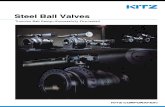

Steel Ball Valves, Floa ng Ball Design F14AZ / SCTDZM-FS Class ...

Transcript of Steel Ball Valves, Floa ng Ball Design F14AZ / SCTDZM-FS Class ...

10

Steel Ball Valves, Floa! ng Ball Design

Features

• An! sta! c device

• Blowout-proof stem

• Fire test cer! fi ca! on é(API 607, ISO 10497)

• High performance HYPATITE®PTFE ball seats

• ISO 5211 top mount and CAPI stem dimension

• Standards: Design: ISO 17292/API 608/ASME B16.34/BS 5351

Class 150 300

Gear Operator

H D C A

150 300 150 300 150 300 150 300

Valve

Size

(inch)

6" 6" 322 335 310 360 165 210 66.5 88.5

8" 8 " 412 412 360 360 210 210 88.5 88.5

10" 448 - 500 - 363 - 93.5 -

Thickness: ISO 17292/ASME B16.34/BS 5351

Flanges: ASME B16.5 Lenghts: ASME B16.10

Fugi! ve emission: ISO 15848. Leak Test: Class VI acc.

EN 12266-1 Rate A. Page 4 for Pressure-Temperature Ra! ngs

Page 11 for Construc! on and Materials

Page 24 for Dimension of Actuator Moun! ng Pad

F14AZ / SCTDZM-FS Class 150/300 - Carbon Steel Ball Valves

Dimensions of 150SCTDZM-FS / 300SCTDZM-FS Unit: mm

Gear Opera! on Unit: mm

Full port, Split body, Side entry design

Valve Size

NPSPort

L D H ISO

5211

Cv

(m³/h

Torque

(N.m)

Weight

(Kg)

A150 A300 A150 A300 A150 A300 A150 A300 A150 A300

1/2” 14 108 140 130 130 108 108 F03 15 4 5 2,6 3

3/4” 19 117 152 130 130 111 111 F03 33 6 7 2,8 4,5

1” 24 127 165 160 160 124 124 F05 59 10 15 4,5 7,2

11/2” 38 165 190 230 230 134 134 F07 181 22 30 8,5 13,9

2” 50 178 216 230 230 143 143 F07 346 25 42 11,4 18,4

21/2” 64 190 241 400 400 179 179 F10 654 40 87.7 19,7 27

3” 76 203 283 400 400 189 189 F10 1020 65 160 25 38

4” 100 229 305 460 750 224 251 F12 1910 125,4 300 45 80

6” 151 394 403 1000 1000 315 315 F14 4317 380 690 112 (1) 150 (1)

8” 202 457 502 1500 1500 406 406 F16 8589 650 1100 186 (1) 230 (1)

10” - - - Gear opera! on - Gear

opera! on - F16 14338 1500 - 269 (1) -

Valve Operator1/2 ∼ 8” : Lever opera! on6” ∼ 8” : Op! onal gear opera! on10” : Standard gear opera! onOp! ons

• Ball and stem to CF8M (316)

(1) : Gear Box included

150SCTDZM-FS 300SCTDZM-FS

Torque ValuesThe values shown are an average of the real values. These values have been taken under ideal condi! ons of clean water, room temperature, standard seats, daily handling and without safety rate.

Worm gear operators may be mounted on KITZ ball valves at your op! on for the smoothest valve opera! on. Electric or pneuma! c actuators are also op! onally available. Contact KITZ distributors for appropriate choice and sizing of valve actuators.

