule membrane, and then AC microencapsulated cellculture was carried out. The PEC membrane thickness, swellingbehavior, substance permeability, and membrane component werebrane

iMtg

2

2

BcTpg(rCs[(icuahfcdpBCg

2

t

W. Yu et al. / Journal of Mem

nvestigated during the process of microencapsulated cell culture.eantime, the effect of the degree of polymerization (DP) of chi-

osan on the membrane characteristics was also studied with cellrowth in AC microcapsules.

. Materials and methods

.1. Cells and materials

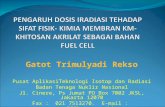

Wild type Saccharomyces cerevisiae strain BY4741 (S. cerevisiaeY4741) was acquired from EUROSCARF (European Saccharomyceserevisiae Archive for Functional Analysis, Frankfurt, Germany).hey were cultured in yeast peptone dextrose (YPD) medium, com-osed of 10 g/L yeast extract, 20 g/L bacto-tryptone, and 20 g/Llucose, respectively. Chitosan samples were degraded by gamma�) rays from raw material (Yuhuan Ocean Biomaterials Corpo-ation, China) by Key Laboratory of Nuclear Analysis Techniques,hinese Academy of Sciences. The average DP of degraded chitosanamples was determined by gel permeation chromatography (GPC)29,30], which gave the values of 125, 245, and 370, respectivelyFig. 1). The polydispersity index (PDI) values were correspond-ngly 1.7, 1.9 and 2.2 suggesting Mw distribution of samples waslose to each other. Therefore, DP125, DP245 and DP370 weresed to denote the different chitosan samples in the study. Sodiumlginate was purchased from the Chemical Reagent Corp (Shang-ai, China). The viscosity was over 0.02 Pa s when dissolved to

orm a 1.0% (w/v) aqueous solution at 20 ◦C. Fluorochrome fluores-einamine labeled alginate was prepared according to the methodeveloped by Strand et al. [31]. Rhodamine-B labeled chitosan wasrepared according to the method developed by our laboratory.ovine serum albumin (BSA) was purchased from Sigma–Aldrichhemical Co. with Mw of 66 kDa. All other reagents were analyticalrade and used as received.

.2. Preparation and culture of AC microencapsulated yeast cells

AC microencapsulated yeast cells were prepared according tohe method developed in our lab [32]. Sodium alginate was dis-

-250.00

-200.00

-150.00

-100.00

-50.00

0.00

50.00

100.00

150.00

200.00

250.00

300.00

350.00

400.00

450.00

500.00

550.00

600.00

650.00

700.00

2.00 4.00 6.00 8.00 10.00 12.00 14.00Eluti on

Mv

DP370

DP245

DP125

Fig. 1. GPC chromatograms of chitosan samples (D

Science 377 (2011) 214– 220 215

solved in 0.9% (w/v) NaCl solution to form final concentration of1.5% (w/v), and was sterilized by filtration through a 0.22 �m mem-brane filter. The sodium alginate solution was stored overnightbefore use to facilitate deaeration. Yeast cells S. cerevisiae BY4741, inlate exponential phase, were centrifuged and suspended in sodiumalginate solution. Then the suspension was extruded through a0.50-mm needle into calcium gelling solution using electrostaticdroplet generator (YD-06, Dalian Institute of Chemical Physics, Chi-nese Academy of Sciences, China) to form CAG beads. The CAGbeads were immersed in 0.5% (w/v) chitosan solution to formalginate–chitosan microcapsule membrane, followed by rinsingwith 0.9% (w/v) NaCl solution. After being liquidized for 5 min using0.055 mol/L sodium citrate and rinsed three times with 0.9% (w/v)NaCl solution, AC microencapsulated yeast cells were formed andstored for further use.

0.8 mL AC microcapsules (1–2 × 104 microcapsules) envelopingyeast cells were added in 9.2 mL YPD medium. Then AC microen-capsulated cells were cultured in a shaking incubator at 28 ◦C and170 rpm for 24 h. All experiments regarding cells were carried outin triplicate samples.

2.3. Characterization of the morphology, membrane thickness ofAC microcapsules enveloping yeast cells during cell culture process

After preparation and culture, the morphology of AC microen-capsulated yeast cells was observed with a Nikon Eclipse TE2000Inverted Research Microscope (Nikon Corp., Japan). Different visualfields were randomly selected and recorded to obtain 8–10 micro-scopic images of microcapsules for each chitosan sample. Themembrane thicknesses of at least forty AC microcapsules weremeasured from microscopic images using software ImageJ, andpresented as mean ± standard deviation.

