STATE GEOLOGICAL SURVEY - COnnecting REpositories · 2015. 5. 27. · Location...

Transcript of STATE GEOLOGICAL SURVEY - COnnecting REpositories · 2015. 5. 27. · Location...

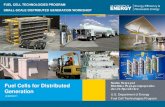

-

f?T ft

STATE OF ILLINOIS

DWIGHT H. GREEN, GovernorDEPARTMENT OF REGISTRATION AND EDUCATION

FRANK G. THOMPSON, Director

DIVISION OF THE

STATE GEOLOGICAL SURVEYM. M. LEIGHTON, CkUf

URBANA

REPORT OF INVESTIGATIONS — NO. 78

CORRELATION OF DOMESTIC STOKER COMBUSTIONWITH LABORATORY TESTS AND TYPES OF FUELS

I. PRELIMINARY STUDIES

BY

L. C. McCABE, S. KONZO, AND O. W. REES

In Cooperation With the University of Illinois

Engineering Experiment Station

PRINTED BY AUTHORITY OF THE STATE OF ILLINOIS

URBANA, ILLINOIS

1942

-

ORGANIZATION

STATE OF ILLINOISHON. DWIGHT H. GREEN, Governor

DEPARTMENT OF REGISTRATION AND EDUCATIONHON. FRANK G. THOMPSON, Director

BOARD OF NATURAL RESOURCES AND CONSERVATIONHON. FRANK G. THOMPSON, ChairmanEDSON S. BASTIN, Ph.D., D.Sc, GeologyROGER ADAMS, Ph.D., D.Sc, ChemistryLOUIS R. HOWSON, C.E., Engineering

WILLIAM TRELEASE, D.Sc, LL.D., BiologyEZRA JACOB KRAUS, Ph.D., D.Sc, ForestryARTHUR CUTTS WILLARD, D.Engr., LL.D.,

President of the University of Illinois

GEOLOGICAL SURVEY DIVISIONM. M. LEIGHTON, Chief

(22289)

14

-

SCIENTIFIC AND TECHNICAL STAFF OF THE

STATE GEOLOGICAL SURVEY DIVISION100 Natural Resources Building, Urbana

M. M. LEIGHTON, Ph.D., Chief

Enid Town-ley, M.S., Assistant to the Chief

Jane Titcomb, M.A., Geological Assistant

GEOLOGICAL RESOURCES GEOCHEMISTRY

Coal

G. H. Cady, Ph D., Senior Geologist and HeadL. C. McCabe. Ph.D., Geologist (on leave)R. J. Helfinstine, M.S., Assoc. Mech. Eng.James M. Schopf, Ph.D., Asst. GeologistJ. Norman Payne, Ph.D., Asst. GeologistCharles C. Boley, M.S., Asst. Mining Eng.Bryan Parks, M.S., Asst. Geologist

Industrial Minerals

J. E. Lamar, B.S., Geologist and HeadH. B. Willman, Ph.D., Assoc. GeologistDouglas F. Stevens, M.E., Research AssociateRobert M. Grogan, Ph.D., Asst. GeologistRobert R. Reynolds, B.S., Research Assistant

Oil and GasA. H. Bell, Ph.D., Geologist and HeadG. V. Cohee, Ph.D., Asst. GeologistFrederick Squires, B.S., Assoc. Petr. Eng.Charles W. Carter, Ph.D., Asst. GeologistWilliam H. Easton, Ph.D., Asst. GeologistPaul G. Luckhardt, M.S., Research AssistantWayne F. Meents, Research Assistant

Areal and Engineering GeologyGeorge E. Ekblavv, Ph.D., Geologist and HeadRichard F. Fisher, M.S., Asst. Geologist

Subsurface Geology

L. E. Workman, M.S., Geologist and HeadTracy Gillette, Ph.D., Asst. GeologistArnold C. Mason, B.S., Asst. GeologistKenneth O. Emery, Ph.D., Asst. GeologistMerlyn B. Buhle, M.S., Asst. GeologistFrank E. Tippie, B.S., Asst. GeologistRuth E. Roth, B.S., Research Assistant

Stratigraphy and Paleontology

J. Marvin Weller, Ph.D., Geologist and HeadChalmer L. Cooper, M.S., Assoc. Geologist

Petrography

Ralph E. Grim, Ph.D., PetrographerRichards A. Rowland, Ph.D., Asst. Petrographer

Physics

R. J. Piersol, Ph.D., PhysicistB. J. Greenwood, B.S., Mech. EngineerDonald O. Holland, M.S., Asst. Physicist (on leave)

Frank H. Reed, Ph.D., Chief ChemistH. W. Jackman, M.S.E., Chem. Eng.Roberta M. Langenstein, B.S., Chemical AssistantMelville A. Rogers, B.S., Research Assistant