1 Cv = 1,16 Kv

11

Steel Ball Valves, Floa! ng Ball Design

Construc! on and Materials

No. Parts150SCTDZM-FS

300SCTDZM-FS

1 Body ASTM A216 Gr.WCB

2 Body Connector ASTM A216 Gr.WCB

3 An! sta! c Stem ASTM A276 Type 316

4 Ball ASTM A276 Tipo 316 or

ASTM A351 Gr. CF8M

7 Gland ASTM A351 Gr.CF8

8 Gland Packing Flexible graphite

9 Handle*1 Duc! le iron

9A Handle bar*1 Carbon steel

9B Handle head*1 Duc! le iron

16 Name Plate ASTM A276 Type 304*3

19 Gasket Flexible graphite

20 Packing Washer*2 ASTM A276 Type 316L*4

30 Ball Seat HYPATITE®PTFE

33 Cap Nut ASTM A194 Gr.2HM

35 Cap Bolt ASTM A193 Gr.B7M

36 Gland Bolt Stainless steel

40 Keylock Plate ASTM A276 Type 304*3

43 Handle-lock Plate ASTM A276 Type 304*3

48 Snap Ring ASTM A276 Type 304*3

49 Stopper ASTM A276 Type 304*3

51 Stopper Plate ASTM A276 Type 304*3

57 Gland Bush PTFE + 20% Glass Filled

58 Gland Washer ASTM A276 Type 304*3

67 Stem Bearing PTFE + 20% Glass Filled

123A Handle-lock Plate Bolt Stainless steel

123B Handle Bolt Stainless steel

124 Spring & Pin ASTM A313 & A276 Type 316

126 Stopper Plate Bolt Stainless steel

145 Coned Disc Spring Stainless steel

¡ Standard material confi gura! on can be applied to

sour service.

*1 Class 150 : Bar type handle used for size 6” & 8”.

Class 300 : Bar type handle used for size 4” to 8”. *2 Up to size 1”. *3 A S T M A276 Type 304 or equal. *4 A S T M A276 Type 304 or equal.

All part numbers are corresponding with those shown in valve assembly drawings.

rts150SCTDZM-FS

300SCTDZM-FS

ASTM A216 Gr.WCB

nector ASTM A216 Gr.WCB

tem ASTM A276 Type 316

ASTM A276 Tipo 316 or

ASTM A351 Gr. CF8M

ASTM A351 Gr.CF8

ing Flexible graphite

Duc! le iron

*1 Carbon steel

d*1 Duc! le iron

ASTM A276 Type 304*3

Flexible graphite

sher*2 ASTM A276 Type 316L*4

HYPATITE®PTFE

ASTM A194 Gr.2HM

ASTM A193 Gr.B7M

Stainless steel

ate ASTM A276 Type 304*3

k Plate ASTM A276 Type 304*3

ASTM A276 Type 304*3

ASTM A276 Type 304*3

ate ASTM A276 Type 304*3

PTFE + 20% Glass Filled

sher ASTM A276 Type 304*3

ng PTFE + 20% Glass Filled

Plate Bolt Stainless steel

t Stainless steel

in ASTM A313 & A276 Type 316

ate Bolt Stainless steel

Spring Stainless steel

¡ Standard material confi gura! on can be applied to

sour service.

*1 Class 150 : Bar type handle used for size 6” & 8”.

Class 300 : Bar type handle used for size 4” to 8”. *2 Up to size 1”. *3 A S T M A276 Type 304 or equal. *4 A S T M A276 Type 304 or equal.

Illustra! on shows Size 1" design.

12

Steel Ball Valves, Floa! ng Ball Design

F14AZ / UTDZM-FS Class 150/300 - Stainless Steel Ball Valves

Dimensions of 150UTDZM-FS / 300UTDZM-FS Unit: mm

Gear Opera! on Unit: mm

Full port, Split body, Side entry design

Class 150 300

Gear Operator

H D C A

150 300 150 300 150 300 150 300

Valve

Size

(inch)

6" 6" 322 335 310 360 165 210 66.5 88.5

8" 8" 412 412 360 360 210 210 88.5 88.5

10" 448 - 500 - 363 - 93.5 -

Valve Size

NPSPort

L D H ISO

5211

Cv

(m³/h)

Torque

(N.m)

Weight

(Kg)