2.4. Characterization of cell growth in AC microcapsules during

cell culture processAfter 0.1 mL AC microcapsules (1.5–2.5 × 103 microcapsules)were broken up using a chemical method [33], yeast cells were col-

16.00 18.00 20.00 22.00 24.00 26.00 28.00 30.00 time (min)

P of chitosan is DP125, DP245, and DP370).

2 brane

lm(a

2m

yldm

S

wccm

2g

Rs2dml5G

2m

1wbsc

2m

thawwmstpni

C

wf

microcapsules with cells cultured at 12 and 24 h were broken up,respectively, the densities of yeast cells in microcapsules were alsomeasured and shown in Fig. 3. In comparison with the inoculum celldensity of 1 × 107/mL microcapsule, yeast cells in microcapsules

16 W. Yu et al. / Journal of Mem

ected and re-suspended. The OD600 values of cell suspension wereeasured at 600 nm using a UV-2550 visible spectrophotometer

Shimadzu Co., Kyoto, Japan). Then the cell density was obtainedccording to the established standard curve.

.5. Characterization of the swelling behavior of ACicrocapsules enveloping yeast cells during cell culture process

The size and size distribution of AC microcapsules envelopingeast cells were determined with laser diffraction particle ana-yzer (LS100 Q, Beckman-Coulter Corp., USA). The volume swellingegree (Sw) was used to characterize the swelling behavior of ACicrocapsules [34]. The Sw of microcapsules is defined as:

w (%) = 100

[(Dt

D0

)3− 1

]

here D0 represents the diameter of AC microcapsules before cellulture, and Dt represents the diameter of AC microcapsules afterell culture. The larger the volume swelling degree is, the easier ACicrocapsule swell.

.6. Analysis of microcapsule membrane component with cellrowth in AC microcapsules

Fluorochrome fluoresceinamine labeled alginate andhodamine-B labeled chitosan were used to prepare AC microcap-ules enveloping yeast cells according to the method in Section.2. Then the alginate and chitosan distribution in microcapsulesuring cell culture was observed by confocal laser scanningicroscope (CLSM) (Leica, TCS-SP2, Germany), equipped with

aser sources both blue (Ar 488 nm/5 mW) and green (HeNe43 nm/1.2 mW), and an inverted microscope (Leica, DMIRE2,ermany).

.7. Characterization of proteins secreted by cells in ACicrocapsules during cell culture process

When AC microencapsulated yeast cells were cultured for 0,2, and 24 h, respectively, the microcapsules were collected andashed by 0.9% (w/v) NaCl. Then 0.1 mL AC microcapsules were

roken up. The final volume was adjusted to 5 mL, and the brokenolution was centrifuged to eliminate yeast cells. The protein con-entration of supernatant was measured by the Bradford method.

.8. Characterization of membrane permeability of ACicrocapsules enveloping yeast cells during cell culture process

Bovine serum albumin (BSA) was used as standard proteino characterize membrane permeability of AC microcapsule. Theigher concentration of BSA in microcapsules, the higher perme-bility of membrane is. When AC microencapsulated yeast cellsere cultured for 0, 12, and 24 h, respectively, the microcapsulesere collected and washed by 0.9% (w/v) NaCl. Then 0.1 mL ACicrocapsules were put into a 0.5 mL tube, and 0.1 mL physiological

aline was added to re-suspend microcapsules. 0.2 mL BSA solu-ion (1 mg/mL) was added into the tube to characterize membraneermeability. After 6 min, the residual BSA concentration in super-atant was measured by the Bradford method. The protein diffusing

nto AC microcapsules was calculated using the following equation:

0.2 − 0.3C

(mg/mL) = iVi

here Ci is the protein concentration in the supernatant after dif-usion, and Vi is the volume of AC microcapsules.

Science 377 (2011) 214– 220

3. Results and discussion

3.1. Characterization of the morphology, membrane thickness ofAC microcapsules enveloping yeast cells during cell culture process

AC microencapsulated yeast cells were made by two-stageprocedure. Firstly, alginate solution containing yeast cells, withinoculum cell density of 1 × 107/mL microcapsule, was droppedinto calcium chloride solution to produce CAG beads. Secondly,the beads were immersed in chitosan solution (DP125, DP245 andDP370) for 20 min to form PEC microcapsule membrane. After beingliquidized, AC microencapsulated yeast cells were formed.

