Three-Phase Flow over Rectangular and Semicircular Ribbed ...

Stress and strain concentration factors for tension bars of circular cross-section with semicircular...

Click here to load reader

-

Upload

zheng-yang -

Category

Documents

-

view

216 -

download

2

Transcript of Stress and strain concentration factors for tension bars of circular cross-section with semicircular...

Engineering Fracture Mechanics 76 (2009) 1683–1690

Contents lists available at ScienceDirect

Engineering Fracture Mechanics

journal homepage: www.elsevier .com/locate /engfracmech

Stress and strain concentration factors for tension bars of circularcross-section with semicircular groove

Zheng Yang *

Department of Civil Engineering, Xi’an Jiaotong University, Xi’an 710049, China

a r t i c l e i n f o

Article history:Received 5 May 2008Received in revised form 28 January 2009Accepted 16 March 2009Available online 24 March 2009

Keywords:Stress concentration factorStrain concentration factorTension barSemicircular groove

0013-7944/$ - see front matter � 2009 Elsevier Ltddoi:10.1016/j.engfracmech.2009.03.005

* Tel.: +86 29 82665876; fax: +86 29 82665111.E-mail addresses: [email protected], zyang

a b s t r a c t

In this paper, the elastic stresses and strains in the circular cross-section bars with semicir-cular groove subjected to uniaxial tension are systematically examined using the finite ele-ment method. It is shown that the stress and strain concentration factors are different evenif the material is in the elastic state. Poisson’s ratio can have a significant effect on thestrain concentration factor. The relation of stress and strain concentration factors is alsoobtained for stress concentration region in cylindrical coordinates. This relation dependson Poisson’s ratio, the radial stress factor and the triaxial stress constraint factor.

� 2009 Elsevier Ltd. All rights reserved.

1. Introduction

Cracks in structures often initiate and propagate from the locations of stress or strain concentration. Stress and strain con-centration locations are the critical structural details to determine crack initiation and growth in engineering structures. Thestress concentration problem in round bar with a groove is especially important for test specimens used to investigate thefatigue strength of materials. Exhaustive stress concentration factor figures and tables published by Pilkey and Youngaccount for a wide variety of possible specimen configurations [1,2]. An extensive analysis of grooved bars under a varietyof loading conditions was described by an empirical equation which was derived based on theoretical results of semi-infiniteplates with a notch [3]. For three-dimensional problems, the stress concentration factors may change with different mate-rials. Poisson’s ratio m is often involved in a three-dimensional stress concentration analysis. The influence of Poisson’s ratioon the stress and strain concentration factors varies with the geometric configuration. This is because the stress and straindistributions depend on the change of the element volume and the change of the element volume depends on Poisson’s ratio.For a hyperbolic circumferential groove in a round bar under tensile load, the stress concentration factors in the axial andcircumferential directions are the functions of Poisson’s ratio [4]. On the other hand, the stress and strain concentration fac-tors are different even if the material is in the elastic state and the relation of stress and strain concentration factors dependson Poisson’s ratio and the triaxial stress constraint factor. Though the effect of Poisson’s ratio on stress concentration factor ismentioned in the literatures [5,6], the effect of Poisson’s ratio on strain concentration factor and the relation of stress andstrain concentration factors are not mentioned for tensile bars of circular cross-section with semicircular grooves.

In this paper, the coupled influences of Poisson’s ratio and the geometric configuration upon the stress concentration fac-tor and the strain concentration factor of circular cross-section bar with semicircular groove are investigated using the finiteelement method. The main purpose of this work is not primarily to provide numerical solutions for certain geometries but tohighlight the difference between the stress concentration factor and the strain concentration factor, and the effect of

. All rights reserved.

Nomenclature

E Young’s modulusKt stress concentration factor calculated from the referencekr stress ratioKr stress concentration factorke strain ratioKe strain concentration factorL half-length of barr1 radius of semicircular grooveR radius of the round barTr radial stress factorTh triaxial stress constraint factorx distance from groove notch rootr, h, y cylindrical coordinatesD element length of groove notch rootd difference between Ke and Krerr, ehh, eyy strain componentsenet mean strain of the grooved sectionry0 the uniform stress applied on the end of barrnet mean stress of the grooved sectionrrr, rhh, ryy stress componentsm Poisson’s ratio

1684 Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690

Poisson’s ratio on stress and strain concentration factors for the tensile bar of circular cross-section with semicircular grooveand consequently to provide general advice for this problem.

