Structural design at the polymer surface interface in nanoporous silica polyamine composites

Click here to load reader

-

Upload

jesse-allen -

Category

Documents

-

view

218 -

download

3

Transcript of Structural design at the polymer surface interface in nanoporous silica polyamine composites

Sp

JEa

b

a

ARRA

KABCD

1

faRtst[i(rtTpmoit

0d

Materials Chemistry and Physics 126 (2011) 973–982

Contents lists available at ScienceDirect

Materials Chemistry and Physics

journa l homepage: www.e lsev ier .com/ locate /matchemphys

tructural design at the polymer surface interface in nanoporous silicaolyamine composites

esse Allena, Matthew Berlina, Mark Hughesa, Erik Johnstona, Varadharajan Kailasama,dward Rosenberga,∗, Tova Sardota, Jessica Wooda, Carolyn Hartb

Department of Chemistry, University of Montana, 32 Campus Drive, Missoula, MT 59812, United StatesPurity Systems Inc., 1121 Broadway, Missoula, MT 59812, United States

r t i c l e i n f o

rticle history:eceived 2 July 2010eceived in revised form 29 October 2010ccepted 29 November 2010

eywords:. Composite materials. Chemical synthesis

a b s t r a c t

The factors affecting the rate of silica leaching in alkaline aqueous media from surface silanized,nanoporous, amorphous, silica gels and from silanized silica gels that have been modified with polyaminesto form the previously reported silica polyamine composites (SPCs), BP-1 and BP-2 have been investi-gated. Silanization with alkyl trichlorosilanes slows the rate of silica leaching relative to the unmodifiedsilica gels. The use of bulkier aryl silanes somewhat decreases the silica leaching under the same condi-tions. Interestingly, after modification of the silanized silica with poly(allylamine) (PAA) to make BP-1, theleaching increases, but subsequent modification of the SPC with chloroacetic acid to make BP-2, quenchesthis increase. A mechanism explaining these results is discussed. Analogous composites have been pre-

. NMR. Surface properties pared using sol–gel chemistry. These materials were characterized and their silica leaching propertieswere compared with the original BP-1. CPMAS 13C and 29Si NMR of the various surfaces have been appliedto better understand the nature of the modified surfaces. Significant changes in the nature of the surfacesiloxanes are observed for the different matrices and on their conversion to the polyamine composite.

scopyl che

Scanning electron microsilica gel and from sol–ge

. Introduction

Amorphous silica gels have been a favored solid state matrixor applications in chromatography, catalysis, colloid chemistrynd as drying agents since the middle of the 20th century [1–4].ecent developments in sol–gel chemistry have further expandedhe scope and type of solid silica phases that can be made [5,6]. Theurface modification of silica gels with organic ligands via silaniza-ion of surface hydroxyl groups has been an area of intense activity7–9]. We have been making a systematic study of the character-stics and applications of the related silica polyamine compositesSPCs), which provide nanoporous hybrid organic–inorganic mate-ials that have found applications in metal ion separations and inhe remediation of toxic anionic and cationic pollutants [11–21].hese studies have focused on the impact of using a mixture ofropyl and methyl silanes, [11,12], the thermal stability of the

aterials [13], and the impact of polymer and ligand structuren metal ion selectivity [12,14,16,17]. Despite all of the usefulnformation that was revealed regarding the surface features ofhese commercialized and industrially relevant composites, several

∗ Corresponding author. Tel.: +1 406 243 2592; fax: +1 406 243 4227.E-mail address: [email protected] (E. Rosenberg).

254-0584/$ – see front matter © 2010 Elsevier B.V. All rights reserved.oi:10.1016/j.matchemphys.2010.11.053

and pore size distributions for the composites made from commercialmistry are also reported and compared.

© 2010 Elsevier B.V. All rights reserved.

important questions remain to be answered. For instance, it is wellknown that amorphous silica gels are attacked by base at elevatedpH but it is not known how the silica leaching is impacted by thenature of silane anchors, the subsequent reaction of the silanizedsilica surface with the polyamine, and modification of the polymerwith metal selective ligands (Fig. 1). The impact of polymer bindingon the distribution of the surface siloxane species is not well under-stood either. We report here an attempt to address these questionsby a systematic study of surface silica leaching as a function ofpH, silane anchor and polymer–surface interactions. Multinuclear,solid state NMR studies are used to elucidate the general surfacefeatures and the nature of the changes associated with surface func-tionalization. Finally, in order to further develop the SPC technologyand to see how the synthetic method used to make the silanizedgel impacts surface leaching, we have also examined leaching andsurface structures of composites made via sol–gel chemistry. To ourknowledge, this represents the first direct comparison of a compos-ite material made by these two different routes.

2. Experimental

2.1. Materials and methods

All chemicals were purchased from Sigma–Aldrich and used as received. Thesilanized silica gels, the poly(allylamine) composite (BP-1), and the chloroacetic

974 J. Allen et al. / Materials Chemistry and Physics 126 (2011) 973–982

ynthe

acsQmtp

paummawmfa5

ahs

trF

2

namM

Fig. 1. Schematic drawing of the stepwise s

cid modified BP-1 (BP-2) were prepared according to the published literature pro-edures [10–12].Raw silica gel (10 nm average pore diameter, 150–250 �m particleize, 450 m2/g surface area) was obtained from INEOS, UK or from Qing Dao Mei Gow,ing Dao, China. Poly(allylamine) PAA-15B (15,000 MW) was obtained from Sum-it Chemicals Inc., NJ, USA as a 15% by weight aqueous solution. Alkoxysilanes for

he sol–gel preparations were purchased from Gelest Inc. Alkylchlorosilanes wereurchased from Aldrich Chemicals.