Coal

G. R. Yohe, Ph.D., Assoc. ChemistMyron H. Wilt, B.S., Research Assistant

Industrial Minerals

J. S. Machin. Ph.D., Chemist and HeadDelbert L. Hanna, A.M., Research Assistant

Fluorspar

G. C. Finger, Ph.D., Assoc. ChemistEverett W. Maynert, B.S., Research Assistant

X-ray and SpectrographyW. F. Bradley, Ph.D., Assoc. Chemist

Analytical

O. W. Rees, Ph.D., Chemist and HeadL. D. McVicker, B.S., Asst. ChemistP. W. Henline. M.S.. Asst. Chemical EngineerWilliam F. Wagner, M.S., Asst. ChemistK. F. Bursack, B.A., Research AssistantMarion Lund Dickman, B.S., Research Assistant

MINERAL ECONOMICSW. H. Voskuil, Ph.D.,Grace N. Oliver, A.B.

Mineral EconomistAssistant in Mineral Economics

EDUCATIONAL EXTENSIONDon L. Carroll, B.S., Assoc. Geologist

PUBLICATIONS AND RECORDSGeorge E. Ekblaw, Ph.D., Geologic EditorChalmer L. Cooper, M.S., Geologic EditorDorothy E. Rose, B.S., Technical EditorKathryn K. Dedman, M.A., Asst. Technical EditorAlma R. Sweeny. A.B., Technical Files ClerkPortia Allyn Smith, Research AssistantMeredith M. Calkins, Geologic DraftsmanLeslie D. Vaughan, Asst. PhotographerDolores Thomas Sims, B.A., Geologic Clerk

Special Staff to Aid in the War Effort

Oil and Gas ResourcesEarle F. Taylor, M.S., Asst. GeologistArnold Brokaw, M.S., Spec. Asst. GeologistM. W. Pullen, Jr., M.S., Spec. Asst. GeologistPaul K. Sims, M.S., Spec. Asst. GeologistJohn A. Harrison, B.S., Spec. Research Assistant

Underground Water Geology

Carl A. Bays, Ph.D., Spec. GeologistC. Leland Horberg, Ph.D., Spec. Asst. GeologistStewart Folk, M.S., Spec. Asst. GeologistErnest P. DuBois, B.S., Spec. Asst. GeologistRobert R. Storm, A.B., Spec. Asst. GeologistPaul Herbert, Jr., B.S., Spec. Asst. GeologistCharles G. Johnson, A.B., Spec. Asst. Geologist

Consultants: Ceramics, Cullen W. Parmelee, M.S., D.Sc, and Ralph K. Hursh, B.S., University of Illinois;Pleistocene Invertebrate Paleontology, Frank Collins Baker, B.S., University of Illinois;Mechanical Engineering, Seichi Konzo, M.S., University of Illinois.

Topographic Mapping in Cooperation with the United States Geological Survey.

April 1, 1942

-

CONTENTS

Page

Introduction 7

Description of the coals studied . . . ." 7

Description of stoker and furnace 11

Laboratory tests 12

British Standards Swelling Index Number 12

Agglutinating value 13

Agde Damm test 13

Photographic procedure 14

Results of tests 14

Discussion of results 15

Summary 19

TABLES

1 Analyses of coals used in tests

2 Comparison of laboratory test values with stoker operation

ILLUSTRATIONS

Figure

1 Block of banded coal from southern Illinois showing fusain, vitrain, and

clarain 10

2 Block of banded coal from southern Illinois showing clarain and durain 10

3 Diagram of conversion stoker installation 12

4 View of the furnace 14

5 British swelling index buttons for hand-picked banded ingredients 15

6 British swelling index buttons for certain stoker fuels studied 16

7 Photographs of stoker fires with various fuels 17

8 Photographs of stoker fires with various fuels 18

9 Clinkers from vitrain- and clarain-rich fuels 19

-

Digitized by the Internet Archive

in 2012 with funding from

University of Illinois Urbana-Champaign

http://archive.org/details/correlationofdom78mcca

-

CORRELATION OF DOMESTIC STOKER COMBUSTION WITHLABORATORY TESTS AND TYPES OF FUELS

I. PRELIMINARY STUDIESBy

L. C. McCabe,* S. Konzo,t and 0. W. Rees %

INTRODUCTION

I n 1937 the Illinois Geological Sur-* vey made exploratory stoker tests ofcoals from Franklin Comity, Illinois. 1

which demonstrated that in these coalsconcentration of vitrain causes excessive

swelling and coke-tree formation where-as clarain is more free-burning and hasconsiderably less tendency to form coketrees. The behavior of these two typesof coal or mixtures of them could bedemonstrated in stokers but no exacttests short of combustion were availablefor determining their suitability. Theneed for such test methods to evaluatecoals for stoker use is generally recog-

nized.

