Structures—From Trellis to Greenhouse

Transcript of Structures—From Trellis to Greenhouse

Structures—From Trellis to Greenhouse by David S. Ross

Structures can add to your garden- ing enjoyment in a number of ways. The beginning gardener may get along with a minimum, just a place to keep tools and supplies. Others will find additional structures advantageous and reasonable.

Coldframes, hotbeds, and green- houses provide a place to start seed- lings or to grow an early crop of let- tuce. A storage shed or area is needed for rakes, hoes, power tillers, fertil- izers, and numerous other items. Gar- dening space can be expanded verti- cally by using a fence or trellis to support a growing vine or even a fruit tree. And when the harvest is over, a place must be available to store the surplus produce until it can be con- sumed.

The environment in plant growing and food storage structures is quite important. Environmental control equipment such as heaters, coolers, ventilation fans, and thermostats are necessary to maintain the appropriate temperature conditions. Light and wa- ter are essential for plant growing and must be supplied in a suitable way.

Plans and information releases from the U.S. Department of Agriculture are available from your county Ex- tension office. These offices have additional information and will be able to answer questions on specific gardening subjects,

A hotbed or coldframe is well suited for starting seedlings early for transplanting into the home garden. It can double as a place to grow cool- season vegetables in the spring for table use or to extend the fall grow- ing season.

The coldframe is generally a wood-

David S. Ross is Extension Agricul- tural Engineer, University of Maryland, College Park.

en frame box about 3 by 6 feet in size with the back (north side) higher than the front so as to slope the top to capture the most sunlight, and for rain runoff. The sloped top, attached by hinges, is made of window sash» storm windows, or a frame covered with polyethylene film. The hotbed differs by having a source of heat to warm the soil and in colder climates to warm the air.

A sunny well-drained location with wind protection is ideal, A location near the south side of the house is good because it is close to water and electricity, and the young plants can be given the frequent attention they need.

Good construction conserves the soil heat at night. Make the joints as airtight as possible. Soil can be banked up around the sides to keep it warmer. The wood parts should be painted with a primer and one or two coats of white paint to reflect the light.

A wood preservative, such as 2 per- cent copper naphthenate, is safe near plants and can be used to give addi- tional protection before painting. Creosote and pentachlorophenol are

Coldframe.

sash support weatherstripped

61

toxic to plants and should not be used.

A convenient size may depend on the building materials available, but a 3- by 6-foot coldframe or hotbed gives plenty of room for young to- mato, pepper, cabbage, onion, and other plants for a big home garden. Height of the frame can be 12 inches in front (south side) and 18 inches in the back (north side). However, these dimensions can be reduced; the top may be open most of the time after the last frost when the plants are tall The length can be in multiples equal to the width of the window sash or other material used for the cover.

Heat for the coldframe comes from the sun which warms the soil and air. At night the heat is slowly lost through the cover. The temperature must be controlled during the day so it does not get too high for the plants (maximum of 100° F). The cover must be raised to permit ventilation, or you can install a small ventilation fan controlled by a thermostat.

Cool-season crops, such as cabbage, cauliflower, and lettuce, can stand a day temperature of 60'' to 65° F. Warm-season crops, such as eggplant, peppers, tomatoes, and melons, do better at 65"^ to 75° day temperature. The night air temperature can be 5° to 10° lower with good results. Cold- frame temperature may not be easy to control, depending on weather con- ditions and the frequency wàth which someone can check the temperature. However, with experience a satisfac- tory operating procedure should be found.

The hotbed is heated by an electri- cal cable placed under the soil. In northern areas of the United States, 12 to 16 watts of heating cable per square foot of bed area is needed. In southern areas 10 watts per square foot should be adequate.

Heating cables vary in length and wattage rating. Select the number of cables needed for the total wattage.

thermostat and remote bulb

banked soil

Be sure adequate electrical service with ground fault interrupter (GFI] is available to meet requirements of the National Electrical Code and any local codes.

Lay the heating cable on the ground 6 inches below the intended planting surface. Carefully spread the cable so it is uniformly spaced on the bottom. Avoid kinks. Do not lay cable across another cable as overheating damage may result.