After preparation and cultured for 24 h, AC microcapsuleswere observed with optical microscope. Fig. 2 presented therepresentative microscopic images of prepared and cultured ACmicrocapsules. It can be seen that AC microcapsules were spher-ical and intact with smooth surface. The bright outer layer ofmicrocapsules demonstrated the PEC membrane (Fig. 2, arrowindicated). AC microcapsules after preparation (Fig. 2A) showedobvious thinner PEC membrane than that of microcapsules culturedfor 24 h (Fig. 2B). Moreover, at least forty microcapsules for bothcondition were randomly selected for membrane measurementusing software ImageJ, which provided membrane thicknessesof 5.6 ± 1.4 �m (Fig. 2A) and 18.9 ± 2.4 �m (Fig. 2B), a three-foldincrease after culture.

Yeast cells uniformly scattered in microcapsules after prepara-tion (Fig. 2A), while filled the inner space of microcapsules aftercultured for 24 h demonstrating obvious cell growth (Fig. 2B). AC

Fig. 2. Optical images of AC microencapsulated cells with chitosan of DP245 beforeculture (A), and after culture for 24 h (B), bar = 100 �m.

W. Yu et al. / Journal of Membrane

0

20

40

60

80

100

120

140

160

180

200

220

Cel

l den

sity

(10E

7 pe

r ml m

icro

caps

ules

)

*

* DP125 DP245 DP370

12 24 Culture time (hour)

Fr

gs1t

3m

dcwdo

tlotsoc

F2

ig. 3. Cell densities in AC microcapsules after culture for 12 and 24 h (n = 3, * rep-esents p < 0.05).

rew remarkably with cell density over 100 × 107/mL microcap-ule at 12 h (an increment with two order of magnitude), and over70 × 107/mL microcapsule at 24 h (an increment of 70% comparedo that at 12 h).

.2. Characterization of the swelling behavior of ACicrocapsules enveloping yeast cells during cell culture process

According to the described method in Section 2.5, the swellingegrees of AC microcapsules with cells during culture process werealculated and shown in Fig. 4. The Sw values of AC microcapsulesith cells displayed increment trend in 24-h culture period, whichemonstrated that the volume of AC microcapsules increased obvi-usly during cell culture process.

Before cell culture, yeast cells were distributed in alginate solransformed by the liquefaction process. When AC microencapsu-ated cells were incubated, yeast cells gradually grew (Fig. 3) andccupied the inner space of AC microcapsules (Fig. 2). As a result,he dissolved alginate molecules from hydrogel network were

queezed outward to microcapsules. However, only a small fractionf the dissolved alginate molecules can permeate out of the micro-apsules due to the selective permeation of the membrane pores0

2

4

6

8

10

12

14

16

18

20

Sw

ellin

g de

gree

(%)

DP125 DP245 DP370

12 24 Culture time (hour)

ig. 4. Swelling behavior of AC microcapsules with cells after culture for 12 and4 h.

Science 377 (2011) 214– 220 217

as demonstrated with alginate–poly-lysine microcapsule [35–37].The outward movement of alginate molecules and prevention bymembrane resulted in the concentrated alginate molecules at theinner layers of PEC membrane, together with high concentrationof sodium ions, which caused the difference of osmotic pressureat both sides of microcapsule membrane. Therefore, the influentof water for balancing the osmotic pressure inside and outside themembrane contributed to the swelling behavior of microcapsule.

It was also noticed that Sw values showed positively dependenton the DP of chitosan samples. In general, chitosan with low DPmeans short molecular chain and low steric hindrance, many chi-tosan molecules can easily diffuse into deep area of Ca–alginatehydrogel network to form thick PEC membrane with small insidespace [30]. The thick PEC membrane has strong anti-swelling abil-ity [34], and the small inside space means the dissolved alginatemolecules squeezed by cells were relatively lower. Therefore, bothreasons contributed to the lowest Sw values for chitosan samplewith lowest DP. On the contrary, it was difficult for chitosan withhigh DP to diffuse into hydrogel network, the complex reactionoccurred mainly at CAG bead surface to form thin membrane butleave big inside space. The weak anti-swelling ability of thin PECmembrane and more alginate molecules squeezed by cells make iteasy for microcapsule to swell during cell culture process.

