static-content.springer.com10.1007... · Web viewFor analysis of VOCs, a gas chromatography/mass...

Transcript of static-content.springer.com10.1007... · Web viewFor analysis of VOCs, a gas chromatography/mass...

Supplementary Material

Characterization of Trace Contaminants in Syngas from the Thermochemical Conversion of Biomass

S. Kent Hoekman*1, Curtis Robbins1, Xiaoliang Wang1, Barbara Zielinska1, Dennis Schuetzle2 and Robert Schuetzle3

1Division of Atmospheric Sciences, Desert Research Institute (DRI), 2215 Raggio Parkway, Reno, NV 89512

2Renewable Energy Institute International (REII), McClellan, CA 95652

3Pacific Renewable Fuels and Chemicals, McClellan, CA 95652

Part 1: Protocols for Sampling and Analysis of Syngas………………………………………2

Part 2: Results from Analysis of Syngas Samples Collected from Synterra IBR……….….15

Reference List...…………………………………………………………………………………22

Part 1: Protocols for Sampling and Analysis of SyngasA. Canister Samples

1. Canister preparation and collection

Prior to use, electro-polished canisters are cleaned by alternating evacuation and flushing through

seven cycles with humid, ultra high purity (UHP) air at 140 ºC. Ten percent of the cleaned canisters

are then pressurized with humid UHP air, allowed to equilibrate overnight, then analyzed by gas

chromatography with flame ionization detection (GC/FID). For blank samples, each individual target

compound should be present at concentration less than 0.2 ppbv; total non-methane hydrocarbon

concentration should be less than 10 ppbC. Before shipping to a field site for use, the canisters are

evacuated in the laboratory by connection to a vacuum line. When collecting syngas, the evacuated

canister is opened by a solenoid valve, and the flow is regulated through a critical orifice.

2. Canister Analysis (for C2-C11)

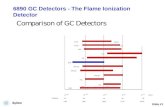

For analysis of VOCs, a gas chromatography/mass spectrometry/flame ionization detector

(GC/MS/FID) method is employed, based upon guidance provided by EPA Method TO-15.1 The

integrated GC/MS/FID system includes a Lotus Consulting Ultra-Trace Toxics sample pre-

concentration system built into a Varian 3800 GC instrument with a FID, coupled to a Varian Saturn

2000 ion trap mass spectrometer. The Lotus pre-concentration system consists of three traps. Mid-

and heavier weight hydrocarbons are collected on the front trap consisting of 1/8” nickel tubing

packed with multiple adsorbents. Trapping is performed at 55 ºC and eluting is performed at 200 ºC.

The rear traps consist of an empty 0.040” ID nickel tubing (for light hydrocarbons) and a cryo-

focusing trap (for mid and higher weight hydrocarbons isolated in the front trap). The cryo-focusing

trap is built from 6’ x 1/8” nickel tubing filled with glass beads. Trapping in both rear traps occurs at

-180 ºC and eluting at 200 ºC. Light hydrocarbons are deposited onto a Varian CP-Sil5 column (15m

x 0.32mm x 1µm) plumbed to a column-switching valve within the GC oven, then to a Chrompack

Al2O3/KCl column (25m x 0.53mm x 10µm) leading to the flame ionization detector (FID) for

quantification of light hydrocarbons (C2-C4). The mid-range and heavier hydrocarbons cryo-focused

in the rear trap are deposited onto a J&W DB-1 column (60m x 0.32mm x 1µm) connected to an ion

trap mass spectrometer. The GC initial temperature is 5 ºC, held for approximately 9.5 minutes, then

ramped at 3 ºC/min to 200 ºC for a total run time of 80 minutes.

2

Calibration of the system is conducted with a mixture that contains commonly found hydrocarbons

(75 compounds from ethane to n-undecane, purchased from Air Environmental) in the range of 0.2 to

10 ppbv. Three point external calibrations are run prior to analysis, and one calibration check is run

every 24 hours. If the response of an individual compound is more than 10% off, the system is

recalibrated.

Replicate analyses are conducted at least 24 hours after the initial analyses to allow re-equilibration

of the compounds within the canisters. All replicate analyses are flagged in the project database. The

data processing program extracts these replicates and determines a replicate precision. Replicate

analysis is important because it provides a continuous check on all aspects of each analysis, and

highlights analytical problems before they become significant.

Method detection limit (MDL) is determined as recommended by the EPA Method TO-15 (according

to the Code of Federal Regulations, 40 CFR 136 Appendix B). Briefly, seven consecutive replicate

measurements of the compounds of interest at concentrations near (within a factor of 5) the expected

detection limits are made, and the standard deviations for these 7 replicate concentrations are

calculated. The MDL is obtained by multiplying these standard deviations by 3.14 (i.e. the Student’s

t-value for 99 percent confidence for 7 values). In general, MDLs for VOC measurements are 0.1 –

0.2 ppbv.

3. Canister Analysis of Permanent Gases (CO, CO2, N2, CH4, H2)

3a. Methane, Carbon Monoxide, and Carbon Dioxide

Methane (CH4), carbon monoxide (CO) and carbon dioxide (CO2) are measured from canister

samples using GC/FID (Shimadzu GC-17A). Since the FID does not respond to CO and CO2, these

species are converted to methane by a methanator, positioned immediately after the GC column, but

ahead of the detector. The methanator comprises a firebrick powder impregnated with nickel catalyst,

through which a stream of hydrogen gas flows continuously at ~450 C.

For compound separation, a 20-ft x 1/8-in. inner-diameter (i.d.) column, packed with 60/80 mesh of

Carboxen 1000 (Supelco) is used. This column provides sufficient separation between CH4 and CO

without retaining CO2. Five-ml samples are injected using a constant volume loop. An initial column

temperature of 35 °C is held for 8-min., followed by a gradient of 15 °C/min to a final temperature of

3

200 °C. Response factors are determined by calibrations with gaseous standard mixtures (Scott

Specialty Gases or AGA Specialty Gases, NIST-traceable) containing CO, CO2 and CH4 in zero air.