A150 A300 A150 A300 A150 A300 A150 A300 A150 A300

1/2” 14 108 140 130 130 108 108 F03 15 4 5 2,6 3

3/4” 19 117 152 130 130 111 111 F03 33 6 7 2,8 4,5

1” 24 127 165 160 160 124 124 F05 59 10 15 4,5 7,2

11/2” 38 165 190 230 230 134 134 F07 181 22 30 8,5 13,9

2” 50 178 216 230 230 143 143 F07 346 25 42 11,4 18,4

21/2” 64 190 241 400 400 179 179 F10 654 40 87.7 19,7 27

3” 76 203 283 400 400 189 189 F10 1020 65 160 25 38

4” 100 229 305 460 750 224 251 F12 1910 125,4 300 45 80

6” 151 394 403 1000 1000 315 315 F14 4317 380 690 112 (1) 150 (1)

8” 202 457 502 1500 1500 406 406 F16 8589 650 1100 186 (1) 230 (1)

10” - - - Gear opera! on - Gear

opera! on - F16 14338 1500 - 269 (1) -

Features

• An! sta! c device

• Blowout-proof stem

• Fire test cer! fi ca! on é(API 607, ISO 10497)

• High performance HYPATITE®PTFE ball seats

• ISO 5211 top mount and CAPI stem dimension

• Standards: Design: ISO 17292/API 608/ASME B16.34/BS 5351

Thickness: ISO 17292/ASME B16.34/BS 5351

Flanges: ASME B16.5 Lenghts: ASME B16.10

Fugi! ve emission: ISO 15848. Leak Test: Class VI acc.

EN 12266-1 Rate A.

Page 4 for Pressure-Temperature Ra! ngs

Page 13 for Construc! on and Materials

Page 24 for Dimension of Actuator Moun! ng Pad

Valve Operator1/2 ∼ 8” : Lever opera! on6” ∼ 8” : Op! onal gear opera! on10” : Standard gear opera! on

(1) : Gear Box included

150UTDZM-FS 300UTDZM-FS

Torque ValuesThe values shown are an average of the real values. These values have been taken under ideal condi! ons of clean water, room temperature, standard seats, daily handling and without safety rate.

Worm gear operators may be mounted on KITZ ball valves at your op! on for the smoothest valve opera! on. Electric or pneuma! c actuators are also op! onally available. Contact KITZ distributors for appropriate choice and sizing of valve actuators.

1 Cv = 1,16 Kv

13

Steel Ball Valves, Floa! ng Ball Design

Construc! on and Materials

No. Parts150UTDZM-FS

300UTDZM-FS

1 Body ASTM A351 Gr.CF8M

2 Body Connector ASTM A351 Gr.CF8M

3 An! sta! c Stem ASTM A276 Type 316

4 Ball ASTM A276 Type 316 or

ASTM A351 Gr.CF8M

7 Gland ASTM A351 Gr.CF8

8 Gland Packing Flexible graphite

9 Handle*1 Duc! le iron

9A Handle bar*1 Carbon steel

9B Handle head*1 Duc! le iron

16 Name Plate ASTM A276 Type 304*3

19 Gasket Flexible graphite

20 Packing Washer*2 ASTM A276 Type 316L*4

30 Ball Seat HYPATITE®PTFE

33 Cap Nut ASTM A194 Gr.8M

35 Cap Bolt ASTM A193 Gr.B8M

36 Gland Bolt Stainless steel

40 Keylock Plate ASTM A276 Type 304*3

43 Handle-lock Plate ASTM A276 Type 304*3

48 Snap Ring ASTM A276 Type 304*3

49 Stopper ASTM A276 Type 304*3

51 Stopper Plate ASTM A276 Type 304*3

57 Gland Bush PTFE + 20% Glass Filled

58 Gland Washer ASTM A276 Type 304*3

67 Stem Bearing PTFE + 20% Glass Filled

123A Handle-lock Plate Bolt Stainless steel

123B Handle Bolt Stainless steel

124 Spring & Pin ASTM A313 & A276 Type 316

126 Stopper Plate Bolt Stainless steel

145 Coned Disc Spring Stainless steel

*1 Class 150 : Bar type handle used for size 6” & 8”.