Cover the cable with 2 inches of soil or sand. Then place Va-inch mesh hardware cloth across the surface of the sand to protect the cable from gardening tools. Add a 4-inch layer of soil or soil mix on top of the wire mesh for growing plants. Sometimes 2 inches of sand or vermiculite is placed below the cable to conserve heat.

Early hotbeds had 12 to 24 inches of animal bedding and manure in them to provide heat as the manure composted. These beds generally grew better plants because of carbon dioxide released by the manure.

A thermostat, normally built into the heating cable, is used to control soil temperature. A separate thermo- stat with remote sensing bulb works well because the sensing bulb can be placed in the root zone, A tempera- ture of 70° to 75° F is ideal for ger-

Layout of heating cable in hothed. Cable is covered with soil.

62

minating most seeds. A good ther- mometer should be used to check operation of the thermostat at seed depth and to measure air temperature.

Cost of operation depends on the weather, location, and construction. A 3- by 6-foot bed will use 1 to 2 kilowatt-hours of electricity per day.

Operating costs can be reduced by adding insulation to the sides, cover- ing the bed at night with straw or other insulating material, and keeping the frame in good repair and airtight.

Watering is important. Try to have the bed moist at all times but not soaked. Apply water in the morning so plant foliage can dry by evening.

Greenhouses A greenhouse can open a new world

of enjoyment for the seasonal gar- dener who otherwise has to put away his gardening tools each fall. It can also increase the pleasure of the in- door plant grower who needs better light and better control of tempera- ture and humidity.

Rising fuel costs, the relative high cost of the structure, and the needed environmental equipment limit the number of people who can invest in a hobby greenhouse. Although food can be grown in the off-season, the expense generally will be greater than buying the product in the super- market.

A small greenhouse can be designed and built by an individual or can be purchased from one of the many manufacturers. Some shapes and styles look quite different from the conventional and show that one's imagination is the limit. They can be attached to the house or freestand- ing, away from any building.

The home greenhouse can be at- tached to the home where space is limited or where it blends well into the architecture and landscaping. The attached greenhouse is conveniently accessible and water, electricity, and heating facilities may be shared with

the house. Heat loss is less since one side is shared with the house and not exposed to the weather. The amount of sunlight may be less because of shading if the greenhouse is on the east or west wall of the house.

Choice of location for your green- house may be limited but there are several things to consider. Of primary importance is available sunlight. A southern or southeastern exposure would be first choice for good winter lighting when young seedlings are growing. The east side is second choice because it gives exposure to the morning sun. The north side of a building is the least desirable location unless only shade-loving plants are grown.

The greenhouse can be partially shaded in summer by deciduous trees, but should not be shaded in winter. Keep in mind that the winter sun is lower in the sky and shadows of ever- greens and buildings are much longer.

The building site should be well- drained with the greenhouse floor built up and the surrounding ground sloped from the site to carry rain- water away. Water, fuel for heating, and electricity should be available nearby so utility connections can be made. Check local electrical and plumbing codes, and get qualified people to do the work. Shelter from wind helps reduce heat loss.

Size of the greenhouse will often be limited by cost and available space. If cost is a major factor, con- sider a coldframe or hotbed instead. The temperature is more difficult to control in a very small greenhouse and heat loss is high compared to a larger house. A 6- by 6-foot green- house could better be replaced by one or two 3- by 6-foot hotbeds.

Greenhouse size depends on the amount of growing space you feel you need and can maintain. Also bear in mind that many people soon find they run out of space. Space may be needed in the greenhouse for working

63

and for storing soil mix, chemicals, tools, and other items. However, heat- ing the work and storage space will be expensive. Estimate the amount of use throughout the year in justifying an investment.

Width of the greenhouse is fixed once construction is completed. But with prior planning, the length can be increased in the future to give more growing space. Benches generally are 2 to 4 feet wide for easy working from one side, and 2^2 to 3 feet high. Aisles would be a minimum of 2 feet wide, or 2^2 to 3 feet wide if a cart, v^heelchair, or wheelbarrow is used.

Leave at least 6 inches between each sidewall and the bench to per- mit good air circulation. Do not crowd yourself on headroom either. Gable roof houses should have at least 5V2 feet eave heights and a minimum of 8 feet at the ridge.