Atomic absorption (AA) analyses were done on an S series Thermo Electron cor-oration AA spectrometer. Metal ion solutions were run in a 2% nitric acid solutionnd were diluted to give approximately 0.1–0.2 absorbance units. AA analysis wassed to determine the metal ion remaining bound on the surface of composites byeasurement of the difference between the total in the initial solution and the totaletal ion in the filtrate and rinses. Solution silica concentrations were measured onPerkinElmer ICPAES on the acidified leach solutions (5%HCl/5%HNO3). Standardsere run every 10–15 samples, and the initial leach solutions were examined toake sure they contained no silica. Mercury porosimetry measurements were per-

ormed on a 9500 Micromeritics Autopore Series Mercury Porosimeter operating atmaximum pressure 36,000 psi corresponding to a minimum intrusion diameter ofnm. Elemental analyses were done by Galbraith Analytical Labs, Lexington, KY.

Stock solutions of Cu2+ were prepared using Cu(SO4)·10H2O. Solution pH wasdjusted from the intrinsic pH, where necessary, using hydrochloric acid or sodiumydroxide. Stripping and recovery of copper was achieved with 2M−H2SO4. Metaltandards for AA/ICP analyses were obtained from Fisher Scientific Co.

Solid state 13C and 29Si CPMAS NMR were done on a 500 MHz Varian NMR spec-rometer using a 4 mm rotor at spinning speeds of 10 kHz at 125 and 99.4 MHzespectively. FT-IR spectra were recorded as KBr pellets on a Nicolet Nexus 670T-IR.

.2. Synthesis of xerogels by the sol–gel method

Sol–gel syntheses used the two step process modeled after the work of Bren-an and Dong [22]. To a 50 mL polyethylene beaker was added 6 mL of MeOHnd 3.7 mL of pH = 2 HCl solution. To this mixture was added 20 mL of premixedethyl(trimethoxy)silane (MTMOS) and 3-chloropropyl(trimethoxy)silane (CPT-OS) in a 7.5:1 molar ratio (17.1 mL MTMOS and 2.9 mL CPTMOS).

sis of the poly(allylamine) composite BP-1.

For the synthesis of sol–gels containing tetramethoxysilane (TMOS), which wasadded for the formation of quaternary silica structures, a similar procedure wasused.To a 50 mL polyethylene beaker was added 6 mL of MeOH and 3.7 mL of pH = 2HCl solution. To this mixture was added 20 mL of premixed MTMOS, CPTMOS, andTMOS in a 7.5:1:4.25 molar ratio (11.4 mL MTMOS, 1.9 mL CPTMOS, and 6.7 mLTMOS).

For the synthesis of sol–gels containing tetraethoxysilane (TEOS), the same pro-cedure was used. To a 50 mL plastic beaker was added 6 mL of MeOH and 3.7 mL ofpH = 2 HCl solution. To this mixture was added 20 mL of premixed MTMOS, CPTMOS,and TEOS in a 7.5:1:4.25 molar ratio (9.8 mL MTMOS, 1.7 mL CPTMOS, and 8.6 mLTEOS).

After 1 h of magnetic stirring, 3.7 mL of 7 M ammonium hydroxide was added toeach sol–gel reaction. Upon gelation of the materials, stirring is stopped, and theyare allowed to age overnight at room temperature. This is followed by aging at 40 ◦Cfor 24 h followed by aging at 100 ◦C for 24 h. The materials are then crushed with amortar and pestle followed by sieving to a particle size of 150–250 �m.

2.3. Conversion of the sol–gel xerogels to the polyamine composite BP-1

The reaction of the resulting sol–gels with poly(allyl amine) (PAA) was done byplacing 2.0 g of sol–gel in a 250 mL 3 neck round bottom flask, 16 mL of methanolis added and the mixture degassed for 5 min. 64 mL of 15% by volume PAA is thenadded. The reaction mixture was fitted with a condenser and fitted with an over-head stirrer. The mixture was then heated to 60–70 ◦C and stirred for 48 h. Thesolution was decanted from the solid while still warm and then washed 5 timeswith 80 mL water, 1 time with 80 mL 1 M NaOH, 3 times with 80 mL water, 2 timeswith 80 mL methanol, and 1 time with 80 mL acetone. All washes are stirred for15 min. After washing the composite is dried overnight at 70 ◦C. Copper capacitiesfor the three sol–gel composites were determined as described in the equilibrium

batch experiment below.Elemental analyses for the sol–gel: 20.27% C, 4.69% H, 3.66% Cl. Sol–gel madewith TMOS: 8.30% C, 3.39% H, 2.73% Cl. Elemental analyses for sol–gel made withTEOS: 11.02% C, 3.35% H, 2.59% Cl. Elemental analyses for the sol–gel BP-1: 24.3%C, 5.29% H, 3.27% Cl, 2.59% N. Sol–gel BP-1 with TMOS: 18.37% C, 4.19% H, 1.86% Cl,2.34% N. Sol–gel BP-1 with TEOS: 17.69% C, 4.02% H, 2.01% Cl, 2.04% N.

