Steel Design Project (INTAN BERLIAN)

-

Upload

syafiqlatif -

Category

Documents

-

view

220 -

download

0

Transcript of Steel Design Project (INTAN BERLIAN)

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 1/52

U

6

J

T

FACULTY OF CI

STRUCTU

S

NAME :

S

COURSE : 4

LECTURER :

NIVERSITY TUN HUSEIN ONN MA

000 PARIT RAJA, BATU PAHAT,

HOR DARUL TAKZIM.

L : 07-4537000

VIL ENGINEERING & ENVIRO

BFC 4091

AL STEEL AND TIMBER DESIG

EEL DESIGN PROJECT

EE KAR FUNG

CF 070236

ARIDAH BINTI MD TAIB

CF 070238

AUPIAH BINTI MOHAMED

CF 070211

ARIA SIMAA BINTI YUSOFF @ C

CF 070256

BFF (SECTION 1)

N. HJ. ROSLAN BIN KOLOP

LAYSIA

MENT

E MAN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 2/52

GROUP MEMBER

Lee Kar F

CF0702

Faridah Binti Md Taib

CF070238

Saupiah Binti

CF07021

Maria Simaa Binti Yusoff @ Che

Man

CF070256

By LE

ng

6

Faridah Binti Md Taib

CF070238

ohamed

1

Maria Simaa Binti Yusoff

Man

CF070256

2

KAR FUNG

Lee Kar Fung

CF070236

Saupiah Binti Mohamed

CF070211

Che

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 3/52

3

By LEE KAR FUNG

CONTENT

i. GROUP MEMBER 2

1. PROJECT DESCRIPTION AND ARCHITECTURE DRAWING 4

2. STEEL STRUCTURAL PLANNING AND DRAWING 6

3. CALCULATION OF ROOF TRUSS DESIGN 9

3.1. PURLIN DESIGN 9

3.2. LOADING OF TRUSS 11

3.3. SUMMARY FORCE OF MEMBER 12

3.4. COMPRESSION MEMBER 14

3.4.1. Top Chord 14

3.4.2. Internal Vertical Member (All, except node 7-20) 16

3.5. TENSION MEMBER 18

3.5.1. Internal Vertical Member (Node 7-20) 18

3.5.2. Internal Sloped Member 19

3.5.3. Bottom Chord 20

4. CALCULATION OF CONNECTION DESIGN 21

4.1. CONNECTION AT ROOF TRUSS (TRUSS AND TRUSS) 22

4.2. CONNECTION AT COLUMN WITH TRUSS 24

5. CACULATION OF BRACING DESIGN 27

6. CALCULATION OF CONNECTION DESIGN 32

6.1. CONNECTION AT BRACING (BRACING AND BRACING) 33

6.2. CONNECTION AT COLUMN WITH BRACING 35

7. WEIDING CONNECTION DESIGN AT GUSSET PLATE 38

8. CACULATION OF COLUMN DESIGN 40

9. CALCULATION OF SLAB BASE DESIGN 44

10. ELEMENT SUMMARY 48

11. REFERENCE 50

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 4/52

4

By LEE KAR FUNG

1. PROJECT DESCRIPTION AND ARCHITECTURE DRAWING

SIZE OF STRUCTURE :

Project = Single Storey Factory

Height = 7.77 m

Width = 15 m

Length = 42 m

PROJECT :

The factory is design using steel structural.

The plan is shown in the architect plan.

The frame D-D is select as critical frame and choosing to design the steel

structural.

Roof truss analysis is using Staad Pro 2006.

The element for steel design is following :

Roof truss

Connection (Truss)

Connection (Truss and Column)

Bracing

Connection (Bracing)

Connection (Bracing and Column)

Column

Base plate design

The standard reference is based on BS 5950, Part 1 (2000). The calculation

references are listed in topic REFERENCE in the last page of this project.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 5/52

5

By LEE KAR FUNG

ARCHITECTURE

DRAWING

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 6/52

6

By LEE KAR FUNG

2. STEEL STRUCTURAL PLANNING

*Modeling by TEKLA V15.

Figure 1: 3D view of steel Structural

Figure 2: Plan view of steel structural

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 7/52

7

By LEE KAR FUNG

Figure 3: Section A-A of steel structural

Figure 4: Section B-B of steel structural

Figure 5: Section B-B of steel structural (Braced)

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 8/52

8

By LEE KAR FUNG

STEEL

STRUCTURAL

DRAWING

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 9/52

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 10/52

10

By LEE KAR FUNG

Table 27

B-45

D = L/45 = 5000/45 = 111.11 mm

Assume sag rod are assigned on the middle of purlins between two trusses

B = (L)/60 = (5000)/60 = 83.33 mm

Therefore, use single angle 150 x 90 x 10L (Zx = 53.3 cm3)

use single angle (upper) 200 x 100 x 10L (Zx = 93.2 cm3)

use single angle (side) 150 x 90 x 12L (Zx = 63.3 cm3)

Loading Transferred to the Trusses (on nodes)

Self weight of truss (on slope) = 0.20 kN/m2

Dead load = 0.35 + 0.2 = 0.55 kN/m2

(on slope)

Imposed load = 0.73 kN/m2

(on slope)

Total dead load

Gk = 0.55 x 1.53 x 6 = 5.05 kN

Gk upper = 0.55 x (4.6 +.