A minimum greenhouse size is about 8 by 10 feet for a freestanding house; A lean-to greenhouse is limited to widths of 7 to 12 feet by the roof slope. Roof slope for glass green- houses should be 6 inches of rise per foot of width, and 7 to 8% inches of rise per foot for fiberglass and poly- ethylene [film plastic] houses.

The steep slope is to permit mois- ture condensing on the inside of the roof to run off instead of dripping onto the plants, promoting disease. It also allows snow to slide off to let light in.

Ideally, a greenhouse has a mini- mum framework needed to support a translucent cover so the maximum amount of light is received. The sup- porting frame can be made of wood, aluminum, plastic, and black or gal- vanized iron. The cover may be glass, rigid plastic or fiberglass, or plastic film. Each material has advantages and disadvantages which should be considered for the type greenhouse planned.

Glass greenhouses are long lasting; require a good foundation and strong,

bench width aisle width

rigid frame; and have high initial cost. Maintenance is reduced but heat loss is increased if a metal frame is used instead of wood. Fiberglass has a variable service life depending on the quality product used.

Film plastic has a service life of one or two years and can be used on quite temporary frames. Annually or every second year, commercial people replace polyethylene on good frames which last many years. This spreads

Top, freestanding, slant-leg greenhouse. Bottom, suggested minimum dimensions for a greenhouse. Benches should be placed far enough from side wall to allow adequate ventilation.

64

out the cost of the cover over the life of the greenhouse.

Regardless of the cover used, be sure it is a high quality material made for greenhouses.

A recent development is the use of two layers of film plastic spaced % of an inch to 4 inches apart to reduce heat loss by 30 percent. The two layers are often installed together and then separated by a small fan.

Polyethylene houses lose heat by radiation more rapidly than glass and fiberglass and therefore require more heat. Polyethylene houses are tighter than glass houses so less heat is lost by air infiltration or leakage.

The small greenhouse requires heat- ing and ventilating equipment. Part of the winter heat is received from the sun, and on mild sunny days you may have to ventilate to reduce the temperatures. However, at night no heat is received from the sun and heating units are required to maintain the temperature.

Heat can be distributed in the

exhaust vents are required (except for eiectric heaters) '

fmned-pipe radiator

Some heating systems for greenhouses.

Heat Loss Factors Typical Small Greenhouse

Heat loss factor

Calm Windy Greenhouse covering area area

Polyethylene or Fiberglass 1.2 1.4 Glass 1.5 1.8 Double layer plastic

or glass 0.8 1.0

greenhouse in three v^ays: forced hot air; natural convection from small space heaters, hot water or steam pipes; and direct radiation. Any of the common fuels may be used.

A good quality heater has a ther- mostat and is vented to the outside, except for electrical units. Unvented heaters can discharge gases harmful to plants and deadly to humans into the greenhouse, and should never be used.

The amount of heat required for a greenhouse depends on the maximum temperature difference between out- side and inside, the surface area of the greenhouse, the quality or tight- ness of construction, and the wind.

A simple formula for determining heat loss is (surface area of trans- parent greenhouse cover) times (maxi- mum temperature difference to be maintained) times (heat loss factor for the covering and wind) equals (heat loss, in BTU/hr.) To convert to kilowatts for electric heaters, divide by 3,413. Heater output should equal the heat loss calculated.

Heat loss factors are given in the table. Maximum heat loss is normally about an hour before sunrise.

Ventilation is an exchange of air inside the greenhouse with outside air. Ventilation is needed for cooling, to reduce high humidity, and to re- plenish carbon dioxide. The air ex- change can be achieved by opening vents and doors or by using fans.

Exhaust fans in combination with inlet louvers are a good ventilation

65

exhaust fan

■:^-ß/-—,

/ ^ <*! 1

/ /'' /

butterfly ridge vent

i

system used by many greenhouse operators. Fans can be wired to a thermostat for automatic operation, and sized to seasonal requirements of the greenhouse. A two-speed fan is desirable to permit spring and fall ventilation at half the summer rate. The exhaust fan and inlet louver should be placed at opposite ends of the greenhouse.

Small fans can be used in the green- house to circulate the air continuous- ly to maintain a more uniform tem- perature during the heating period.