J. Allen et al. / Materials Chemistry and Physics 126 (2011) 973–982 975

Si Si

CH2Cl

Si

CH2

Si

CH3

H2C

CH2

Cl

PhCMPh

Si Si

CH2Cl

Ph:CMPh 7.5 :1

Si

CH3

Si

CH2Cl

M:CMPh 7.5 :1

Si

CH2

Si

CH3

H2C

CH2

Cl

art 1

2

osaamba4frlb

2

mmsat1c

2m

p

123

CP M

Ch

.4. Silicate leaching protocol

The silica leaching as a function of pH was determined by combining 0.5 mLf methanol with 9.5 mL of water adjusted to the desired pH in a 30 mL Nalgenecrew cap bottle. The pH was then checked and 100 mg of silica or composite wasdded and allowed to stand for 48 h. The vials were not put on a shaker in order tovoid the particles from sticking to the sides of the plastic vials. For the subsequenteasurements at pH = 10; to 100 mg of composite in a 30 mL Nalgene screw cap

ottle was added 0.5 mL of MeOH to wet the materials for testing. To this was thendded 9.5 mL of pH = 10 NaOH solution. This mixture was allowed to equilibrate for8 h, after which it was filtered using a 1.0 �m nylon syringe filter and then analyzedor concentration of silicon via ICPAES after a 1:10 dilution with 5%HCl/5%HNO3. Theaw data were converted to ppm of SiO2 and all the data are reported as SiO2. Alleaching experiments were done in triplicate and the error bars in Figs. 3 and 4 areased on the standard deviations of the triplicate data.

.5. Equilibrium batch experiments

Batch extraction tests were conducted by adding 100 mg of SPC to 10 mL ofetal solution at selected pH values. To ensure equilibrium, the metal ion and SPCixtures were placed in a shaker bath. After 24 h the mixtures were allowed to

ettle. Each supernatant was extracted and diluted using a 2% nitric acid solution fornalysis using the AA method. The sol–gel BP-1 gave copper capacity of 87.1 mg/g,he TMOS sol–gel BP-1 had a copper capacity 68.7 mg/g and the TEOS sol–gel BP-had a copper capacity of 56.8 mg/g. The copper capacities for the BP-1 and BP-2

omposites made with the silane anchors shown in Chart 1 are reported in Table 2.

.6. Method for calculating the number of surface anchor points per polymerolecule

The following stepwise method was used to calculate the number of anchoroints per polymer molecule. The following assumptions were made:

. All nitrogen is from PAA of MW = 15,000.

. Change in mass is only due to polymer addition.

. Each chloride that reacts does so with the polymer, forming an anchor point.(1) Amount of chlorine

%Clmol Cl35.45 g

/100 = mol Clg composite

(2) Amount of nitrogen

%Nmol N

14.01 g/100 = mol N

g BPcomposite(3) PAA loaded

mol Ng BPcomposite

57g PAA15, 000 g PAA

= mol PAAg BPcomposite

M:CP 7.5 :1

.

(4) PAA mass%mol N

g BPcomposite57 g PAA

mol N∗ 100 = % PAA

(5) Mass correctionmol Cl on CP

g CPcomposite

(1 − %PAA

100

)= mol Cl on CP

g BPcomposite(6) Reacted chlorines

mol Cl on CPg BPcomposite

− mol Cl on BPg BPcomposite

= mol Cl reactedg BPcomposite

(7) Number of anchor pointsmol Cl reactedg BPcomposite

g BPcompositemol PAA

= # of anchor pointsmolecule PAA

3. Results and discussion

3.1. Relative silicate leaching rates for silanized silica surfacesversus silica gel

It is well known that amorphous silica gels are subjected todegradation by aqueous alkaline solutions [1–4]. This property rep-resents a serious obstacle to the use of silica gels as ion exchangematerials at elevated pH. In the case of the SPC materials underconsideration here and related organic–inorganic hybrid materi-als, it is not understood how the relative rate of silicate leaching isinfluenced by silanization, polymer grafting and the subsequentligand modifications that we have previously reported [10–21].Hydrophobicity parameters based on measured surface tensionshave been assigned to various silanes but these parameters have notbeen directly related to base induced leaching rates on amorphoussilica gels[1–4]. We have previously reported that only 45–55%of the surface of SPCs are covered by the silane anchors used intheir synthesis, suggesting that silicate leaching could still be a sig-nificant problem under alkaline conditions[11,12]. We thereforeundertook a systematic study of silica leaching as a function of the

nature of the silane anchors and the impact that the polyaminegrafting and its subsequent modification has on the rate of thisprocess. We previously reported that the use of a mixture ofhalogenated silane anchor with methyl trichlorosilane gave SPCmaterials with better capacities and mass transfer kinetics. Because

976 J. Allen et al. / Materials Chemistry an

0.1

1

10

100

1000

10000

M:CP 7.5:1CP Silica

Silic

a (

pp

m)

2

6

10

14

Fpi

oc

cpcpt7tioplwaps

T1

TE

ig. 2. Silica leaching data for the commercial/conventional silica gel, the chloro-ropyl silanized gel (CP gel) and the methyl:chloropropyl 7.5:1 mixed silane (M:CP)

n pH range of 2–14. Vertical axis is a logarithmic scale.

f this, we have examined leaching rates for these mixed silaneomposites [11].

All leaching experiments were conducted under identical batchonditions. We began these studies by first doing a leaching pHrofile in order to bracket the rate of silicate dissolution from theomposite and silica gels (see Section 2). The leaching data in theH range of 2–14 is shown in Fig. 2 for the commercial silica gel,he chloropropyl silanized gel (CP gel) and the methyl:chloropropyl.5:1 mixed silane (M:CP 7.5:1). At pH = 14, 43%, 33% and 33% ofhe silica has been leached into the solution for the unmodified sil-ca, CP gel and M:CP respectively. These results illustrate that therganic silanes offer minimal protection to the surface at this pH. AtH = 10 and below however, there is a significant difference in the

eaching between the silanized materials and the starting silica gelith the M:CP material showing about the same degree of leaching

s the CP (Fig. 2). Thus, although silanization does not give com-lete surface coverage it does afford some protection from alkalineolutions.

able 13C Chemical shifts for silanized gels and compositesa.