It was with this need in mind thatthe exploratory stoker tests were con-tinued and were supported by a varietyof laboratory procedures in 1939 and1940 by the Illinois Geological Surveyin cooperation with the Department ofMechanical Engineering of the Univer-

sity of Illinois. These tests and the sup-porting laboratory data are described

in this report.

The coals were collected and preparedunder Dr. McCabe 's supervision. Dr.Rees directed the routine analyses andthe special laboratory tests. The com-bustion tests were made in a domesticunderfeed stoker in the Warm Air Re-search Residence at the University of

Illinois under Professor Konzo's super-vision.

The writers gratefully acknowledgethe helpful suggestions of Dr. G. H.

Cady, Head of the Coal Division of theSurvey, and of Professor A. P. Kratz

of the Engineering Experiment Stationof the University of Illinois.

DESCRIPTION* OF THECOALS STUDIED

The investigation was primarily con-cerned with Illinois coals and the differ-ences inherent in them. However inorder to inquire more adequately intothe problems met in burning bituminouscoals in stokers and better to test thelaboratory procedures, a few coals thatoriginated outside the State were in-cluded. The origin and the proximateand ultimate analyses of the coals usedin the tests are given in table 1.

The banded character of coals, insouthern Illinois particularly, has animportant bearing on their preparationand utilization. The three most commoncomponents, fusain. vitrain, and clarain,are illustrated in figure 1. The fourth.durain or splint ('fig. 2), occurs infre-

quently in Xo. 6 coal in Franklin Countyand more abundantly in the splint coalsof the Appalachian fields.

Fusain, the most friable of the fourcomponents, breaks down during themining and preparation until the greaterpart of it will pass a 100-mesh screen. 2, 3

Little of it is found, therefore, in well

prepared stoker coals.Vitrain does not break as easily as

fusain but it is much more friable thanclarain. Clarain is closelv knit and

* Geologist, Illinois Geological Survey.t Special Research Associate Professor of Mechanical

Engineering, University of Illinois.% Chemist, Illinois Geological Survey.1 McCabe, L. C, Illinois coals; Constitution important

with reference to their utilization: Mech. Engr.. p. 217,March 1933 ; Illinois Geol. Survey Cir. 26, 1938.

2 Parks, B. C, and McCabe. L. C Fusain content offine sizes of Illinois coal : Trans. Illinois Acad. Sci.vol. 33, no. 2, Dec. 1940 ; Illinois Geol. Survev Cir. 68,1940.

3 Thiessen, Gilbert, Fusain content of coal dust froman Illinois dedusting plant : Am. Inst. Mining and MetEngr. Tech. Pub. 664, 1936.

[7]

-

Location

DOMESTIC STOKER COMBUSTION

TABLE 1.

—

Analyses of

Fixedcarbon

Illinois

Franklin Co

Franklin Co

Franklin Co

St. Clair Co.

St. Clair Co,

Gallatin Co.

West VirginiaRaleigh Co.

Raleigh Co.

Labor- Vola-Coal atory Condi- Mois- tilebed Sample number tion* ture matter

6 A C-2204 12

5.7 42.845.4

6 E C-2212 12

7.9 35.038.0

6 B C-1988 12

6.5 34.436.8

6 C C-2133 12

9.2 41.846.1

6 D C-2134 12

10.2 36.941.1

5 G C-2132 12

3.6 36.638.0

Eagle F C-2252 12

1.5 29.930.3

Poca- H C-2135 1 0.8 18.3hontas 3 2 18.4

46.649.448.152.252.255.943.247.542.247.048.049.8

63.464.475.275.9

TABLE 2.

—

Comparison of Laboratory

Coking tendency British Standard Agglutinating Softening Temp.observed in the fuel bed Swelling Index No. Value (15:1) Agde Damm

Sample 1 Indication Sample 1 Value Sample Value Sample 1 Value

A None A 3 A 2.5 G 324 °CB None B 3 F 2.02 C 330C None C 4 E 4.1 D 331D Slight D \y2 H 6.3 E 348E Slight E 4H C 6.6 F 353F Positive F 5 G 8.0 A 361G Very positive g iy2 D 8.1 B 366H Very positive H 9 H 412

( 1. As received ; 2. Moisture-free.