The ventilation rate is calculated by multiplying the greenhouse floor area, in square feet, times 12 to give the fan capacity, in cubic feet per minute (CFM). Since there are pressure losses in moving air through the greenhouse, the fan should have the required capacity at a pressure rating of Vs inch of water static pressure (s.p.). Check your catalog for the pressure rating or ask the salesperson for assistance.

The number 12 is cubic feet per

minute per square foot of floor area. The number is 1.5 to 2.0 times the average greenhouse height so the fan capacity is, in reality, 1.5 to 2.0 times the volume of the greenhouse. This volume is necessary to remove the summer heat load.

Vents at the ridge, side walls, and door can be used for natural con- vective air exchange. Using the prin- ciple that warm air rises, the vents are opened and closed manually or by motorized unit in response to the inside temperature. Cooler outside air enters to replace escaping warm in- side air.

Shading devices over the green- house can reduce the light intensity and heat load in summer. Evaporative coolers can be used effectively where the temperature exceeds 90° F for more than 10 to 15 days a year. In dry areas of the country the inside temperature can be reduced 20° or more. In humid areas the temperature reduction is less. The evaporative cooler fan pulls air through a wet pad. Heat is removed from the air to evaporate the water, thus reducing the air temperature.

Big Investment The greenhouse requires the great-

est commitment of money. Shortcuts in equipping the greenhouse with proper heating and ventilating equip- ment can lead to disappointments. Consult local greenhouse owners be- fore making your investment, A good manual for hotbeds, coldframes, and greenhouses is available from the Northeast Regional Agricultural Engi- neering Service for $2.00. Ask for Wohhy Greenhouses and Other Struc- tures, NRAES-2, from NRAES, Riley- Robb Hall, Cornell University, Ithaca, N.Y. 14853.

A propagation unit is used to start

Ventilation systems for greenhouses. Top, mechanical, and bottom, convec- five.

plants from seeds or cuttings by pro- viding the environmental factors which encourage good groM^th. The unit typically has lights and may be equipped with a water misting sys- tem and heating cable or other means of providing bottom heat to the soil. A ventilation fan is often needed to remove lamp heat.

Good controls are needed to do the job right. Time clocks can control the lighting and misting cycles. Thermo- stats can be used to control the air and soil temperatures.

Typically, people start vegetable seed in their homes under fluorescent lamps. The plant containers may be wooden or plastic boxes. To maintain a high humidity, the propagating con- tainers are enclosed by a plastic cover. Heat may be supplied by the room air temperature or by locating the propagating unit over a radiator or other heat source. This simple ar- rangement works well for the once-a- year spring project—if you exercise care.

Young vegetable plants grow best with a lot of light, and a minimum of 1,000 foot-candles is desirable. Good light can be supplied by 40-watt cool

white fluorescent lamps spaced 6 inches apart and hung a few inches above the plants. A height equal to the spacing between lamps will give fairly uniform lighting.

At a 6-inch height the plants re- ceive about 500 foot-candles from a standard 40-watt, 2-lamp fixture. Two 1,500 milliampere fluorescent lamps give 1,000 foot-candles at 6 inches. The 2 types of lamps cannot be in- terchanged. Reflectors improve the lighting at plant level.

Major disadvantage of the fluo- rescent lamp is that the light de- creases as the lamps age, so a lamp lighted for 8,000 hours may give less than half the light of a new one. For

Left, corrugated fiberglass 8- by 12-foot portable greenhouse. Right, plants being started in greenhouse. This type green- house was buiJt and sold by Future Farmers of America chapter as part of school vo-ag project in Burlington, Wash. PJans are available from North- western Vocational Curriculum Man- agement Center, Commission for Vocational Education, Building 17, Air- dustriaJ Park, Olympia, Wash. 98504, for $1.25.

67

growing plants they should be re- placed before that time.

Incandescent lamps are the ones commonly used around the home. They are easy to install and the least expensive. However, they have a low efficiency and a short operating life (1,000 hours).

Fluorescent light is broad spectrum, operates cooler, and has greater light intensity so it is better suited for plant lighting. Incandescent light is in the red and far red portion of the spec- trum which triggers certain plant pro- cesses; it can be used to supplement fluorescent lamps.

