Study of ohmic contact formation on AlGaN/GaN ...1353343/...Since the ohmic contacts constitute...

Transcript of Study of ohmic contact formation on AlGaN/GaN ...1353343/...Since the ohmic contacts constitute...

-

IN DEGREE PROJECT INFORMATION AND COMMUNICATION TECHNOLOGY,SECOND CYCLE, 30 CREDITS

, STOCKHOLM SWEDEN 2019

Study of ohmic contact formation on AlGaN/GaN heterostructures

KAI-HSIN WEN

KTH ROYAL INSTITUTE OF TECHNOLOGYSCHOOL OF ELECTRICAL ENGINEERING AND COMPUTER SCIENCE

-

D F KTH Royal Institute of

Technology

Study of ohmic contact formation on Al-GaN/GaN heterostructures

Master’s thesis in Nanotechnology

Kai-hsin Wen

Information and Communication TechnologyKTH ROYAL INSTITUTE OF TECHNOLOGYStockholm, Sweden 2019

-

Master’s thesis 2019

Study of ohmic contact formation onAlGaN/GaN heterostructures

Kai-hsin Wen

Information and Communication TechnologyKTH Royal Institute of Technology

Stockholm, Sweden 2019

-

Study of ohmic contact formation on AlGaN/GaN heterostructuresKai-hsin Wen

© Kai-hsin Wen, 2019.

Supervisors: Niklas Rorsman, Chalmers University of TechnologyDing-yuan Chen, Chalmers University of Technology

Examiner: Mattias Hammar, KTH Royal Institute of Technology

Master’s Thesis 2019Information and Communication TechnologyKTH Royal Institute of TechnologySE-100 44 StockholmTelephone +46 8 790 60 00

Cover: The contour plot of the obtained Rc from the laser focus/dose matrix.

Typeset in LATEX, template by David FriskPrinted by KTHStockholm, Sweden 2019

iv

-

Study of ohmic contacts formation on AlGaN/GaN heterostructuresKai-hsin WenInformation and Communication TechnologyKTH Royal Institute of TechnologySE-100 44 Stockholm

AbstractIt is challenging to achieve low-resistive ohmic contacts to III-nitride semiconductorsdue to their wide bandgap. A common way to reduce the contact resistance is torecess the ohmic area prior to metallization. In the minimization of the contactresistance, parameters like the recess depth, anneal temperature and design of themetal stack are commonly optimized. In this work, three other approaches havebeen evaluated. All experiments were performed on AlGaN/GaN heterostructures.The fabricated ohmic contacts were recess etched, metallized with a Ta/Al/Ta stack,and annealed at 550-575◦C.

Firstly, it is shown that the laser writer intensity, transmittance and focus offsetduring optical lithography affect the contact resistance. The reason is believed tobe the variation in the resist profile, which has an impact on the metal coverage. Atthe optimum intensity/transmittance/focus condition, which generates a relativelymedium undercut, a contact resistance of 0.23 Ωmm was obtained.

In the second approach, the metal layer of annealed contacts was removed by wetetching, followed by the re-deposition of a metal stack and annealing. The purposewas to increase the amount of N vacancies in the AlGaN, which are responsible forthe contact formation. A minimum contact resistance of 0.41 Ωmm was achievedwith this method, compared to 0.28 Ωmm with the regular method (without re-metallization).

In the last approach, the bottom Ta layer was sputtered, whereas evaporation wasused in all other cases. The minimum contact resistance was found to be 0.6 Ωmm,which was higher than for the evaporated contacts. The reason was assumed thatthe thickness of sputtered Ta should be thinner than the evaporated Ta due to itshigher density. Moreover, the obtained lower sheet resistance is assumed to causedby the atomic scale damage due to the high energy ions during sputtering.

Keywords: ohmic contacts, wide bandgap, Ta-based, recess etch, N-vacancies

v

-

SammanfattningEn utmaning med III-nitrid-halvledare är att uppnå låg-resistivitetskontakter, pågrund av deras breda bandgap. Ett konventionellt tillvägagångsätt för att reducerakontaktresistansen är att fördjupa ohmska ytan före metallisering. I strävandet avatt minska den ohmska resistansen sker vanligtvis en optimering av följande parame-trar, recessddjup, anlöpningstemperatur och metallagersdesign. I detta arbete såhar samtliga tre parametrar evaluerats. Alla experiment utfördes på AlGaN/GaN-heterostrukturer. De tillverkade ohmska kontakterna var recesssetsade, metalliser-ade med ett Ta/Al/Ta lager och anlöpt vid 550-575◦C.

Den primära undersökningen, visar att laserritar-intensitet, -transmission och -fokusförskjutning under optisk litografi inverkar på kontaktresistansen. Anledningenantas vara variation i resistprofilen, vilket påverkar metallbeläggningen. Vid opti-mal intensitet/transmission/fokus-förhållanden, (som genererar en underskärning),blev den resulterande kontaktresistansen 0.23 Ωmm uppmätt.

I en sekundär undersökning, avlägsnas ohmska kontaktens metallager genom våtet-sning, följt av en återdeponering av ett nytt metallager, samt anlöpning. Syftet varatt öka mängden N-vakanser i AlGaN-lagret, som formar ohmska kontakten. Min-sta kontaktresistansen uppmätt var 0.41Wmm, att jämföras med 0.28 Ωmm, somuppnåddes genom den konventionella metoden (utan återmetallisering).Den sista undersökningen jämförde sputtrade med evaporerade bottenlager av Ta,(evaporation användes som standardmetod i de tidigare undersökningarna). Medsputtrning blev den minsta kontakresistansen 0.6 Ωmm, (högre än de evaporeradekontakterna). En hypotetisk förklarning kan vara att det sputtrade Ta-lagret ärtunnare än det evaporerade Ta-lagret, på grund av en dess högre densitet. Därutöver,den uppmätta lägre skiktresistansen antas bero på den skada i atomskala som skervid de höga energi-kollisioner som joner skapar vid sputtrning.

vi

-

AcknowledgementsThis thesis work is pursued at the Department of Microtechnology and Nanoscience- MC2, Microwave Electronics Laboratory. It is a great experience for me to workhere and during this period I have gained so much knowledge.

I would like to sincerely thank my supervisor Niklas Rorsman for giving me thechance to come to Chalmers and work with him. Despite his tight schedule, hisdoor is always open for discussion whenever I have any question. Furthermore Iwould like to express my deepest gratitude to my daily supervisor Ding-yuan Chenfor his patience and guidance. Thank you for teaching me the processing techniquesin the cleanroom and all the measurements used in this thesis. I would also like tothank Hans Hjelmgren for helping me build a simulation model and teaching me touse TCAD simulation. Also, I would like to appreciate all the people in MicrowaveElectronics Laboratory for creating such a fantastic working environments.

Finally, I am deeply grateful to my family and all my friends for always beingsupportive encouraging me to push on.

Kai-hsin Wen, Gothenburg, June 2019

viii

-

x

-

Contents

List of Figures xiii

List of Tables xv

1 Introduction 11.1 Thesis objectives and summarized results . . . . . . . . . . . . . . . . 21.2 Thesis outline . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

2 Ohmic contact technology 52.1 Metal-semiconductor contact . . . . . . . . . . . . . . . . . . . . . . . 5

2.1.1 Current transport mechanisms . . . . . . . . . . . . . . . . . . 62.2 Ohmic contact mechanism . . . . . . . . . . . . . . . . . . . . . . . . 82.3 Ohmic contact types . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

2.3.1 Planar contacts . . . . . . . . . . . . . . . . . . . . . . . . . . 92.3.2 Recessed contacts . . . . . . . . . . . . . . . . . . . . . . . . . 102.3.3 n+-GaN regrowth contacts . . . . . . . . . . . . . . . . . . . . 12

2.4 Physical modelling . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

3 Fabrication Process 173.1 Standard Cleaning . . . . . . . . . . . . . . . . . . . . . . . . . . . . 173.2 LPCVD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 183.3 Mesa . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

3.3.1 Photolithography . . . . . . . . . . . . . . . . . . . . . . . . . 193.3.2 Plasma Ashing . . . . . . . . . . . . . . . . . . . . . . . . . . 203.3.3 Plasma Etching . . . . . . . . . . . . . . . . . . . . . . . . . . 21

3.4 Ohmic Contact . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 213.4.1 Metal Deposition . . . . . . . . . . . . . . . . . . . . . . . . . 213.4.2 Re-metalization . . . . . . . . . . . . . . . . . . . . . . . . . . 223.4.3 Sputtered Ta . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

4 Characterization 254.1 Scanning electron microscopy . . . . . . . . . . . . . . . . . . . . . . 254.2 Transmission line method . . . . . . . . . . . . . . . . . . . . . . . . 26

4.2.1 TLM structure . . . . . . . . . . . . . . . . . . . . . . . . . . 264.2.2 Epi-layer sheet resistance Rsh . . . . . . . . . . . . . . . . . . 274.2.3 Contact resistance Rc and specific contact resistivity ρc . . . . 27

xi

-

Contents

5 Results 315.1 Laser writer focus/intensity test . . . . . . . . . . . . . . . . . . . . . 315.2 Ohmic contact re-metallization . . . . . . . . . . . . . . . . . . . . . 335.3 Sputtered Ta . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

6 Conclusion and future work 39

Bibliography 41

xii

-

List of Figures

1.1 Schematic of GaN HEMT structure. . . . . . . . . . . . . . . . . . . . 1

2.1 Band diagram of metal-semiconductor in equilibrium [18] . . . . . . . 52.2 Schematic of three different carrier transport mechanism for different