The minimum detection limits are 0.06 ppmv for CO, 0.2 ppmv for CH4, and ~3 ppmv for CO2

(MDLs determined as described above). The precision of measurements is generally better than 10%.

3b. Hydrogen and Nitrogen

Hydrogen (H2) and nitrogen (N2) concentrations are measured using a SRI 8610C gas chromatograph

with a 0.5 ml sample loop and a thermal conductivity detector. A SRI Molecular Sieve 13x (6 ft x 1/8

in ID) GC column is used. The initial GC oven temperature is 40°C, followed by a temperature ramp

of 50°C/min to 200°C and final hold of 6.8 minutes, giving a total run time of 10 minutes.

A single stock calibration standard was obtained from Airgas containing a blend of H2 (50.04%

±1%), CO (19.98% ±1%), CO2 (19.98% ±1%), and CH4 (10% ±1%). Lower calibration levels were

prepared by quantitatively diluting the stock gas with ultra high purity N2 into 6-liter stainless steel

canisters. H2 calibration levels were 7.48%, 20.28%, 30.17%, and 50.04%. N2 standards were

prepared from an ultra high purity (UHP) N2 sample mixed with helium (He).

B. Carbonyl Samples

1. Carbonyl Collection

Carbonyl compounds are collected by drawing air through silica gel Sep-Pak® cartridges impregnated

with acidified 2,4-dinitrophenylhydrazine (DNPH), available commercially from Waters, Inc. The

resulting products (hydrazones) in the cartridges are measured in the laboratory using high

performance liquid chromatography (HPLC). The dilution sampler system used for carbonyl

collection includes check valves, solenoid valves and a pump to enable flow control and

measurement for each cartridge. Used cartridges are immediately removed from the sampler,

plugged, put into vials, and stored in a refrigerator until they are returned to the laboratory (in a

cooler) for final analysis.

2. Carbonyl Analysis

After sampling, the DNPH Sep-Pak® cartridges are eluted with 2-mL acetonitrile to remove the

hydrazone products produced during sampling of carbonyl compounds. An aliquot of the eluent is

transferred into a 2-mL septum vial and injected with an autosampler into a high performance liquid

4

chromatograph (HPLC; Waters 2690 Alliance System with 996 Photodiode Array Detector) for

separation and quantification of the hydrazones.2 The chromatographic conditions are as follows:

Polaris C18-A 3µm 100 x 2.0 mm HPLC column, flow rate of 0.2 ml/min, injection volume of 2.0

µl, solvent A: water, solvent B: acetonitrile. The HPLC program is: 60% A, 40% B for 0.02 min.,

50% A and 50% B over 15 min., 30% A and 70% B over 6 min., and 100% B over 1 min., final hold

at 100% B for 1 min. Total run time is 30 min. C1 through C7 carbonyl compounds are analyzed,

including the following: formaldehyde, acetaldehyde, acetone, acrolein, propionaldehyde,

crotonaldehyde, methyl ethyl ketone, methacrolein, butyraldehyde, benzaldehyde, glyoxal,

valeraldehyde, m-tolualdehyde, and hexanaldehyde. The original carbonyl concentrations in the

syngas (in units of ppbv) are computed from the amounts measured after blank correction, and after

accounting for the volume of syngas sampled. MDLs are determined according to the method

described above for VOC, and are generally in the range of 0.1-0.2 ppbv.

C. Tenax C8-C20 VOC Samples

1. Tenax Collection

Tenax sampling and analysis is employed for compounds that are too heavy to be quantitatively

retrieved from canisters. [These higher MW VOCs are sometimes called semi-volatile organic

compounds (SVOCs).] Prior to use, the Tenax-TA solid adsorbent is cleaned by a Dionex

Accelerated Solvent Extractor (ASE) method using hexane/acetone mixture (4/1 v/v), and dried in a

vacuum oven at ~80 ºC. The dry Tenax is packed into Pyrex glass tubes (4 mm i.d. x 15 cm long;

each tube containing 0.2 g of Tenax) and is thermally conditioned for four hours by heating in an

oven at 300 ºC under a nitrogen purge (25 mL/min N2 flow). Approximately 10% of the pre-cleaned

Tenax cartridges are tested by GC/MS for quality assurance prior to sampling. After cleaning, the

Tenax cartridges are capped tightly using clean Swagelok caps (brass) with graphite/vespel ferrules,

placed in metal containers with activated charcoal on the bottom, and kept in a clean environment at

room temperature.

As described above for the DNPH cartridges, flow control and measurement is done for each

individual Tenax cartridge during use. After use, the exposed cartridges are removed, immediately

plugged with Swagelok caps, and stored in the same metal containers with activated charcoal on the

bottom. The exposed cartridges are stored under refrigeration until they are returned to the laboratory

in a cooler containing blue ice.

5

2. Tenax Analysis

The Tenax samples are analyzed by a thermal desorption-cryogenic pre-concentration method,

followed by high-resolution gas chromatographic separation and mass spectrometric detection

(GC/MS) of individual compounds.3 A Gerstel ThermoDesorption System (TDS) unit, equipped with

a 20 position autosampler is used for these analyses. This TDS unit is coupled to a Varian Saturn

2000 GC/MS system, equipped with sample desorption and cryogenic pre-concentration capabilities.

A DB-1 capillary column (60 m x 0.32 mm i.d., 0.25 µm film thickness; J&W Scientific, Inc.) is

used to achieve separation of the target species. The GC initial temperature of 30 °C is held for 3-

min., then increased to 250 °C at 5 °C/min., and held for 3-min. for a total run time of 50 min.

For calibration purposes, Tenax cartridges are spiked with a methanol solution of standard

hydrocarbons, prepared from high-purity commercially available C8-C20 aliphatic, oxygenated, and

aromatic hydrocarbons. The solvent is then removed with a stream of He (2 min, 100 mL/min at

room temperature) and the Tenax cartridges are thermally desorbed into the GC system. Three

concentrations of each standard compound are employed and two replicate sample injections per

calibration level are made. Area response factors per nanogram of compound per Tenax cartridge are

calculated by the instrument software for each concentration. All response factors are recorded in the

software program and the mean or median value is taken. The original concentrations of SVOCs in

the syngas (expressed in units of µg/m3) are computed after accounting for the volume of syngas

sampled. MDLs are determined as described above for VOC, and are generally in the range of 0.01-

0.02 µg/cartridge.