Material Ph PAA CH2, CH

CMPh 125, 128, 132, 138PhCMPh 125, 128, 132, 137b

MCMPh 128, 135, 141CMPhBP-1c 129, 133, 141 34.9PhCMPhBP-1c 125, 131 31.7MCMPhBP-1c 140, 131, 124 33.6CMPhBP-2 129 25.6PhCMPhBP-2 126, 132 28.3MCMPhBP-2 125, 136 33.7

a All chemical shifts are given relative to external TMS and were run in the CPMAS modb Peaks of lower intensity than the other peaks due to reactant ratios.c All the BP-1 spectra showed a relatively low intensity peak at 162 ppm. We tentative

primary amines with carbon dioxide.d Resonances hidden by polymer carbon resonances.

able 2lemental analyses, anchor points and Cu2+ capacities for silanized gels and composites m

Material %C %H %N

CMPh 9.99 0.93PhCMPh 9.20 0.93MCMPh 2.67 0.75CMPhBP-1 19.25 3.1 4.18PhCMPhBP-1 16.55 2.44 3.32MCMPhBP-1 11.58 2.19 3.30CMPhBP-2 20.93 2.88 3.42PhCMPhBP-2 17.83 2.77 2.93MCMPhBP-2 13.07 2.40 2.76

a Number of anchor points per molecule of polymer calculated from the difference in Cb Batch capacity at pH = 2 for BP-2 and 3.5–4 for BP-1 in mg/g as measured by AA.

d Physics 126 (2011) 973–982

3.2. Synthesis of silanized silica surfaces made with differentsilanes and conversion to the corresponding composites

Based on these results we decided to examine the impact ofvarying the nature of the silane on the degree of silica leach-ing. We chose a pH = 10 for these studies because this was thelowest pH where significant leaching is observed and where sig-nificant protection of the surface by the silane was realized.The silane anchors chosen for this study and the mixed silanecombinations used are shown in Chart 1. The silanized silicagels and the corresponding PAA composites were synthesized bythe methods previously reported[11,12]. The ratio of the methylor phenyl to the chloromethylphenylsilane of 7.5:1 was chosenbecause previous studies with methyltrichlorosilane and chloro-propyltrichlorosilane showed that this ratio was optimal for metalloading capacities. Characterization of the silanized gels and thecorresponding composites was done by solid state CPMAS 13CNMR (Table 1), elemental analysis and by measuring the coppercapacities for the composites (Table 2). The copper capacities forall the chloromethylphenylsilane derivatives are slightly greaterthan the capacities of the chloropropyl analogs after conversionto the silica polyamine composite, BP-1 (90–105 mg/g for BP-1,made with methyl/chloropropylsilane mixtures) [11,12]. The chlo-rine analysis gives a measure of the silane loading and it can beseen that the chloromethylphenylsilane (CMPh) has a chlorinecontent similar to the corresponding composite made with onlychloropropyl silane [11,12]. The somewhat higher copper capaci-ties reflect the higher polymer loading and this can be attributed tothe greater reactivity of the benzylic halide relative to the alkyl

halide. The mixed silane silica gels phenyl:chloromethylphenyl7.5:1 (Ph:CMPh) and methyl/chloromethylphenyl 7.5:1 (M:CMPh)both show much lower chlorine content because the phenyl andmethyl silanes effectively compete with the chloromethylphenylsi-lane for binding to the surface (Table 2). However, polymer loadingSi–Me CH2 (silane) Carboxyl

41.741.3b

−6.0 45.0b

44.1d

−6.0 42.646.0 165

b 168−6.0 b 171

e.

ly assign this resonance to a formamide carbonyl formed by the reaction of the

ade with aromatic silanes and aromatic/methyl mixed silanes.

%Cl #Anchorsa Cu Capb

4.94 -0.36 -0.29 -0.02 101 1280.04 9 1060.03 7 98

171820

l content before and after polymer grafting, %N and MW of polymer.

try and Physics 126 (2011) 973–982 977

iwyamnehpmToo

pvbp

J. Allen et al. / Materials Chemis

s relatively unaffected based on the observed copper capacitieshich are only slightly lower than for the CMPh only silica gel. Anal-

sis of the residual chlorine content after polymer loading allowsn estimate of the average number of anchor points per polymerolecule after correcting for the mass gains. The much smaller

umber of anchor points for the mixed silane has only a minimalffect on polymer loading as the copper capacities remain fairlyigh relative to CMPh only. We observed a similar constancy in cop-er capacities in our prior studies using polymers of very differentolecular weights and silica gels with different surface areas [19].

hus polymer loading seems to be related to available surface arean the silica rather than to the number of covalent anchor pointsr the overall size of the polymer.

In order to understand the impact of modifying the basic amine

olymer with an acidic substituent on silica leaching we con-erted the BP-1 composites made with the CMPh anchor to BP-2y reaction with sodium chloroacetate according to the literaturerocedure used for the chloropropylsilane analog [15]. The 13C NMRFig. 3. Silica leaching from silanized silica gels using different silanes: chloropropyl(CP), methyl mixed with chloropropyl in a 7.5:1 ratio (M:CP), methyl mixed withchloromethylphenyl in a 7.5:1 ratio (M:CMPh), phenyl mixed with chloromethylphenyl in 7.5:1 ratio (Ph:CMPh) and chloromethylphenyl (CMPh).

Fig. 4. (a) schematic diagram of the mechanism of amine promoted silicate leaching in BP-1; (b) schematic diagram of the quenching of silicate leaching in BP-2.