Nd. [24] . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 72.3 E00 plotted as a function of doping concentration for GaN at T= 300K. 82.4 Illustration of three different recess depth cases. (a)the barrier is still

present (b)the barrier is still present but it is too thin to retain 2DEGunder it (c)the barrier is completely removed in etching process. . . . 11

2.5 The simulation model structure(a)model from software (b)schematicof the model . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

2.6 Schematic of the simulation model structure and the obtained resultsof various doping depth, concentration and the temperature. . . . . . 15

3.1 Schematic of the ohmic structure in this work. . . . . . . . . . . . . . 173.2 The schematic of the position of photoresist and the laser beam. . . . 193.3 The etchant versus etching target material (X: The target material

can not be etched by the etchant, ©: The target material can beetched by the etchant, –: Not found from the literature). . . . . . . . 23

4.1 (a)Schematic TLM strcture (b)Microscope image of the TLM structure 264.2 (a)A schematics shows the different components of Rtot. (b) Total

resistance Rtot plotted as a function of isolation distance dx . . . . . . 274.3 Current flow through contact for high and low ρc . . . . . . . . . . . 29

5.1 Illustration of the laser focus/transmittance/intensity matrix with theexact energy received on the substrate. . . . . . . . . . . . . . . . . . 31

5.2 The contour plot of the obtained Rc from the laser focus/dose matrix. 325.3 The schematic of (a) larger sidewall angle (b) smaller sidewall angle

and (c) the GaN depletion region due to too small sidewall angle. . . 325.4 (a)Rc comparison of original and re-deposited ohmic metal stack.

(b)The plot of Rc versus annealing time and the comparison of orig-inal and re-deposited ohmic metal stack. . . . . . . . . . . . . . . . . 33

5.5 The plot of Rc versus annealing time while first Ta layer thicknessdiffers. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 34

5.6 The schematic shows the enlargement of the photoresist and the crosssection of the ohmic contact. . . . . . . . . . . . . . . . . . . . . . . . 34

xiii

-

List of Figures

5.7 Cross sectional SEM image of the sample with the measured Ta thick-ness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 35

5.8 The obtained (a)Rc and (b)Rshversus annealing time with differentmetal thickness. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 36

xiv

-

List of Tables

2.1 Comparison of Rc values and different metal schemes on differentheterostructure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

2.2 Literature values of Rc for recess contacts on different heterostructure 122.3 Rc of regrowth n-GaN contacts on different heterostructure . . . . . . 132.4 The obtained ρc of different doping concentration . . . . . . . . . . . 152.5 The obtained ρc of different doping depth . . . . . . . . . . . . . . . . 152.6 The obtained resistance under different temperature . . . . . . . . . . 15

xv

-

List of Tables

xvi

-

1Introduction

The gallium nitride (GaN) based high electron mobility transistor (HEMT) hasattracted considerable attention during the past two decades and has become anattractive candidate for high frequency and high power applications [1, 2]. GaN is asemiconductor material which possesses a wide bandgap, a high breakdown field anda high saturation electron drift velocity. Furthermore, the GaN HEMT is based on aheterojunction, commonly AlGaN/GaN, which generates a two-dimensional electrongas at the interface with enhanced electron mobility compared to doped GaN. Grownon silicon carbide (SiC) substrate, high thermal conductivity is also possible. Fig.1.1 shows a cross-section of a SiNx-passivated AlGaN/GaN HEMT with the threeterminals gate, source, and drain marked out. As shown in the figure, the source-and drain terminals are ohmic contacts, while the gate is a Schottky contact.

Figure 1.1: Schematic of GaN HEMT structure.

Since the ohmic contacts constitute parasitic elements in the GaN HEMT, it isessential to minimize the contact resistance (Rc) in order to promote a good per-formance. However, the wide band gap of AlGaN between 3.4 (GaN) and 6.2 eV(AlN) makes this a challenge. The standard ohmic metal stack for GaN HEMTs isTi/Al/Ni/Au [3, 4, 5, 6]. However, with the Ti-based metal scheme, a high anneal-ing temperature of 800 to 900◦ C is required. Such high anneal temperature maylead unwanted effects on the heterostructure, such as increasing of sheet resistanceRsh as well as rough surface morphology and poor edge acuity due to the formationof highly resistive Al- and Au containing compounds. Previously, the Mo-basedohmic contacts were developed to obtain low-resistance contacts for low annealingtemperature needed. Roccaforte et al [7] demonstrated that with the metal scheme

1

-

1. Introduction

of Mo/Al/Mo/Au and a pre-treatment with SiCl4 plasma, a very low Rc of 0.15Ωmm was obtained at an annealing temperature of 650◦ C.

Ta- based metal schemes have also been investigated in several studies. The metalstacks of Ta/Ti/Al [8, 9, 10] require annealing temperature of 700 to 950◦ C. An-other Ta- based metal scheme,Ta/Al/Ta, was developed demonstrating a lower an-nealing temperature. The lowest Rc of 0.06 and 0.28 were achieved with differentAl thickness and annealing temperature of 550 and 575◦, respectively [11]. Lin et aldemonstrated recessed Ta/Al/Ta ohmic contacts, where the ohmic contact is formedon the recess sidewall. The lowest Rc obtained is 0.24 Ωmm with a tilt angle of 10◦during evaporation of the first Ta layer and an annealing temperature of 575◦C [12].

To improve the ohmic contacts, several studies have focused on recessed ohmiccontact. Zhang et al performed recess etching by inductive coupled plasma etching(ICP) before metal deposition and obtained a Rc of 0.3 Ωmm [13]. Wang et alreported that with 2DEG totally removed, a very low Rc of 0.26 Ωmm was obtaineddue to direct contact between ohmic electrode and 2DEG [14]. Although the recessetching yields a low Rc, the ohmic recess process needs to have excellent depthcontrol and be low-damage since ion damage on the epitaxial layer may lead toworse Rc. Regrown ohmic contact can produce excellent ohmic contact with an Rcof 0.16 Ωmm [15, 16]. However, the processing is complicated and the associatedcosts much higher compared to recess etching, which may make it less suitable forlarge scale processes. Consequently, recess ohmic contacts are preferable and anohmic recess below 2DEG is performed in order to avoid the requirement of precisecontrol of recess depth.

1.1 Thesis objectives and summarized resultsThe main purpose of this thesis is to investigate and evaluate three different meth-ods intended for decreasing Rc. In the first method, the parameters of the opticallithography are optimized in order to investigate the impact of the resist profile onrecessed contacts. The second method is the removal of the annealed metal, followedby re-metallization to increase the formation of TaN. The third method is to sputterthe first Ta layer to improve the metal coverage of the sidewall and the in-situ Arcleaning is also performed to improve the Rc.

Electrical characterization was performed by the transfer length method (TLM).Scanning electron microscopy is also used to check the cross section of ohmic con-tact. Additionally, technology computer-aided design (TCAD) simulations were per-formed to study the impact of doping concentration, doping depth and temperatureon the formation of ohmic contact.

Characterization results show that the lowest Rc of 0.23 Ωmm can be achieved withthe optimal laser writer focus offset and intensity. With the optimal laser writerfocus/intensity, photoresist profile can be better controlled. Therefore, a mediumundercut can be generated and affect the metal coverage. However, with the secondapproach to re-metalize the ohmic metal, the obtained Rc is 0.41 Ωmm which shows

2

-

1. Introduction

that the idea of enhancing N atoms extraction mechanism is not achieved in thiswork. The third approach, sputtered first Ta layer, shows the highest Rc of 0.6Ωmm in this work. Assumptions are made according to the observed Rc, Rsh andthe SEM characterization, and these assumptions may be the factors that lead tothe failure of lowering the Rc. Further study on the adequate first Ta thickness aswell as the in-situ Ar cleaning are required to decrease the Rc.

1.2 Thesis outlineThis thesis is organized in six chapters:

• The topic and a brief background are introduced in Chapter 1 followed by theaim and outline of the thesis.

• Theory concerning the mechanism of ohmic contact formation, current trans-port mechanism and different types of ohmic contacts are presented in Chapter2.

• The fabrication process is described in Chapter 3.• The main characterization methods are introduced in Chapter 4.• The results are presented and discussed in Chapter 5.• A brief conclusion with a future outlook are presented in Chapter 6.

3

-

1. Introduction

4

-

2Ohmic contact technology

2.1 Metal-semiconductor contactContacts between metal and semiconductor is an essential part of all the electronicdevices. A low contact resistance Rc is an important factor in ohmic contacts.However, ohmic contact formation in III-nitride semiconductors, eg. (Al)GaN, hasbeen an issue due to its wide bandgap. In this project, we investigate various aspects,which potentially could improve the formation of ohmic contact, including electronbeam evaporation and sputtering and re-deposition of ohmic metal stack.

Metal-semiconductor contacts can be divided into two types. One is Schottky con-tact acting as a diode with the rectifying property. The other is a low resistiveohmic contact linear I-V characteristic. Generally, the Schottky barrier is formedby a metal contacting with an undoped or low-doped semiconductor. In contrast,when metal contacts with a highly-doped semiconductor and an additional thermaltreatment can form ohmic contacts.