2. Computational procedure and modeling

2.1. Definition

This study considers a tensile bar of circular cross-section with semicircular groove (see Fig. 1a). The radii of semicirculargroove and the round bar are r1 and R, respectively, and the length of the bar is 2L. The material is homogeneous, isotropicand elastic. The cylindrical coordinates (r,h,y) are used in this paper.

The stress and strain ratios are defined, respectively, as

kr ¼ ryy=rnet and ke ¼ eyy=enet: ð1Þ

The stress concentration factor (Kr) is

Kr ¼ ryy0=rnet: ð2Þ

r1

2R

r

y

σ y0

σy0

Axi

sym

met

ric

axis

r

y

(a) (b)

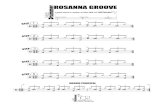

Fig. 1. Illustration of the problem: (a) geometric configuration of grooved bar; (b) the finite element model near the groove root.

1E-4 1E-3 0.01 0.1 12.0

2.1

2.2

2.3

2.4

2.5

2.6

2.7

K

Δ /r1

Kσ

Kε

Kt

Kt

Reference [1]

Reference [2]

r1 /R = 0.1

E = 200GPa, v = 0.3

Fig. 2. Mesh convergence.

Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690 1685

The strain concentration factor (Ke) is

Ke ¼ eyy0=enet: ð3Þ

Here, ryy and eyy are the stress and strain components in the round bar, ryy0 and eyy0 are the stress and strain components atthe groove root, rnet (=ry0R2/(R � r1)2) and enet (=ry0R2/E (R � r1)2) are the mean stress and strain in the net section, respec-tively. E is Young’s modulus. ry0 is the uniform stress applied on the end of bar.

To describe the three-dimensional characteristics of the stress fields clearly, two stress parameters are introduced. Thetriaxial stress constraint factor, which is the ratio of the stress in the circumferential direction to the summation of stressesin the radial and axial directions, is

Th ¼rhh

rrr þ ryyð4Þ

and the radial stress factor is

Tr ¼rrr

ryy: ð5Þ

The triaxial stress constraint factor, Th, is strongly dependent on Poisson’s ratio and the ratio of groove radius to bar radius. Itis zero for the plane stress state and m for plane strain state [7–9].

2.2. Finite element model

In the computations, the length of bar is 100 mm and the radius of the semicircular groove is 1 mm. The bar radius isvaried from 1.11 mm to 20 mm corresponding to the value of r1/R from 0.9 to 0.05. Poisson’s ratio is varied from 0.15 to0.45 and Young’s modulus, E, is set to be 200 GPa according to Ref. [6]. A uniform stress of 100 MPa is applied on the endof bar. Due to axisymmetry of geometric configuration and load, the finite element mesh is constructed with 4-node solidlinear axisymmetric elements, shown in Fig. 1b. Owing to the symmetry, only half of each bar is modelled. Appropriateboundary constraints are placed at all lines of symmetry. To accommodate the variations of the field quantities near thegroove root, the size of the element decreases gradually with decreasing distance from the groove root. All analyses are car-ried out using the software ANSYS. For all the analyses, mesh convergence tests have been performed to ensure that the re-sults given below are the converged values, shown in Fig. 2. The D in this figure is the length of element at the groove rootand the Dr1 is about 1E-3 in this research.

3. The distributions of stress and strain near the groove root

The distributions of stress and strain in the axial directions are described by the stress and strain ratios, kr and ke,respectively. The distributions of stress and strain ratios near the groove root for different Poisson’s ratios and differentr1/R are shown in Fig. 3. Here x is the distance from the groove root and R � r1 is the radius of the bar at the groove root.

1686 Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690

Both stress and strain ratios decrease with the distance from the groove root. The effect of Poisson’s ratio on the distributionof the strain ratio is larger than the one on the distribution of the stress ratio. The strain ratio near the groove root increaseswith decreasing Poisson’s ratio. The stress and strain ratios at the groove root increase with the radius of the bar for the samedepth of groove. The larger the value of r1/R is, the smaller the stress and strain ratios at the groove root are and the more flatthe kr �x/(R � r1) and ke �x/(R � r1) curves are.