3.3. Analysis of microcapsule membrane component with cellgrowth in AC microcapsules

Both membrane thickness and swelling results demonstratedthat the growth of entrapped cells clearly have effect onthe PEC membrane characteristics of AC microcapsules. Touncover the reasons beyond these results and phenomena, thefluoresceinamine-labeled alginate (green) and rhodamine-labeledchitosan (red) were used to display the membrane and to investi-gated the changes of membrane during cell culture process.

Fig. 5 showed CLSM images of fluorescence labeled AC micro-capsules with cells before culture (A), after culture for 24 h (B), andfluorescence intensity after culture (C). Both Fig. 5A and B containedtwo images providing the information from transmitted light chan-nel (left), and the overlay of transmitted and fluorescence lightchannels (right). It can be seen that the membrane of AC micro-capsules in optical image was thinner before culture (Fig. 5A, left)than that after culture (Fig. 5B, left). While the membrane thick-ness in merged optical and fluorescence images was almost same(right of Fig. 5A and B, yellow fluorescence layer represent thereal PEC membrane formed by green fluorescence labeled algi-nate and red fluorescence labeled chitosan). By drawing a straightline through the observed section of AC microcapsule with cells(Fig. 5B), the change of fluorescence intensity along the straightline (Fig. 5C) could be plotted via software. The peak width repre-senting the membrane thickness in transmitted light image (lastcurve of Fig. 5C) was wider than that representing fluorescencelabeled membrane (first and second curves of Fig. 5C). Consideringthe cell growth, it was deduced that the accumulation of macro-molecular metabolites such as proteins secreted by entrapped cellscontributed to the difference of membrane thickness between opti-cal and fluorescence images.

To validate above deduction, AC microcapsules with yeast cellswere broken after culture for 12 and 24 h, respectively. The sus-pension was centrifuged, and the supernatant was analyzed by theBradford method for protein quantification. Fig. 6 showed that pro-tein concentration increased with the culture process. For example,protein concentration after culture 24 h was over 10 mg/mL. It

proved that cells secreted plenty of proteins during culture pro-cess, but most of these macromolecular metabolites accumulatedin microcapsules due to the retention effect of PEC membrane.According to the fact that cells grew and almost occupied the218 W. Yu et al. / Journal of Membrane Science 377 (2011) 214– 220

Fig. 5. CLSM images of fluorescence labeled AC microcapsules with cells before culture (A), after culture for 24 h (B), and the corresponding fluorescence intensity curves (C).

W. Yu et al. / Journal of Membrane

0

2

4

6

8

10

12

14 DP125 DP245 DP370

*

Pro

tein

of c

ell s

ecre

ting

in m

icro

caps

ule(

mg/

ml)

12 24

Culture time (hour)

Fc

itdpulPcwcmcw

btas1iai

Ff

ig. 6. Concentration of proteins secreted by cells and accumulated in AC micro-apsules after culture for 12 and 24 h (n = 3, * represents p < 0.05).

nner space of microcapsules (Fig. 2), the ever existed inner solu-ion was squeezed out of microcapsules. The metabolized proteinsiffused toward the membrane with solution. As a result, theseroteins with higher Mw could not permeate outward and grad-ally accumulate at the inner surface of membrane to form new

ayer, which displayed the similar optical refraction property withEC membrane under optical microscope. Therefore, it was con-luded that the component of cultured microcapsule membraneas composed of the former alginate/chitosan membrane, con-

entrated alginate layer squeezed by cells, and macromolecularetabolites layer. In fact, it is no longer a strictly defined micro-

apsule membrane but an ‘apparent membrane’ or ‘microcapsuleall’.

Furthermore, the substance permeability of the apparent mem-rane was also investigated during cell culture process. Becausehe culture medium is too complicated to analysis, bovine serumlbumin (BSA) was used as model protein to evaluate the inwardubstance diffusion to the apparent membrane. At culture time of 0,

2 and 24 h, AC microcapsules were collected, rinsed and immersednto BSA solution. The inward diffusion of BSA was calculated bynalyzing supernatant. It was shown in Fig. 7 that BSA permeabil-ty at 12 h was somewhat same as that at 0 h, but decreased almost

0.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

*

*

*

BS

A d

iffus

ion

into

mic

roca

psul

e(m

g/m

l)

DP125 DP245 DP370

12 24 0 Culture time (hour)

ig. 7. The inward BSA diffusion to ‘apparent membrane’ before and after cultureor 12 and 24 h (n = 3, * represents p < 0.05).

