Strengthening of Offshore Platform for Accidental Loads

-

Upload

hyacinth-rocha -

Category

Documents

-

view

91 -

download

1

description

Transcript of Strengthening of Offshore Platform for Accidental Loads

Beryl Alpha

Strengthening of Offshore Platform for Accidental LoadsCase Study Ship Impact Damage at BP Facility4/24/2014

##Offshore Structural Engineering

#Platform DescriptionLocation Off East Coast of TrinidadWater Depth 278ftHelideck elevation above MSL - 91ftStructure X-H Braced 4 Legged jacket with skirt piles

#Platform DescriptionLocation Off East Coast of TrinidadWater Depth 278ftHelideck elevation above MSL - 91ftStructure X-H Braced 4 Legged jacket with skirt piles

#The IncidentDuring a routine visit to the platform, a work crew observed items thrown about the office, as well as the platform crane dislodged from its rest positionFurther investigation by the crew revealed damage to one of the platform legs at the elevation of the splash zoneAt the time the structure was not yet commissioned

#Damage Inspection Topside

[Leg Size: 48f x 1; Brace Size:24f x 0.75]#Damage Inspection - Topside

Dented LegDented Brace#Damage Inspection - Topside

#Damage Inspection - Topside

#Damage Inspection - Topside

#Damage Inspection - Underwater

#Damage Inspection - Underwater

#Damage Inspection - Underwater

#Engineering EvaluationStructural damage was limited to Leg B1 and an adjacent brace on face elevation B

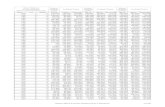

Vessel Collision Damage#Engineering EvaluationDent dimension on brace = 1 deep x 12 wideDent depth on leg = 11, Leg bulge = 51 Leg damage range from El:+15 to El: -14ft

#Engineering EvaluationInitial screening of the dent section profile at damaged area was executed using linear static analysesThe design load cases, included operational, storm and extreme level earthquake (ELE) casesStress utilisation at the detended section was found to well under 80%, for all inplace cases

#Engineering EvaluationPreliminary analytical assessment results suggested that the structure was fit for purpose, it was however considered prudent to conduct repair work to:Contain dent deformation under load, so that fatigue cracking would be inhibitedReinstate resistance to possible future vessel impacts, andProvide confidence to platform personnel that platform integrity had not been compromised

#Repair / Assessment ScopeRepair DentAppraise alternative conceptsVerify that selected repair scheme meets design basis requirements via nonlinear FE analysisDevelop design drawings of repairDevelop an installation procedure for the repair solution

Global assessment of platform:Nonlinear Pushover assessment for storm conditionsNonlinear timehistory of platform for abnormal level earthquake conditions

#Nonlinear Timehistory Analysis

#Leg Repair Concept SelectionA local repair (one that does not require a change in load paths) to the leg was opted for. Three alternative concepts were consideredWeld on doubler plates/shellsInternal leg groutingProvision of a clamp/sleeve

#Leg Repair Option 1 (Doubler Plates)Consist of shell plates covering the dent.a cofferdam would need to be constructed and assembled around the leg, with its lower end below the extent of the damaged regionThe presence of the riser that is piggy-backed to the leg complicates the construction of the cofferdam as well as creating challenges for installation and sealingTimescales for habitat construction would be comparatively longThe welded option was therefore discounted early on in the scheme selection process

#Leg Repair Option 2 (Grout Filled Leg)Consist of a fully or partially grout filled legThe basis of enhanced capacity for dented members is stabilisation of the dented cross-sectionThe grout does not, however, remove the eccentricity of axial load with respect to the centroid.Practical challenges include setting of grout plug, quantity of grout required, access holes for inflatable plugs and their subsequent making good The additional mass of grout would need consideration in seismic analyses. Also due to leg diameter heat of hydration and thermal cracking.Internal grouting would not give platform personnel the psychological comfort of seeing a visible repair