The kr distribution is different from the ke distribution in the bar. The ke/kr distributions near the groove root are shownin Fig. 4. It is shown that the distribution of ke/kr depends on Poisson’s ratio, the radial stress factor and the triaxial stressconstraint factor, whenas, the radial stress factor and the triaxial stress constraint factor depend on the ratio of groove radiusto bar radius, r1/R, and the location in the bar. So the distribution of ke/kr depends on Poisson’s ratio, the value of r1/R and thelocation in the bar. The ke/kr is different in different locations in the bar. The ke is smaller than the kr in the stress or strainconcentration region. For the bar with small r1/R, the ke/kr �x/(R � r1) curve is not a monotonic function of distance fromgroove root. The ke/kr �x/(R � r1) curve near the groove root has a minimum value of which magnitude and location dependon the r1/R. But for the bar with large r1/R, the location of this minimum value is at the central point of the bar and theke/kr �x/(R � r1) curve is a monotonic descending function of distance from groove root. Poisson’s ratio influences theke/kr �x/(R � r1) curve only on its magnitude, as shown in Fig. 4a and the r1/R influences the ke/kr �x/(R � r1) curves bothon its magnitude and on the location of the minimum value, as shown in Fig. 4b.

(a)

(b)

0.00 0.05 0.10 0.15 0.20 0.25 0.300.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

kε

kσ

k σ and

kε

r1 / R =0.1ν =0.15ν =0.25ν =0.35ν =0.45

x / (R-r1)

ν =0.15ν =0.25ν =0.35ν =0.45

0.00 0.05 0.10 0.15 0.20 0.25 0.300.6

0.8

1.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

kε

kσ

r1 / R =0.1r1 / R =0.3r1 / R =0.5r1 / R =0.7

r1 / R =0.1r1 / R =0.3r1 / R =0.5r1 / R =0.7

x / (R-r1)

k σ and

kε

ν =0.30

Fig. 3. The distributions of stress and strain ratios near the groove root for (a) different Poisson’s ratios and (b) different r1/R.

(a)

0.00 0.05 0.10 0.15 0.20 0.25 0.30 0.35 0.40 0.45 0.500.725

0.750

0.775

0.800

0.825

0.850

0.875

0.900

0.925

0.950

0.975

1.000

r1 / R =0.1

x / (R-r1)

ν =0.15ν =0.20ν =0.25ν =0.30ν =0.35ν =0.40ν =0.45

k ε / k σ

(b)

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.9 1.00.80

0.82

0.84

0.86

0.88

0.90

0.92

0.94

0.96

0.98

1.00

x / (R-r1 )

ν =0.30

r1 / R =0.7

r1 / R =0.6r1 / R =0.5r1 / R =0.4

r1 / R =0.3

r1 / R =0.2k ε / k σ

r1 / R =0.1

Fig. 4. The distributions of ke/kr near the groove root for (a) different Poisson’s ratios and (b) different r1/R.

Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690 1687

4. The relation of stress and strain concentration factors in cylindrical coordinates

For the three-dimensional stress state in cylindrical coordinates, the strain components produced by each of the threestresses can be denoted as

err ¼1E½rrr � mðryy þ rhhÞ�;

eyy ¼1E½ryy � mðrhh þ rrrÞ�;

ehh ¼1E½rhh � mðrrr þ ryyÞ�:

According to Eqs. (1), (4), and (5),

ke ¼eyy

enet¼ ryy � mðrhh þ rrrÞ

enetE;

the following expression can be obtained

ke ¼ kr½1� mðTr þ Th þ Tr � ThÞ�: ð6Þ

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.90.00

0.05

0.10

0.15

0.20

0.25

0.30

0.35

r1 / R

ν =0.15ν =0.20ν =0.25ν =0.30ν =0.35ν =0.40ν =0.45

T θ

Fig. 5. The variations of the triaxial stress constraint factor at the groove root with r1/R for different Poisson’s ratios.

1688 Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690

It is indicated that the stress ratio and the strain ratio of the grooved bar are different even if the material is in an elastic statebecause the radial stress factor and the triaxial stress constraint factor cannot be zero simultaneously in the stress or strainconcentration region. This has been confirmed by the finite element results given in Section 3.

The radial stress factor Tr is zero around the groove root. So at the groove root, the relation of stress and strain concen-tration factors can be expressed as

Ke ¼ Kr½1� mTh�: ð7Þ

It is indicated that the stress concentration factor and the strain concentration factor are different even in an elastic statebecause the triaxial stress constraint factor cannot be zero at the groove root in a grooved bar. The relation of stress concen-tration factor and the strain concentration factor depends on the triaxial stress constraint factor at groove root and on Pois-son’s ratio.

