Starting Methods

Transcript of Starting Methods

Department of Electrical Engineering University of Moratuwa

Starting methods of induction motors

Name: Ratnayaka S.R.M.C.D.Index No: 050374RDate of Submission: Field: Electrical Engineering

7) Advantages and disadvantages of the 3 types of single phase induction motors

Advantages

Split-phase induction motor- Available in different powers and speeds so can be use for relevant applications

Produces a high power factor at full load

Capacitor induction motors- Can be run in different speeds Produces a high starting torque and low starting current

Cost effective and small in size

shaded-pole motor- Cheap and reliable

Disadvantages

Split-phase induction motor- Produces a low starting torqueCapacitor induction motors-Produces a huge noise Shaded pole induction motor-Has a low power factor and a low efficiency

8)Application of Single Phase motor

Agricultural Equipment

Small scale Industrial machinery

Water Pumps

Used in washing machines and fans

9)Advantages and disadvantages of Induction motors over other motors

Advantages

More reliableProduces relatively enough efficiencySimple Construction

Cost effective

Disadvantages Has a lower power factor Has a lower efficiency over other motors

Experiment

In this practical we were taught why the starting methods for induction motors are

important and what the starting methods are and how desired goal is achieved using

starting methods. Here we have started different motors which are use different types

of methods for starting. Then we were noted down the name plate date of the motors

as observations. In addition all the motors were coupled with a load because if there is

no load the motor runs to saturation region and leads uncontrollable.

Discussion

Here in this practical what we have done is observing the starting methods of three

phase induction motors. We need starting methods for these motors because when

these motors are starting their stator winding takes high power. As a result of that the

motor pulls high current from the supply. If it takes that much current it can be

harmful for both motors and building’s installations. So for protect the installation

from heating and cause hazards starting methods are very important. As there are

number of starting methods for starting induction motors here are short description

about those methods.

Rotor resistance starting

By adding eternal resistance to the rotor circuit any starting torque up to the

maximum torque can be achieved; and by gradually cutting out the resistance a high

torque can be maintained throughout the starting period. The added resistance also

reduces the starting current, so that a starting torque in the range of 2 to 2.5 times the

full load torque can be obtained at a starting current of 1 to 1.5 times the full load

current.

Name plate data

Voltage(V) Current (A) r.p.m Power factor

245/425 14.5/8.3 1395 0.81

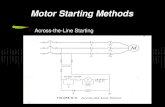

Direct-on-line starting

This is the most simple and inexpensive method of starting a squirrel cage

induction motor. The motor is switched on directly to full supply voltage. The initial

starting current is large, normally about 5 to 7 times the rated current but the starting

torque is likely to be 0.75 to 2 times the full load torque. To avoid excessive supply

voltage drops because of large starting currents the method is restricted to small

motors only. To decrease the starting current cage motors of medium and larger sizes

are started at a reduced supply voltage. The reduced supply voltage starting is applied

in the next two methods.

Star-Delta starting

This is applicable to motors designed for delta connection in normal running

conditions. Both ends of each phase of the stator winding are brought out and

connected to a 3-phase change -over switch. For starting, the stator windings are

connected in star and when the machine is running the switch is thrown quickly to the

running position, thus connecting the motor in delta for normal operation.

The phase voltages & the phase currents of the motor in star connection are reduced to

1/3 of the direct -on -line values in delta. The line current is 1/3 of the value in delta.

A disadvantage of this method is that the starting torque (which is proportional to the

square of the applied voltage) is also reduced to 1/3 of its delta value.

Name plate data

Voltage (V) Current (A) Power (kW) Power

factor

r.p.m. Frequency

(Hz)

Automatic star delta motor

415 66 50 0.87 2910 50

Manual star delta motor

245/425 13.8/7.6 - 0.88 2835 50

Manual star delta motor 2

220/380 3.8/2.2 1 0.85 2860 50

Auto-transformer starting

This method also reduces the initial voltage applied to the motor and therefore

the starting current and torque. The motor, which can be connected permanently in

delta or in star, is switched first on reduced voltage from a 3-phase tapped auto -

transformer and when it has accelerated sufficiently, it is switched to the running (full

voltage) position. The principle is similar to star/delta starting and has similar

limitations. The advantage of the method is that the current and torque can be adjusted

to the required value, by taking the correct tapping on the autotransformer. This

method is more expensive because of the additional autotransformer.