A—Franklin County, 111. Durain-rich No. 6B—Franklin Countv, 111. Clarain-rich No. CC—St. Clair Countv, 111. Top coal No. 6D—St. Clair County, 111. Bottom coal No. 6E—Franklin County, 111. Vitrain-rich No. 6F—Raleigh County, West Virginia. Eagle seamG—Gallatin County, 111. No. 5H—Raleigh County, West Virginia. Pocahontas No.

1 Silicon carbide to coal ratio, 20 to 1

-

Coals Used in Tests

COALS STUDIED

Ash Sulphur Hydrogen Carbon Nitrogen Oxygen B. t. u. Description

4.9 1.37 5.99 73.66 1.58 12.50 13,260 Durain-rich5.2 1.46 5.69 78.13 1.68 7.84 14,0649.0 1.75 5.43 67.29 1.49 15.00 11.941 Vitrain-rich9.8 1.90 4.94 73.08 1.62 8.64 12,9716.9 1.09 12,532 Clarain-rich7.3 1.16 13.4055.8 3.03 5.94 67.05 1.68 16.48 12.212 Top coal6.4 3.34 5.43 73.84 1.85 9.14 13.44910.7 3.71 5.53 61.77 1.19 17.06 11.131 Bottom coal11.9 4.13 4.89 68.79 1.32 8.91 12.39511.8 3.85 5.19 70.02 1.42 7.76 12,719 2x1 in. screen12.2 3.99 4.97 72.60 1.48 4.76 13,189

5.2 0.59 5.14 81.57 1.54 5.96 14,468 Lump5.3 0.60 5.06 82.81 1.57 4.68 14,6885.7 0.77 4.59 84.24 1.59 3.13 14,576 Lump5.7 0.78 4.54 84.92 1.60 2.43 14,693

Test Values With Stoker Operation

Decomposition Setting Temp. Initial Contraction Plastic IntervalTemp. Agde Damm Agde Damm Interval. Agde Damm Agde Damm

Sample1 Value Sample 1 Value Sample 1 Value Sample 1 Value

G 384°C D 414°C H 38°C H 58°CC 392 C 416 B 49 B 67D 401 B 433 A 58 A 73F 415 F 434 C 62 F 81B 415 E 436 F 62 D 83E 417 A 438 G 64 C 86A 419 G >444 E 69 E 88H 450 H 470 D 70 G >120

-

10 DOMESTIC STOKER COMBUSTIOX

Fig. 1.—Block of banded coal from southernIllinois showing fusain (F), vitrain (V),

and clarain (C).

withstands breaking when mechanicallyhandled. Durain is the toughest andmost resistant component. The follow-ing excerpt from a recent U. S. Bureauof Mines publication 4 describes theenergy consumed in pulverizing thefour coal constituents

:

" Contrary to general belief the ash-bearing constituents are not always mostresistant to crushing, as was shown intests of coal constituents, that is vitrain,

clarain, durain, and fusain—from theSouthern Illinois field. The net powerconsumed in crushing the constituentsfrom minus 20-mesh to minus 150-mesh,with their ash content is given in the

following table

:

CoalConstituent Fusain Vitrain Clarain Durain

Net horsepower—hours perton ofminus150-meshproduct.

.

1.8 3.8 5.1 13.6Ash, per-

cent 15.6 22 8.3 5.2

Fig. 2.—Block of banded coal from southernIllinois showing clarain (C), and

durain (D).

It is shown that the durain, the hardestconstituent, contains less ash than the

clarain, although comparison of thevalues for fusain with any of the othersis even more startling. It has beenrecognized that fusain is the most easily

crushed constituent, in spite of its rela-

tively large percentage of ash."Study of production has shown that

the breakage characteristics of the con-

stituents in commercial coal are reflected

by the energy necessary to pulverizethem. Both vitrain and clarain can befound in lump sizes, and the partingsurfaces may have a thin layer of fusainon them. Most of the fusain will havebeen broken off, however, and can befound in the screenings ; or if the coalsare dedusted, it will be in the deduster

dust. In wet-washing most of the fusain

is carried to the settling pond. For thisreason, it is not considered in the stoker

tests.

The 3- by 2-inch egg contains some ofthe smaller vitrain bands, but for the

most part is clarain. The No. 2 nut (2- byl^-inch) is still richer in clarain. The

4 Fieldner, A. C, and Rice, W. E., Annual report ofresearch and technologic work on coal, fiscal year 1940:U. S. Bur. Mines I. C. 7143, pd. 23-24. 1940.

-

STOKER AND FURNACE 11

No. 3 nut (1U- by %-inch) of well-banded coals has eight to ten percentmore vitrain than the coal bed fromwhich it is mined. This concentrationprevails down to the 100- or 200-meshsize, but fusain is the predominant com-ponent in smaller sizes.