Continuous light can be used for most seedlings for the first 2 and 3 weeks, but then the young plants should have a dark period of 4 to 8 hours per day. The best way to con- trol the lighting period is with a 24- hour time clock.

Air and soil temperatures are im- portant factors in germination. A heating cable with thermostat is one way to maintain the soil temperature at a desired 70° to 75° F. The pres- ence of lamps helps keep the soil warm.

As the plants get older, the tem- perature should gradually be reduced so the temperature change at trans- planting outdoors will not be too great. Young seedlings will grow tall and spindly in high air temperatures and poor light.

Rapid growth is encouraged by high humidity and good soil moisture. Watering or misting frequently can meet these requirements.

Most garden supply houses have fairly simple and inexpensive water- ing systems. Typically, a time clock is used to control a small solenoid valve which turns the water on and off automatically. A misting system requires a time clock which permits 6 seconds of mist each 6 minutes, as an example. Lamps must be protected from the water.

Carbon dioxide is another impor-

tant factor for good growth. If a small fan is used to move the lamp heat away, it will also keep fresh carbon dioxide moving in contact with the plant leaves. Direct a gentle breeze of air over the plants.

While these environmental factors are needed to achieve the best growth, success also depends on use of high- quality seed and stock plants, a suit- able growing medium, and simul- taneous control of all environmental factors. The growing medium must provide good moisture conditions, a high nutrient level, and proper aeration.

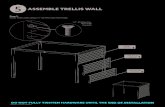

Your imagination is the limit on using fences, trellises, and other struc- tures to support plants. One person grew squash in a small 8- by 15-foot garden by getting the vines to grow up a 6-foot wooden fence. The vines were partially supported by string. The string was first tied tightly around vertical boards of the fence, and then the ends were tied loosely around the squash vines.

Tomatoes can be tied up to stakes. Peas and beans can grow on a fence made of several strands of string at- tached to closely spaced stakes. Cu- cumbers and other vines can grow on a trellis made by nailing wood strips on stakes driven into the ground. Va- rieties of fruit trees are adaptable to trellis arrangements and can be used as a hedgerow in the landscape.

Trellis provides support for vine plants as well as decorative touch.

68

The plant support structure can be functional to create additional garden space in a crowded area, or it can be decorative and express creative- ness in the landscape design if done properly.

In windy areas, take steps to pro- tect the vegetable or fruit plantings from damage. Wind can cause struc- tural damage, and windborne soil particles can injure leaves. An 80 per- cent solid fence near the planting will give good wind protection. Buildings, hedges, and trees afford wind pro- tection if the garden can be located to take advantage of it.

For long range protection, plant short and tall trees, hedges, and shrubs on the windward side. A good tree windbreak reduces wind veloci- ties for 10 to 30 tree heights down- wind and for 5 to 10 tree heights up- wind. Give consideration to both sum- mer and winter wind directions and to the resultant winter snow drifts.

Equipment Storage Gardening requires an investment

in tools, fertilizers, pesticides, spray- ers, seeds, stakes, and numerous other items. Amount of the investment de- pends on how much you wish to spend and the size of your garden. Hand-operated equipment will be less expensive than powered units.

A clean, dry place is needed to keep tools, treated seeds, fertilizer, and pesticides out of reach of chil- dren and pets. A safe, lockable cabi- net in a dry, well-ventilated location would be ideal for keeping harmful tools and chemicals away from chil- dren. This is a simple safety require- ment but is often disregarded.

Tools and leftover supplies should be prepared for storage in fall unless a label indicates a chemical should not be stored for another season. Hand tools can be washed to remove dirt particles. After they dry, apply a light coat of oil with a cloth to pro- tect against rusting.

Clean up your power equipment ac- cording to the manufacturer's direc- tions. Gasoline engines should have the gas drained, the oil drained and replaced with new oil, and a small amount of oil put into the cylinder through the sparkplug hole. With the sparkplug removed, turn the engine over by hand so the cylinder walls are lubricated.

A light coat of oil can be put on parts which contact the soil when in use; other bare metal should be painted if the original paint has been damaged. Properly maintained equip- ment will give many years of service.