Figure 2.1: Band diagram of metal-semiconductor in equilibrium [18]

5

-

2. Ohmic contact technology

The band diagram of metal contacting an n-type semiconductor is shown in Fig.2.1. The Fermi level, EF , should be flat when there is no bias applied across thejunction [19]. This results in band bending and causes a depletion region with thewidth W. The Schottky barrier height, φB, is a barrier to electrons. φB depends onthe metal work function, φM , and electron affinity, χ, of the semiconductor. Themetal work function φM is the the work that is required to remove the electronfrom the metal surface to the vacuum level, Evacuum. The semiconductor electronaffinity, χ, is the energy difference between Evacuum and the conduction band of thesemiconductor.The Schottky barrier height is given in Equation.2.1.

φB = φM − χ (2.1)

In order to reach the full potential of semiconductor device technologies, it is nec-essary to minimize parasitic losses. Therefore, ohmic contacts with low resistanceand linear I-V characteristic are needed.

In III-nitride devices it is not enough to only deposit metals on the semiconductorto form an ohmic contact. Thermal annealing is required to form a metal nitride atthe interface [22, 23].

Specific contact resistivity ρc is commonly used to characterize ohmic contacts. ρcis defined in Equation 2.2, where J is the current density and the voltage is at zerobias. In this project, contact resistance per width, Rc, is calculated with the unit ofΩmm, and is used to evaluate the performance of the ohmic contacts.

ρc =(∂J

∂V

)−1v=0

(2.2)

2.1.1 Current transport mechanismsThere are three different mechanisms for carrier transport which is dependent onthe n-type doping concentration, Nd. The depletion width is proportional to Nd(Equation 2.3).

W ∝ 1√Nd

(2.3)

For low-doped semiconductor, Nd < 1017 cm−3, thermal energy for the carriers isrequired to overcome the Schottky barrier, and therefore this mechanism is namedthermionic emission (TE, Fig. 2.2a). If the semiconductor is highly-doped, theSchottky barrier height is constant, but with a much narrower depletion width(Equation 2.3). Due to the small W, it is possible for carriers to tunnel throughthe barrier. This tunnel mechanism is called field emission (FE, Fig. 2.2b). Fieldemission occurs when the doping concentration Nd is higher than 1019 cm−3. For themoderately-doped semiconductors, Nd between 1017 cm−3 and 1019 cm−3, the cur-rent transport is a combination of TE and FE. This mechanism is called thermionic

6

-

2. Ohmic contact technology

field emission (TFE, Fig. 2.2c). The depletion width is too large for carriers to tun-nel through, but with the extra thermal energy, carriers can be thermally excited toan energy above EF where W is thin enough to tunnel through the barrier.

(a) Thermionic emission (b) Field emission (c) Thermionic fieldemission

Figure 2.2: Schematic of three different carrier transport mechanism for differentNd. [24]

The dominant mechanism can be predicted by the calculated value of kTqE00

(Equation2.4). This calculation gives ratio between TE and the other two mechanisms.

E00 =h

4π (Ndmε

) 12 (2.4)

where h, m and ε is Plank’s constant, effective mass and the dielectric constantrespectively. The calculated value of kT

qE00gives the ratio between TE and the other

two mechanisms. When kT/qE00 � 1 , field emission is the dominating mechanismfor carrier transport. Thermionic emission dominates when kT/qE00 � 1 whilekT/qE00 = 1 indicates that thermionic field emission is dominant. This behaviordescribed in Fig. 2.3, in which E00 is plotted as a function of doping concentration[?].

7

-

2. Ohmic contact technology

Figure 2.3: E00 plotted as a function of doping concentration for GaN at T= 300K.

2.2 Ohmic contact mechanismThe mechanism of forming ohmic contact at AlGaN/GaN heterostructures is com-plicated and has not been fully understood. Many studies were performed to inves-tigate the mechanisms of obtaining the low Rc in ohmic contacts with Ti/Al basedcontacts. The most frequent and acceptable explanation is that nitrogen atoms areextracted from AlGaN layer and thus leaving N-vacancies as n-dopants [25, 26, 27].Another explanation for the mechanism of ohmic contact formation is that with thelow work function compound/alloy formed at the metal-semiconductor interface, alow barrier height is formed which enhance the thermionic or thermionic field emis-sion [28]. Luther et al proposed that the diffusion of native oxide on GaN and Althrough Ti will be reduced, and therefore the ohmic contact with low work functionAl-Ti intermetallic phase is formed [28].

The formation of TiN is the most common mechanism adopted to explain the low Rc.Nitrogen atoms are extracted from AlGaN to form TiN, which results N-vacanciesin the barrier layer acting as n-dopants. Therefore, the barrier layer becomes heavilydoped, which increases the tunneling probability and lowers the Rc [27]. Moreover,it was proposed by Luther et al that during the process, not only TiN but AlN wasalso formed [28]. Formation of AlN also creates N-vacancies, leaving heavily dopedinterface that narrows the depletion region. The barrier height might also be de-creased because of the potential across AlN [29]. Chaturvedi et al developed a modelto study the mechanism of Ti/Al/Mo/Au metal stacks forming ohmic contacts onAlGaN/GaN heterostructure and the model disclosed that Ga diffused throughoutthe metal and reacted with Mo [30]. The Ga-vacancies lead to a charge imbalanceand therefore, N atoms nearby replace the vacant Ga site in the lattice causingN-vacancies acting as n type dopants as described above.

It is believed that the formation of TaN has the same mechanism as TiN [27]. Inthis work, we assume that the formation of a thick TaN layer between Ta andAlGaN possibly terminates the mechanism of extracting N from AlGaN. Therefore,

8

-

2. Ohmic contact technology

removing TaN by wet chemical etching and the re-depositing the metal stack wereanticipated to increase the extraction of N from AlGaN.

2.3 Ohmic contact types

2.3.1 Planar contacts

Approaches to fabricate ohmic contact on AlGaN/GaN heterostructure includesplanar, MBE regrowth and recess etched contacts. Planar contact is the simplest andthe standard method to fabricate ohmic contacts on GaN HEMTs. A planar ohmiccontact is formed by metallizing the contact area followed by annealing. Values ofRc from the literature are shown in Table. 2.1.

It is clearly found that typical annealing temperature are over 800◦C with an excep-tion of an Mo/Al/Mo/Au metal stack that the required annealing temperature of650 ◦C. In addition, for Ti/Al based planar ohmic contacts, higher Al concentrationin AlGaN barrier leads to higher Rc, which might due to the larger energy barrier.Ruvimov et al suggested that Al might form a barrier for the diffusion of N atomsand therefore higher Al composition in AlGaN layer might lead to higher Rc [31].

9

-

2. Ohmic contact technology

Metal Stack Barrier layer Annealing T Rc Ref(◦C) (Ωmm)

Ti/Al/Ni/Au GaN/Al0.28Ga0.72N/AlN 820 0.45 [4]

Ti/Al/Ni/Au Al0.24Ga0.76N 830 0.2 [5]

Mo/Al/Mo/Au In0.17Al0.83N/AlN 650 0.15 [7]

Ti/Al/Ni/Au In0.18Al0.82N/AlN 900 0.15 [32]

Ta/Si/Ti/Al/Ni/Au In0.18Al0.82N/AlN 825 0.36 [33]

Ti/TiN GaN/Al0.2Ga0.8N/AlN 850 0.13 [34]

Ti/TiN GaN/Al0.35Ga0.65N/AlN 850 0.6 [34]

Table 2.1: Comparison of Rc values and different metal schemes on different het-erostructure

2.3.2 Recessed contactsFor planar contacts, the distance between ohmic metal stack and 2DEG is largeand makes it difficult to obtain low Rc. In order to reduce the distance between2DEG and ohmic metal, and avoid the required high anneal temperature of planarcontacts and the complex process of regrown n+-doped contacts, recessed contactshas been extensively studied. Prior to the ohmic metallization, an recess etchingstep is performed, which is able to reduce the annealing temperature.

Čičo et al reported the Rc of 0.39 Ωmm obtained by recess etching before metal de-position and annealing with temperature of 700◦C while the conventional annealingtemperature was above 800◦C [39].

However, the concept of recessed contacts adds more process parameters, such asrecess depth and the sidewall slope that have to be optimized. In general, therecess depth can be divided into three different cases. The first case is that partof the barrier is still present and the contact mechanism of this case is similar toplanar contacts as in Fig. 2.4(a), but with smaller distance between ohmic metaland 2DEG. However, a thinner barrier results in a smaller 2DEG density, which

10

-

2. Ohmic contact technology

aggravates the formation of ohmic contact. Fig. 2.4(b) and (c) show that thebarrier is still presented but it is so thin that there is no 2DEG formed under it andthe barrier is completely removed during the etching process, respectively. In thiswork, to avoid the difficulty of controlling the etching depth precisely, the recess isetched below 2DEG. Therefore, the deposited ohmic metal can have direct contactto the AlGaN and GaN layer at the sidewall.

Figure 2.4: Illustration of three different recess depth cases. (a)the barrier is stillpresent (b)the barrier is still present but it is too thin to retain 2DEG under it(c)the barrier is completely removed in etching process.

Bergsten demonstrated a very low Rc of 0.14 Ωmm with the almost removed InAlNbarrier [40]. Lin et al reported a low Rc of 0.24 Ωmm with the completely removedAlGaN barrier layer[12]. Buttari et al obtained the Rc of 0.27 Ωmm with the barrieronly slightly etched [41]. Generally, there is no clear conclusions of the recess depthsince etching depth is not uniform. Table. 2.2 shows some literature values of Rcobtained from recessed contacts. It can be seen that the annealing temperature ofrecess contacts is lower than planar contacts.