978 J. Allen et al. / Materials Chemistry and Physics 126 (2011) 973–982

Fa

dTtmccapccfcmTcftWBiwds

3

swwmcompcsnAbwap

3d

cm

Fig. 6. Solid state CPMAS 29Si NMR of: (a) commercial silica gel; (b) silanized silica

ig. 5. Silica leaching from sol–gel materials and the corresponding PAA compositest pH = 10.

ata and elemental analyses for these BP-2 composites are given inables 1 and 2, respectively. This composite was designed to cap-ure metal ions at lower pH than BP-1 and the copper capacities are

easured at pH = 2 while those for BP-1 are measured at intrinsicopper solution pH (3.5–4.0). The copper capacities for CMPh-BP-2omposites are much lower than for their BP-1 precursors. This islso the case for the BP-1 chloropropylsilane analogs where cop-er capacities decrease to 30–35 mg/g from 90 to 105 mg/g ononversion to BP-2 [15]. The decrease in copper capacity for thehloromethylphenylsilane analogs is even more drastic decreasingrom 98–106 mg/g to 17–20 mg/g on going from BP-1 to BP-2. Thisould be because the more rigid aromatic anchors prevent someetal chelating active sites from participating in metal binding.

he overall decrease in copper capacity on modification with thehloroacetate ligand suggests that the equilibrium binding constantor the acetate modified surface at pH = 2 is significantly lower forhe amino acetate ligand than that for the amine ligand at pH = 3–4.

e have previously shown that almost all of the amine groups inP-1 are modified with 1–2 acetate groups [15]. Polymer leaching

s not considered to be significant for the mixed silane compositesith fewer anchor points reported here as this has been previouslyemonstrated in our prior work with methyl/chloropropyl mixedilanes [11,12].

.3. Silica leaching from the silanized silica surfaces

The results of the silica leaching studies on silica gelsilanized with different silanes: chloropropyl (CP), methyl mixedith chloropropyl in a 7.5:1 ratio (M:CP), methyl mixedith chloromethylphenyl in a 7.5:1 ratio (M:CMPh), phenylixed with chloromethylphenyl in 7.5:1 ratio (Ph:CMPh) and

hloromethylphenyl only (CMPh) are illustrated in Fig. 3. The usef the chloromethylphenyl silane on its own or mixed with theethyl silane gives silica leaching values similar to the chloro-

ropyl and mixed methyl-chloropropyl silane. However, if thehloromethylphenyl is mixed with the phenyl silane, leaching isignificantly lowered. This suggests that the use of a bulky andon-polar silane is necessary to reduce surface leaching of silica.lthough the chloromethylphenyl is bulkier and more hydropho-ic than the CP or M:CP, the presence of the polar benzylic chloridehich probably undergoes hydrolysis on extended exposure to

lkaline solutions, presents a more polar surface to the aqueoushase and gives higher leaching rates.

.4. Silica leaching from silica polyamine composites made with

ifferent silane anchorsInterestingly, the conversion of these silanized silica gels to theorresponding silica–polyamine composites, BP-1, results in a dra-atic increase in the silica leaching for the less bulky and less rigid

gels made from commercial silica gel and a sol–gel matrix made with the additionof TMOS; (c) silica polyamine composites (BP-1) made from silanized silica gel andfrom the sol–gel with added TMOS.

CP and M:CP as well as the M:CMPh but not for the Ph:CMPh andCMPh only. We interpret this phenomenon in terms of an amineassisted hydrolysis of surface siloxane bonds (Fig. 4a). In the caseof Ph:MCPh and CMPh these more rigid and longer polymer anchorsprevent the amine polymer from directly interacting with the sur-face. In the case of M:CMPh dilution of the aromatic anchor withmethyl silane leaves enough flexibility in the polymer to inter-act with the surface. Modification of all of these poly(allylamine)composites with sodium chloroacetate to give the correspondingaminoacetate composites, BP-2, almost completely eliminates sil-ica leaching at pH = 10 (Fig. 3). Our prior work with this modificationindicated that almost all of the amine sites have at least one if nottwo acetate groups on each amine. [15] At pH = 10 the aminoacetategroups would be negatively charged inhibiting the diffusion of thenegatively charged hydroxide ions to the silica surface. Further-

more, substitution of the amines on the polymer would be expectedto impart an additional degree of conformational rigidity thus lim-iting access of any unmodified basic amine groups to the surface(Fig. 4b).

J. Allen et al. / Materials Chemistry and Physics 126 (2011) 973–982 979

with

3b

hapniicsppst7rpTtamMattbit

Fig. 7. Solid state CPMAS 29Si NMR of a silanized silica gel made

.5. Synthesis, characterization and silica leaching of SPC madey the sol–gel method

As part of the general development of the SPC technology weave been looking into alternatives to the commercially availablemorphous silica gels. This prompted us to synthesize the SPC com-osite BP-1 by the sol–gel method. These studies were undertakenot only to evaluate their resistance to silica leaching for compar-

son with the SPC materials previously reported but also to seef these alternatives offered other advantages with regard to theommercial development of the SPC technology. In the case of theol–gel method a more uniform surface, more careful control overore size distribution and the possibility of development of a oneot SPC synthesis were the primary goals. The sol–gel matrix wasynthesized by a two step hydrolysis-polymerization process usingrimethoxy(chloropropyl)silane and trimethoxy(methyl)silane in a.5:1 ratio according to previously published procedures [22]. Thisatio was chosen as it proved to have the best metal adsorptionroperties for the SPCs made from the commercial silica gel [11,12].he sol–gel made by this method was ground and sieved to the par-icle size distribution, 150–250 �m, commonly used for the SPCsnd then converted to the BP-1 by a procedure listed in the experi-ental, which is similar to the previously reported method [11,12].ercury porosimetry analysis revealed a surface area of 163 m2/g

nd an average pore diameter of 13.2 nm. This material appeared

o have good mechanical strength but without the addition of aetraalkoxysilane to the sol–gel formulation there will not be aulk silica phase within the sol–gel. This adds mechanical stabil-ty and creates the surface and pore structure of the SPC. Thereforehe above procedure was repeated using both tetramethoxysilane

only CPTCS before (top) and after reaction with TMCS (bottom).