The modern home differs from homes of earlier generations when people produced much of their own food and stored it for winter use in root or storm cellars, attics, closets, cellar shelves, and even in the gar- den. Today we use a minimum of a refrigerator/freezer and kitchen shelves to store our food supply. Of course, the "old ways" are not gone and are being revived as more people grow their own food and seek to pre- serve it.

Specific details on harvesting ma- turity and storage requirements can be found in other chapters. In gen- eral, note that well matured, good- quality vegetables or fruits are the first requirement. The storage space must have proper moisture and tem- perature conditions. Frequent sort- ing and removal of decayed produce is essential.

Providing the proper conditions for all items may not be easy, and storage planning must be done be- fore the harvest season. As an ex- ample of the varied conditions re- quired, here are three groups and their needs: warm dry for squash and pumpkin; cooi dry for onions and dried peas and beans; and cool moist for root crops, potatoes, cabbage, and apples.

Warm dry storage conditions are 50 to 70 percent relative humidity and

69

40^ to 50'' F temperatures. These conditions can be provided in a room not heated for family use but having minimum heat to maintain the cool environment in areas of extreme temperature.

Cool dry storage means 25° to 32° F and 70 to 75 percent hu- midity. Unheated attics or closets or even a garage may be used. An old freezer or refrigerator may be adapted to provide these conditions in warmer areas.

Cool moist storage calls for tem- peratures of 32° to 40° F and high humidity. This is difficult to obtain in a home. An insulated room in a basement can be vented to the out- side for cooling. The insulation pro- tects stored produce from basement heat and outside frost. Ventilation is used to drop the temperature in fall and to hold the temperature in winter. Outside air is brought in when it is cooler than inside air. A fan and thermostat arrangement can be used to automate the temperature control Humidity is maintained by sprinkling the floor frequently with water.

Carrots, beets, rutabagas, turnips, and parsnips, for example, need high humidity to reduce shriveling. These vegetables can be stored in containers or buried in sand and covered with moist burlap or cloth to keep the air moist. Parsnips can be left in the ground over winter and dug in spring before they start to grow.

Excess fresh fruit and vegetables can be stored, but unless you have sufficient quantities to justify setting aside a room, building a special room, or buying a used refrigerator or stor- age unit, the expenses may be greater than the benefit. Be careful to evalu- ate the savings in the supermarket versus the cost of the investment in

facilities and their operating cost at home.

The U.S. Department of Agricul- ture has made up plans for various types of garden structures. Some of these can be obtained through your county Extension office. The office has additional publications available and can answer specific questions.

Plans are available from the Exten- sion Agricultural Engineer at your State land grant university if the county Extension office does not have them. The county Extension agent can request the plans for you.

For Further Reading: Building Hohhy Greenhouses, U.S. De-

partment of Agriculture Inf. Bui. 357, on sale by Superintendent of Docu- ments, U.S. Government Printing Of- fice, Washington, D.G. 20402. 30^.

Electric Heating of Hotbeds, U.S. De- partment of Agriculture L 445, on sale by Superintendent of Documents, U.S. Government Printing Office, Wash- ington, D.G. 20402. 3H.

Hobby Greenhouses and Other Gar- dening Structures, NRAES-2, 1976, NRAES, Riley-Robb Hall, Gornell Uni- versity, Ithaca, N.Y. 14853. $2.00.

Mini-Hothed and Propagating Frame, U.S. Department of Agriculture M 1184, on sale by Superintendent of Documents, U.S. Government Printing Office, Washington, D.G. 20402. 54,

Storage Building for Garden Tools, U.S. Department of Agriculture M 1192, on sale by Superintendent of Docu- ments, U.S. Government Printing Of- fice, Washington, D.G. 20402. 25^.

Storing Vegetables and Fruit in Base- ments, Cellars, Outbuildings, and Pits, U.S. Department of Agriculture H&G Bui. 119, on sale by Superintendent of Documents, U.S. Government Printing Office, Washington, D.G. 20402. 40^.

Utility Shed, U.S. Department of Agri- culture M 1196, on sale by Superin- tendent of Documents, U.S. Govern- ment Printing Office, Washington, D.G. 20402. 25^

70