Class 300 : Bar type handle used for size 4” to 8”. *2 Up to size 1”. *3 A276 Type 304 or equal. *4 A276 Type 316 or equal.

¡ Standard material confi gura! on can be applied to

sour service.

All part numbers are corresponding with those shown in valve assembly drawings.

rts300UTDZM-FS

ASTM A351 Gr.CF8M

nector ASTM A351 Gr.CF8M

tem ASTM A276 Type 316

ASTM A276 Type 316 or

ASTM A351 Gr.CF8M

ASTM A351 Gr.CF8

ing Flexible graphite

Duc! le iron

*1 Carbon steel

ead*1 Duc! le iron

te ASTM A276 Type 304*3

Flexible graphite

Washer*2 ASTM A276 Type 316L*4

HYPATITE®PTFE

ASTM A194 Gr.8M

ASTM A193 Gr.B8M

Stainless steel

ate ASTM A276 Type 304*3

k Plate ASTM A276 Type 304*3

ASTM A276 Type 304*3

ASTM A276 Type 304*3

ate ASTM A276 Type 304*3

sh PTFE + 20% Glass Filled

sher ASTM A276 Type 304*3

ng PTFE + 20% Glass Filled

k Plate Bolt Stainless steel

t Stainless steel

in ASTM A313 & A276 Type 316

ate Bolt Stainless steel

Spring Stainless steel

*1 Class 150 : Bar type handle used for size 6” & 8”.

Class 300 : Bar type handle used for size 4” to 8”. *2 Up to size 1”. *3 A276 Type 304 or equal. *4 A276 Type 316 or equal.

sour service.

Illustra! on shows Size 1" design.

14

Steel Ball Valves, Floa! ng Ball Design

F14A Class 150/300 - Carbon Steel Ball Valves

Features

• An! sta! c device

• Blowout-proof stem

• Fire test cer! fi ca! on é(BS6755 P2/API 607)

• High performance PTFE ball seats

• ISO 5211 top mount and CAPI stem dimension

• Standards: Design: ISO 17292 P2/ANSI B16.34

Class150

300

Gear Operator

H P C A

150 300 150 300 150 300 150 300

Valve

Size

(inch)

4" - - 300 300 282 282 71 71

6" - - 300 300 282 282 71 71

8" 342 342 400 400 340 340 86 86

10" 378 378 500 500 365 365 130 130

12" 440 440 500 500 365 365 130 130

Gear Opera! on Unit: mm

Dimensions of F14A Class 150/300 Unit: mm

Valve Operator3” ∼ 6” : Lever opera! on4” ∼ 6” : Op! onal gear opera! on8” ∼ 12”: Standard gear opera! on

(1) : Gear Box included

Full port, Split body, Side entry design

Valve Size

NPSPort

L X P

HISO

5211

Cv

(m³/h)

Torque

(N.m)

Weight

(Kg)

A150A300 A150 A300 A150 A300

A150 A300

Corta Larga A150 A300 Corta Larga Corta

3” 76 203 241 283 90 127 250 350 148 F07 980 60 90 21 25,8 29,5

4” 102 229 305 305 114 152 500 500 196 F10 1600 120 175 38 42,6 53

6” 152 267 394 403 133 201 750 1000 223 F10 4100 250 350 74 87,5 110

8” 203 457 - 502 228 251 - - Gear opera! on F14 8850 500 750 180 (1) - 196 (1)

10” 254 533 - 568 266 284 - - Gear opera! on F16 14700 1400 1600 255 (1) - 297 (1)

12” 305 610 - 648 305 324 - - Gear opera! on F16 23200 2000 2100 360 (1) - 450 (1)

Thickness: ISO 17292/ANSI B16.34 Flanges: ANSI B16.5 RF

Lenghts: ANSI B16.10 (Short and Long pa$ ern);

3”~6” A150 (Long pa$ ern): BS-EN-558/2.T1.S12

Leak test: Class VI acc. EN 12266-1 Rate A.