11

-

2. Ohmic contact technology

Metal Stack Barrier layer Annealing T (◦C) Rc (Ωmm) Ref

Ti/Al/Ni/Au In0.18Al0.82N 700 0.39 [39]

Ta/Al/Ta In0.17Al0.83/AlN 550 0.14 [40]

Ta/Al/Ta Al0.25Ga0.75N 575 0.24 [12]

Ti/AlMo/Au GaN/Al0.3Ga0.7N/AlN 850 0.26 [42]

Table 2.2: Literature values of Rc for recess contacts on different heterostructure

2.3.3 n+-GaN regrowth contacts

Regrowth contacts process starts from etching past the barrier layer, and a latticematched, highly doped n-GaN is then grown in the recess. Saunier et al utilizedthe regrowth n-doped GaN contacts to achieve extremely low Rc of 0.1 Ωmm [35],which is similar in Tang’s study [36]. Regrowth n-GaN in the recess improves theRc due to the direct contact to 2DEG. This fabrication method can offer extremelylow Rc value, but the process is complicated and the cost is high, which possiblymakes this method unsuitable for mass production. Moreover, to obtain low Rc, alarge density of 2DEG is required while the standard electron sheet concentrationns of AlGaN/GaN heterostructure is about 1013 cm−2 which makes it more difficultto achieve. Literature values of the contact resistance on different heterostructureare shown in Table. 2.3. From those papers, higher ns in the barrier decreases thecontact resistance while the obtained value of Rc from barriers with moderate nsare similar to those metal-based contacts.

12

-

2. Ohmic contact technology

Berrier Rc ns Ref(Ωmm) (cm−2)

In0.17Al0.83N/AlN 0.16 1.92× 1013 [15](2.5/1.5 nm)

In0.18Al0.82N/AlN 0.10 — [35](8/1 nm)

In0.17Al0.83N/AlN 0.16 2× 1013 [37](5.6/1 nm)

GaN/In0.17Al0.83N/AlN 0.22 1.6× 1013 [38](2/3.5/1 nm)

Table 2.3: Rc of regrowth n-GaN contacts on different heterostructure

2.4 Physical modellingTCAD simulation was made to promote further understanding of the ohmic con-tact formation. The simulation model was based on the thermionic field emissionmechanism. In the simulation the contact on the top of the structure is modelledas a Schottky contact while the bottom contact is a perfect ohmic contact (Fig.2.5b). The GaN layer and the lower part of the AlGaN layer are assumed to have abackground doping of 1015cm−3.

The n-doping, representing the N-vacancies, is distributed in the upper part ofAlGaN layer where the dopants are. The simulations study the impact of n-doping(N-vacancies), doping depth and working temperature.

(a) (b)

Figure 2.5: The simulation model structure(a)model from software (b)schematicof the model

13

-

2. Ohmic contact technology

As expected, the contact resistance is inversely proportional to the doping concen-tration (Fig. 2.6a and b). The specific contact resistivity is obtained from theslope in Fig. 2.6 and is listed in Table. 2.4. For doping concentration higher than> 1019cm−3, field emission (FE) is dominant. The depletion width becomes thinnerwhile the Schottky barrier keeps the same height. Therefore, it becomes easier forcarrier to tunnel through the barrier and hence, the ρc is decreased. For thermionicfield emission (TFE), the doping concentration is simulated from 1018 to 1019cm−3.The carriers with enough thermal energy can tunnel through the midsection of thebarrier, which implies a direct temperature dependence. The relation between Rcand doping concentration of FE and TFE is shown below [43].

Rc ∝ exp[φB√ND

](FE) (2.5)

Rc ∝ exp[

φB√ND cosh E00kT

](TFE) (2.6)

From the equations, it is clearly shown that for FE and TFE, Rc is proportional to1√ND

. The simulation results is consistent to the experimental results reported byYu et al [43]. The investigation of re-metallization is motivated by the assumptionthat the creation of N-vacancies is limited by the availability of Ta near the metaland semiconductor interface. By removing the metal nitride, more N-vacancies maybe created in the barrier layer, and Rc is anticipated to be decreased.

The depth of the region where N-vacancies are created is unknown. From the sim-ulations, it is clear that a larger doping depth promotes a low contact resistivity(Fig. 2.6c and Table 2.5). The doping depth starts at the surface and with largerdoping depth, the dopants spread deeper in the AlGaN layer, which increases theeffective area. Due to the current crowding effect, which is introduced in Chapter4, the resistance has an inversely proportional relation to the effective area [46].Consequently, with a larger doping depth, lower resistance is obtained.

The temperature dependence of the contact resistivity is simulated with a constantdoping concentration of 1019cm−3 while the temperature is varied from 300K to450K. From the Fermi-Dirac distribution function, more carrier are excited abovethe Fermi level at higher temperature. Therefore, current density increases andleads to smaller Rc. Chang et al reported that for moderate doping concentration,Rc has strong dependence on temperature [44]. The reported results are consistentto the simulation results (Fig. 2.6d and Table 2.6).

14

-

2. Ohmic contact technology

(a) (b)

(c) (d)

Figure 2.6: Schematic of the simulation model structure and the obtained resultsof various doping depth, concentration and the temperature.

Doping concentration (cm−3) 1× 1018 5× 1018 9× 1018 1× 1019 1× 1020 K 1× 1021ρc (Ωcm2) 6.98 1.16× 10−4 1.18× 10−6 1.04× 10−6 8.11× 10−9 4.47× 10−9

Table 2.4: The obtained ρc of different doping concentration

Doping depth (µm) 0.01 0.025ρc (Ωcm2) 1.79× 10−6 5.57× 10−7

Table 2.5: The obtained ρc of different doping depth

Temperature (K) 300 350 400 450ρc (Ωcm2) 1.79× 10−6 1.07× 10−6 6.18× 10−7 3.53× 10−7

Table 2.6: The obtained resistance under different temperature

15

-

2. Ohmic contact technology

16

-

3Fabrication Process

The fabrication process for ohmic contacts on AlGaN/GaN heterostructures is in-troduced in this chapter. The process starts from standard cleaning. Then a siliconnitride passivation layer with a thickness of 55 nm is deposited by low-pressurechemical vapor deposition (LPCVD). Device isolation is achieved with mesa etchingby inductive coupled reactive ion etching (ICP-RIE) plasma after photolithographydefinition of the mesa structure. Then the ohmic structure is patterned with laserwriter where an image reversal photoresist AZ5214 is utilized for lift off. After theohmic recess etching with ICP-RIE, the ohmic metal stack Ta/Al/Ta is deposited byelectron beam evaporator with the same resist, making the ohmic metal self-alignedto the recess. In the final step, lift-off is performed to obtain the TLM structure(Fig. 3.1).

Figure 3.1: Schematic of the ohmic structure in this work.

3.1 Standard Cleaning

The 15×15mm2 samples used in our project is diced from the same epitaxial wafer,which the AlGaN/GaN epitaxial heterostructures are grown on SiC by metal-organicchemical vapor deposition (MOCVD). Before the high temperature LPCVD SiNxdeposition, samples must be cleaned by standard RCA cleaning process to removeall particles and metal contamination on the sample surface to prevent pollutionof the LPCVD chamber. Samples are first immersed in remover 400, isopropanoland deionized water for five minutes respectively to remove the photoresist used forprotection during dicing. Remover 400 is usually used for photoresist removal andis composed by 1-methyl-2-pyrrolidone. This is followed by cleaning in SC1 solutionNH4OH(25%):H2O2:H2O=1 : 1 : 5 at 80◦C for 10 minutes to remove organics; thenimmersed in SC2 solution HCl : H2O2 : H2O=1 : 1 : 6 at 75◦C for 2 minutes tostrip metallic particles. Subsequently immersed in NH4OH(25%):H2O=1 : 20 fortwo minutes to remove oxide residues on the sample surface.

17

-

3. Fabrication Process

3.2 LPCVDLow-pressure chemical vapor deposition is one of the most common manufacturingprocess in thin film deposition. LPCVD reactors can be divided into hot wall andcold wall system [47]. Temperature distribution in hot wall system is more uniformthan cold wall systems and the convection effects can be reduced in hot wall systems[48]. With the advantages of better uniformity, reduced convection effect and goodconformal step coverage [49], hot wall LPCVD is used in this study for depositingSiNx passivation layer.

Silicon nitride is a dielectric material that has high electrical resistivity, high chem-ical resistance to acids, bases, salts and molten metals, as well as the ability towithstand elevated temperature exposure. Therefore, silicon nitride thin films havebeen widely used in device processing such as passivation layer, mechanical protec-tive mask, diffusion barrier and gate dielectrics [50, 51, 52]. For instance, they couldbe used as passivation layer because they are good barriers to water and sodium,and they can serve as masks during selective oxidation process since they oxidizevery slowly.

After cleaning, the wafers were placed on quartz boat in the furnace. Dummy siliconwafers were also placed on the quartz boat in order to stimulate a fully loaded boatand present a consistent thermal mass [48, 53]. A 55nm SiNx passivation layerwas grown under temperature of 820◦C, a pressure of 250 mTorr with dichlorosilane(DSC) and ammonia (NH3) flows of 224 sccm and 23 sccm, respectively to supplythe silicon and nitrogen. The reaction is described by the formula:

3SiCl2H2 + 4NH3 → Si3N4 + 6HCl + 6H2

3.3 MesaDevice isolation is commonly achieved by ion implantation or mesa etching. Mesaetching is often performed with Cl2 based plasma dry etching to define the activeregion of a device [54]. However, 2-D electron gas (2DEG) channel will be exposedon the side wall which may cause excessive gate leakage when contacted with thegate metalization [55]. Another approach to achieve device isolation is high energyion implantation, which can creates point defects or simple defects that producedeep-level electron and hole traps [56]. Through these defects, high-resistivity isachieved. Ion implantation has the advantage of maintaining the surface flat whichsimplifies further processing and having lower gate leakage compared to mesa etching[55]. However, the thermal stability of ion implanted material affects the reliabil-ity since implant-damaged material might degrade at high temperature [57, 58].Consequently, mesa etching is preferred than ion implantation in this work.