(TMOS) and tetraethoxysilane (TEOS). The ratio of the alkoxysi-lanes used was 7.5:1:4.25 for CP:M:TMOS or TEOS. This ratioprovides two tetraalkoxysilanes for each trialkoxy(organo)silane.These TMOS and TEOS derivatives were converted to the cor-responding BP-1 composites by reaction with PAA and mercuryporosimetry analysis revealed a surface area of 50 m2/g and of48 m2/g and an average pore diameter of 6.7 nm and 7.4 nm forthe TMOS and TEOS, respectively. The corresponding values for theBP-1 made from the commercial silica gels are 165 m2/g and havean average pore diameter of 9.1 nm. It should be pointed out herethat binding of the polymer to the silica matrices lowers both poresize and surface area [23].

As expected, elemental analyses for the composites reveal thatthe addition of the tetraalkoxysilanes lowers the carbon content ofthe resulting sol–gels due to the formation of bulk silica regions(going from 20.3% in the original sol–gel to 8.30 and 11.02% in theTMOS and TEOS gels, respectively) while the percentage of chlorineis in a much narrower range for all three materials (3.66–2.59%) andsuggests a similar rate of incorporation of the chloropropyl silane.On conversion to BP-1 only 32 and 22% of the chlorines are uti-lized in reaction with the polyamine in the case of TMOS and TEOSrespectively. The better utilization of the chlorines in the case ofTMOS is probably due to less steric interference with the chloro-propyl groups by the methyl group compared with the ethyl groupin TEOS. This makes TMOS a better choice for future work. Chlo-

rine analyses of these sol–gels before and after reaction with PAAallows estimates of the number of anchor points per polymer chainby making use of the nitrogen analysis and the average molecu-lar weight of the polymer. The BP-1 made without TMOS or TEOSshowed very little change in chlorine content and gave a value of

9 try and Physics 126 (2011) 973–982

∼miiptTwctmtcTcBha

svfmpltttbforlas

3s

htrfosdptcomFfTt2

stttssab

Fig. 8. Solid state CPMAS 13C NMR of the sol–gels made with TMOS and TEOS (top)

80 J. Allen et al. / Materials Chemis

0.2 anchors per polymer molecule. This means that the polymerolecules have very few or no anchor points but the chlorine data

s not precise enough to discern which is the case. This, in turn,ndicates that the chloropropyl groups are not accessible to theolymer on the pore surfaces. This situation changes entirely whenhe poly(allylamine) is reacted with the gels made with TMOS orEOS. Here the change in chlorine content is more substantial ande calculate 19 and 27 anchors per polymer molecule for the BP-1

omposites made with TEOS and TMOS respectively, even thoughhere remain many unreacted chloride sites. These values compare

ore favorably with the value of 24, obtained for BP-1 made withhe commercially available silica gels, although here there are fewerhlorine sites and so almost all react with the PAA. The TMOS andEOS containing poly(allylamine) composites have lower copperapacities than the commercially produced BP-1. The initial sol–gelP-1 gave a copper capacity of 87.1 mg/g, the TMOS sol–gel BP-1ad a copper capacity of 68.7 mg/g and the TEOS sol–gel BP-1 hadcopper capacity of 56.8 mg/g.

The silica leaching data for the composites synthesized from theol–gels are shown in Fig. 5. All of these materials show leachingalues comparable to values seen for the BP-1 composites maderom the commercial silica gel and higher than the silanized com-

ercial silica gels. In the case of the sol gels we attribute this to theresence of unpolymerized methoxysilyl and silanol groups most

ikely situated on pore peripheries. Conversion of the sol–gels tohe corresponding polyamine composites however, does not leado increased leaching as observed for the composites made fromhe silanized commercial silica gels. We suggest here that this isecause there are not any bare silica areas or unpolymerized sur-aces within the pores where the polymer resides. This is bornut by the fact that when the silanized commercial silica gels areeacted with trimethyl chlorosilane we observe ∼75% decrease ineaching presumably due to the reaction of unreacted silanol sitesfter silanization. These interpretations are supported by the solidtate NMR data discussed below.

.6. Solid state CPMAS 13C and 29Si investigations of the polymerurface interface

Solid state CPMAS 13C and 29Si investigations of silica basedybrid organic–inorganic materials have proven to be valuableools for characterizing the surface compositions of these mate-ials [24–28]. The CPMAS 29Si NMR of the materials synthesizedor this report are shown in Fig. 6 and the assignments are basedn the well established chemical shifts for similar silica gel andol–gel materials [24–28]. Although we cannot interpret theseata quantitatively, the expected similarities in the extent of crossolarizations for these materials allows some important qualita-ive conclusions. Fig. 6a shows the surface siloxane species of theommercial silica gels. It can be seen that that the relative numberf Q2, Q3 and Q4 sites are approximately the same and that bothaterials provide a similar starting point for further modifications.

ig. 6b shows the CPMAS 29Si NMR of the silanized silica gels maderom commercial silica as well as the sol–gel made with TMOS.here are some notable differences. As expected, the sol–gel wherehe Q sites can be controlled by the amount of added TMOS has a9Si NMR with more T3 sites than T2 sites but here the Q3 and Q4ites are of equal intensity whereas in the amorphous silica gels thehere are more Q3 sites than Q4 sites. Fig. 6c shows the 29Si NMR ofhe same two materials (as in Fig. 6b) after reaction with PAA. Here

he sol–gel and the silica gel made from commercial silica gel bothhow a significant decrease in the number of T2 relative to the T3ites. This is consistent with the idea that the amine polymer inter-cts with the surface and perhaps promotes formation of siloxaneonds from residual silanols in addition to increasing leaching.and the resulting composites after reaction with PAA (bottom). The resonanceslabeled SiC1, C2, ClC3, and NC3 are due to the propyl groups of the silane anchor.