D. Filter Packs

1. Filter Sample Collection

No single filter medium is appropriate for all desired analyses, so it is necessary to sample on

multiple substrates for chemical speciation. Filter packs containing 47-mm diameter Teflon-

membrane, quartz fiber, and cellulose filters are used for syngas sampling and analysis. All filter

batches are conditioned and acceptance tested prior to use in sampling. Two percent of filters from

each batch are subjected to identical blank analyses, to ensure that they are sufficiently clean before

use in actual sampling. The following three types of filters are used:

6

1. Teflon-membrane filters are used for measurement of mass and elemental concentrations.

These filters are obtained from Pall Corporation (Part No. R2PJ047) or Whatman Inc.

(Part No. 7592-104). They have a 2 µm pore size, and are used with polymethylpropylene

(PMP) support rings.

2. Quartz fiber filters are used for determination of carbon fractions and ions in the

particulate phase. These filters are obtained from Pall Corporation (Part No. 7202) or

Whatman Inc. (Part No. 1851-047). They have an approximate thickness of 432 µm, fiber

diameter of 0.6 µm, and packing density of 0.038 g/cm3.

3. Cellulose fiber filters are placed behind the more efficient particle-collecting filters

(Teflon-membrane and quartz fiber). They are impregnated with gas-absorbing

compounds, and are used to capture ammonia (with citric acid impregnation), acidic

gases (with K2CO3 impregnation), and H2S (with AgNO3 impregnation). These filters are

obtained from Whatman Inc. (31ET and 41), and have a thickness of 0.50 mm.

2. PM Mass by Gravimetric Analysis

Unexposed and exposed Teflon-membrane filters are equilibrated at a temperature of 21.5 ± 1.5 °C

and a relative humidity of 35 ± 5% for a minimum of 24 hours prior to weighing. Weighing is

performed on a Metter Toledo MT5 electro-microbalance with ±0.001 mg sensitivity. The charge on

each filter is neutralized by exposure to a 210Po ionizing source for 30 seconds or more prior to the

filter being placed on the balance pan. The balance is calibrated with a series of three Class 1 weights

(50, 100, and 200 mg) and the tare is set prior to weighing each batch of filters. After every 10 filters

are weighed, the calibration and tare are re-checked. If the results of these performance tests deviate

from specifications by more than ±5 g, the balance is re-calibrated.

Replicate weights are determined on 100% of the filters before sampling (initial weights or pre-

weights), and on 30% of the filters after sampling (final weights or post-weights) by an independent

technician. Replicate pre-sampling (initial) weights must be within ± 0.010 mg of the original

weights. Replicate post-sampling (final) weights on lightly-loaded samples (i.e., less than 1 mg) must

be within ± 0.015 mg. Post-sampling weights on heavily loaded (i.e., greater than 1 mg) samples

must be within 2% of the net weight. Pre- and post-weights, check weights, and re-weights (if

required) are recorded on data sheets as well as being directly entered into a database via an internet

connection.

7

3. Elements by X-Ray Fluorescence

Individual elements are analyzed on Teflon-membrane filters using a PANalytical Epsilon 5, energy

dispersive x-ray fluorescence (ED-XRF) analyzer.4 The emissions of x-ray photons from the sample

are integrated over time and yield quantitative measurements for 51 elements ranging from aluminum

(Al) through uranium (U), and semi-quantitative measurements of sodium (Na) and magnesium

(Mg). A spectrum of x-ray counts versus photon energy is acquired and displayed during analysis,

with individual peak energies corresponding to each element, and peak areas corresponding to

elemental concentrations. The advantages of XRF analysis include high sensitivity for a large

number of elements, the ability to analyze small sample quantities, and the non-destructive nature of

the analysis.

The source of x-rays in the PANalytical Epsilon 5 analyzer is a side-window, liquid-cooled, 100

KeV, 24 milliamp gadolinium anode x-ray tube. X-rays are focused on one of 11 secondary targets

(Al, Ca, Ti, Fe, Ge, Zr, Mo, Ag, Cs, Ba, Ce) which in turn emit polarized x-rays to excite a sample.

X-rays from the secondary target or the tube are absorbed by the sample, exciting electrons to higher

level orbitals. As the electrons return to their ground state, photons are emitted which are

characteristic of the quantum level jumps made by the electron; the energy of the emitted photons

are, therefore, characteristic of the elements contained in the sample. The fluoresced photons are

detected in a solid state germanium x-ray detector. Each photon that enters the detector generates an

electrical charge whose magnitude is proportional to the photon's energy. The number of these

photons is proportional to the number of atoms present. Ten separate XRF analyses are conducted on

each sample to optimize detection limits for the specified elements. The ED-XRF system is

calibrated using Micromatter (Arlington, WA) thin film standards. Multielement standards are

analyzed daily to monitor for any instrument drift. Method detection limit (MDL) is defined as 3

times the standard deviation of multiple measurements of a laboratory blank filter.

4. Carbon Analysis by Thermal/Optical Reflectance/Transmittance (TOR/TOT)

The thermal/optical reflectance and transmittance (TOR/TOT) method measures organic carbon

(OC) and elemental carbon (EC) on filter samples.5 This method is based on the principle that

different types of carbon-containing particles are converted to gases under different temperature and

oxidation conditions. The different carbon fractions from TOR/TOT are useful for comparison with

8

other methods, which are specific to a single definition for organic and elemental carbon. The seven

carbon fractions measured by the DRI Model 2001 Thermal/Optical Carbon Analyzer are the

following:

1) OC1: Carbon evolved in a helium atmosphere at temperatures between ambient and 140 °C

2) OC2: Carbon evolved in a helium atmosphere at temperatures between 140 and 280 °C

3) OC3: Carbon evolved in a helium atmosphere at temperatures between 280 and 480 °C

4) OC4: Carbon evolved in a helium atmosphere between 480 and 580 °C

5) EC1: Carbon evolved in an oxidizing atmosphere at 580 °C

6) EC2: Carbon evolved in an oxidizing atmosphere between 580 and 740 °C

7) EC3: Carbon evolved in an oxidizing atmosphere between 740 and 840 °C

The thermal/optical reflectance carbon analyzer contains a thermal system and an optical system. The

thermal system consists of a quartz tube placed inside a coiled heater. Current through the heater is

controlled to attain and maintain pre-set temperatures for given time periods. A portion of a quartz

filter is placed in the heating zone and heated to different temperatures under non-oxidizing and

oxidizing atmospheres. The optical system consists of a He-Ne laser, a fiber optic transmitter and

receiver, and a photocell. The filter deposit faces a quartz light tube so that the intensity of the

reflected laser beam can be monitored throughout the analysis.