Page 4 for Pressure-Temperature Ra! ngs

Page 15 for Construc! on and Materials

Page 25 for Dimension of Actuator Moun! ng Pad

Torque ValuesThe values shown are an average of the real values. These values have been taken under ideal condi! ons of clean water, room temperature, standard seats, daily handling and without safety rate.

Worm gear operators may be mounted on KITZ ball valves at your op! on for the smoothest valve opera! on. Electric or pneuma! c actuators are also op! onally available. Contact KITZ distributors for appropriate choice and sizing of valve actuators.

1 Cv = 1,16 Kv

15

Steel Ball Valves, Floa! ng Ball Design

Construc! on and Materials

No. PartsF14A Class 150

F14A Class 300

1 Body ASTM A216 WCC*1

4 Body Connector ASTM A216 WCC*1

5 An! sta! c Stem*2 ASTM A479 Type 410

6 Gland Ring ASTM A479 Type 316

8 Stop Pin Steel

9 Stop Plate Steel zinc plated

11 Gland Washer Blued steel

12 Nut DIN 267/3 C8.8 blued

17 Stud Bolt-Bolt ASTM A193 /A193M B7M blued

18 Nut ASTM A194/A194M 2HM blued

21 Ball*3 ASTM A217/A743 Gr. CA15

22 Ball Seat PTFE

24 Body Seal 316L+Graphite

25 Gland Packing Graphite

26 Stem Seal PTFE

31 Handle head GGG40

32 Handle bar GGG40

33 Handle bolt Stainless Steel

35 Bolt Steel

36 Washer Steel

40 Stem O’ringr FKM

*1 WCC = WCB (0,25% C Max.) *2 DN < 10” : ASTM A479 Type 316 (Op! onal)

DN ≥ 10” : ASTM A479 Type 316

*3 DN < 10” : ASTM A479 Type 316 (Op! onal)

DN ≥ 10” : ASTM A479 Type 316

Valve fi nish: phosphate and oil dipped.

Opera! on group: DN ≤ 6”: by wrench.

DN ≥ 8”: by gear box.

¡ Standard material confi gura! on can be applied to

sour service.

All part numbers are corresponding with those shown in valve assembly drawings.

16

Steel Ball Valves, Floa! ng Ball Design

F14A Class 150/300 - Stainless Steel Ball Valves

Gear Opera! on Unit: mm

Dimensions of F14A Class 150/300 Unit: mm

Worm gear operators may be mounted on KITZ ball valves at your op! on for the smoothest valve opera! on. Electric or pneuma! c actuators are also op! onally available. Contact KITZ distributors for appropriate choice and sizing of valve actuators.

Full port, Split body, Side entry design

Class150

300

Gear Operator

H P C A

150 300 150 300 150 300 150 300

Valve

Size

(inch)

4" - - 300 300 282 282 71 71

6" - - 300 300 282 282 71 71

8" 342 342 400 400 340 340 86 86

10" 378 378 500 500 365 365 130 130

12" 440 440 500 500 365 365 130 130

Features

• An! sta! c device

• Blowout-proof stem

• Fire test cer! fi ca! on é(BS6755 P2/API 607)

• High performance PTFE ball seats

• ISO 5211 top mount and CAPI stem dimension

• Standards: Design: ISO 17292/ANSI B16.34

Thickness: ISO 17292/ANSI B16.34 Flanges: ANSI B16.5, RF

Lenghts: ANSI B16.10 (Short and Long pa$ ern);

3”~6” A150 (Long pa$ ern): BS-EN-558/2.T1.S12

Leak test: Class VI acc. EN 12266-1 Rate A.