In general, 800 to 1000 pounds of coalwere prepared for the stoker tests, andabout 50 pounds were riffled from thissample for the proximate and ultimateanalyses and special tests. The high-vitrain sample (70 percent vitrain, 30percent clarain) from Franklin County,Illinois, was taken directly from the7/16-inch by 10-mesh stoker coal-load-ing chute at the mine. The high-clarainsample (84 percent clarain, 16 percentvitrain) from the same mine was pre-pared by crushing 3- by 2-inch egg-coalto stoker size. The durain sample wasprepared by crushing to stoker size 6- by3-inch egg-coal from which the otherconstituents had been removed.

In the Belleville district near Darm-stadt in St. Clair County the upper twofeet of Xo. 6 coal is a bright micro-bandedclarain with silky luster, low ash andhigh volatile content, and a relativelyhigh B.t.u. value. The lower four feetof the bed consists of alternating bandsof clarain, vitrain. and fusain. The ashof the bottom coal is higher and thevolatile matter and B.t.u. values are con-siderably lower than in the top coal(table 1). When coals of this type arepoorly prepared, lack of uniformity dueto segregation and other factors maycause difficulties in stoker operation.

Because the rocks of Gallatin Countyhave been folded and faulted, the Xo. 5coal bed of that region is of higher rankthan the same bed in Saline County. Al-though clarain predominates in this bed,the coal has been so increased in rankthat it is all strongly swelling.

The Eagle Seam and Pocahontas coalsof Raleigh County, West Virginia, arehigh-rank coals not represented in Illi-

nois but were tested in order to have awider range of coals in the stoker andlaboratory tests. Run-of-mine wascrushed in both instances to make thestoker coals used in the tests.

DESCRIPTION OF ST< >KERAND FURNACE

A complete description of the WarmAir Research Residence and the forcedwarm-air heating system, together withthe automatic control system used tooperate the stoker and the circulatingfan, has been reported in two papers. 5,

6

The heating plant consisted of a warm-air furnace used in connection with theforced-air heating system. The furnacewas of the cast-iron circulator-radiatortype having a 27-inch firepot and 23-inchgrate. As shown in figure 3. the stokerwas of the underfeed type, and the coalwas delivered from the hopper to the re-tort by means of a rotating screw. The re-tort was located in the center of thehearth. Both the rate of fuel input andthe rate at which air was supplied tothe tuyeres could be independently regu-lated. Xo cut-off damper was providedin the air tube to prevent air being

drawn through the blower and into thefuel bed during the off periods of thestoker. The overfire damper in the fir-ing door was left open prior to thephotographing of the fuel bed. Thepyrex plate glass door which was placedin position just prior to the photo-

graphic study was fitted loosely on thefurnace front to give a total overfire air

opening approximately equivalent to

that provided by the regular firing doorand the overfire damper opening. Abalanced check damper was installed inthe clean-out of the chimney and wasregulated to maintain a constant draft

of approximately 0.05 inches of water

in the smoke pipe.

After a new batch of coal had beenadded to the hopper the plant was al-lowed to operate intermittently underthermostatic control for two or threedays, at the end of which time the fuelbed had assumed the characteristics ofthe coal under test. During this pre-liminary period of adjustment approxi-

mately 300 to 600 pounds of coal were

5 Kratz, A. P., Konzo, S., and Engdahl, R. B., Per-formance of stoker-fired and hand-fired warm-air fur-naces in the research residence: A.S.H.V.E. Journalsection. Heating, Piping, and Air Conditioning, pp.732-742, Nov. 1933.

-

12 DOMESTIC STOKER COMBUSTION

PLAN VIEW

22'

18" 6f

BALANCED DRAFTDAMPER IN CLEANOUT

ELEVATIONVIEW

77

POT

BRICK

OVERFIREDAMPER 300- LB. j HP.

-""' HOPPER MOTOR

29^

Fig. 3.—Diagram of conversion stoker installation in furnace in research residence.

burned. The feed rate maintained dur-ing the tests was about 26 pounds perhour. The setting for air-rate to thestoker was maintained the same in alleases. The resulting burning rate6

varied somewhat depending upon thecoal used, but averaged about 13 poundsper hour. It is possible that the rate at

which air is supplied to the fuel bedmay affect the coking characteristics ofthe fuel. Hence the results obtained inthis preliminary survey may not be en-tirely representative of the coking action

of the coal over a wide range of air ratesand feed rates. It would be advisablein any later studies to investigate thisphase of the problem.