Further corroboration of the interpretations presented herecomes from an experiment in which a silanized silica gel madewith only chloropropyltrichlorosilane (CPTCS) was reacted withtrimethylchlorosilane (TMCS). The CPTCS gels have been shown tohave less surface coverage relative to the mixed silane silanized gels[11,12]. This suggests that the poorer surface coverage leaves moreunreacted surface hydroxyl groups. The 29Si NMR of a CPTCS gelbefore and after reaction with TMCS is shown in Fig. 7. The overallincrease in T sites relative to Q sites is the result of the silanizationof unreacted surface hydroxyl groups and the reaction of silanolson surface alkyl silanes with the TMCS. The trimethyl silyl groupwould give a T3 chemical shift where R = SiMe3 and similarly for theT2. The small amount of T1 observed could arise from the reactionof a surface –O–Si(OH)3 site. This experiment verifies our earlier

reports where the SPC properties implied a poorer surface cover-age for gels made with only CPTCS. [11] Indeed, leaching of the 7.5:1MTCS:CPTCS gel decreased by 53% after treatment with TMCS.

J. Allen et al. / Materials Chemistry an

F(

saptwr[c

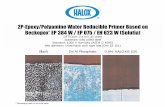

Fs

ig. 9. Scanning electron micrographs at 20,000 magnification of BP-1 made from:a) commercial silica gel; (b) a sol–gel with 4.25:7.5:1 TMOS:MTMOS:CPTMOS.

The choice to use TMOS as the preferred tetraalkoxysilane forynthesis of the polyamine composites is additionally based on thenalysis of the CPMAS 13C NMR of the sol–gels made with this com-ound versus TEOS (Fig. 8). It can be seen that there are resonanceshat can be assigned to unreacted ethoxy groups in the case of TEOS

hile for TMOS no residual methoxide is observed (the methoxideesonance would be expected to appear at ∼55 ppm, Fig. 7(top))19]. In addition, on conversion of the TEOS sol–gel to the polyamineomposite the resonances associated with the ethoxy groups are

ig. 10. Mercury porosimetry data for BP-1 made from commercial silica gel; and aol–gel with 4.25:7.5:1 TMOS:MTMOS:CPTMOS.

d Physics 126 (2011) 973–982 981

significantly diminished (Fig. 8(bottom)). This observation givesstrong support for our hypothesis that the PAA interacts directlywith the surface and is responsible for the increased leachingobserved for the composites relative to the silanized silica gels.Finally, it should be noted that the C3 carbon of the propyl grouphas two different chemical shifts. This is only observed when mixedmethyl- and chloropropylsilanes are used in the silanization pro-cess and is also observed in the CPMAS 13C NMR for the compositesmade with commercial silica gels. We tentatively interpret this interms of the existence of two gross environments on the gel surface.One chemical shift arises from C3 carbons that are surrounded bymethyl groups and one where some of the near neighbors are otherpropyl groups. This idea is supported by the observation of thisdoubling in the case of silanized silica gels made with methyl andpropylsilanes but not with gels silanized with only propyl or chloro-propyl silanes. It seems reasonable that the carbon most remotefrom the surface would feel the presence of a neighboring propylgroup most.

3.7. SEM and pore size distributions of BP-1 made by the twodifferent methods

Scanning electron microscopy (SEM) imaging was performedon the SPC organic–inorganic hybrid material BP-1 made on thetwo different matrices: (a) commercial amorphous silica gel pur-chased from Qing Dao Mei Gow; (b) a sol–gel xerogel made withTMOS, MTMOS and CPTMOS. In Fig. 9 the surface morphology ofthe three SPC are illustrated at the same scale and magnification.The sol–gel BP-1 has a distinctly smoother appearance than theother two materials and suggests a smaller average pore size (videsupra) and/or a tighter pore size distribution. Fig. 10 shows thepore size distribution curves for the two materials measured ona mercury porosimeter up to 30,000 psi. In the region between 5and 10 nm (region with highest pore populations) it can be seenthat the sol–gel SPC has a much sharper pore size distribution thanthe amorphous silica gel. Although the formulation of the sol–gelSPC is still under development, these preliminary results hold outthe promise that the sol–gel method for making these SPC couldprovide a more uniform material with better flow properties.

4. Conclusions

There are a number of important conclusions that can madefrom the work reported here:

1. Silicate leaching is a significant process for the silanized sur-faces at pH > 10 and the use of bulkier hydrophobic silanes isonly marginally effective in mitigating the rate of leaching.

2. On conversion to the SPC, silicate leaching increases signifi-cantly as a result of base promoted hydrolysis by the polyaminedirectly interacting with the surface but this effect is almostcompletely mitigated by modification of the amine functionalitywith a chloroacetate moiety suggesting that surface pH and zetapotential have profound effect on the leaching process.

3. Sol–gel chemistry offers an alternative to commercial silica gelsas a matrix for synthesizing the SPC. Although silicate leachingfrom the sol–gel is similar to that of the silica gels, introductionof the polyamine does not result in an increase in leaching andthe spectroscopic studies reported here indicate that this is dueto the more complete coverage of the sol–gel surface by T3 sites.