Page 4 for Pressure-Temperature Ra! ngs

Page 17 for Construc! on and Materials

Page 25 for Dimension of Actuator Moun! ng Pad

Valve Operator3” ∼ 6”

: Lever opera! on4” ∼ 6” : Op! onal gear opera! on8” ∼ 12”: Standard gear opera! on

(1) : Gear Box included

Valve Size

NPSPort

L X P

HISO

5211

Cv

(m³/h)

Torque

(N.m)

Weight

(Kg)

A150A300 A150 A300 A150 A300

A150 A300

Corta Larga A150 A300 Corta Larga Corta

3” 76 203 241 283 90 127 250 350 148 F07 980 60 90 21 25,8 29,5

4” 102 229 305 305 114 152 500 500 196 F10 1600 120 175 38 42,6 53

6” 152 267 394 403 133 201 750 1000 223 F10 4100 250 350 74 87,5 110

8” 203 457 - 502 228 251 - - Gear opera! on F14 8850 500 750 180 (1) - 196 (1)

10” 254 533 - 568 266 284 - - Gear opera! on F16 14700 1400 1600 255 (1) - 297 (1)

12” 305 610 - 648 305 324 - - Gear opera! on F16 23200 2000 2100 360 (1) - 450 (1)

Torque ValuesThe values shown are an average of the real values. These values have been taken under ideal condi! ons of clean water, room temperature, standard seats, daily handling and without safety rate.

1 Cv = 1,16 Kv

17

Steel Ball Valves, Floa! ng Ball Design

Construc! on and Materials

No. PartsF14A Class 150

F14A Class 300

1 Body ASTM A351 CF8M

4 Body Connector ASTM A351 CF8M

5 An! sta! c Stem ASTM A479 Type 316

6 Gland Ring ASTM A479 Type 316

8 Stop Pin Stainless steel (DIN 267/11 A2-70)

9 Stop Plate Steel nickel plated

11 Gland Washer Stainless steel 304 CSP

12 Nut Stainless steel (DIN 267/11 A2-70)

17 Stud Bolt-Bolt*1 DIN 267/11 or A193/A193M B7M

18 Nut *1 DIN 267/11 or A194/A194M 2HM

21 Ball DIN 1.4408 (CF8M )

22 Ball Seat PTFE

24 Body Seal 316L+Grafi to

25 Gland Packing Grafi to

26 Stem Seal PTFE

31 Handle head GGG40

32 Handle bar GGG40

33 Handle bolt Stainless Steel

35 Bolt Steel

36 Washer Steel

40 Stem O’ring FKM

*1 Class 150

DN ≤ 8” : DIN 267/11 A2-70

DN ≤ 8” + Nace : ASTM A193/A194 B7M/2HM deltatone coat.

DN ≥ 10” : ASTM A193/A194 B7M/2HM deltatone coated

Class 300

DN ≤ 4”

: DIN 267/11 A2-70

DN ≤ 4” + Nace : ASTM A193/A194 B7M/2HM deltatone coat.

DN ≥ 6” : ASTM A193/A194 B7M/2HM deltatone coated

Valve fi nish: (SS ) Natural

Opera! on group: DN ≤ 6” : by wrench.

DN ≥ 8”: by gear box.

¡ Standard material confi gura! on can be applied to

sour service.

All part numbers are corresponding with those shown in valve assembly drawings.

18

Steel Ball Valves, Floa! ng Ball Design

Valve Operator1/2” ∼ 6” : Lever opera! on4” ∼ 6” : Op! onal gear opera! onNote(1): Also available RB (2): Only available RB

Dimensions of F14A Class 600 Unit: mm

Full port, Split body, Side entry design

Class 600Gear Operator

H P1 C A

Valve Size

(inch)

4" 196 300 282 71

6" 254 300 282 71

Gear Opera! on Unit: mm

F14A Class 600 - Carbon Steel / Stainless Steel Ball Valves

Features

• An! sta! c device

• Blowout-proof stem

• Fire test cer! fi ca! on é(BS6755 P2/API 607)

• High performance PTFE ball seats

• ISO 5211 top mount and CAPI stem dimension

• Standards: Design: ISO 17292/ANSI B16.34

Thickness: ISO 17292/ANSI B16.34 Flanges: ANSI B16.5, RF

Lenghts: ANSI B16.10

Leak test: Class VI acc. EN 12266-1 Rate A.