#Leg Repair Option 3 Sleeve around LegClamp/sleeve technology includes four main types of strengthening/repair systems: mechanical steel-on-steel friction clamps, neoprene-lined clamps,stressed grouted clamps, andunstressed grouted clamps

#23

Mechanical ClampNeoprene-lined ClampLeg Repair Option 3 Sleeve around LegGrouted Clamp

#24

Leg Repair Option 3 Sleeve around Leg#25Clamp Detailed Design To facilitate detailed design of the clamp the following analyses were to be completedA nonlinear FE analysis of the dent and the repaired leg so as to achieve the followingValidate the proposed design in lieu of appropriate design provisionsDetermine stresses developed in the steel and grout to confirm adequacy of the flanges and grout strengthShip impact analysis of the platformMeasured observations of the damaged leg were not able to record the bow in the leg resulting from the ship impact. The objective of this analysis was to approximate the leg bow via analytical assessmentThe results were used to verify the adequacy design repair clamp-leg annulus.

#Ship Impact AnalysisPreliminary estimated of energy required to produce a 11 dent on the leg was calculated as 0.72 MJ (Amdahl Equation)Starting from impact energy of 0.72 MJ, the analyses were iterated increasing the impact energy until the observed denting deformations were reached. This was achieved with impact energy of 2.24MJ

Before ImpactMax deformation during impactPost Impact#Analysis sensitivity to varying soil and dent extent investigated, was investigatedMaximum possible bow was found to be 2.4in, clamp annulus utilized was 4.5in

Ship Impact Analysis#Finite Element Analysis

Leg model with idealised dent#

Leg model with idealised dent & local buckling imperfectionsFinite Element Analysis#

Local buckling eigenmodesFinite Element Analysis#

Local deformation by local inward buckling (without sleeve clamp)Finite Element Analysis#

Local deformation with sleeve clamp (local inward buckling is prevented)Finite Element Analysis#

Plot of hoop stressThe bolts were sized to sustain the hoop tensions on the basis of full plastic moment in the leg, and taking into account full prying action at the flanged connectionFinite Element Analysis#

Axial load-shortening curve for leg with & without sleeve clampFinite Element Analysis#

Moment-Curvature curve for leg with & without sleeve clampFinite Element Analysis#Friction or bond between the sleeve and the grout is not assumed. Thus, bending in the leg (from P-delta or from moment as shown by the red arrows) is resisted by bearing from the leg to the sleeve via the grout at 3 points as shown by the black arrows. The bearing described above provides an increased inertia and thus global buckling capacity is increased.Review of FE resultsFinite Element Analysis#The clamp sleeve will confine the outward radial deformation of the leg that would occur as a consequence of the leg compressionThis confinement induces hoop compression in the leg and hoop tension in the sleeveThe leg is thus in biaxial compression and the clamp is in hoop tensionLocal buckling is prevented in an outward radial direction by the sleeve. Also, local buckling in an inward direction is represented by non-linear geometry and large deformation in the ABAQUS model. The model (with imperfections to ensure inward local buckling) shows the failure of the un-repaired leg. This model was re-analysed with the sleeve clamp and that inward local buckling is prevented and the axial capacity is increasedReview of FE results contdFinite Element Analysis#38Thus, internal grouting of the leg is not required and also it would reduce the pile capacity.The above points result in the sleeved section of the leg having a greater axial and bending capacity than the parts of the leg immediately above and below the sleeve. The capacity of the leg is thus increased to the strength (not stability) capacity of a 48x1x50ksi tubular. This was seen on the load shortening curves

Review of FE results contdFinite Element Analysis#

Ultimate Strength Damaged State#Ultimate Strength Repaired State

#Ultimate Strength Enhanced Soil

#Ultimate Strength Pinned Support

#Clamp GA and details

#Clamp GA and details

#Fabrication Photos

#Fabrication Photos

#Fabrication Photos

#Fabrication Photos

#Installation Sequence

#50ENDThank You

Special Thanks to#