In order to use this approach the incorporation of tetraalkoxysi-lanes is needed or the halide functionalized alkyl group is notaccessible to surface reactions.4. The number of anchor points to the polyamine has little effect onoverall polymer loading as evidence by the comparable capaci-

9 try an

taTp

A

F

R

[

[

[[

[[[

[[[

[

[

[

82 J. Allen et al. / Materials Chemis

ties of the CMPh BP-1 versus the mixed silane analogs but wehave previously shown that reducing the number of anchorpoints does impact polymer modification with metal selectiveligands [11].

Further studies to optimize the ratios of the mixed silanes andhe tetraalkoxysilanes using the sol–gel approach are underway,s well as the application of surface analytical techniques (AFM,EM) to deepen our understanding of molecular interactions at theolymer–surface interface.

cknowledgements

We gratefully acknowledge the support of the National Scienceoundation (CHE-0709738) for support of this research.

eferences

[1] R.K. Iler, The Chemistry of Silica, Wiley Interscience, New York, 1978.[2] M. Alkan, M. Dogan, Silica gels surface chemistry, in: M. Somasunderan (Ed.),

Encyclopedia of Surface and Colloid Chemistry, vol. 7, Taylor and Francis, NewYork, 2006, p. 5608.

[3] R.P. Scott, W. Silica, Gel and Bonded Phases, John Wiley and Sons, New York,1993.

[4] E. Papirer (Ed.), Adsorption on Silica Surfaces, Marcel-Dekkar, New York, 2000.[5] C.J. Brinker, G. Scherer, Sol–Gel Science: The Physics and Chemistry of Sol–Gel

Processing, Academic Press, New York, 1990.[6] L.L. Hench, Sol–Gel Silica: Properties, Processing and Technology Transfer,

Prentice-Hall PTR, New York, 2005.[7] N.L. Dias-Filho, Y. Gushikem, Sep. Sci. Tech. 32 (1997) 2335;

[[[[[[

d Physics 126 (2011) 973–982

M.E. Mahmoud, E.M. Soliman, J. Liquid Chromatogr. Related Technol. 26 (2003)3045;E.M Soliman, Anal. Lett. 30 (1997) 1739.

[8] R.K. Dey, U. Jha, T. Patnaik, A.K. Singh, V.K. Singh, Sep. Sci. Tech. 44 (2009) 1829.[9] J. Wang, D. Zhang, T.R. Lawson, R.A. Bartsch, Talanta 78 (2009) 477.10] M. Hughes, P. Miranda, D. Nielsen, E. Rosenberg, R. Gobetto, A. Viale, S.D. Bur-

ton, in: R. Barbucci, F. Ciardelli, G. Ruggeri (Eds.), Recent Advances and NovelApproaches in Macromolecule–Metal Complexes, Wiley-VCH (Macromolecu-lar Symposia 235), Weinheim, 2006, p. 161.

11] M. Hughes, D. Nielsen, E. Rosenberg, R. Gobetto, A. Viale, S.D. Burton, Ind. Eng.Chem. Res. 45 (2006) 6538.

12] M. Hughes, E. Rosenberg, Sep. Sci. Tech. 42 (2007) 261.13] T.J. Bandosz, M. Seredych, J. Allen, J. Wood, E. Rosenberg, Chem. Mater. 19 (2007)

2500.14] Y.O. Wong, P. Miranda, E. Rosenberg, J. Appl. Polymer Sci. 115 (2010) 2855.15] M.A. Hughes, J. Wood, E. Rosenberg, Ind. Eng. Chem. Res. 47 (2008) 6765.16] J.J. Allen, E. Rosenberg, M.R. Chierotti, R. Gobetto, R. Inorg. Chim. Acta 363 (2010)

617.17] V. Kailasam, E. Rosenberg, D. Nielsen, Ind. Eng. Chem. Res. 48 (2009) 3991.18] D. Nielsen, J. Mckenzie, J. Clancy, E. Rosenberg, Chimica Oggi. 26 (2009)42.19] E. Rosenberg, in: C.E. Carraher, C.U. Pittman, A.S. Abd-El-Aziz, M. Zeldin, J.E.

Sheats (Eds.), Macromolecules Containing Metal and Metal Like Elements, vol.4, J. Wiley & Sons, New York, 2005, p. 51.

20] C. Anderson, E. Rosenberg, C.K. Hart, L. Ratz, Y. Cao, in: C. Young (Ed.), Pro-ceedings of the 5th International Symposium on Hydrometallurgy, 2003, vol.1, Leaching and Purification, TMS, Warrendale, PA, p393.

21] E. Rosenberg, R.C. Fischer, C.K. Hart, in: M.E. Schlesinger (Ed.), EPDProceedings—Mercury Management TMS, Warrendale, PA, 2003, p. 285.

22] H. Dong, J.D. Brennan, Chem. Mater. 18 (2006) 541.

23] E. Rosenberg, Z. Fan, D. Li, Yingyong Huaxue 20 (2003) 867.24] M.J. Wirth, H.O. Fatumbi, Anal. Chem. 65 (1993) 822.25] P.W.J.G. Wijnen, T.P.M. Beelen, R.A. van Santen, Surf. Sci. Series 131 (2006) 597.26] M.D. Bruch, H.O. Fatunmbi, J. Chromatogr. A 1021 (2003) 61.27] F. del Monte, D. Levy, Opt. Mater. 13 (1999) 17.28] T. Kobayashi, J.A. DiVerdi, G.E. Maciel, J. Phys. Chem. C 112 (2008) 4315.