18

-

3. Fabrication Process

3.3.1 PhotolithographyPhotolithography is a technique that transfer a desired pattern to the photoresist onthe wafer surface and is extensively used in IC fabrication. In this work, photolithog-raphy was performed using a non-contact laser writer (Heidelberg Instruments DWL2000). The lithography process includes spin coating, exposure and development.

A laser writer is used instead of stepper or mask aligner since maskless lithographyprocess could increase the precision and flexibility, and direct writing system couldobtain better control of the photoresist profile through the control of the exposuredose and focus settings compared to the mask lithography, where mask contactintroduces uncertainty in dimension control and resist profiles. The irradiance oflaser beam can be described by Gaussian distribution, and the focus offset is thedeviation of best exposure focus from default lens position. Focus off set is optimizedto ensure that the photoresist is positioned at the best focal plane (Fig. 3.2).

Figure 3.2: The schematic of the position of photoresist and the laser beam.

Prior to the photoresist coating, hexamethyldisilazane (HMDS) was coated on sam-ple, which acts as an adhesion promoter. After applying the HMDS on samplesurface, the photoresist is spin coated. The sample is then mounted on a vacuumchuck of a spinner. Spin coating is commonly used to coat thin films in order toobtain good uniformity of the films. The thicknesses are usually of the order ofmicrometers and the thickness of the resist is determined by spinning acceleration,spinning speed, spinning time and the viscosity of the photoresist.

19

-

3. Fabrication Process

Mesa isolation and recess ohmic contact are both achieved by ICP-RIE. However, thephotoresists used in both process are different. Positive photoresist is used in mesaetching, where the chemical structure of exposed area on the photoresist becomesmore soluble and can be removed easily in developer. An image reversal photoresistis applied on the wafer during ohmic contact lithography process. Since ohmiccontact is formed at the sidewall between the 2DEG channel and ohmic metals bye-beam evaporation followed by lift-off process [12], the applied photoresist becomesan important factor.

A positive photoresist (S1813) was applied for the definition of the mesa, while anegative, image reversal resist (AZ5214) is used for the ohmic contact definition.The AZ5214 is exposed by laser writer and the exposed area becomes soluble asnormal positive photoresist. However, a special crosslinking agent in AZ5214 be-comes active after reversal baking at 125◦C for 1 minutes. The originally exposedarea becomes almost insoluble and no longer light sensitive while the unexposedarea still remains as normal positive resist. After flood exposure, the originallyunexposed area becomes soluble and is developed in spin developer.

In this work, the resist is deposited with a rotation speed of 4000 rpm for 30 s.After spin coating, samples are softbaked at 110◦C for 2 minutes and 1 minute forthe S1813 and AZ5214 resist, respectively. Softbake is performed to drive off mostof the solvent in the resist since the dissolution rate in the developer can be affectedby the solvent concentration in the photoresist. Then the resist coated sample isexposed by laser writer developed in developer MFCD26 for 90 seconds and 351Bfor 25 s for the S1813 and AZ5214 resists, respectively. Finally, the developed areasare subjected to plasma ashing.

3.3.2 Plasma AshingPlasma ashing process and plasma descum process are carried out after samples areexposed by laser writer and developed. This step is in order to remove the residualresist, which might affect the uniformity of the etching rate across the whole sample.It is a common used cleaning method, which is highly effective and environmentallysafe method. Oxygen is the common gas used in plasma ashing. The samples areput in a vacuum chamber. Oxygen gas fills the chamber and a plasma is generatedby RF-power. The oxygen ions break the bonds of the resist. Water and carbondioxide are generated during the process which is pumped from the chamber. Inthis work, the sample is etched by oxygen plasma with the power of 40 W for 30seconds.

20

-

3. Fabrication Process

3.3.3 Plasma EtchingThe mesa etching is performed by an inductive coupled plasma reactive ion etching(ICP-RIE) system, which is a common type of high density plasma etching system.ICP-RIE is an anisotropic etching process that can be used to etch a great varietyof materials; for instance, semiconductors, metals, dielectrics and polymers. Twoseparate energy sources independently control the ion density and energy in thesystem. One is applied to generate bias power to the lower electrode to controlthe ion energy, while the other applies power to ICP coil and hence can controlthe ion flux. An oscillating magnetic field is generated by the RF current throughthe coil. By controlling the induced magnetic field, the plasma density can increasesignificantly [47]. Different reactive gases are used when etching different materials;for instance, NF3 is commonly used for SiN and Si etching, argon plasma is used asphysical etching gas, and Cl2 and SiCl4 gases are often used in III-V etching.

In our work, NF3 gas was used to etch silicon nitride layer with 50 sccm flow rate.The heterostructure was etched with Cl2 gas with flow rate of 20 sccm and Ar gaswith 10 sccm flow rate. After mesa etching, an oxygen plasma striping of 100W for 2minutes was carried out in order to remove etching residues. Then, the samples werecleaned in remover 400, isopropanol and deionized water for five minutes respectivelyin order to fully remove the photoresist S1813.

3.4 Ohmic ContactSimilar to mesa etching, ohmic recess is also etched by ICP-RIE. Silicon nitride isetched by NF3 with the flow rate of 50 sccm while the heterostructure is etchedby Cl2, SiCl4, and Ar gases with the flow rate of 39 sccm, 1 sccm, and 10 sccm,respectively. An oxygen plasma ashing is also carried out with the RF power of 40Wfor 30 seconds to remove etching residues. Subsequently, ohmic metal deposition andlift-off are performed.

3.4.1 Metal DepositionE-beam evaporation is a form of physical vapor deposition in which the electronbeam from charged tungsten filament bombards the target material which is thenevaporated to the gaseous state and deposited on the wafer surface. When heatingmetals in the evaporator, the electron beam commonly sweeps over the target inorder to heat the target material with a even heat distribution.

Prior to metal deposition, the wafer is immersed in HF : H2O=1:10 solution for4 minutes and HCl : H2O=1:10 solution for 60 seconds to strip oxides and otheretching residues. In this work, the ohmic metal stack Ta/Al/Ta is deposited byelectron beam evaporator in a ultra high vacuum chamber. However, Ta has avery high melting point of 3017◦ C which makes it difficult to evaporate with thesweeping mode. Consequently, the electron beam focuses at a fixed position. Thethickness of first Ta layer is investigated in this work since it is considered to affectthe formation of the ohmic contact. The Al layer of 280 nm is evaporated in the

21

-

3. Fabrication Process

sweep mode since the melting point of Al is 660◦ C which is lower than Ta and easierto evaporate. The second 20 nm Ta layer is deposited to prevent the oxidation ofAl. After the metalization completed, lift-off was performed in remover400 at 65◦ Cand ultrasonic bath for 5 minutes.

3.4.2 Re-metalization

The re-metalization step starts from the removal of the original ohmic metal stackand the TaN formed during annealing. Tantalum’s chemically inert and is resistantto most chemicals. The most common method used to etch Ta is dry etching withCF4/O2 gas [68]. Although dry etching is also high selective, coating photoresistas a mask needs to ensure the alignment during the exposure which makes it morecomplicated compared to wet etching. Therefore, wet chemical etching is chosen inthis work. Wet chemical etching is a process that immerse the sample in a bathof liquid chemicals in order to remove a certain type of material. Wet etching is asimple and low cost etching technique. However, etching with liquid chemicals isusually isotropic and less controllable and hence the reproducibility is low comparedto dry etching. Since the aim is to etch Ta/TaN, while other layers such as theherterostructure AlGaN/AlN, the buffer layer GaN and the substrate SiC should beremain unaffected.

As listed in table (Fig. 3.3), the heated solution of KOH/NaOH with water canetch most of the material including the AlGaN/GaN heterostructure, making it anunsuitable etchant in this investigation. In this work, we choose HF (5%) : HNO3 :H2O(20%) =1 : 2 : 1 to selectively etch the ohmic contact at room temperature.This solution is suggested in [59] without stating the etching rate. We repeated theTa etching for several times and obtained two methods. The first way is immersingthe sample in Ta etchant for over 50 minutes. However, it is too time-consumingto perform. Since the ohmic metal stack formation was Ta/Al/Ta, another way isusing standard Al etchant composed ofH3PO4 : CH3COOH : HNO3= 60% : 3.5% :2.5%. The etching rate is 30 Å/sec.Subsequently, the sample was immersed in Taetchant, Al etchant and Ta etchant again for 6, 9, 20 minutes respectively. In bothmethods, agitation during etching secures a scalable etch rate, which otherwise islimited by the formation of bubbles of etching products generated during the process.

22

-

3. Fabrication Process

Figure 3.3: The etchant versus etching target material (X: The target materialcan not be etched by the etchant, ©: The target material can be etched by the

etchant, –: Not found from the literature).