Direct On Line

From several ways of starting methods of induction motors the simplest form

of motor starter for the induction motor is the Direct on Line starter. The DOL starter

comprises a switch and an overload protection relay.

The switch may be a manually operated load break switch, but more

commonly it would be an electromagnetic contactor which can be opened by the

thermal overload relay. Typically, the contactor will be controlled by separate start

and stop buttons, and an auxiliary contact is used as a hold in contact. I.e. the

contactor is electrically latched closed while the motor is operating.

To start, the contactor is closed, applying full line voltage to the motor

windings. The motor will draw a very high inrush current for a very short time, to

establish the magnetic field in the iron, and then the current will be limited to the

Locked Rotor Current of the motor. The motor will develop Locked Rotor Torque and

begin to accelerate towards full speed. As the motor accelerates, the current will begin

to drop, but will not drop significantly until the motor is at a high speed, typically

about 85% of synchronous speed. The actual starting current curve is a function of the

Supply

motor design, and the terminal voltage, and is totally independent of the motor load.

The motor load will affect the time taken for the motor to accelerate to full speed and

therefore the duration of the high starting current, but not the magnitude of the starting

current.

Provided the torque developed by the motor exceeds the load torque at all

speeds during the start cycle, the motor will reach full speed. If the torque delivered

by the motor is less than the torque of the load at any speed during the start cycle, the

motor will stops accelerating. If the starting torque with a DOL starter is insufficient

for the load, the motor must be replaced with a motor which can develop a higher

starting torque. The acceleration torque is the torque developed by the motor minus

the load torque, and will change as the motor accelerates due to the motor speed

torque curve and the load speed torque curve. The start time is dependant on the

acceleration torque and the load inertia.

The shortcoming which is involved in this is DOL starting results in maximum

start current and maximum start torque. This may cause an electrical problem with the

supply, or it may cause a mechanical problem with the driven load. So this will be

inconvenient for the users of the supply line, always experience a voltage drop when

starting a motor. But if this motor is not a high power one it does not affect much.

When we have a power guard (which are used in refrigerators to protect it from over

loads) gets off (at low voltages also) and will take some time to start it again. These

kinds of problems are can be experienced in these cases.

To reverse the direction of rotation of an induction motor can be done by

interchanging any two phases. Here for example we can interchange Y phase with G

one or B one. Like this we can interchange the phase wires and reverse the direction

of rotate. This may also causes reduces life time of electrical equipments.

Also this can cause high wear in mechanical components connected to it. And

as a result it reduces life time of components like drivers and chains also.

Here seeking for what is the suitable method star delta method or auto

transformer method we have to concern about several parameters. Let’s see what the

advantages are in the star delta method. This method is low cost and simple in

operation. In here the disadvantages are in this method if the torque delivered is very

high, it can cause snatch. If it delivers low torque it cause stalls the motor. And also

motor can stall in transient. In auto transfer method it is also simple in operation. But

this has lots of disadvantages than previous methods this is very poor in controlling

and bulky as well as very expensive. So we can say star delta method is better than

auto transformer method.

To start a wound rotor induction motors we can use several methods but rotor

resistance method is much reliable because by adding eternal resistance to the rotor

circuit any starting torque up to the maximum torque can be achieved; and by

gradually cutting out the resistance a high torque can be maintained throughout the

starting period. The added resistance also reduces the starting current, so that a

starting torque in the range of 2 to 2.5 times the full load torque can be obtained at a

starting current of 1 to 1.5 times the full load current.

To reverse the direction of rotating of a three phase induction motors we have

to interchange any two phase supply line wires. For example we can interchange Y

wire with the B wire or R wire. And by doing interchanging other lines also we can

reverse the direction of rotation.

As in other induction motors the rotating part is a squirrel cage rotor. All single-phase

motors require a means of producing a rotating magnetic field for starting. In the

shaded-pole type, a part of the face of each field pole carries a copper ring called a

shading-coil. Currents in this coil delay the phase of magnetic flux in that part of the

pole enough to provide a rotating field. The effect produces only a low starting torque

compared to other classes of single-phase motors. This implies the torque is always

produced in the direction of unshaded portion to shaded portion.

Motor Advantages Disadvantages

shaded-pole motor, Cheap and reliable Deliver low torque

Capacitor starting motor Can be run in different

speeds

Expensive due to

capacitance used

Split phase induction

motors

Available in different

powers and speeds so can

be use for relevant

applications

Take bit time to start due to

method of starting