) x 6 = 17.70 kN

Gk side = 0.55 x (3.07 +.

) x 6 = 12.65 kN

Total imposed load

Qk = 0.73 x 1.53 x 6 = 6.70 kN

Qk upper = 0.73 x (4.6 +.

) x 6 = 23.50 kN

Qk side = 0.73 x (3.07 + . ) x 6 = 16.80 kN

Design Load

P = 1.4 Gk + 1.6 Qk = 1.4 x 5.05 + 1.6 x 6.70 = 17.79 kN

Pupper = 1.4 Gk + 1.6 Qk = 1.4 x 17.70 + 1.6 x 23.50 = 62.38 kN

Pside = 1.4 Gk + 1.6 Qk = 1.4 x 12.65 + 1.6 x 16.80 = 44.59 kN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 11/52

11

By LEE KAR FUNG

LOADING OF TRUSS

Figure 7: Point Load from Purlin

Figure 8: Number of Node used for Staad Pro Analysis

Figure 9: Reaction on Support by using Staad Pro 2006

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 12/52

12

By LEE KAR FUNG

SUMMARY FORCE OF MEMBER

(Analysis using Staad Pro 2006)

*Highlight load are used to truss design.

Member Node Load (kN)

Top Chord 2-3

3-4

4-5

5-6

6-7

7-9

9-10

10-11

11-12

12-13

232 (Compression)

432 (Compression)

590 (Compression)

706 (Compression)

776 (Compression)

776 (Compression)

706 (Compression)

590 (Compression)

432 (Compression)

232 (Compression)

Internal Vertical

Member

2-15

3-16

4-17

5-18

6-19

7-20

9-21

10-22

11-23

12-24

13-25

145 (Compression)

99.8 (Compression)

82.5 (Compression)

65.3 (Compression)

46.3 (Compression)

230 (Tension)

46.3 (Compression)

65.3 (Compression)

82.5 (Compression)

99.8 (Compression)

145 (Compression)

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 13/52

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 14/52

14

By LEE KAR FUNG

B-43

Table 11

Truss Member Design Description

All the member in the truss are subjected to the compression and tension

force. The truss members are design with the double bolt connection at the

gusset plate. The bolts size 20 mm (with allowance 2 mm) is apply for all

the member connection.

COMPRESSION MEMBER

Top ChordPreliminary Sizing (Weld end)

Fc = 776 kN

py = 275 N/mm2

Assume pc = 0.4py

Ag = Fc / py = 776 x 1000 / 275 = 2821.82 mm2

Try angle 150 x 150 x 15L

Ag = 4300mm2

r a = r b = r y = r x = 45.7mm, rv = 29.3mm

Section Classification (consider a single angle)

ε = (275/275)0.5

= 1.0

b/t = 150/15 = 10 < 15ε = 15

d/t = 150/15 = 10 < 15ε = 15

( b + d )/ t = (150 + 150)/15 = 20 < 24ε = 24 Class 3 semi compact

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 15/52

15

By LEE KAR FUNG

Table 25

Table 23

Table 24 c)

cl. 4.7.4

Slenderness

Lb = Lx = 1.53m (top chord nodes spacing), La = Ly = 1.53m (purlin

spacing), Lv = Lb = 1.53m

λ v

λ v = 0.85 Lv /rv = 0.85 (1530/29.3) = 44.39

λ v = 0.7 Lv /rv + 15 = 0.7 (1530/29.3) + 15 = 51.55

λ a

λ a = La /ra = 1530/45.7 = 33.48

λ a = 0.7 La /ra + 30 = 0.7 (1530/45.7) + 30 = 53.44

λ b

λ b = 0.85Lb /rb = 0.85(1530/45.7) = 28.46

λ b = 0.7 Lb /rb + 30 = 0.7 (1530/45.7) + 30 = 53.44

λ max = 53.44

Compression capacity

Since λ max = 53.44 and p y = 275 N/mm2, pc = 214 N/mm

2

Therefore the compression capacity of the angle (class 3)

Pc = Agpc

= 4300 x 214 x 10-3

= 920.2 kN > Fc = 776 kN….ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 16/52

16

By LEE KAR FUNG

B-43

Table 11

Table 25

Internal Vertical Member (All, except node 7-20)

Preliminary Sizing (Bolt end)

Fc = 145 kN

py = 275 N/mm2

Use the section thickness t = 10mm

Ah = (20 + 2) x 10 = 220 mm2

Assume pc = 0.4py

Ag = Fc / (0.4py) = 145 x 1000 / [(0.4 x 275) + 220] = 202.80 mm2

Try angle 100 x 100 x 10L

Ag = 1900 mm2

ra = rb = ry = rx = 30.4 mm, rv = 19.5 mm

Section Classification (consider a single angle)

ε = (275/275)0.5

= 1.0

b/t = 50/4 = 10 < 15ε = 15

d/t = 50/4 = 10 < 15ε = 15

( b + d )/ t = (100 + 100)/4 = 20 < 24ε = 24 Class 3 semi compact

Slenderness

La = Lb = Lv = 0.32m

λ v

λ v = 0.85 Lv /rv = 0.85 (320/19.5) = 13.95

λ v = 0.7 Lv /rv + 15 = 0.7 (320/19.5) + 15 = 26.48

λ a

λ a = 1.0 La /ra = 320/30.4 = 10.53

λ a = 0.7 La /ra + 30 = 0.7 (320/30.4) + 30 = 37.37

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 17/52

17

By LEE KAR FUNG

Table 23

Table 24 c)cl. 4.7.4

λ b

λ b = 0.85 Lb /rb = 0.85 (320/30.4) = 8.95

λ b = 0.7 Lb /rb + 30 = 0.7 (320/30.4) + 30 = 37.37

λ max = 37.37

Compression capacity

Since λ max = 37.37 and p y = 275 N/mm2

, pc = 242.5 N/mm2

Therefore the compression capacity of the angle (class 3)