3.4.3 Sputtered TaSputtering is a type of physical vapor deposition techniques which is based on ionbeam bombardment. Sputtering is a commonly used method of thin film deposition,which can be divided into several types such as DC sputtering, magnetron sputtering,and RF sputtering etc. In the DC sputtering system, the target material is placedon the cathode while the substrate is placed on anode. Usually, the sputtering gasfilled in the chamber is inert gas (typically Ar). The applied DC voltage betweenelectrodes maintains the glow charge in which the Ar+ is generated. The Ar+ ionsare accelerated at the cathode and thus sputter the target material on the cathoderesulting the thin film deposition of the target material on the substrate.

In this project, sputtered Ta layer was investigated in order to improve the sidewallcoverage. Furthermore, sputtering also offers in-situ cleaning with Ar-plasma. Thefirst Ta layer was changed to be deposited with DC sputtering while the followingAl/Ta was still deposited by evaporation since there is no Al in the sputtering toolat Chalmers.

23

-

3. Fabrication Process

24

-

4Characterization

In this work, two main characterization techniques are used. The first one is trans-mission line method (TLM), which is extensively used to examine the ohmic contactbehavior by characterizing the contact resistance and sheet resistance. The other isthe scanning electron microscopy (SEM), which is used to check the cross section ofohmic contact. Both methods are introduced in this chapter.

4.1 Scanning electron microscopyScanning electron microscope (SEM) is a widely used instrument to examine surfacecharacteristics. Instead of light as the illumination source, a focused electron beamis emitted from the electron gun and focused on the sample surface. A SEM imageis formed by collecting the scattered electrons. The electro-optical path of the SEMcontains several electromagnetic lenses and deflection coils to control the diameterand astigmatism of the electron beam. Due to the interaction between the elec-tron beam and the sample surface, secondary electrons (SE) can be generated fromthe inelastic scattering, while backscattered electrons (BSE) can be produced fromelastic scattering which often retain 60 to 80% of the incident electrons’ energy.

SEs usually have the energy of several electron volts, and SEs can only escape fromthe volume near the sample surface of the interaction zone. However, BSEs havehigher energy and can escape from deeper level of the interaction zone compared toSEs. Consequently, images generated by SEs will have higher resolution of surfacetopography while images produced by BSEs demonstrate clear compositional con-trast if the sample contains more than one chemical elements. The compositionalcontrast depends on the backscatter coefficient, η, which increases with the atomicnumbers of the chemical elements in the sample.

η = nBSEni

(4.1)

η represents the ratio of the number of the BSEs escaping from the sample nBSEto the number of incident electrons ni [69]. Thus, the sample that contains higheratomic number elements would generates more BSEs. The different number of thecollected BSEs appear different gray color levels in a black and white image. Hence,the higher atomic number elements the area contains, the brighter it appears in theSEM image. Despite that the SE signal contributes to form compositional contrastimage, the contrast is not clear since the SE signal does not have as strong depen-dence on the atomic number as BSE [69]. In this work we use SEM to characterize

25

-

4. Characterization

the cross-sections of the samples in backscattered electrons mode to identify theepitaxial layers and metal stacks.

4.2 Transmission line methodNumerous of techniques can be used to obtain contact resistance, the transmissionline method (TLM) is the most common and popular method. It was originally pro-posed by Shockley [70] and was further studied and extended by Berger [71], whichprovided a convenient and simple method to determine resistive performance of theohmic contacts, including the contact resistance (Rc), specific contact resistance,(ρc), sheet resistance (Rsh) and transfer length.

4.2.1 TLM structureThe ladder structure consisting of more than three rectangular metal contacts, whichare identical in the area, are used as the test structure for TLM (Fig. 4.1). Thesemetal pads are separated with adjacent contact pads with incrementing spacing dis-tances (ranging from 5 to 30 µm (d1 to d5) in this work). The resistance betweenevery contact pads are measured with four probes. The outer two probes give thecurrent and the inner two probes measure the voltage difference, and the resistancevalues are given. Four-probe measurement is utilized instead of two-probe mea-surements since the current and voltage are separated which eliminate the lead andcontact resistance from the measurement [72].

(a) (b)

Figure 4.1: (a)Schematic TLM strcture (b)Microscope image of the TLM structure

26

-

4. Characterization

4.2.2 Epi-layer sheet resistance RshThe resistance of a homogeneous semiconductor can be expressed by the sheet re-sistance if the semiconductor is homogeneous rectangular. The resistance and sheetresistance is expressed as:

R = ρ LtW

(4.2)

Rsh =ρ

t(4.3)

where ρ, L, t, and W represents the resistivity, length, thickness, and width ofthe semiconductor, respectively. Introducing the Rsh enables to consider resistorsas numbers of squares since the resistance can be simply obtained by multiplyingby Rsh. However, it is hard to consider semiconductor as a homogeneous materialsince the semiconductor is usually a diffusion or epitaxially grown layer. Hence, anaverage resistivity ρ̄ can be calculated as a first approximation by considering thedoping profile of the layers.

4.2.3 Contact resistance Rc and specific contact resistivityρc

The plot of Rtot as a function of dx is shown in Fig. 4.2b. Rtot is the sum ofseveral components, in which Rm is the resistance of contact metal, Rsemi is resis-tance due to the semiconductor, and Rc is the contact resistance between metal andsemiconductor interface.

(a) (b)

Figure 4.2: (a)A schematics shows the different components of Rtot. (b) Totalresistance Rtot plotted as a function of isolation distance dx

From the Fig. 4.2b, Rc and Rtot can be obtained. An extrapolation at the pointof zero distance d=0 represents 2Rc. In this work, Rc is scaled with the width ofthe contact, and hence has the unit of Ωmm. Moreover, Rtot can be expressed byEquation 4.4.

27

-

4. Characterization

Rtot = 2Rm + 2Rc +Rsemi (4.4)

In general, the contact metal resistance Rm is usually much smaller than contactresistance Rc, and hence can be ignored. The slope of the fitting line (Fig. 4.2b)represents the sheet resistance Rsh. Consequently, Rtot can be expressed by Equation4.7.

Rc >> Rm (4.5)

Rsemi =RshW

d (4.6)

Rtot = 2Rc +RshW

d (4.7)

The transfer length is defined as where the voltage, caused by current transferringbetween semiconductor and metal contacts, drops to 1/e of its maximum value,which is usually at the contact edge. The transfer length is dependent on specificcontact resistance and sheet resistance, and the relation can be expressed as:

LT =√ρcRsh

(4.8)

If L ≥ 1.5LT , the effective contact area, Aeff , can be treated as LTW . Due to thecurrent crowding effect, LT can be much smaller than L, and consequently, Aeff canalso be much smaller than the contact metal area. Hence, this means that in theclose proximity of the contacts, the current density would be higher than expectedand therefore needs to be considered.

Specific contact resistivity,ρc, is usually measured in Ωmm2 which independent ofcontact area or geometry. It can be defined as in Equation 4.9:

ρc =(∂J

∂V

)−1v=0

(4.9)

The specific contact resistance contains the contact resistivity of both the interfaceand the regions above and below it. ρc can also be determined directly by the contactresistance Rc, transfer length LT and the width of contact pads. It can be expressedas:

ρc = RcLTW = RcAeff (4.10)

Aeff in the equation is the effective contact area. The contact area is always differentfrom the Aeff due to the current crowding effect which is presented by Kennedy et al[73]. The current going through the semiconductor is uniform; however, the currentflow is not uniform through the metal contacts. Since the current flows through themetal contacts with low resistance, and therefore, the current density at the edgeof the contacts are higher and will drops to zero at the far edge. For small ρc, onlythe edge is used for current conduction and the used area of the contacts would be

28

-

4. Characterization

expanded for high ρc because of the high transition resistance which is shown in Fig.4.3.

(a) High ρc]

(b) Low ρc

Figure 4.3: Current flow through contact for high and low ρc

29

-

4. Characterization

30

-

5Results

The main results of this project will be presented in this chapter and can be dividedinto three sections, including laser writer intensity and focus offset optimization,re-metallization ohmic contact, and initial results of ohmic contacts fabricated bysputter deposition.

5.1 Laser writer focus/intensity test

The optimal laser writer focus offset and dose enable to obtain better control of thephotoresist, laser writer focus offset was from 5% to 35%, dose intensity from 30%to 60% and the transmittance keeps constant at 25%. The focus/transmittance/in-tensity matrix settings and the equivalent energy are shown in Fig. 5.1.

Figure 5.1: Illustration of the laser focus/transmittance/intensity matrix with theexact energy received on the substrate.

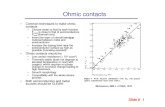

After evaporation and lift-off, the sample was annealed at 575◦C for 40 minutes, andthe contact resistance obtained through TLM is presented as a contour plot in Fig.5.2.

31

-

5. Results

Figure 5.2: The contour plot of the obtained Rc from the laser focus/dose matrix.

Lin et al reported that the sidewall angle can be controlled by reversal bakingtemperature and laser writer exposure intensity [12]. For steeper sidewall angle, Rcincreases due to the smaller contact area. However, Rc also increases with smallersidewall angle since the increase of depleted GaN leads to decreasing AlGaN andhence, hinder the formation of 2DEG [40] (Fig. 5.3). Moreover, photoresist profileis an important factor to determine the sidewall angle. Consequently, the optimalexposure intensity is studied in this work to control the photoresist profile throughvarying the laser writer focus offset and dose while the transmittance is constant.It can be seen from the plot that the lowest Rc obtained is around 0.23 Ωmm andfrom Fig. 5.1, the corresponding laser energy received on the substrate is 9 mJ/cm2.This optimal laser writer focus/transmittance/intensity is applied in the subsequentparameter testing.