As the temperature increases from ambient (~25 °C) to 580 °C, organic compounds are volatilized

from the filter in a non-oxidizing (He) atmosphere while elemental carbon is not oxidized. When

oxygen is added to the helium at temperatures greater than 580 °C, the elemental carbon burns and

enters the sample stream. The evolved gases pass through an oxidizing bed of heated manganese

dioxide where they are oxidized to carbon dioxide, then across a heated nickel catalyst, which

reduces the carbon dioxide (by reaction with hydrogen) to produce methane (CH4). The methane is

then quantified with a flame ionization detector (FID).

The laser light for reflectance and transmittance is continuously monitored throughout the analysis

cycle. The negative change in laser signal is proportional to the degree of pyrolytic conversion from

OC to EC that takes place during OC analysis. After O2 is introduced, the laser signal increases

rapidly as the light-absorbing carbon is burned off the filter. The carbon measured after the

reflectance attains the value it had at the beginning of the analysis cycle is classified as EC. This

9

adjustment for pyrolysis (i.e., optical pyrolysis [OP]) in the analysis is significant, and cannot be

ignored. OC and EC are calculated as OC = OC1 + OC2 + OC3 + OC4 + OP and EC = EC1 + EC2 +

EC3 - OP.

The carbon analyzer system is calibrated by analyzing samples of known amounts of CH4, CO2,

sucrose, and potassium hydrogen phthalate (KHP). The FID response is ratioed to a reference level of

CH4 injected at the end of each sample analysis. Performance tests of the instrument calibration are

conducted at the beginning and end of each day's operation. Intervening samples are re-analyzed

when calibration changes of more than ±10% are found. Known amounts of American Chemical

Society (ACS) certified reagent grade crystal sucrose and KHP are committed to carbon analysis as a

verification of the OC fractions. Fifteen different standards are used for each calibration.

5. Filter Extraction

Water-soluble cations and anions are obtained by extracting a quartz-fiber filter in 15 mL of

deionized-distilled water (DDW). The filter is placed in a 16 x 150 mm polystyrene extraction vial

with a screw cap (e.g., Falcon #2045). Each vial is labeled with a bar code sticker containing the

filter ID code. The extraction tubes are placed in tube racks, and the extraction solutions are added.

The extraction vials are capped and sonicated for 60 minutes, shaken for 60 minutes, then aged

overnight to assure complete extraction of the deposited material into the solvent. The ultrasonic bath

water is monitored to prevent temperature increases from the dissipation of ultrasonic energy in the

water. After extraction, these solutions are stored under refrigeration prior to analysis.

6. Water-Soluble Particulate Anion Analyses

Water-soluble particulate anions (Cl-, NO2-, NO3

-, PO43-, and SO4

2-) are collected on a quartz-fiber

filter, and extracted into water using 15-mL of DDW, as described above. The anions are then

analyzed using a Dionex ICS-3000 ion chromatograph (IC; Sunnyvale, CA).6 An ion-exchange

column is used to separate the ions for individual quantification by a conductivity detector. Prior to

detection, the column effluent enters a suppressor column where the chemical composition of the

component is altered, resulting in a matrix of low conductivity. The ions are identified by their

elution/retention times and are quantified by the conductivity peak area, as compared with calibration

curves derived from solution standards.

10

250-µL of filter extract is injected into the Dionex IC. The system used for anion analysis contains a

guard column (AG14 column, Cat. No. 046134) and an anion separator column (AS14 column, Cat.

No. 046129) with a strong basic anion exchange resin, and an anion micro membrane suppressor

column (250 × 4 mm ID) with a strong acid ion exchange resin. The anion eluent consists of 0.0035

M sodium carbonate (Na2CO3) and 0.001 M sodium bicarbonate (NaHCO3) prepared in DDW. The

DDW is verified to meet ATSM Type 1 specifications prior to preparation of the eluent. For

quantitative determinations, the IC is operated at a flow rate of 2.0 mL/min.

NIST traceable primary standard solutions are purchased from Environmental Research Associates

(ERA; Arvada, CO) or Dionex (Sunnyvale, CA). Calibration standards are prepared monthly by

diluting primary standard solutions to a range of concentrations expected in filter extracts. These

standards are stored in a refrigerator. The calibration concentrations prepared are at 0.05, 0.1, 0.2,

0.5, 1.0, 2.0 and 3.0 g/mL for each of the analysis species. Calibrations are performed daily.

A DDW blank is analyzed after every 20 samples and a calibration standard is analyzed after every

10 samples. These quality control checks verify the baseline and calibration, respectively. ERA

standards (ERA Wastewater Nutrient and ERA Mineral WW) are used daily as an independent

quality assurance (QA) check. If the values obtained for these standards do not coincide within a pre-

specified uncertainty level (typically three standard deviations of the baseline level or ±5%), the

samples analyzed between that standard and the previous calibration standards are re-analyzed.

After analysis, the printout for each sample in the batch is reviewed for the following: 1) proper

operational settings, 2) correct peak shapes and integration windows, 3) peak overlaps, 4) correct

background subtraction, and 5) quality control sample comparisons. When values for replicates differ

by more than ±10%, or values for standards differ by more than ±5%, samples before and after these

quality control checks are designated for re-analysis in a subsequent batch. Individual samples with

unusual peak shapes, background subtractions, or deviations from standard operating parameters are

also designated for re-analysis. Dionex Chromeleon software operating on a Dell Optiplex

microcomputer controls the sample throughput, calculates concentrations, and records data in the

laboratory data base. MDL is defined as 3 times the standard deviation of multiple measurements of a

laboratory blank filter.