Pc = Agpc

= 1920 x 242.5 x10-3

= 465.6 kN > Fc = 145 kN….ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 18/52

18

By LEE KAR FUNG

B-43

cl. 3.4.3

cl. 4.6.3.1

TENSION MEMBER

Internal Vertical Member (Node 7-20)

Preliminary Sizing (Bolt end)

Ft = 230 kN

py = 275 N/mm2

Use the bolt size D = 20 mm

Bolt hole size = D + Allowance = D + 2 = 20 + 2 = 22 mm

Use the section thickness is 10mm.

Area needed = 230 x 103 / [275 + (22 x 10)] = 531.31 mm

2

Try angle 100 x 100 x 10L

Ag = 1920 mm2

Tension Capacity

Assume the longer leg of the section welded to gusset; therefore the

neutral axis is eccentric away.

Since the member is grade S 275, Ke = 1.2

An = Ag – Ah = 1920 – (22 x 10) = 1700

Ae = Ke an = 1.2 An = 1.2 x 1700 = 2040 mm2

a1 = (100 x 10) – (22 x 10) = 780 mm2

a2 = Ag - a1 = 1920 - 780 = 1140 mm2

Pt = py (Ae - 0.5a2)

= 275 x (2040 - 0.5 x 1140) x 10-3

= 404.25 kN > Ft = 230 kN….Ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 19/52

19

By LEE KAR FUNG

B-43

cl. 3.4.3

cl. 4.6.3.1

Internal Sloped Member

Preliminary Sizing (Bolt end)

Ft = 222 kN

py = 275 N/mm2

Use the bolt size D = 20 mm

Bolt hole size = D + Allowance = D + 2 = 20 + 2 = 22 mm

Use the section thickness is 10mm.

Area needed = 222 x 103 / [275 + (22 x 10)] = 448.48mm

2

Try angle 100 x 100 x 10L

Ag = 1920mm2

Tension Capacity

Assume the longer leg of the section welded to gusset; therefore the

neutral axis is eccentric away.

Since the member is grade S 275, Ke = 1.2

An = Ag – Ah = 1920 – (22 x 10) = 1700

Ae = Ke an = 1.2 An = 1.2 x 1700 = 2040 mm2

a1 = (100 x 10) – (22 x 10) = 780 mm2

a2 = Ag - a1 = 1920 - 780 = 1140 mm2

Pt = py (Ae - 0.5a2)

= 275 x (2040 - 0.5 x 1140) x 10-3

= 404.25 kN > Ft = 222 kN….Ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 20/52

20

By LEE KAR FUNG

B-43

cl. 4.6.3.1

Bottom Chord

Preliminary Sizing (Weld end)

Ft = 712 kN

py = 275 N/mm2

Use the section thickness is 15mm.

Area needed = 712 x 103 / (275) = 2589.09 mm

2

Try angle 120 x 120 x 15Ag = 3400 mm

2

Tension Capacity

Assume the longer leg of the section welded to gusset; therefore the

neutral axis is eccentric away.

Since the member is grade S 275, Ke = 1.2

a1 = 120 x 15= 1800 mm2

a2 = Ag - a1 = 3400 - 1800 = 1600 mm2

Pt = py (Ag - 0.3a2)

= 275 x (3400 - 0.3 x 1600) x 10-3

= 803 kN > Ft = 712 kN….Ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 21/52

21

By LEE KAR FUNG

4. CALCULATION OF TRUSS CONNECTION DESIGN

Reference Calculation

CONNECTION AT ROOF TRUSS

(Bolts Connection)

Figure 10: Truss connection between Top chord and vertical member

(front)

Figure 11: Truss connection between Top chord and vertical member

(behind).

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 22/52

22

By LEE KAR FUNG

Table 30

Table 31

Connection Gusset Plate and Internal Truss Member

The figure above show the internal connection of roof truss. The truss

connections design are carry out at Node 7 – 20. In the connection, the 2

diagonal members are subjected to compression force and the vertical

angle member is subjected to tension force. In the connection, two bolts of

20mm diameter in Grade 8.8 are used to connect the angle member of

10mm thickness in Grade S275 to the gusset plate of 8mm thickness in

Grade S355.

Figure 12: Dimension of bolts connection

Shear capacity of bolt:

Ps = ps As (ps = 375 N/mm2)

= 375 ( (20)2 /4) = 117.8 kN (single shear)

Bearing capacity of bolt.