LABORATORY TESTSProximate and ultimate analyses were

made on all samples tested according tostandard procedures of the AmericanSociety for Testing Materials. 7

British Standards SwellingIndex Number

Swelling index numbers were deter-mined according to the British Standardmethod 8 with the following modifica-tions :

1. Instead of the B.S. 72-mesh test

sieve specified by the British Standardmethod for preparation of the testsample a No. 60 U. S. Standard sieve

was used.

8 Kratz, A. P., and Konzo, S., Performance of a stoker-fired warm-air furnace as affected by burning rate andfeed rate: A.S.H.V.E. Journal section, Heating, Piping,and Air Conditioning, pp. 55-60, January 1940.

7 Standard methods of laboratory sampling and analy-sis of coal and coke: A.S.T.M. designation, D271-37.

8 British standard method for the crucible swellingtest for coal: British Standards Institution pub. no.

804, 1938.

-

LABORATORY TESTS 13

2. In place of the "Teclu" burner aFisher high temperature usual styleburner with grid top was used. By plac-ing- a thermocouple inside the crucibleand experimentally adjusting the gasflow to the burner, it was possible to es-tablish conditions of proper temperatureand proper rate of heat rise. Naturalgas of approximately 1000 B.t.u. calo-rific value was used.

3. Transite pipe class F was used forthe draught shield. This pipe was 4%inches outside diameter and 4 inches in-side diameter. It was cut according tothe specifications given in the standardmethod.

4. The crucibles which were usedwere glazed vitreosil of the followingspecifications

:

External height 26 to 26.6 mmExternal diameter at top. .40 to 41.5 mmInternal diameter at base. .13 to 14 mmCapacity 17 to 17.5 mlWeight 11 to 12 gms.

5. Silica triangles which are suppliedas standard items by most chemical ap-paratus supply houses were used. Thoseused in this work were about 63.5 mm inlength of side with a diameter of in-scribed circle of about 31.75 mm.

Briefly the test consists of heating

one-gram portions of coal in the stand-ard crucibles at a specified rate of tem-perature rise until all the volatile mat-ter has been expelled. The buttons arethen removed from the crucibles andcompared to standard outlines to whichhave been assigned numbers from 1 to 9.The average of four such tests is thevalue reported.

Agglutinating Value

Agglutinating value determinations

were made according to the "ProposedMethod of Test for Agglutinating Valueof Coal" as published by the AmericanSociety for Testing Materials. A ratio of15 silicon carbide to 1 coal was used forall samples with the exception of sampleF where a ratio of 20 to 1 was used.

The apparatus used for crushing testbuttons was designed and built in thislaboratory.

This method is a laboratory test forobtaining information on the coking andcaking properties of coal. It is an ap-proximate measure of the material incoal which becomes plastic under theinfluence of heat. Briefly the procedureconsists of mixing coal with an inert ma-terial such as silicon carbide, coking themixture as in a volatile matter deter-mination and determining the compres-sion strength of the buttons so formed.

Agde Damm Test

The apparatus used in this test wassimilar to that described in U. S. Bureauof Mines Bulletin 344. 10 This apparatuswas further described by Thiessen. 11 Itconsists essentially of a cylindrical cop-

per block three inches in diameter andseven inches long which is fitted into aspecially built electric furnace. TwoV2-inch holes are provided in this copperblock for the small sample tubes. Theapparatus is so arranged that a one-pound rod rests on one sample while amicrometer distance gauge is mountedon the top of the rod in such a way as toregister contraction or expansion of the

sample. The other sample is allowed toexpand and contract freely. Thermo-couples are provided for temperaturereadings. In the tests the samples of

coal which have been compressed in thesample tubes under a weight of 5.8 kilo-grams are heated at a specified rate, anddistance gauge and temperature read-ings are recorded. When plotted, thesedata show the initial softening tempera-ture, the decomposition temperature, the

solidification temperature, and the plas-tic interval.

9 Proposed method of test for agglutinating value ofcoal (proposed draft) : A.S.T.M. Standards on Coal andCoke, p. 96, 1938.

10 Fleldner, A. C, Davis, J. D., Thiessen, R., Kester,E. B., and Selvig, W. A., Methods and apparatus usedin determining the gas-, coke-, and by-product-makingproperties of American coals : U. S. Bur. Mines Bull.344, p. 16, 1931.

11 Thiessen, G., Coke from Illinois coals: IllinoisGeol Survey Bull. 64, Appendix B, page 22"), 1937.

-

14 DOMESTIC STOKER COMBUSTION

Fig. 4.—View of the furnace showing pyrex door, lamps, and camera in position forphotographing fuel bed.