11

7. Water-Soluble Particulate Cation Analyses

Water-soluble particulate cations (NH4+, K+, Na+, Mg2+, and Ca2+) are collected on the same quartz-

fiber filters used for collection of particulate anions (see above), and are isolated in the same water

extract solution. Different analytical methods are then used to measure NH4+ (automated colorimetry)

and the rest of the cations (atomic absorption). These methods are described below:

a) NH4+ measurement

Ammonium concentrations are measured using the indol-phenol method with an automated

colorimetric analyzer system (Astoria Analyzer AC; Astoria Pacific, Clackamas, OR, USA).7 The

heart of the AC system is a peristaltic pump, which introduces air bubbles into the sample stream.

Each sample is mixed with reagents and subjected to appropriate reaction periods before submission

to a colorimeter. Beer’s Law relates the liquid’s light absorbency to the concentration of the ion in

the sample. A photomultiplier tube measures this absorbency through an interference filter that is

specific to the species being measured.

Water-soluble NH4+ in the extract is reacted with phenol and alkaline sodium hypochlorite to produce

indol-phenol, a blue dye. The reaction is catalyzed by the addition of sodium nitro-prusside. The

absorbency of the solution is measured at 630 nm. Two mL of extract in a sample vial is placed in an

autosampler that is controlled by a computer. Eight standard concentrations (i.e., 0.05, 0.1, 0.2, 0.5,

1.0, 2.0, 5.0, and 10.0 µg/mL) are prepared from ACS reagent-grade (NH4)2SO4. Each set of samples

consists of two distilled water blanks to establish a baseline, seven calibration standards and a blank,

then sets of 10 samples followed by analysis of one of the standards and a replicate from a previous

batch. The system determines carry-over by analysis of a low concentration standard following a

high concentration standard. The percent carry-over is then automatically calculated and can be

applied to the samples analyzed during the run. Astoria’s FASPac software operating on a Dell

Optiplex microcomputer controls the sample throughput, calculates concentrations, and records data

in the laboratory data base.

When present in high concentrations (>20% of the NH4+ level) formaldehyde has been found to

interfere with NH4+ measurements. Hydrogen sulfide (H2S) also interferes when it is present in

concentrations that exceed 1 mg/mL. Also, NO3- and SO4

= are potential interferents when present at

levels that exceed 100 times the NH4+ concentration, although these levels are rarely observed. The

12

precipitation of hydroxides of heavy metals such as calcium and magnesium is also a potential

problem, but this is prevented by addition of sodium citrate/sodium potassium tartrate buffer solution

to the sample stream.

b) K+, Na+, Mg2+, and Ca2+ measurement

The remaining water-soluble cations are measured by atomic absorption (AA) spectrometry, using a

Varian SpectrAA 880 Double Beam Atomic Absorption Spectrometer (Varian, Palo Alto, CA,

USA).8 Atomic absorption methods rely on the principle that free, uncombined atoms will absorb

light at specific wavelengths corresponding to the energy requirements of the specific atom. Atoms in

the ground state absorb light and are exited into a higher energy state. Each transition between energy

states is characterized by a different energy, and therefore a different wavelength of light. The atomic

spectrum of each element comprises a number of discrete lines arising from both the ground and

exited states. The lines which originate in the ground state atoms, called resonance lines, are usually

of interest in atomic absorption spectrometry, as ground state atoms are most prevalent in practical

atomization methods.

The amount of light absorbed is proportional to the concentration of the atoms over a given

absorption path length and wavelength. Standards of known concentration are prepared, matched to

the sample matrix, and measured. The unknown sample absorbencies are compared to the

absorbencies of the standards. Since the measured absorbance is directly proportional to the

concentration of analyte, this gives a simple and accurate method of determining the unknown

concentration.

The Varian SpectrAA instrument uses a hollow-cathode lamp that emits wavelengths appropriate for

each analysis. The monochrometer is set at 766.5 nm for K+, 589 nm for Na+, 285.2 nm for Mg2+, and

422.7 nm for Ca2+. Approximately 1-2 mL of the aqueous filter extract solutions are aspirated (at 0.5

mL/min) into an air/acetylene flame within the AA spectrometer. The output of the photomultiplier is

recorded at a rate of two readings per second. These readings are averaged over 2.5-second intervals

and compared to the results from standard analyses over the same averaging times.

For routine analysis, up to 120 sample vials containing 1 mL of solution per cation analyzed are

loaded into the autosampler. Sets of 13 vials follow, with each set containing 10 filter extract

13

samples, one standard, one blank, and one replicate from a previous batch. Samples are re-analyzed

when quality control standards differ from specifications by more than ±5% or when replicates (at

levels exceeding 10 times detection limits) differ by more than ±10%.

NIST traceable ICP grade standards at concentration levels of 1,000 µg/mL are used for stock

standard solutions. Stock solutions are diluted monthly for use as calibration standards. Ionization

interference is eliminated by addition of cesium chloride (CsCl) to both samples and standard

solutions. Varian SpectrAA Pro software operating on a Dell Optiplex microcomputer controls the

sample throughput, calculates concentrations, and records data in the laboratory data base. MDL is

defined as 3 times the standard deviation of multiple measurements of a laboratory blank filter.

8. Ammonia

Ammonia is collected on a citric acid impregnated cellulosic fiber filter, where it is chemically

reacted to produce ammonium citrate. The filter is then extracted with DDW, and the extract is

analyzed for ammonium ion using the indol-phenol method with an automated colorimetric analyzer

system, as described above.

9. Acid Gases

Acid gases (HCl, HNO3, and H2SO4) are collected on a cellulose fiber filter that is impregnated with

potassium carbonate (K2CO3). During collection, these acid gases react with the potassium carbonate

to produce the corresponding potassium salts (KCl, KNO3, and K2SO4). This filter is then extracted

with DDW, and the extract is analyzed for anions using the same ion chromatographic (IC) method

described above.6 In addition, sulfur dioxide (SO2) present in the gas phase reacts on the filter to

produce sulfite, which is further oxidized by hydrogen peroxide (H2O2) to sulfate before IC analysis.