Poisson’s ratio influences the distribution of Th near the groove root. The variations of Th at the groove root with r1/R forgiven Poisson’s ratios are shown in Fig. 5. The larger Poisson’s ratio is, the larger the triaxial stress constraint factor at thegroove root is. It should be noticed that the variation of Th at the groove root with r1/R is not a monotonic function ofr1/R for a given Poisson’s ratio. This value increases with increasing r1/R to its maximum value, and then decreases gradually.The maximum value and the r1/R corresponding maximum value depend on Poisson’s ratio. The larger Poisson’s ratio is, thelarger the maximum value is and the smaller the r1/R corresponding maximum value is. The maximum value of Th is about0.317 for Poisson’s ratio of 0.45 when the value of r1/R is 0.075.

The variations of Ke/Kr at the groove root with r1/R for given Poisson’s ratios depend on the triaxial stress constraint factoraccording to Eq. (7). The variation of Ke/Kr at groove root with r1/R for a given Poisson’s ratio is also not a monotonic functionof r1/R. The value of Ke/Kr decreases with increasing r1/R to its minimum value, and then increases gradually. The minimumvalue and the r1/R corresponding minimum value depend on Poisson’s ratio. The Ke/Kr�r1/R curves are sensitive to Poisson’sratio. The larger Poisson’s ratio is, the smaller the minimum value is and the smaller the r1/R corresponding minimum valueis. The minimum value of Ke/Kr is about 0.857 for Poisson’s ratio of 0.45 when the value of r1/R is 0.075.

From Eq. (7), the difference between Ke and Kr at the groove root can be expressed as

d ¼ Kr � Ke

Kr¼ mTh: ð8Þ

The difference between Ke and Kr at the groove root depends on the triaxial stress constraint factor and Poisson’s ratio. Thelarger the triaxial stress constraint factor and Poisson’ ratio are, the larger the difference between Ke and Kr at the grooveroot is. The difference between Ke and Kr at the groove root of different r1/R values is less than 3% when Poisson’s ratio is0.15. But these differences are about 14.3% and 14.2% for r1/R = 0.075 and r1/R = 0.10 when Poisson’s ratio is 0.45 and about7.2% for r1/R = 0.25 when Poisson’s ratio is 0.30, respectively.

5. The stress and strain concentration factors at the groove root

The theoretical stress concentration factor (TSCF) [1,2] is a widely used concept in both the academic and practical envi-ronment. The existing values of TSCF for different forms of stress raiser were originally determined experimentally and

Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690 1689

reported in Refs. [10,11]. The stress concentration factor figures and tables of the grooved bar have been published by Youngand Budynas [1] and Pilkey [2,12]. But in all of these references, only the stress concentration factor is considered. Inanalyzing certain stress concentrations, the present author realized that the stress concentration factor is different fromthe strain concentration factor in the three-dimensional stress state and that Poisson’s ratio affects both stress and strainconcentration factors. The stress and strain concentration factors at the groove root versus r1/R for different Poisson’s ratiosare shown in Fig. 6. The stress and strain concentration factors at the groove root all decrease with increasing r1/R. The effectof Poisson’s ratio on the stress concentration factor in bars with large and small values of r1/R is smaller than that in barswith middle values of r1/R, shown in Fig. 6a. The stress concentration factors calculated by using the formula given in Ref.[2] are all smaller than the values of FE result for different Poisson’s ratios when the value of r1/R is smaller than 0.6. Thesmaller the value of r1/R is or the smaller Poisson’s ratio is, the larger the difference between the values from the Ref. [2]and from FE result is. The effect of Poisson’s ratio on strain concentration factor in bars with small values of r1/R is largerthan that in bars with large values of r1/R, shown in Fig. 6b. The smaller the value of r1/R is, the larger the effect of Poisson’sratio on strain concentration factor is. It should be noticed that the strain concentration factor calculated by using the for-mula from Ref. [2] and the value from the FE results are almost equal when the value of r1/R is smaller than 0.4 for Poisson’sratio 0.3.