Figure 5.3: The schematic of (a) larger sidewall angle (b) smaller sidewall angleand (c) the GaN depletion region due to too small sidewall angle.

32

-

5. Results

5.2 Ohmic contact re-metallization

The re-metallization process includes etching away the ohmic metal stack and re-depositing the metal again. The re-deposition metal stack annealed at 600◦C wascharacterized by TLM. Rc and Rsh before and after re-metallization process areplotted in Fig. 5.4.

(a) Rc versus annealing time (b) Rsh versus annealing time

Figure 5.4: (a)Rc comparison of original and re-deposited ohmic metal stack.(b)The plot of Rc versus annealing time and the comparison of original and re-deposited ohmic metal stack.

The lowest Rc of the re-deposited metal contacts obtained in Fig. 5.4a is 0.5 Ωmmwhile the lowest Rc of original metal contacts is 0.28 Ωmm. It is clearly shownthat the Rc increases after re-metallization process. The Rsh versus annealing time(Fig. 5.4b) shows that the sheet resistance keeps similar values, which is around267 Ω/�, after the etching followed by metal re-deposition process. The similar Rshindicates that the epi-layer is not damaged during the wet etching step and hence,the increase in Rc is not caused by epi-layer damage.

The sample was originally deposited with the metal stack Ta/Al/Ta with thicknessof 15/280/20 nm respectively, and annealed at 600◦C. Due to the increase in Rcand unaffected Rsh, we assumed that the cause of the increasing Rc might be theannealing temperature and the thickness of the first Ta layer according to the resultsfrom Lin et al [12]. Consequently, we reduced the annealing temperature to 575◦Cand the thickness of the first tantalum layer was changed to 5 and 10 nm.

33

-

5. Results

(a) 5 nm (b) 10 nm

Figure 5.5: The plot of Rc versus annealing time while first Ta layer thicknessdiffers.

Fig. 5.5 is the plot of Rc and Rsh versus annealing time for the Ta thickness of 5and 10 nm respectively. Compared to the results of 15 nm Ta in Fig. 5.4a, valueof the lowest Rc for 10 nm Ta decreases from 0.5 Ωmm to 0.41 Ωmm while thelowest Rc for 5 nm Ta increases from 0.5 Ωmm to 0.67 Ωmm. This might be relatedto the larger mask we applied during the re-metallization process. During the firstmetallization step, the applied mask was smaller, and hence the samples had to beevaporated with a tilt angle. However, the mask was enlarged in the re-metallizationstep to ensure the correct alignment. Fig. 5.6a illustrates the original mask in thefirst metallization process and the larger mask in re-metallization process and thecross section after re-metallization is shown in Fig. 5.6b.

(a) The schematic of the larger pho-toresist .

(b) The cross section of first andre-metallization.

Figure 5.6: The schematic shows the enlargement of the photoresist and the crosssection of the ohmic contact.

34

-

5. Results

Because of the smaller mask and the tilt angle during the first metal evaporation,the sidewall Ta thickness is thinner than the bottom Ta thickness which is expectedto be 15 nm (Fig. 5.7). The exact sidewall thickness measured with SEM is shownto be 13.95 nm. However, with the larger mask used in the re-metallization step,the re-metallization sidewall Ta thickness is thicker than the sidewall thickness inthe first metallization step. Consequently, the expected re-deposited sidewall Tathickness for 10 nm is close to the original deposited sidewall Ta thickness while 5nm Ta is too thin for the contacts. This is the possible explanation for the decreasedRc for 10 nm and the increased Rc for 5 nm.

Figure 5.7: Cross sectional SEM image of the sample with the measured Ta thick-ness.

35

-

5. Results

5.3 Sputtered TaTo improve the sidewall metal coverage, the first Ta layer were deposited by sput-tering for three different thickness (10, 15, 20 nm) with the following Al/Ta layer(280/20 nm) deposited by e-beam evaporation. The contact resistance was also beencharacterized and is shown in Fig. 5.8a.

(a) Rc (b) Rsh

Figure 5.8: The obtained (a)Rc and (b)Rshversus annealing time with differentmetal thickness.

Compared to the lowest Rc of evaporated metal stack (0.23 Ωmm), the lowest Rc ofsputtered Ta was 0.6 Ωmm with the Ta thickness of 10 nm and annealing at 575◦Cfor 64 minutes. However, the sample with thickness of 15 nm did not perform asohmic contacts even after annealing for 32 minutes while the lowest Rc obtainedat the annealing time of 16 minutes was 6.65 Ωmm. Similarly, the lowest Rc ofthe sample with Ta thickness of 20 nm was obtained at the annealing time of 16minutes, which is 1.72 Ωmm. The Rc started to rise after 16 minutes annealing forthe samples with 15 and 20 nm Ta. The sheet resistance of 10 nm Ta sample issimilar to the evaporated sample which is around 280 Ω/�. However, Rsh of 15 nmsample is around 215 Ω/� which slightly lower than the evaporated sample whileRsh of 15 nm is much lower than other samples, seen in Fig. 5.8b.

There are two assumptions that we made for the observed high Rc of all sputteredsamples and the slightly lower Rsh of 20 nm Ta. The first assumption is that sincethe sputtered thin film is denser than evaporated thin film due to the incidentmomentum [74], the sputtered thin film should be thinner than the evaporatedthin film. Consequently, the sample with 10 nm sputtered Ta obtained the lowestRc obtained the lowest Rc while the optimized thickness of evaporation is 15 nm.Another assumption was made due to the lower Rsh of 20 nm Ta. The high energyion in sputtering process might lead to atomic scale damage on/below the samplesurface [75, 76], and thus the damaged epi-layer leads to the lower Rsh.

36

-

5. Results

Moreover, the Al and second Ta layer are deposited by e-beam evaporation after thefirst Ta is deposited by sputtering. However, once the sample contact with air, theremay be oxide layer formed on the first Ta layer. Therefore, future investigation ofdepositing Au on Ta while sputtering to prevent from oxidation is also required.

37

-

5. Results

38

-

6Conclusion and future work

The aim of this thesis is to optimize different aspects of ohmic contact formation.There are three types of ohmic contacts, planar contacts, regrowth n+-regrowthcontacts and recess etched contacts. In this thesis, recess contacts are used andin order to avoid the depth control problem, the recess was etched beyond the2DEG. The ohmic contact optimization in this work includes laser writer focus/-transmittance/intensity test, re-metallization as well as electron beam evaporationand sputtering were also investigated.

The optimal laser writer focus/transmittance/intensity test was tested on a sample,which composed of a focus/transmittance/intensity matrix. The lowest Rc obtainedin this work is 0.23 Ωmm and the corresponding optimal laser focus/intensity is25%/35% while transmittance keeps constant at 25% i.e. the laser power receivedon the substrate is 9 mJ/cm2.

One of the widely accepted explanations of ohmic contact mechanism is that theformation of TiN extracts the nitrogen atoms from AlGaN layer, and hence the N-vacancies are created and act as n-dopants, which makes the barrier layer heavilydoped. In this work, we assumed that the formation of TaN between Ta and GaNwould block the extraction mechanism of nitrogen atoms. Therefore, wet chemicaletching was performed to remove the original ohmic metal stack and the formed TaN.Then the re-deposition of ohmic metal stack was carried out in order to extract morenitrogen atoms from GaN i.e. creating more N-vacancies in barrier layer.

The Rsh obtained from the characterization of re-metallized samples indicates thatthe epi-layer was not damaged during the wet etching process. However, com-paring the lowest achieved Rc between original metallization (0.28 Ωmm) and re-metallization (0.41 Ωmm), it can be concluded that a lowering of the contact resis-tance was not achieved by re-metallization described in this report.

Different sputtered Ta thickness (10/15/20 nm) was investigated in this project. Thelowest contact resistance of the sputtered Ta was 0.6 Ωmm when the Ta thicknesswas 10 nm, annealed for 64 minutes at 575◦C. Although the samples with 20 nmTa showed ohmic behavior, the Rsh was about 65 Ω/� lower than the evaporatedsamples. These are results from the initial tests of sputtered Ta and thus furtherinvestigation about the possible damage caused by high energy ions and the thicknessof the sputtered Ta is needed.