Thus, the total sulfate measurement by IC represents the sum of H2SO4 and SO2 present in the

original gas sample.

10. Hydrogen Sulfide (H2S)

Hydrogen sulfide (H2S) is collected on a cellulosic fiber filter that is impregnated with silver nitrate

(AgNO3). During collection, the H2S is reacted to produce silver sulfide (Ag2S). This filter is not

extracted, but is analyzed directly by XRF, to quantify the sulfur on the filter, from which the

original H2S concentration in the sampled gas is computed.4

14

Part 2: Results from Analysis of Syngas Samples Collected from Synterra IBR

Configuration of Filter Packs used for Syngas CollectionFilter Pack No. 1 Filter Pack No. 2 Filter Pack No. 3

Filters Species Sampled Filters Species

Sampled Filters Species Sampled

Teflon

Citric Acid

Total PMPM Elements

NH3

Quartz 1

K2CO3

OC/EC,Carbon

Fractions

HCl, HNO3, H2SO4

Quartz 2

AgNO3

NH4+, K+,

Na+, Cl-, NO3

-, SO4=

H2S

Summary Results of Syngas Trace Contaminants Collected on Cartridges and in Canisters(concentrations expressed as ppbv or µg/m3 in undiluted syngas)

Analytical Method(Sampling Method)

Species Measured

#1 Blank

#3 Rice Hulls

#5 Wood Chips*

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

Scrubber*

GC/MS/FID(Canister Samples)ppbv

Acetylene 0.00 179816 856278 853185 442435 827000 1566368Ethene 0.00 618851 1964919 2434249 1458876 2877900 5802287Ethane 0.00 53304 111525 119662 71527 157919 359199Propene 0.00 1365 8460 7678 518 9179 222751,3-butadiene 0.00 367.1 2629.8 1675.0 756.1 1766.5 5616.21,2-butadiene 0.00 265.8 1388.9 1270.8 554.7 1238.0 2671.4Cyclopentene 0.00 0.00 0.00 19.69 0.00 14.87 0.00Benzene 132.8 802395 344970 948279 871753 1630000 5845000Toluene 0.00 43.04 102.82 194.41 214.25 663.22 3879.5Furan 0.00 9.34 54.45 9.82 20.74 7.25 120.94

Sum of others 0.00 0.00 0.00 0.00 0.03 0.00 0.00

GC/MS(Tenax Cartridges)µg/m3

Styrene 0.95 20.73 50.04 4.06 27.98 51.94 4194.10Ethylbenzene 1.05 2.18 6.41 0.43 1.99 4.26 238.31Indene 0.07 9.59 48.78 2.23 2.56 12.23 2254.24

Naphthalene 1.87 10.34 43.84 2.14 11.86 11.44 1804.68

HPLC(DNPH Cartridges)ppbv

Formaldehyde 0.37 0.94 1.75 0.72 0.44 0.78 2.11Acetaldehyde 0.63 82.93 102.93 479.18 511.18 428.77 365.00Acetone 4.58 25.10 4.44 5.18 6.17 3.55 3.26Acrolein 0.00 0.98 1.74 0.62 2.03 1.83 0.00Propionaldehyde 0.22 0.54 0.00 1.63 1.19 0.00 0.002-Butanone (MEK) 0.15 6.17 3.53 6.13 6.23 17.41 6.19Methacrolein 0.00 0.00 3.40 2.32 1.16 72.71 14.96Benzaldehyde 0.00 0.49 7.25 2.91 2.47 8.10 9.32Sum of Others 0.00 0.53 1.05 0.15 0.00 1.09 2.15

*Syngas dilution factors: 4.6 for Sample #5; 5.0 for Sample #10

15

Detailed Analysis of Syngas Samples

Analytical Method(Sampling Method) Species Measured

DF*

units

#1 Blank

#3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

Gravimetry(Teflon Filters) Mass Concentration µg/m3 7.03 12.74 0.00 11.88 108.84

Thermal Optical(Quartz Filters)

Total Organic Carbon (OC) µg/m3 158.48 18.43 295.43 21.69 331.66

Total Elemental Carbon (EC) µg/m3 22.39 0.12 25.58 1.57 60.08

Total Carbon µg/m3 180.87 18.55 321.01 23.26 391.73

OC/EC Ratio 7.08 155.04 11.55 13.80 5.52

Ion Chromatography(Quartz Filter)

Chloride µg/m3 0.00 0.00 0.00 0.00 0.55

Nitrate µg/m3 1.87 0.87 5.32 0.55 4.84

Sulfate µg/m3 1.79 0.40 2.45 0.35 4.43

Ammonium (NH4+) µg/m3 5.59 0.93 16.25 0.90 11.94

Sodium (Na+) µg/m3 0.80 0.54 0.00 0.00 0.00

Potassium (K+) µg/m3 4.82 0.67 1.38 0.12 5.33Automated Colorimetry(Citric Acid CelluloseImpregnated Filters)

NH3 µg/m3 33.43 35.35 200.60 24.17 120.82

Ion Chromatography(K2CO3 ImpregnatedCellulose Filters)

HCl µg/m3 N/A N/A N/A N/A N/A N/A N/A N/A N/A

HNO3 µg/m3 15.27 2.62 31.97 3.08 91.02

SO2 µg/m3

H2SO4 µg/m3 0.00 5.74 0.00 0.00 1798.15

X-Ray Fluorescence(AgNO3 Impregnated Filter)

H2S µg/m3 0.00 0.53 0.00 767.1

* DF = Dilution Factor

16

Analytical Method(Sampling Method) Species Measured

DF*

units

#1 Blank #3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

GC/MS/FID(Canister Samples)