Pbb = d.t.pbb (pbb = 460 N/mm2)

= 20 x 8 x 460/1000 = 73.6 kN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 23/52

23

By LEE KAR FUNG

Table 32

Table 32

cl 6.2.4

Bearing capacity of plate of the angle member,

Pbs = d.t.pbs < 0.5.e.t.pbs (pbs = 460 N/mm2)

= 20 x 10 x 460/1000 = 0.5 x 45 x 10 x 460/1000

= 92 kN = 103.5 kN

Therefore, Pbs = 92 kN

Bearing capacity of gusset plate,

Pbs = d.t.pbs < 0.5.e.t.pbs

= 20 x 8 x 550/1000 = 0.5 x 40 x 8 x 550/1000= 88 kN = 88 kN

Therefore, Pbs = 88 kN

The capacity of the connection is controlled by the bolt shear capacity of

117.8 kN.

The connection uses two bolts in series, therefore the connection capacity

= 2 x 117.8 = 235.6 kN > 230 kN (Maximun force internel truss

member) …….ok

Check the block shear capacity:

Pr = 0.6 py t{Lv + Ke(Lt – kDt)}

Lv = 50 + 40 = 90 mm

Lt = 40 mm

Dt = 22mm

K = 0.5 (single row)

Ke = 1.2

Pr = 0.6 x 275 x 8 [90 + 1.2(40 - 0.5 x 22)]

= 164 kN > 100.6 kN …….ok

Therefore, the bolt connection is adequate for gusset plate.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 24/52

24

By LEE KAR FUNG

Connection Top Chord and Bottom Chord

The truss connections top and bottom chord is design subjected to

compression force and tension force. In the connection, welding connection

is used to connect the top and bottom chord member in truss. In the

connection, splice plate 60mm x 400mm with thickness 10mm is used to

welding connection.

(Maximum Force at Node 6-7 = 776 kN)

The strength of butt weld,

Pw /L = 0.7 s pw = 0.7 x 12 x 220 x 10-3

= 1.848 kN/mm

Total length of weld, L = 60 + 200 + 200 = 460mm

The capacity of welded connection = 1.848 x 460 = 850 kN > 776 kN

Therefore, welding 12mm weld is adequate.

Angle 100mm x 100mm x 10L

Splice plate 60mm x 400mm

200mm

60 mm

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 25/52

25

By LEE KAR FUNG

cl. 6.2.2.4

Table 29

cl. 6.2.1.1

CONNECTION AT COLUMN WITH TRUSS

Figure 13: Connection bolt for truss and column

Vertical member at node 2-5 and 13-25

Size = angle 100 x 100 x 10L

Axes Load = 146.94 kN

End distance

Minimum end distance = 1.25D = 1.25 x 23 = 28.75 mmEdge distance, from vertical member = 100/2 = 50 mm > 28.75 mm …..ok

Minimum spacing bolts = 2.5d = 2.5 x 20 = 50 mm

From vertical member, spacing bolts = 200 mm > 50 mm ….ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 26/52

26

By LEE KAR FUNG

Table 30

Table 31

cl. 6.3.3.3

Table 32

Connection At Column With Truss Description

The connection column with truss is design using bolt connection grade

4.6. 3 bolt size 20mm diameter bolts with 10mm splice (100mm x 640mm)

is apply for this connection.

Use 3-20mm diameter bolts with 10mm splice (100mm x 640mm).

Use grade 4.6 bolts, ps = 160 N/mm2

Strength of 20 mm bolts :Single shear capacity on threads = 160 x 245 = 91.875 = 39.2 kN

Bearing capacity of bolt.

pbb = 1000 N/mm2

Pbb = d tp pbb

= 20 x 10 x 460 / 1000 = 92 kN

Bearing capacity of splice plate member,

Pbs = k bs d tp pbs < 0.5 k bs e tp pbs

Where,

pbs = 460 N/mm2

Pbs = k bs d tp pbs = 1(20)(10)(460) = 92 kN

Pbs = 0.5 k bs e tp pbs = 0.5(1)(120)(10)(460) = 600 kN

Bolt capacity 3 bolts are in single shear.

Shear = (3 x 91.86) + 92 = 367.58 kN

Therefore, the capacity of the end bolt bearing on 10mm thick splice plate

is controlled by the end distance.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 27/52

27

By LEE KAR FUNG

B-43

cl.4.6.3.3

cl. 3.4.2

Table 9

Strength of angles

Gross area = 1920 mm2 per angle

The standard clearance holes = 20 + 2 = 22 mm

Net area = 1920 – 22 x 10 = 1700 mm2

Design strength py = 275 N/mm2

Capacity Pt = 275 x 1700/1000 = 467.5 kN

The angle is adequate to resist the applied load.Since capacity Pt (467.5 kN) > Axes Load (146.94 kN ).

Splice plate

Effective area = 1.2[(100 – 22)10] = 936 mm2

Gross area = 100 x 10 = 1000mm2

Gross area > Effective area …ok

Capacity, Pt = 275 x 936/1000 = 257.4 kN

The splice is adequate to resist the applied load.

Since capacity Pt (257.4 kN) > Axes Load (146.94 kN ).

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 28/52

28

By LEE KAR FUNG

5. CALCULATION OF BRACING DESIGN

Reference Calculation

Analysis loading horizontal using julur method with loading 1.2Wk.

Figure 14: Dimension of bracing

By referring the example of note UTM concrete structural design II,

the analysis wind loading for pressure horizontal = 0.87 kN/m

Self weight of bracing = 0.20 kN/m2

Horizontal for frame = 0.87 x 4.8 + 0.2 = 4.376 kN/m height

1.2Wk = 1.2 x 4.376 = 5.2512 = 5.25 N/m height

Point load at each level as following :

Level 3.8m = 5.25 x (.