Science 377 (2011) 214– 220 219

half at 24 h. Based on above results and discussion, the decline ofsubstance permeability could be ascribed to the increase of appar-ent membrane thickness during cell culture, which consequentlyincreased the diffusion resistance of protein.

Generally, AC microcapsules with low chitosan DP form thickand loose membrane, but thin and dense membrane with highchitosan DP. Although both the thickness and pore size of mem-brane are the barriers for substance diffusion, the latter is usuallydominant factor as shown in Fig. 7 (0 h). With the time courseof culture, yeast cells in AC microcapsules with chitosan DP 125and DP 245 in first 12 h could get much nutrients for growth,but the high diffusion resistance by membrane with chitosan DP370 due to fast block of pores (Fig. 7, 12 h) gave significant lowcell growth (Fig. 3, 12 h). Meantime, AC microencapsulated cellssecreted metabolites such as proteins, and many proteins wereretained in microcapsules with chitosan DP 370 for high diffu-sion resistance (Fig. 6, 12 h). When AC microencapsulated cellswere cultured for 24 h, the substance permeability of AC micro-capsules with chitosan DP 125 and DP 245 remarkably decreased(Fig. 7). In consideration of protein analysis in Fig. 6, it was thoughtthat the secreted proteins gradually blocked the loose membranepores of microcapsules with low chitosan DP, and then accumu-lated to form new layer as part of ‘apparent membrane’. As aresult, the resistance for both BSA and secreted proteins diffu-sion also increased correspondingly due to extension of diffusiondistance and increase of compactness of ‘apparent membrane’. Fur-thermore, the nutrients supply for cell growth correspondinglydecreased, which resulted in the slow increase of cell densitiesat 24 h (Fig. 3). Cell increment in AC microcapsules with chitosanDP 125 showed significant lower than that in microcapsules withchitosan DP 245 and DP 370 (Fig. 3). The smallest inner space ofmicrocapsule with chitosan DP 125 had been occupied by cells,which limited the further cell growth. Therefore, the cell incrementwas slowest in the second 12 h. However, microcapsules with chi-tosan DP 370 had the largest inner space, which was beneficial forfurther cell growth though the nutrients supply was slow. There-fore, the growth space limitation became the dominant factor forcell growth in the second 12 h. As a whole, chitosan DP, as a param-eter, was no longer an only factor on membrane characteristicsduring cell culture, and could not show definite effect tendencywith cell growth.

4. Conclusion

AC microcapsule entrapping yeast cells (S. cerevisiae BY4741)was used as model, and the PEC membrane characteristics includ-ing membrane thickness, swelling behavior, permeability, andcomponent were studied with the emphasis on cell culture pro-cess. The membrane thickness and the volume swelling degreesof AC microcapsules showed obvious increment during cell cul-ture process, however, membrane permeability decreased with thegrowth of entrapped yeast cells, which suggested the growth ofentrapped yeast cells clearly affected the PEC membrane charac-teristics. The reasons on the increment of membrane thicknessand swelling degree were further analyzed based on fluores-cence labeled technique and substance diffusion studies. Theformerly alginate–chitosan PEC membrane, concentrated alginatelayer squeezed by cells, and macromolecular metabolites layersecreted by cells constituted the ‘apparent membrane’ during cul-ture process.

Acknowledgements

The authors thank the National Natural Science Foundation ofChina (No: 20806080, 20876018, 20736006) and the National Basic

2 brane

Rsot

R

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

[

20 W. Yu et al. / Journal of Mem

esearch Program of China (No: 2007CB714305) for the financialupport. And we also thank Prof. Guozhong Wu at Key Laboratoryf Nuclear Analysis Techniques, Chinese Academy of Sciences forhe degradation of chitosan samples by gamma ray.

eferences

[1] T.M. Chang, Semipermeable microcapsules, Science 146 (1964) 524–525.[2] W. Wang, X.D. Liu, Y.B. Xie, H.A. Zhang, W.T. Yu, Y. Xiong, W.Y. Xie, X.J. Ma,

Microencapsulation using natural polysaccharides for drug delivery and cellimplantation, J. Mater. Chem. 16 (2006) 3252–3267.