39

-

6. Conclusion and future work

40

-

Bibliography

[1] Bright, A., Thomas, P., Weyland, M., Tricker, D., Humphreys, C.,Davies, R.:Correlation of contact resistance with microstructure for Au/Ni/al/Ti/AlGaN/-GaN ohmic contacts using transmission electron microscopy. Journal of AppliedPhysics89(6) (2001) 3143–3150

[2] Ambacher, O., Foutz, B., Smart, J., Shealy, J., Weimann, N., Chu, K.,Murphy,M., Sierakowski, A., Schaff, W., Eastman, L., et al.: Two dimensional electrongases induced by spontaneous and piezoelectric polarization in undoped anddoped AlGaN/GaN heterostructures. Journal of applied physics87(1) (2000)334–344

[3] Jacobs, B., Kramer, M., Geluk, E., Karouta, F.: Optimisation of theTi/Al/Ni/Au ohmic contact on AlGaN/GaN FET structures. Journal of Crys-tal Growth241(1-2) (2002) 15–18

[4] Mahajan, S.S., Dhaul, A., Laishram, R., Kapoor, S., Vinayak, S., Seh-gal,B.: Micro-structural evaluation of Ti/Al/Ni/Au ohmic contacts with differentTi/Al thicknesses in AlGaN/GaN HEMTs. Materials Science and Engineering:B183(2014) 47–53

[5] Xin, H., Poust, S., Sutton, W., Li, D., Lam, D., Smorchkova, I., Sandhu,R.,Heying, B., Uyeda, J., Barsky, M., et al.: Optimization of AlGaN/GaN HEMTohmic contacts for improved surface morphology with low contact resistance.In: CS MANTECH Conf. (2010) 149–152

[6] Liu, Q., Yu, L., Deng, F., Lau, S., Chen, Q., Yang, J., Khan, M.: Study of con-tact formation in AlGaN/GaN heterostructures. Applied physics letters71(12)(1997) 1658–1660

[7] Lee, J., Yan, M., Ofuonye, B., Jang, J., Gao, X., Guo, S., Adesida, I.:Low resis-tance Mo/Al/Mo/Au ohmic contact scheme to InAlN/AlN/GaN heterostruc-ture. physica status solidi (a)208(7) (2011) 1538–1540

[8] Qiao, D., Jia, L., Yu, L., Asbeck, P., Lau, S., Lim, S.H., Liliental-Weber,Z.,Haynes, T., Barner, J.: Ta-based interface ohmic contacts to AlGaN/GaNheterostructures. Journal of Applied Physics89(10) (2001) 5543–5546

[9] Kim, K.H., Jeon, C.M., Oh, S.H., Lee, J. L., Park, C.G., Lee, J.H., Lee,K.S.,Koo, Y.M.: Investigation of Ta/Ti/Al/Ni/Au ohmic contact to AlGan/GaNheterostructure field-effect transistor. Journal of Vacuum Science & TechnologyB: Microelectronics and Nanometer Structures Processing, Measurement, andPhenomena23(1) (2005) 322–326

[10] Lim, S.H., Washburn, J., Liliental-Weber, Z., Qiao, D.: Microstructural ev-idence on electrical properties of Ta/Ti/Al and Ti/Ta/Al ohmic contacts ton-AlGaN/GaN. Applied Physics Letters78(24) (2001) 3797–3799

41

-

Bibliography

[11] Malmros, A., Blanck, H., Rorsman, N.: Electrical properties, microstructure,and thermal stability of ta-based ohmic contacts annealed at low temperaturefor GaN HEMTs. Semiconductor Science and Technology26(7)(2011) 075006

[12] Lin, Y.K., Bergsten, J., Leong, H., Malmros, A., Chen, J.T., Chen,D.Y.,Kordina, O., Zirath, H., Chang, E.Y., Rorsman, N.: A versatile low-resistance ohmic contact process with ohmic recess and low-temperature an-nealing for GaN HEMTs. Semiconductor Science and Technology33(9)(2018)095019

[13] Zhang, J., Wang, L., Wang, Q., Jiang, Y., Li, L., Zhu, H., Ao, J.P.: Plasma-assisted ohmic contact for AlGaN/GaN heterostructure field-effect transistors.Semiconductor Science and Technology31(3) (2016) 035015

[14] Wang, L., Kim, D.H., Adesida, I.: Direct contact mechanism of ohmic metal-lization to AlGaN/GaN heterostructures via ohmic area recess etching.AppliedPhysics Letters95(17) (2009) 172107

[15] Yue, Y., Hu, Z., Guo, J., Sensale-Rodriguez, B., Li, G., Wang, R., Faria,F.,Fang, T., Song, B., Gao, X., et al.: InAlN/AlN/GaN HEMTs with regrownohmic contacts and fTof 370 GHz. IEEE Electron Device Letters33(7)(2012)988–990

[16] Guo, J., Cao, Y., Lian, C., Zimmermann, T., Li, G., Verma, J., Gao, X.,Guo,S., Saunier, P., Wistey, M., et al.: Metal-face InAlN/AlN/GaN high electronmobility transistors with regrown ohmic contacts by molecular beam epitaxy.physica status solidi (a)208(7) (2011) 1617–1619

[17] Joglekar, S., Azize, M., Beeler, M., Monroy, E., Palacios, T.: Impactof recessetching and surface treatments on ohmic contacts regrown bymolecular-beamepitaxy for algan/gan high electron mobility transistors.Applied Physics Let-ters109(4) (2016) 041602

[18] Grover, Sidhant Effect of transmission line measurement (TLM) geometry onspecific contact resistivity determination. Master’s thesis, Rochester Instituteof Technology (2016)

[19] Tung, R.T.: Recent advances in schottky barrier concepts. Materials Scienceand Engineering: R: Reports35(1-3) (2001) 1–138

[20] C.A.J. Ammerlaan, A. Chantre, P.W.: Science and Technology of DefectsinSilicon. Volume 9. Elsevier Science Publisher B.V. (2014)

[21] Lyubomirsky, I., Lyahovitskaya, V., Cahen, D.: Dopant accumulation dur-ing substitutional–interstitial diffusion in semiconductors. Applied physics let-ters70(5) (1997) 613–615

[22] Nikitina, I., Vassilevski, K., Wright, N., Horsfall, A., ONeill, A., Johnson,C.:Formation and role of graphite and nickel silicide in nickel based ohmic contactsto n-type silicon carbide. Journal of Applied Physics97(8) (2005)083709

[23] Kuchuk, A., Kladko, V., Guziewicz, M., Piotrowska, A., Minikayev, R.,Stonert,A., Ratajczak, R.: Fabrication and characterization of nickel silicide ohmiccontacts to n-type 4H silicon carbide. In: Journal of Physics:Conference Series.Volume 100., IOP Publishing (2008) 042003

[24] Greco, G., Iucolano, F., Roccaforte, F.: Ohmic contacts to gallium nitridematerials. Applied Surface Science383(2016) 324–345

42

-

Bibliography

[25] Kim, J.K., Jang, H.W., Lee, J.L.: Mechanism for ohmic contact formationof ti on n-type GaN investigated using synchrotron radiation photo emissionspectroscopy. Journal of applied physics91(11) (2002) 9214–9217

[26] Wang, D.F., Shiwei, F., Lu, C., Motayed, A., Jah, M., Mohammad, S.N.,Jones,K.A., Salamanca-Riba, L.: Low-resistance Ti/Al/Ti/Au multilayer ohmic con-tact to n-GaN. Journal of Applied Physics89(11) (2001) 6214–6217

[27] Mohammad, S.N.: Contact mechanisms and design principles for nonal-loyedohmic contacts to n-GaN. Journal of applied physics95(9) (2004)4856–4865

[28] Luther, B., Mohney, S., Jackson, T., Asif Khan, M., Chen, Q., Yang,J.:Investigation of the mechanism for ohmic contact formation in Al and Ti/Alcontacts to n-type GaN. Applied physics letters70(1) (1997) 57–59

[29] Motayed, A., Bathe, R., Wood, M.C., Diouf, O.S., Vispute, R., Mohammad,S.N.: Electrical, thermal, and microstructural characteristics of Ti/Al/Ti/Aumultilayer ohmic contacts to n-type GaN. Journal of applied physics93(2) (2003)1087–1094

[30] Chaturvedi, N., Zeimer, U., Wurfl, J., Tr ankle, G.: Mechanism of ohmiccontact formation in AlGaN/GaN high electron mobility transistors. Semi-conductor Science and technology21(2) (2006) 175

[31] Ruvimov, S., Liliental-Weber, Z., Washburn, J., Qiao, D., Lau, S., Chu,P.K.:Microstructure of ti/al ohmic contacts for n-algan. Applied PhysicsLet-ters73(18) (1998) 2582–2584

[32] Jardel, O., Callet, G., Dufraisse, J., Piazza, M., Sarazin, N., Chartier, E.,Oualli,M., Aubry, R., Reveyrand, T., Jacquet, J.C., et al.: Electrical performancesof AlInN/GaN HEMTs. a comparison with AlGaN/GaN HEMTs with similartechnological process. International Journal of Microwave and Wireless Tech-nologies3(3) (2011) 301–309

[33] Arulkumaran, S., Ng, G.I., Ranjan, K., Kumar, C.M.M., Foo, S.C., Ang,K.S.,Vicknesh, S., Dolmanan, S.B., Bhat, T., Tripathy, S.: Record-low contact re-sistance for InAlN/AlN/GaN high electron mobility transistors on Si with non-gold metal. Japanese Journal of Applied Physics54(4S) (2015)04DF12

[34] Jatal, W., Baumann, U., Tonisch, K., Schwierz, F., Pezoldt, J.: High-frequencyperformance of GaN high-electron mobility transistors on 3C-SiC/Si substrateswith Au-free ohmic contacts. IEEE Electron Device Letters36(2) (2014) 123–125

[35] Saunier, P., Schuette, M.L., Chou, T.M., Tserng, H.Q., Ketterson, A.,Beam, E.,Pilla, M., Gao, X.: InAlN barrier scaled devices for very high fT and for low-voltage RF applications. IEEE Transactions on Electron Devices60(10) (2013)3099–3104

[36] Tang, Y., Shinohara, K., Regan, D., Corrion, A., Brown, D., Wong, J.,Schmitz,A., Fung, H., Kim, S., Micovic, M.: Ultrahigh-speed gan high-electron-mobilitytransistors with fT/fmax of 454/444 GHz. IEEE Electron Device Letters36(6)(2015) 549–551

[37] Guo, J., Li, G., Faria, F., Cao, Y., Wang, R., Verma, J., Gao, X., Guo,S.,Beam, E., Ketterson, A., et al.: MBE-regrown ohmics in InAlN HEMTs witha regrowth interface resistance of 0.05mm. IEEE Electron device letters33(4)(2012) 525–527

43

-

Bibliography