+ ) = 12.6 = 12.6 kN

Level 4.8m = 5.25 x ( ) = 2.625 = 2.63 kN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 29/52

29

By LEE KAR FUNG

Figure 15: Wind loading at bracing

Figure 16: Reaction of Bracing

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 30/52

30

By LEE KAR FUNG

SUMMARY FORCE OF BRACING MEMBER

*Result bellow are analysis using Staad Pro 2006.

*Highlight load are used to bracing design.

Member Node Load (kN)

Top Chord 2-3

3-4

4-5

15.1 (Compression)

6.37 (Compression)

3.43 (Tension)

Vertical Member

Mmax = 15.9 kNm

Mmax = 15.7 kNm

2-6

3-7

4-8

5-9

0-6

11-9

0.122 (Compression)

4.4 (Compression)

4.94 (Compression)

4.42 (Compression)

4.82 (Tension)

4.82 (Compression)

Sloped Member 6-3

7-4

8-5

9.52 (Tension)

10.8 (Tension)

10.3 (Tension)

Bottom Chord 6-7

7-8

8-7

0.83 (Compression)

10.8 (Compression)

20.2 (Compression)

COMPRESSION MEMBER

Bottom Chord (Node 8-7)

Preliminary Sizing (Weld end)

Fc = 20.2 kN

py = 275 N/mm2

Assume pc = 0.4py

Ag = Fc / (0.4py) = 20.2 x 1000 / (0.4 x 275) = 183.64 mm2

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 31/52

31

By LEE KAR FUNG

B-43

Table 11

Table 25

Try angle 60 x 60 x 5L

Ag = 582 mm2

ra = rb = ry = rx = 18.2 mm, rv = 11.7 mm

Section Classification (consider a single angle)

ε = (275/275)0.5

= 1.0

b/t = 60/5 = 12 < 15ε = 15

d/t = 60/5 = 12 < 15ε = 15

(b + d)/t = (60 + 60)/5 = 24 = 24ε = 24 Class 3 semi compact

Slenderness

Lb = Lx = La = Ly = 2m (bottom chord nodes spacing), Lv = Lb = 2m

λ v

λ v = 0.85 Lv /rv = 0.85 (2000/11.7) = 145.30

λ v = 0.7 Lv /rv + 15 = 0.7 (2000/11.7) + 15 = 134.66

λ a

λ a = La /ra = 2000/18.2 = 109.89

λ a = 0.7 La /ra + 30 = 0.7 (2000/18.2) + 30 = 106.92

λ b

λ b = 0.85Lb /rb = 0.85 (2000/18.2) = 93.41

λ b = 0.7 Lb /rb + 30 = 0.7 (2000/18.2) + 30 = 106.92

λ max = 145.30

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 32/52

32

By LEE KAR FUNG

Table 23

Table 24

c)

cl. 4.7.4

cl. 3.4.3

cl. 4.6.3.1

Compression capacity

Since λ max = 145.30 and p y = 275 N/mm2, pc = 72 N/mm2

Therefore the compression capacity of the angle (class 3)

Pc = Agpc

= 582 x 72 x 10-3

= 41.90 kN > Fc = 20.2 kN….ok

TENSION MEMBER

Internal Vertical Member (Node 7-4)

Preliminary Sizing (Bolts end)

Ft = 10.8 kN

py = 275 N/mm2

Use the bolt size D = 20 mm

Bolt hole size = D + Allowance = D + 2 = 20 + 2 = 22 mm

Area needed = 10.8 x 103 / 275 = 39.27mm

2

Try angle 60 x 60 x 5L where Ag = 582 mm2

Tension Capacity

Assume the longer leg of the section welded to gusset; therefore the

neutral axis is eccentric away.

Since the member is grade S 275, Ke = 1.2

An = Ag – Ah = 582 – (22 x 10) = 362

Ae = Ke an = 1.2 An = 1.2 x 362 = 434.4 mm2

a1 = (60 x 5) – (22 x 10) = 80 mm2

a2 = Ag - a1 = 582 - 80 = 502 mm2

Pt = py (Ae - 0.5a2)

= 275 x (434.4 - 0.5 x 502) x 10-3

= 50.44 kN > Ft = 10.8 kN….Ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 33/52

33

By LEE KAR FUNG

6. CALCULATION OF BRACING CONNECTION DESIGN

Reference Calculation

CONNECTION AT BRACING (Internal)

(Bolt Connection)

Figure 17: Connection bolt for bracing

Figure 18: Truss connection between Top chord and vertical member

(behind).

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 34/52

34

By LEE KAR FUNG

Table 30

Table 31

Table 32

Table 32

Connection At Bracing Description

The figure above show the internal connection of bracing. In the

connection, members are subjected to compression force and tension force.

In the connection, two bolts of 20mm diameter in Grade 4.6 are used to

connect the angle member of 5mm thickness in Grade S275 to the gusset

plate of 8mm thickness in Grade S355.

Shear capacity of bolt:

Ps = ps As (ps = 160 N/mm2)

= 160 ( (20)2 /4) = 50.3 kN (single shear)

Bearing capacity of bolt.