It is obvious that the formula given in Ref. [2] does not consider the effect of Poisson’s ratio on the stress concentrationfactor. The stress concentration factor from the FE results is larger than that calculated by using the formula from Ref. [2] in

(b)

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.91.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

ν =0.15ν =0.25ν =0.30ν =0.35ν =0.45

K ε

r1 / R

Reference [2]

(a)

Reference [2]

0.0 0.1 0.2 0.3 0.4 0.5 0.6 0.7 0.8 0.91.0

1.2

1.4

1.6

1.8

2.0

2.2

2.4

2.6

2.8

3.0

ν =0.15ν =0.25ν =0.35ν =0.45

K σ

r1 / R

Fig. 6. The variations of the (a) stress and (b) strain concentration factors with r1/R for different Poisson’s ratios.

1690 Z. Yang / Engineering Fracture Mechanics 76 (2009) 1683–1690

the large range of r1/R value. The difference in the stress concentration factor from the FE result and from formula [2]increases with decreasing Poisson’s ratio. These differences for r1/R = 0.3 and 0.2 are 8.8% and 8.4%, respectively, whenPoisson’s ratio is 0.15. They are 6.8% and 6.7%, respectively, when Poisson’s ratio is 0.30. The difference in the strain concen-tration factor from the FE results and in the stress concentration factor calculated by using the formula from Ref. [2] ispositive when Poisson’s ratio is small (such as m = 0.15 and m = 0.20) and it is negative when Poisson’s ratio is large (suchas m = 0.40 and m = 0.45). These differences for r1/R = 0.3 and 0.2 are 6.4% and 6.1%, respectively, when Poisson’s ratio is0.15. They are �9.1% and �10.1%, respectively, when Poisson’s ratio is 0.45. So the influence of Poisson’s ratio on both stressand strain concentration factors must be considered.

6. Conclusions

By considering the coupled effects of Poisson’s ratio and the geometric configuration on the stress and strain distributionsnear the groove root, some special characteristics of stress and strain concentration factors for the circular cross-section barwith semicircular grooves are revealed:

(1) Due to the three-dimensional stress state in stress or strain concentration region, the stress and strain concentrationfactors are different in the grooved bar even if the material is in the elastic state. The relation of the stress and strainconcentration factors depends on Poisson’s ratio, the radial stress factor and the triaxial stress constraint factor. Theeffects of Poisson’s ratio on the stress and strain concentration factors in the bar depend on the value of r1/R. The var-iation of Ke/Kr at groove root with r1/R for a given Poisson’s ratio is not a monotonic function of r1/R and is sensitive toPoisson’s ratio. The larger Poisson’s ratio is, the smaller the value of Ke/Kr is.

(2) The stress and strain concentration factors at the groove root all decrease with increasing r1/R. The strain concentra-tion factor is more sensitive to Poisson’s ratio than stress concentration factor. Poisson’s ratio can have a significanteffect on the strain concentration factor. The stress and strain concentration factors from FE results are different fromthe stress concentration factor calculated by using the formula from Ref. [2], which does not consider the effect ofPoisson’s ratio on the stress concentration factor.

References

[1] Young WC, Budynas RG. Roark’s formulas for stress and strain. 7th ed. New York: McGraw-Hill; 2002.[2] Pilkey WD. Formulas for stress, strain, and structural matrices. 2nd ed. New York: John Wiley & Sons; 2005.[3] Kato A. Design equation for stress concentration factors of notched strips and grooved shafts. J Strain Anal Engng Des 1992;27:21–8.[4] Grant RJ, Lorenzo M, Smart J. The effect of Poisson’s ratio on stress concentrations. J Strain Anal Engng Des 2007;42:95–104.[5] Neuber H. Theory of notch stresses: principles for exact calculation of strength with reference to structural form and material. 2nd ed. Berlin: Springer

Verlag; 1958.[6] Dundurs J. Dependence of stress on Poisson’s ratio in plane elasticity. Int J Solids Struct 1967;3:1013–21.[7] Timoshenko S, Goodier JN. Theory of elasticity. New York: McGraw-Hill; 1970.[8] Zhang B, Guo WL. Tz constraints of semi-elliptical surface cracks in elastic plates subjected to uniform tension loading. Int J Fract 2005;131:173–87.[9] Guo WL. Theoretical investigation of elastoplastic notch fields under triaxial stress constraint. Int J Fract 2002;115:233–49.

[10] Frocht MM. Factors of stress concentration photoelastically determined. Trans ASME Appl Mech Section 1935;57:A67–8.[11] Ling CB. On stress concentration factor in a notched strip. Trans ASME Appl Mech Section 1968;90:833–5.[12] Pilkey WD. Peterson’s stress concentration factors. 2nd ed. New York: John Wiley & Sons; 1997.