Acetylene ppbv 0.00 179816.52 5235.24 8562.52 856278.71 853185.85 442435.16 827000.25 1566368.75Ethene ppbv 0.00 618851.00 43255.88 74225.23 1964919.90 2434249.75 1458876.25 2877900.25 5802287.50Ethane ppbv 0.00 53304.59 4524.99 9152.21 111525.18 119662.25 71527.15 157919.31 359199.68propene ppbv 0.00 1365.35 178.55 235.94 8460.26 7678.27 518.39 9179.04 22275.23propane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,3-butadiene ppbv 0.00 367.12 0.00 326.92 2629.82 1674.96 756.15 1766.47 5616.161-butene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00c-2-butene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00isobutene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00t-2-butene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-butane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00iso-butane ppbv 0.00 977.39 0.00 0.00 0.00 0.00 0.00 0.00 0.00iso-pentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-pentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,2-butadiene ppbv 0.00 265.80 0.00 0.00 1388.97 1270.80 554.76 1238.03 2671.442,2,4-trimethylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-methyl-1-butene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001-pentene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00isoprene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00t-2-pentene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-methyl-2-butene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00c-2-pentene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002,2-dimethylbutane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00cyclopentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00cyclopentene ppbv 0.00 0.00 0.00 0.00 0.00 19.69 0.00 14.87 0.002,3-dimethylbutane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 26.73 0.00 0.002-methylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-methyl-1-pentene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.003-methylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00t-2-hexene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-hexane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00c-2-hexene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,3-hexadiene (trans) ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

GC/MS/FID methylcyclopentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

17

Analytical Method(Sampling Method) Species Measured

DF*

units

#1 Blank #3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

(Canister Samples)

2,4-dimethylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00benzene ppbv 132.83 802395.94 428961.25 422706.13 344970.53 948279.75 871753.88 1630000.00 5845000.00cyclohexane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00cyclohexene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-methylhexane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002,3-dimethylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,3-dimethylcyclopentane (cis) ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.003-methylhexane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-heptane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002,3-dimethyl-2-pentene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00methylcyclohexane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002,3,4-trimethylpentane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-methylheptane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.004-methylheptane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.003-methylheptane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-octane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00Toluene ppbv 0.00 43.04 137.60 150.58 102.82 194.41 214.25 663.22 3879.46m&p-xylene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00styrene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00o-xylene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-nonane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00isopropylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.003-ethyltoluene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-propylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.004-ethyltoluene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00alpha-pinene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,3,5-trimethylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00o-ethyltoluene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,2,4-trimethylbenzene+t-butylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-decane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00indan ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,2,3-trimethylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

GC/MS/FID(Canister Samples)

1,3-diethylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.001,4-diethylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

18

Analytical Method(Sampling Method) Species Measured

DF*

units

#1 Blank #3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

n-butylbenzene ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00n-undecane ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00furan ppbv 0.00 9.34 12.98 5.22 54.45 9.82 20.74 7.25 120.942-methyl-furan ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-furfural ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.003-furfural ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002,5-dimethyl-furan ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-ethyl-furan ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00

GC/MS(Tenax Cartridges)

styrene µg/m3 0.95 20.73 43.34 9.85 50.04 4.06 27.98 51.94 4194.10ethylbenzene µg/m3 1.05 2.18 4.79 0.82 6.41 0.43 1.99 4.26 238.31Indene µg/m3 0.07 9.59 6.85 12.13 48.78 2.23 2.56 12.23 2254.24naphthalene µg/m3 1.87 10.34 2.88 6.26 43.84 2.14 11.86 11.44 1804.68

HPLC(DNPH Cartridges)

Formaldehyde ppbv 0.37 0.94 0.39 0.72 1.75 0.72 0.44 0.78 2.11Acetaldehyde ppbv 0.63 82.93 38.61 27.53 102.93 479.18 511.18 428.77 365.00Acetone ppbv 4.58 25.10 5.68 5.42 4.44 5.18 6.17 3.55 3.26Acrolein ppbv 0.00 0.98 0.00 0.00 1.74 0.62 2.03 1.83 0.00Propionaldehyde ppbv 0.22 0.54 0.47 0.20 0.00 1.63 1.19 0.00 0.00Crotonaldehyde ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.002-Butanone (MEK) ppbv 0.15 6.17 2.85 1.82 3.53 6.13 6.23 17.41 6.19Methacrolein ppbv 0.00 0.00 0.00 0.00 3.40 2.32 1.16 72.71 14.96 n-Butyraldehyde ppbv 0.00 0.11 0.00 0.00 0.11 0.15 0.00 0.00 0.00Benzaldehyde ppbv 0.00 0.49 0.00 0.17 7.25 2.91 2.47 8.10 9.32Valeraldehyde ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00Glyoxal ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00m-Tolualdehyde ppbv 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.00 0.15Hexaldehyde ppbv 0.00 0.42 0.44 0.00 0.93 0.00 0.00 1.09 2.01

Analytical Method(Sampling Method) Species Measured

DF*

units#1 Blank

#3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

X-Ray Fluorescence Sodium µg/m3 0.00 1.45 59.18 1.95 22.91

19

Analytical Method(Sampling Method) Species Measured

DF*

units#1 Blank

#3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

(Teflon Filters)