Pbb = d.t.pbb (pbb = 460 N/mm2)

= 20 x 8 x 460/1000 = 73.6 kN

Bearing capacity of plate of the angle member,

Pbs = d.t.pbs < 0.5.e.t.pbs (pbs = 460 N/mm2)

= 20 x 10 x 460/1000 = 0.5 x 45 x 10 x 460/1000

= 92 kN = 103.5 kN

Therefore, Pbs = 92 kN

Bearing capacity of gusset plate,

Pbs = d.t.pbs < 0.5.e.t.pbs

= 20 x 8 x 550/1000 = 0.5 x 40 x 8 x 550/1000

= 88 kN = 88 kN

Therefore, Pbs = 88 kN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 35/52

35

By LEE KAR FUNG

cl 6.2.4

The capacity of the connection is controlled by the bolt shear capacity of

50.3 kN.

The connection uses two bolts in series, therefore the connection capacity

= 2 x 50.3 = 100.6 kN > 10.8 (Maximum force internal bracing

member)……ok

Check the block shear capacity:

Pr = 0.6 py t{Lv + Ke(Lt – kDt)}Lv = 50 + 40 = 90 mm

Lt = 40 mm

Dt = 22mm

K = 0.5 (single row)

Ke = 1.2

Pr = 0.6 x 275 x 8 [90 + 1.2(40 - 0.5 x 22)]

= 164 kN > 100.6 kN …….ok

Therefore, the bolt connection is adequate.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 36/52

36

By LEE KAR FUNG

Connection Top Chord and Bottom Chord

The bracing connections top and bottom chord is design subjected to

compression force and tension force. In the connection, welding connection

is used to connect the top and bottom chord member in bracing. In the

connection, splice plate 15mm x 30mm with thickness 10mm is used to

welding connection.

(Maximum Force at Node 8-7 = 20.2 kN)

The strength of butt weld,

Pw /L = 0.7 s pw = 0.7 x 6 x 220 x 10-3

= 0.924 kN/mm

Total length of weld, L = 15 + 15 + 15 = 45 mm

The capacity of welded connection = 0.924 x 45 = 41.58 kN > 20.2 kN

Therefore, welding 6mm weld is adequate.

Angle 100mm x 100mm x 10L

Splice plate 15mm x 30mm

15mm

15 mm

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 37/52

37

By LEE KAR FUNG

cl. 6.2.2.4

Table 29

cl. 6.2.1.1

CONNECTION AT COLUMN WITH BRACING

Figure 19: Connection bolt for truss and column

Vertical member

Size : angle 60 x 60 x 5L

Axes Load = 4.82 kN

End distance

Minimum end distance = 1.25D = 1.25 x 23 = 28.75 mm

Edge distance, from vertical member = 60/2 = 30 mm > 28.75 mm …..ok

Minimum spacing bolts = 2.5d = 2.5 x 20 = 50 mm

From vertical member, spacing bolts = 200 mm > 50 mm ….ok

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 38/52

38

By LEE KAR FUNG

Table 30

Table 31

cl. 6.3.3.3

Table 32

Connection At Column With Bracing Description

The connection column with bracing is design using bolt connection grade

4.6. 3 bolt size 20mm diameter bolts with 10mm splice (100mm x

640mm) is apply for this connection. Use 3-20mm diameter bolts with

10mm splice (100mm x 640mm).

Use grade 4.6 bolts, ps = 375 N/mm2

Strength of 20 mm bolts :Single shear capacity on threads = 160 x 245 = 91.875 = 39.2 kN

Bearing capacity of bolt.

pbb = 1000 N/mm2

Pbb = d tp pbb

= 20 x 5 x 460 / 1000 = 46 kN

Bearing capacity of splice plate member,

Pbs = k bs d tp pbs < 0.5 k bs e tp pbs

Where,

pbs = 460 N/mm2

Pbs = k bs d tp pbs = 1(20)(10)(460) = 92 kN

Pbs = 0.5 k bs e tp pbs = 0.5(1)(120)(10)(460) = 600 kN

Bolt capacity 3 bolts are in single shear.

Shear = (3 x 91.86) + 92 = 367.58 kN

Therefore, the capacity of the end bolt bearing on 10mm thick splice plate

is controlled by the end distance.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 39/52

39

By LEE KAR FUNG

B-43

cl. 4.6.3.3

cl. 3.4.2

Table 9

Strength of angles

Gross area = 582 mm2 per angle

The standard clearance holes = 20 + 2 = 22 mm

Net area = 582 – 22 x 10 = 362 mm2

Design strength py = 275 N/mm2

Capacity Pt = 275 x 362/1000 = 99.55 kN

The angle is adequate to resist the applied load.Since capacity Pt (99.55 kN) > Axes Load (4.82 kN)

Splice plate

Effective area = 1.2[(60 – 22)10] = 456 mm2

Gross area = 60 x 10 = 600mm2

Gross area > Effective area …ok

Capacity, Pt = 275 x 456/1000 = 125.4 kN

The splice is adequate to resist the applied load.

Since capacity Pt (125.4 kN) > Axes Load (4.82 kN).

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 40/52

40

By LEE KAR FUNG

7. WELDING CONNECTION AT GUSSET PLATE DESIGN

Reference Calculation

Welding Connection at Truss (Gusset Plate with truss member)

Node 6-7

Load = 776 kN

Use 12mm fillet weld with electrode 42,

strength welding = 1.85 kN/mm

Length required = 776/1.85 = 419.5 mm

Only the side x of the gusset plate connect with the truss member.