[3] H. Onishi, Y. Machida, Biodegradation and distribution of water-soluble chi-tosan in mice, Biomaterials 20 (1999) 175–182.

[4] H.K. Holme, L. Davidsen, A. Kristiansen, O. Smidsrød, Kinetics and mechanismsof depolymerization of alginate and chitosan in aqueous solution, Carbohydr.Polym. 73 (2008) 656–664.

[5] S.M. Lim, D.K. Song, S.H. Oh, D.S. Lee-Yoon, E.H. Bae, J.H. Lee, In vitro and in vivodegradation behavior of acetylated chitosan porous beads, J. Biomater. Sci. -Polym. Ed. 19 (2008) 453–466.

[6] M. George, T.E. Abraham, Polyionic hydrocolloids for the intestinal delivery ofprotein drugs: alginate and chitosan – a review, J. Control. Release 114 (2006)1–14.

[7] M.S. Crcarevska, M.G. Dodov, K. Goracinova, Chitosan coated Ca–alginatemicroparticles loaded with budesonide for delivery to the inflamed colonicmucosa, Eur. J. Pharm. Biopharm. 68 (2008) 565–578.

[8] E. Taqieddin, M. Amiji, Enzyme immobilization in novel alginate–chitosancore–shell microcapsules, Biomaterials 25 (2004) 1937–1945.

[9] J.S. Lee, D.S. Cha, H.J. Park, Survival of freeze-dried Lactobacillus bulgaricus KFRI673 in chitosan-coated calcium alginate microparticles, J. Agric. Food Chem. 52(2004) 7300–7305.

10] S. Graff, S. Hussain, J.C. Chaumeil, C. Charrueau, Increased intestinal delivery ofviable Saccharomyces boulardii by encapsulation in microspheres, Pharm. Res.25 (2008) 1290–1296.

11] P. Cygan, S. Stolnik, A. Grabowska, S. Wedge, P. Elvin, S. Watson, Char-acterisation of viability and proliferation of 3t3 fibroblasts encapsulatedin alginate–chitosan–hyaluronate capsules, J. Pharm. Pharmacol. 62 (2010)1502–1503.

12] J. Pound, D.W. Green, J.B. Chaudhuri, S. Mann, H.I. Roach, R.O.C. Oreffo, Strategiesto promote chondrogenesis and osteogenesis from human bone marrow cellsand articular chondrocytes encapsulated in polysaccharide templates, TissueEng. 12 (2006) 2789–2799.

13] H.B. Zhu, Z.F. Xi, S.J. Yang, Y.H. Zhang, H. Wang, H.T. Guo, Y. Zhang, D.C.Chen, D.Z. Guo, Responses of free radicals to subcutaneous implantation ofalginate–chitosan–alginate (ACA) microcapsules in mice, Int. J. Artif. Organs 32(2009) 224–231.

14] T. Haque, H. Chen, W. Ouyang, C. Martoni, B. Lawuyi, A.M. Urbanska, S. Prakash,In vitro study of alginate–chitosan microcapsules: an alternative to livercell transplants for the treatment of liver failure, Biotechnol. Lett. 27 (2005)317–322.

15] L. Baruch, M. Machluf, Alginate–chitosan complex coacervation for cellencapsulation: effect on mechanical properties and on long-term viability,Biopolymers 82 (2006) 570–579.

16] W.J. Zhang, B.G. Li, C. Zhang, X.H. Xie, T.T. Tang, Biocompatibility and membranestrength of C3H10T1/2 cell-loaded alginate-based microcapsules, Cytotherapy10 (2008) 90–97.

17] P. Sriamornsak, J. Nunthanid, M. Luangtana-Anan, Y. Weerapol, S. Puttipi-patkhachorn, Alginate-based pellets prepared by extrusion/spheronization:

[

Science 377 (2011) 214– 220

effect of the amount and type of sodium alginate and calcium salts, Eur. J. Pharm.Biopharm. 69 (2008) 274–284.

18] M. Rinaudo, Chitin and chitosan: properties and applications, Prog. Polym. Sci.31 (2006) 603–632.

19] O. Gaserod, O. Smidsrod, G. Skjak-Braek, Microcapsules of alginate–chitosan. I.A quantitative study of the interaction between alginate and chitosan, Bioma-terials 19 (1998) 1815–1825.