PHOTOGRAPHIC PROCEDURE

A pyrex glass door replaced the firing-door while the fuel beds were beingphotographed (fig. 4) so that the normaloperation of the stoker was not affected.The combustion chamber was illuminat-ed by two No. 2 Photoflood lamps in re-flectors; this lighting was necessary toproperly distinguish between coke andclinker masses.

A Weston meter was used to deter-mine the proper exposure of the film.Exposures were made at 16 frames persecond with a 15 mm, F 2.7 lens. Fourhundred feet of 16 mm, Type A, Koda-chrome film was used in making themoving pictures of the fuel beds of theeight coals. This was supplemented by300 feet of film showing the coals, speciallaboratory equipment, and titles. Photo-

graphs of the fuel beds were taken atintervals as follows

:

Fuel bed prior to stoker operation

Start of stoker operation

Fuel bed after five minutes of stokeroperation

Beginning of off-period

Photograph of clinkers.

RESULTS OF TESTS

Analyses of the coals used in thisstudy are given in table 1. Results of

the special tests are given in table 2, andBritish Standards Swelling Index but-tons are shown in figures 5 and 6. Photo-graphs of stoker fires for the fuelsstudied are shown in figures 7 and 8, andclinkers from vitrain- and clarain-richfuels are shown in figure 9.

-

RESULTS 15

Fig. 5.—British swelling index buttons for hand-picked banded ingredients.a. durain; b. clarain; c. vitrain.

DISCUSSION OF RESULTS

The correlations attempted in thisstudy were (1) correlation of laboratorytests with combustion behavior in theunderfeed stoker, and (2) correlation oftypes of coal with combustion behavior.There appeared to be no correlation be-tween agglutinating and AgcleDamm val-ues and the formation of coke in the firebed, which was the principal combustionbehavior characteristic observed. How-ever the authors believe that results of

these tests may be correlated with com-bustion characteristics other than cokeformation. A study of such correlationsand of correlations with other chemicaltests is now in progress. Correlations ofBritish Standards Swelling Index valuesand types of coal with combustion be-havior were possible and the discussiondeals mainly with these correlations.

Figure 5 illustrates the swelling but-tons obtained from hand-picked samplesof durain, clarain, and vitrain from amine in Franklin County, Illinois. Thedurain sample (figure 5a) showed no

tendency to swell and is therefore as-signed a swelling index of one. Clarain

(figure 5b) and vitrain (figure 5c) hadswelling indices of 3 and 5 respectively.Large samples having the purity of

small hand-picked samples could not be

readily prepared. While the 800- to1000-pound samples were not composedentirely of a single ingredient the con-

centration obtained by the preparationmethods described earlier in this reportis sufficient to illustrate the characteris-

tics of the predominant ingredient in thesample.

The egg-coal crushed to make thedurain-rich stoker fuel contained somevitrain and clarain. The standard cokebutton for this fuel is given the number3 in table 2. The predominant duraininfluence on the swelling is brought out

by comparing these buttons (figure 6a)with the hand-picked durain and clarainbuttons (figures 5a and 5b). BritishStandards Swelling Index buttons forcoals A, F, G and H are shown in figures6a, b, c, d. Figures 7a and 7b are en-largements from moving picture film of

-

16 DOMESTIC STOKER COMBUSTION

a

Fig. 6.—British swelling index buttons for certain stoker fuels studied.a. Durain-rich stoker fuel; b. Eagle Seam, West Virginia, stoker fuelc. Gallatin County No. 5 stoker fuel; d. Pocahontas stoker fuel.

two stages in burning of the durain-rich coal. The stoker is just coming onin figure 7a and the fuel bed is readilyseen. Figure 7b, after five minutes ofstoker operation, illustrates the freedomfrom coking and the uniformity of thefuel bed. There is somewhat moresmoke at the beginning of the off-periodwith durain than with the clarain orvitrain.

The clarain-rich fuel ("B", table 2)had a swelling index of 3 as did thehand-picked sample (figure 5b). Figure7c illustrates the beginning of stokeroperation and 7d shows the open natureof the fuel bed after five minutes in theon-period.

The vitrain-rich sample ("E", table2) has a swelling index of 4% as com-pared with an index of 5 for the care-full}^ hand-picked sample, which indi-

cates the presence of a small amount ofdurain or clarain. However, figure 7eillustrates the tendency of the vitrain toform coke in the off-period. Figure 7fillustrates the behavior of this friable

coke tree after five minutes of stokeroperation. Only in mild weather whenthe stoker operates infrequently mightany difficulty be encountered with avitrain-rich coal of this type.