Therefore wielding is apply at side x only.

Side x gusset plate = 419.5 mm

(Add 12mm ), side x gusset plate = 431 mm, use 435 mm (Node 6-7

Only)

For gusset plate connection at other truss member

Load = 432 kN

Use 12mm fillet weld with electrode 42,

strength welding = 1.85 kN/mm

Length required = 432/1.85 = 233.51 mm

Only the side x of the gusset plate connect with the truss member.

Therefore wielding is apply at side x only.

Side x gusset plate = 233.51 mm

(Add 12mm ), side x gusset plate = 245.51 mm,

Therefore, use 250 mm length and 12mm weld at side x gusset plate

for truss.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 41/52

41

By LEE KAR FUNG

Welding Connection at Bracing (Gusset Plate with Bracing member)

For all the gusset plate with bracing member connection

Load = 20.2 kN

Use 6mm fillet weld with electrode 42,

strength welding = 0.92 kN/mm

Length required = 20.2/0.92 = 21.95 mm

Only the side x of the gusset plate connect with the truss member.Therefore wielding is apply at side x only.

Side x gusset plate = 21.95 mm

(Add 12mm ), side x gusset plate = 33.95 mm, use 35 mm

Therefore, use 35 mm length and 6mm weld at side x gusset plate for

bracing.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 42/52

42

By LEE KAR FUNG

8. CACULATION OF COLUMN DESIGN

Reference Calculation

4.7.3

Table 22

Vol 1Page B-8

Page B-9

Vol 1

Page B-8

Fc = 146.94 kN (Truss)

Fc = 4.82 kN (Bracing)

Fc = 23 x 9.81 /1000 = 0.23 kN (Column)

Total Compression Load, Fc = 146.94 + 4.82 + 0.23 = 151.99 = 152kN

Moment Maximum = 15.9 kNm

Determine the effective length

The member is effectively held in position at both ends, but not

restrained in direction at either end. Therefore, the effective length

LE = 0.85L = 0.85 x 4800 = 4080mm

Trial Section

Use 152 x 152 x 23 UC in grade S275

DepthWidth

Web thickness

Flange thickness

Depth between fillets

Radius of gyration about x-x axis

Radius of gyration about y-y axis

Gross area

D = 152.4 mmB = 152.2 mm

t = 5.8 mm

T = 6.8 mm

d = 123.6 mm

rx = 6.54 cm

ry = 3.70 cm

Ag = 29.2 cm2

Local buckling ratios :

Flange b/T = 11.2

Web d/t = 21.3

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 43/52

43

By LEE KAR FUNG

3.11

Table 9

4.7.2

Section Classification

Grade of steel = S275

T < 16 mm,

Therefore, design strength py = 275 N/mm2

ε = = = 1

For the outstand element of a compression flange, the limiting b/T for

class 1 semi-compact flange is 15ε .

Limiting b/T = 15ε = 15 x 1 = 15

The actual b/T = 11.2 < 15

Therefore, the flange is “not class 4 slender”.

For the web of an I or H section under axial compression, the limiting d/t

for a class 3 semi-compact web is but > 40 ε

r2 = = = 0.183

Limiting d/t =( . )

= 87.85

The actual d/t = 21.3 < 87.85

Therefore, the web is “not class 4 slender”.

The cross section is “not class 4 slender”.

Slenderness

λ x = =.

= 62.39

λ y = =.

= 110.27

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 44/52

44

By LEE KAR FUNG

cl. 4.7.4

Table 23

Table 24b

Table 23

Table 24c

Check the compression resistance

Basic requirement Fc < Pc

Pc = Agpc

Ag = 2920 mm

The compressive strength pc is obtained from the relevant strut curve for

buckling about the x-x and y-y axis. For a rolled H-section with T <

16mm:

Buckling about the x-x axisUse strut curve b

For λ x = 62.39 and py = 275 N/mm2, pcx = 217 N/mm

2

Buckling about the y-y axis

Use strut curve c

For λ y = 110.27 and py = 275 N/mm2, pcy = 110 N/mm

2

Therefore, pc = 110 N/mm2

Pc = Agpc

Pc = 2920 x 110 x 10-3

= 321.2 kN

Fc = 152 kN

152 kN < 321.2 kN

Therefore, the compression resistance is adequate.

Combined axial force and moment check

Since only nominal are applied, the column should satisfy the

relationship.

+ + < 1

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 45/52

45

By LEE KAR FUNG

Table 16

B-8

cl. 4.3.6.4

Mx = 15.9 kNm

My = 0 kNm

Mbs is the buckling resistance moment for simple columns. For H

section, it should be taken as the value of Mb determined using an

equivalent slenderness LT given by:

LT = 0.5 L/ry = 0.5(4800/37) = 64.86 = 65

Note: This expression for LT uses the actual length L and not the

effective length LE.

For py = 275 N/mm2 and LT = 65, pb = 201 N/mm2

For class 3 semi-compact cross-sections :

Zx = 164 cm3

Mb = pb Zx

= 201 x 164000 x 10-6

= 32.964 kNm

Therefore, Mbs = 33 kNm

+ + < 1

.+

.+

( . )< 1

0.47 + 0.48 + 0 < 1

0.95 < 1

Therefore, the combined resistance against axial force and moment is

adequate.