20] X.L. Yan, E. Khor, L.Y. Lim, Chitosan–alginate films prepared with chitosans ofdifferent molecular weights, J. Biomed. Mater. Res. 58 (2001) 358–365.

21] J.Z. Knaul, M.R. Kasaai, V.T. Bui, K.A.M. Creber, Characterization of deacety-lated chitosan and chitosan molecular weight review, Can. J. Chem. 76 (1998)1699–1706.

22] O. Gaserod, A. Sannes, G. Skjak-Braek, Microcapsules of alginate–chitosan. II. Astudy of capsule stability and permeability, Biomaterials 20 (1999) 773–783.

23] F.O.M.S. Abreu, C. Bianchini, M.M.C. Forte, T.B.L. Kist, Influence of the compo-sition and preparation method on the morphology and swelling behavior ofalginate–chitosan hydrogels, Carbohydr. Polym. 74 (2008) 283–289.

24] A. Bartkowiak, D. Hunkeler, Alginate–oligochitosan microcapsules. I. A mecha-nistic study relating membrane and capsule properties to reaction conditions,Chem. Mater. 11 (1999) 2486–2492.

25] A. Bartkowiak, D. Hunkeler, Alginate–oligochitosan microcapsules. II. Controlof mechanical resistance and permeability of the membrane, Chem. Mater. 12(2000) 206–212.

26] R.H. Chen, M.L. Tsaih, W.C. Lin, Effects of chain flexibility of chitosan moleculeson the preparation, physical, and release characteristics of the prepared cap-sule, Carbohydr. Polym. 31 (1996) 141–148.

27] R.H. Chen, M.L. Tsaih, Effect of preparation method and characteristics of chi-tosan on the mechanical and release properties of the prepared capsule, J. Appl.Polym. Sci. 66 (1997) 161–169.

28] K.C. Gupta, F.H. Jabrail, Effect of molecular weight and degree of deacetyla-tion on controlled release of isoniazid from chitosan microspheres, Polym. Adv.Technol. 19 (2008) 432–441.

29] D.W. Ren, H.F. Yi, H.A. Zhang, W.Y. Xie, W. Wang, X.J. Ma, A preliminary studyon fabrication of nanoscale fibrous chitosan membranes in situ by biospecificdegradation, J. Membr. Sci. 280 (2006) 99–107.

30] W.T. Yu, J.Z. Lin, X.D. Liu, H.G. Xie, W. Zhao, X.J. Ma, Quantitative characterizationof membrane formation process of alginate–chitosan microcapsules by GPC, J.Membr. Sci. 346 (2010) 296–301.

31] B.L. Strand, Y.A. Morch, T. Espevik, G. Skjak-Braek, Visualization ofalginate–poly-l-lysine–alginate microcapsules by confocal laser scanningmicroscopy, Biotechnol. Bioeng. 82 (2003) 386–394.

32] W.T. Qi, W.T. Yu, Y.B. Xie, X.J. Ma, Optimization of Saccharomyces cerevisiaeculture in alginate–chitosan–alginate microcapsule, Biochem. Eng. J. 25 (2005)151–157.

33] W.M. Xue, W.T. Yu, X.D. Liu, X. He, W. Wang, X.J. Ma, Chemical method of break-ing the cell-loaded sodium alginate/chitosan microcapsules, Chem. J. Chin.Univ. -Chin. 25 (2004) 1342–1346.

34] X.D. Liu, W.M. Xue, Q. Liu, W.T. Yu, Y.L. Fu, X. Xiong, X.J. Ma, Q. Yuan, Swellingbehaviour of alginate–chitosan microcapsules prepared by external gelation orinternal gelation technology, Carbohydr. Polym. 56 (2004) 459–464.

35] I. Pajic-Lijakovic, D. Bugarski, M. Plavsic, Influence of microenvironmentalconditions on hybridoma cell growth inside the alginate–poly-l-lysine micro-capsule, Process Biochem. 42 (2007) 167–174.

36] B. Thu, P. Bruheim, T. Espevik, O. Smidsrod, P. Soon-Shiong, G. Skjak-Braek, Algi-

nate polycation microcapsules. I. Interaction between alginate and polycation,Biomaterials 17 (1996) 1031–1040.37] B. Thu, P. Bruheim, T. Espevik, O. Smidsrod, P. Soon-Shiong, G. Skjak-Braek,Alginate polycation microcapsules. II. Some functional properties, Biomaterials17 (1996) 1069–1079.