Magnesium (Mg) µg/m3 0.00 0.09 13.26 0.33 0.00

Aluminum (Al) µg/m3 3.72 0.87 10.12 0.18 6.73

Silicon (Si) µg/m3 0.02 0.12 2.82 0.02 0.16

Phosphorus (P) µg/m3 0.00 0.00 0.00 0.00 0.00

Sulfur (S) µg/m3 0.00 0.00 0.00 0.00 1.14

Chlorine (Cl) µg/m3 0.04 0.37 0.49 0.07 1.05

Potassium µg/m3 0.03 0.44 0.99 0.05 0.03

Calcium (Ca) µg/m3 0.00 0.04 1.22 0.06 0.00

Scandium (Sc) µg/m3 0.00 0.42 8.86 0.25 0.40

Titanium (Ti) µg/m3 0.16 0.00 0.11 0.06 0.00

Vanadium (V) µg/m3 0.06 0.00 0.00 0.00 0.00

Chromium (Cr) µg/m3 0.00 0.01 0.00 0.01 0.25

Manganese (Mn) µg/m3 0.00 0.03 0.00 0.00 0.15

Iron (Fe) µg/m3 0.00 0.01 0.00 0.08 0.08

Cobalt (Co) µg/m3 0.00 0.00 0.00 0.00 0.05

Nickel (Ni) µg/m3 0.00 0.01 0.00 0.00 0.00

Copper (Cu) µg/m3 0.00 0.00 0.05 0.01 0.12

Zinc (Zn) µg/m3 0.00 0.01 0.23 0.07 6.20

Gallium (Ga) µg/m3 0.02 0.05 0.00 0.00 0.00

Arsenic (As) µg/m3 0.00 0.00 0.00 0.00 0.00

Selenium (Se) µg/m3 0.00 0.00 0.00 0.00 0.00

Bromine (Br) µg/m3 0.16 0.00 0.22 0.03 0.00

Rubidium (Rb) µg/m3 0.00 0.00 0.00 0.00 0.61

Strontium (Sr) µg/m3 0.00 0.02 0.08 0.02 0.60

Yttrium (Y) µg/m3 0.13 0.00 0.00 0.00 0.35

Zirconium (Zr) µg/m3 0.00 0.00 0.00 0.00 0.00

Niobium (Nb) µg/m3 0.00 0.00 0.00 0.00 0.00

Molybdenum (Mo) µg/m3 0.00 0.00 0.00 0.00 0.00

Palladium (Pd) µg/m3 0.00 0.00 0.00 0.03 0.00

Silver (Ag) µg/m3 0.02 0.00 0.44 0.00 0.00

Cadmium (Cd) µg/m3 0.00 0.00 0.35 0.03 0.16Indium (In) µg/m3 0.00 0.00 0.00 0.00 0.00

X-Ray Fluorescence (Teflon Filters)

Tin (Sn) µg/m3 0.00 0.00 0.28 0.00 0.00

Antimony (Sb) µg/m3 0.00 0.00 0.45 0.00 0.00

20

Analytical Method(Sampling Method) Species Measured

DF*

units#1 Blank

#3 Rice Hulls

#3A Rice Hulls

#3B Rice Hulls

#5 Wood Chips

#6 Wood Chips

#7 Wood Chips

#8 Wood Chips

#10 Wood Chips before

ScrubberN/A N/A N/A N/A 4.6 N/A N/A N/A 5.0

Cesium (Cs) µg/m3 0.00 0.00 0.00 0.00 0.00

Barium (Ba) µg/m3 0.00 0.40 0.00 0.00 0.00

Lanthanum (La) µg/m3 2.38 0.18 0.00 0.36 0.00

Cerium (Ce) µg/m3 0.00 0.03 0.00 0.00 0.00

Samarium (Sm) µg/m3 0.00 0.00 3.10 0.50 12.66

Europium (Eu) µg/m3 2.73 0.00 5.73 0.00 2.40

Terbium (Tb) µg/m3 0.00 0.00 0.00 0.42 0.00

Hafnium (Hf) µg/m3 0.65 0.00 2.93 0.00 1.54

Tantalum (Ta) µg/m3 0.00 0.00 0.79 0.08 0.16

Tungsten (W) µg/m3 0.00 0.00 0.00 0.00 2.04

Iridium (Ir) µg/m3 0.00 0.00 0.00 0.02 0.00

Gold (Au) µg/m3 0.00 0.07 0.00 0.02 0.00

Mercury (Hg) µg/m3 0.00 0.00 0.00 0.00 0.00

Thallium (Tl) µg/m3 0.00 0.00 0.00 0.00 0.31

Lead (Pb) µg/m3 0.02 0.00 0.87 0.01 0.08

Uranium (U) µg/m3 0.29 0.00 0.59 0.00 0.36

21

Reference List

1. U.S.EPA Office of R&D, National Risk Management Research Laboratory, and Center for Environmental Research Information; Method TO-15: Determination of Volatile Organic Compounds (VOCs) in Air Collected in Specially-Prepared Canisters and Analyzed by Gas Chromatography Mass Spectrometry (GC/MS). Compendium of Methods for the Determination of Toxic Organic Compounds in Ambient Air. U.S. EPA Office of Research and Development, Cincinnati, OH. 1999.

2. Zielinska, B., J. Sagebiel, G. Harshfield, and R. Pasek; Volatile Organic Compound Measurements in the California/Mexico Border Region During SCOS97. Science of the Total Environment, 276, (1-3), 19-31. 2001.

3. Zielinska, B., J. C. Sagebiel, G. Harshfield, A. W. Gertler, and W. R. Pierson; Volatile Organic Compounds Up to C-20 Emitted From Motor Vehicles; Measurement Methods. Atmospheric Environment, 30, (12), 2269-2286. 1996.

4. Watson, J. G., J. C. Chow, and C. A. Frazier; Chapter 2: X-Ray Fluorescence Analysis of Ambient Air Samples. Elemental Analysis of Airborne Particles, Vol. 1. Landsberger, S. and M. Creatchman, editors. Gordon and Breach Science, Amsterdam. 1999.

5. Chow, J. C., J. G. Watson, L. C. Pritchett, W. R. Pierson, C. A. Frazier, and R. G. Purcell; The DRI Thermal Optical Reflectance Carbon Analysis System - Description, Evaluation and Applications in United-States Air-Quality Studies. Atmospheric Environment Part A-General Topics, 27, (8), 1185-1201. 1993.

6. U.S.EPA; Method 300.0, Determination of Inorganic Anions by Ion Chromatography. Environmental Monitoring Systems Laboratory, Office of Research and Development, 1993.

7. U.S.EPA; Method 350.1: Determination of Ammonia Nitrogen by Semi-Automated Colorimetry. Environmental Monitoring Systems Laboratory, Office of Research and Development, 1993.

8. U.S.EPA; EPA Method 3111: Standard Methods for the Examination of Water and Wastewater. 1995.

22

![· @e] fid\ XelXc](https://static.fdocuments.in/doc/165x107/5c04b62e09d3f2183a8c24fe/-e-fid-xelxc-.jpg)