Page 4 for Pressure-Temperature Ra! ngs

Page 19 for Construc! on and Materials

Page 25 for Dimension of Actuator Moun! ng Pad

Valve Size

NPSPort L X P H

ISO

5211

Cv

(m³/h)

Torque

(N.m)

Weight

(Kg)

1/2” 14 165 82 150 85 F03 18 10 2,9

3/4” 19 190 95 150 90 F03 40 10 4,2

1” 25 216 108 200 104 F05 65 15 5,9

11/2” 38 241 102 200 125 F05 150 30 11,5

2” 51 292 117 350 128 F07 260 40 17,5

3” 76 356 136 350 148 F07 980 120 34,7

4” (1) 102 432 216 500 196 F10 1600 250 68,5

6” (2) 111 559 279,5 1000 254 F10 2200 - -

Torque ValuesThe values shown are an average of the real values. These values have been taken under ideal condi! ons of clean water, room temperature, standard seats, daily handling and without safety rate.

Worm gear operators may be mounted on KITZ ball valves at your op! on for the smoothest valve opera! on. Electric or pneuma! c actuators are also op! onally available. Contact KITZ distributors for appropriate choice and sizing of valve actuators.

1 Cv = 1,16 Kv

19

Steel Ball Valves, Floa! ng Ball Design

Construc! on and Materials

No. PartsCarbon Steel Stainless Steel

F14AClass 600

F14A Class 600

1 Body* ASTM A216 WCC*1 ASTM A351 CF8M

4 Body Connector* ASTM A216 WCC*1 ASTM A351 CF8M

5 An! sta! c Stem*2 316 or A479 410 A479 Type 316

6 Gland Ring A479 Type 316

8 Stop Pin* Steel Stainless Steel*6

9 Stop Plate Steel zinc plated Steel nickel plated

11 Gland Washer Blued steel Stainless Steel 304CSP

12 Nut* DIN 267/3 C 8.8 blued Stainless Steel*6

17 Stud Bolt-Bolt*5 DIN 267/11 or A193/A193M B7M

18 Nut*5 DIN 267/11 or A194/A194M 2HM

21 Ball*3 316 or CA15 316 or CF8M

22 Ball Seat PTFE

24 Body Seal 316L+Graphite

25 Gland Packing Graphite

26 Stem Seal*4 PTFE+C+Gr. or PTFE

30 Handle Steel coated SS + Plas! c

31 Handle head GGG40

32 Handle bar GGG40

33 Handle bolt Stainless Steel

35 Bolt Steel

36 Washer Steel

40 Stem O’ring FKM

*1 WCC = WCB (0,25% C Max.) *2 Material CS

DN ≤ 2” : ASTM A479 Type 316

DN ≥ 3” : ASTM A479 Type 410

Material SS

ASTM A479 Type 316

*3 Material CS

DN ≤ 2” : ASTM A479 Type 316

DN ≥ 3” : ASTM A217/A743 Gr. CA15

Material SS

DN ≤ 2” : ASTM A479 Type 316

DN ≥ 3” : DIN 1.4408 (CF8M)

*4 DN ≤ 1” : PTFE+C+Graphite

DN ≥ 11/2” : PTFE

*5 Material CS

ASTM A193/A194 B7M/2HM blued

Material SS

DN ≤ 2” : DIN 267/11 A2-70

DN ≤ 2” + Nace : ASTM A193/A194 B7M/2HM deltatone coat.

DN ≥ 3” : ASTM A193/A194 B7M/2HM deltatone coated *6 Stainless Steel (DIN 267/11 A2-70)

Valve fi nish: (CS) Phosphate and oil dipped.

(SS) Natural

Opera! on group: by wrench.

¡ Standard material confi gura! on can be applied to

sour service.

All part numbers are corresponding with those shown in valve assembly drawings.

NPS ≤ 1”