Adopt 152 x 152 x 23 UC in S275

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 46/52

46

By LEE KAR FUNG

9. CALCULATION OF SLAB BASE DESIGN

Reference Calculation

Column Dimension = 152 x 152 x 23 UC

Figure 20: Connection column with stump

Figure 21: Detailing connection column with stump

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 47/52

47

By LEE KAR FUNG

cl. 4.13.1

Table 30

cl. 6.3.3.2

Table 31

Loading

Case 1 : Maximum vertical load = 152 kN

Case 2 : X-axis, moment = 15.9 kNm

Bearing Pressure

Assume base 520 x 520mm plate and 4 bolts (grade 4.6) 20mm diameter .

Tension bolt area :

Ay = 2 x 245 = 490 mm2

d = 520 – 20 = 470 mm

Case Loading 1

Assuming a concrete cube strength f cu = 30 N/mm2

Permissible pressure = 0.4 x 30 = 12.0 N/mm2

Pressure = 152 x 103 / (520 x 520) = 0.56 N/mm

2

Bearing pressure satisfactory ( < 12N/mm2)

Case Loading 2

M/F = 15.9/152 x 1000 = 104.60

L/6 = 520/6 = 87 mm

Base area, A = 520 x 520 = 270400 mm2

Base modulus Z = 520 x 5202 /6 mm

3= 23400 cm

3

Pressure = F/A + M/Z = 152000/270400 + 15900000/23400000

= 1.24 N/mm2

Bolt Capacity

Bolt capacity in shear Ps = ps As

Ps = 160 N/mm2

Ps = 160 x 245 /1000 = 39.2 kN

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 48/52

48

By LEE KAR FUNG

Bolt capacity in tension

Pt = 47 kN

py = 275 N/mm2

From load analysis bracing shown:

Moment maximum = 15.9 kNm

Shear = 4.821 kN

Ʃy2

= 4202

= 0.176 mm2

(at based of column)

Maximum bolt in tension:

FT = Max x 0.42/ (2 x 0.176) = 15.93 x 0.42/(2 x 0.176) = 19 kN

Direct shear per bolt = 7.7 kN (Occur from wind at bracing)/ 4

= 1.93

Shear capacity on threads, Ps = 39.2

Tension capacity, Pt = 47 kN

Combined shear and tension:

+ < 1.4

.

.+ < 1.4

.

.+ < 1.4

0.45 < 1.4

Bolts are satisfactory.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 49/52

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 50/52

50

By LEE KAR FUNG

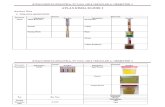

10. ELEMENT SUMMARY

MEMBER ELEMENT TYPE SIZE

TRUSS

PURLIN

Middle

Upper

Side

COMPRESSION

Top Chord

Vertical Member

TENSION

Vertical Member

Internal Sloped Member

Bottom Chord

Unequal Angle

Unequal Angle

Unequal Angle

Equal Angle

Equal Angle

Equal Angle

Equal Angle

Equal Angle

150 x 90 x 10L

200 x 100 x 10L

150 x 90 x 12L

150 x 150 x 15L

100 x 100 x 10L

100 x 100 x 10L

100 x 100 x 10L

120 x 120 x 15

ROOF TRUSS

INTERNAL

CONNECTION

Truss member with truss

member

Bolt and

Gusset Plate

2 Bolts 20mm

(grade 8.8)

8mm thick gusset plate

(grade S355)

Weld 12mm weld and

460mm weld length

Column member with

truss memberBolt

3 bolts 20mm

(grade 4.4)

BRACING

COMPRESSION

Bottom Chord

TENSION

Sloped Member

Equal Angle

Equal Angle

60 x 60 x 5L

60 x 60 x 5L

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 51/52

51

By LEE KAR FUNG

MEMBER ELEMENT TYPE SIZE

BRACING

INTERNAL

CONNECTION

Bracing member and

bracing member

Bolt and

Gusset Plate

2 Bolts 20mm

(grade 4.6)

8mm thick gusset plate

(grade S355)

Weld 6mm weld and

45mm weld length

Column member and

bracing memberBolt

3 bolts 20mm

(grade 4.4)

WELDING

CONNECTION

AT GUSSET

PLATE

Connection gusset plate

with truss member

Connection gusset plate

with bracing member

Welding

Welding

250 mm length and

12mm weld

35 mm length and

6mm weld

COLUMN Column H - Section152 x 152 x 23 UC in

grade S275

SLAB BASEColumn and Stump

Bolt

4 Bolts 20mm

diameter bolts (grade

4.6)

Plate 520 x 520mm plate

Column/base

plate weld6mm fillet weld

*The detailing is shown in the drawing.

8/3/2019 Steel Design Project (INTAN BERLIAN)

http://slidepdf.com/reader/full/steel-design-project-intan-berlian 52/52

11. REFERENCE

a. Tn. Haji Roslon Kolop. (2008). Structural Steel Design Note. Malaysia:

UTHM.

b. Mohd Hanim Osman & Abdul Karim Mirasa. (2008). Structural Steel

Design to BS 5950: Part 1: 2000. Malaysia: UTM.

c. L. J Morris & D. R. Plum. (1996). Structural Steelwork Design to BS 5950.

2nd

Edition. London: Prentice Hall.

d. British Standards Institution (2000). Structural use of steelwork in

building. London: BS 5950-1, 2000.