The top coal of the Belleville Districtof St. Clair County has a swellingindex of 4; the bottom coal has a swell-ing index of 4% (table 2, samples C andD). There is practically no coke forma-tion apparent when the top coal is burn-ed, and only a slight tendency to formcoke in the bottom coal (figures 8a and8b). The difference in swelling tendencyis attributed to the presence of a greater

amount of vitrain in the bottom coal. At

-

RESULTS 17

Fig. 7.—Photographs of stoker fires with fuels as follows:a. Stoker fire, durain-rich fuel, stoker just turned onb. Stoker fire, durain-rich fuel, after 5 minutes of operationc. Stoker fire, clarain-rich fuel, stoker just turned ond. Stoker fire, clarain-rich fuel, after 5 minutes of operatione. Stoker fire, vitrain-rich fuel, stoker just turned onf. Stoker fire, vitrain-rich fuel, after 5 minutes of operation

-

18 DOMESTIC STOKER COMBUSTION

Fig. 8.—Photographs of stoker fires with fuels as follows:a. Stoker fire, top bench St. Clair County No. 6 coal, after 5 minutes of operationb. Stoker fire, lower bench St. Clair County No. 6 coal, after 5 minutes of

operationc. Stoker fire, Eagle Seam, West Virginia coal, after 5 minutes of operationd. Stoker fire, Gallatin County No. 5 coal, after 5 minutes of operatione. Stoker fire, Pocahontas coal, stoker just turned onf. Stoker fire, Pocahontas coal, after 5 minutes of operation

-

SI'MMARY 19

Fig. 9.—Clinkers from vitrain- and clarain-rich fuels.

the beginning of the off-period the topcoal has a considerably greater tendencyto smoke than the bottom coal. This isexplained, in part at least, by the highervolatile content of the top coal (46.1and 41.1 per cent respectively on thedry basis).The Eagle Seam coal (Raleigh Coun-

ty, West Virginia) is assigned a swell-ing number of 5. A peculiarity of thiscoal is that after heat is removed fromthe crucible the apexes of the buttonscollapse. This may have some bearingon the behavior of this coal during com-bustion. In assigning a swelling num-ber this apex is restored, however. Fig-ure 8c shows the condition of the fuelbed after the stoker had operated forfive minutes. Part of the coke ringformed on the hearth appears in theforeground of the figure and a coke treeappears in the center. The coke formedin the stoker was dense but in spite ofthis the response to combustion was notunsatisfactory.

The Gallatin County (Xo. 5) coal,with a swelling index of T 1/^, had a tend-ency to form flat masses of coke in thefurnace rather than coke trees (fig. 8d).Such coke masses ignited less readily

than the original coal when the stokercame on after being off for some time.The Pocahontas fuel bed is shown in

figure 8e and f. Figure e shows theappearance with the stoker just comingon and f shows the appearance afteroperation for five minutes. Referenceto this figure and table 2 shows thatthere is considerable coke formationwith this fuel (swelling index number9) under the conditions used for thisstudy.

Figure 9 shows a vitrain clinker ascompared to a clarain clinker. The vit-rain clinker appears to be denser andharder than the clarain clinker.

SUMMARYThis paper is a preliminary attempt

to correlate behavior of various types ofcoal in an underfeed stoker with labora-tory tests for the few samples studiedunder one specific set of conditions.The tests substantiate earlier findings

in regard to the importance of physicalcomposition of coal, that is, types offuel, as related to combustion behavior.No correlations between agglutinating

value and Agde Damm plasticity testsand coke formation were apparent.

-

20 DOMESTIC STOKER COMBUSTION

Correlation between British Stand-ards Swelling Index values and cokeformation in the stoker fire was appar-ent. This is in accord with the findings

of Sherman. 12 On the basis of thesestudies it appears that coals with B. S. I.numbers below 4% or 5 do not form ap-preciable masses of coke in the fuel bedwhereas coals with B. S. I. numbers of5 or above may form large amounts ofcoke.

Although coals of high-vitrain contenttend to form more coke than those ofhigh-clarain and high-durain content,this difference is not as striking in the

present tests as might be predicted from

the swelling index numbers of the hand-picked constituents of the FranklinCounty coal.

Laboratory tests described in this re-port measure more or less specific char-acteristics of coal. On the other hand,behavior of coal in an underfeed stokeris influenced simultaneously by manyphysical and chemical properties. Theinfluence of certain properties maymask that of others. Studies are now inprogress to clarify some of these rela-tionships.

12 Sherman, Ralph A., The evaluation of coal for usein domestic stokers : Univ. Illinois Eng. ExperimentSta. Cir. ser. 39, pp. 39-57, 1939.

Illinois State Geological Subvet

Report of Investigations No. 78

1942