Standard Morgen – Økt seriøsitet i renholdsbransjen Morgen/Renhold/3 INSTA 800 til...

Transcript of Standard Morgen – Økt seriøsitet i renholdsbransjen Morgen/Renhold/3 INSTA 800 til...

-

SINTEF Building and Infrastructure 1

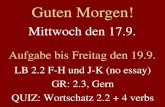

Standard Morgen – Økt seriøsitet i renholdsbransjen

INSTA 800 – Erfaringer og revisjonsarbeid

av Steinar K. NilsenSeniorforsker, SINTEF Byggforsk

21-04-2016

-

SINTEF Building and Infrastructure 2

History

NS-INSTA 800: First edition: October 2000 Second edition: July 2006 Third edition: September 2011

Guidance to NS-INSTA 800: First edition: October 2003 Second edition: May 2008 Third edition: April 2012

-

SINTEF Building and Infrastructure 3

Sales

NS-INSTA 800 ed.: 1st ed.: approx. 1500 2nd ed.: 1218 (dec. 2009) 3rd ed.: 1079 (dec. 2015)TOTAL sold: approx. 4000

Guidance to NS-INSTA 800: 2nd ed.: 585 (dec. 2009) 3rd ed.: 329 (dec. 2015)

-

SINTEF Building and Infrastructure 4

Users Public sector:

Large hospitals (St. Olav/ Trondheim, Rikshospitalet/Oslo)

Universities (NTNU/Trondheim, UiB/Bergen, UiO/Oslo)

The Defence (Norwegian Defence Estates Agency)

Local governments (Oslo, Gjerdrum, Os) Central government

(Regjeringskvartalet/Oslo) Norwegian Broadcasting Coorp. (NRK) ++

Private sector: Large property owners (ENTRA

Eiendom) Private companies (Telenor) Cleaning contractors Cleaning consultants

-

SINTEF Building and Infrastructure 5

Experiences in general INSTA 800 is a good tool for establishing and

assessing cleaning quality INSTA 800 facilitates communication

between contractrors and customers INSTA 800 can be used for improving and

keeping good indoor air quality Focus is lifted from the floor to higher levels in

the room (total evaluation of quality)

A transitional period of 3-6 months may be needed when moving from programmed to quality/demand based cleaning

Some details regarding inspection and evaluation of inspection units are still causingdiscussions when carrying out qualitycontrols

-

SINTEF Building and Infrastructure 6

Experiences – Published research

Indoor Air 2002, Monterrey, USA:“AN INTERVENTION STUDY OF THE RELATIONSHIPS BETWEEN INDOOR AIR-RELATED HEALTH PROBLEMS, PRODUCTIVITY AND CLEANLINESS IN AN OFFICE SETTING”Authors: Steinar K. Nilsen, Peter Blom, James Rydock, Jonny Nersveen, Knut I. Fostervold

Healthy Buildings 2006, Lisbon, Portugal:”Best Practice Cleaning” – Reducing costs, dust levels and chemical load by introducing a modern cleaning concept (Lisbon 2006) Authors: Steinar K. Nilsen, Inger E. Dahl, Trond H. Kristiansen, Bjørn O. Brønnstad, Alf G. Høstmark

Sustainable Buildings 2008, Melbourne, Australia:”Best PracticeCleaning” – Reducing costs, waste and use of chemicals by introducing a modern cleaning concept (Melbourne 2008)Authors: Steinar K. Nilsen, Inger E. Dahl, Trond H. Kristiansen, Bjørn O. Brønnstad, Alf G. Høstmark

-

SINTEF Building and Infrastructure 7

INTERVENTION STUDY - RESULTS:

Visual cleaning qualityFurniture and fixtures

012345

Control Intervention

Group

Qua

lity

leve

lAv

erag

e BeforeAfterIntended, after

Dust on surfaces Difficult accessible furniture and fixtures

0,0

5,0

10,0

15,0

Control Intervention

Group

Dust

cov

erag

e, %

BeforeAfterIntended, after

Differences in cleaning quality between the two groups found for: Dust on difficult accessible surfaces

Tendencies to reduced occurrence of mucousal and diffuse general symptoms in the intervention group

Large reduction in short time sickness absence giving a considerable reduction in production costs (> 2x total cleaning costs)

INSTA 800 proved to be a good tool to assess cleaning quality

No correlation between visual control and measurements of dust

Short time sickness absence

0,0 %

1,0 %

2,0 %

3,0 %

4,0 %

Control Intervention

Group

Sick

leav

e in

% o

f da

y's

wor

k

BeforeAfter

Diagram2

ControlControlControl

InterventionInterventionIntervention

Before

After

Intended, after

Group

Quality levelAverage

Visual cleaning qualityFurniture and fixtures

0.27

1.75

3

0.33

2.62

3

Diagram1

U. ETG

U. ETG.INVENTAR (lt)VEGG (lt)GULV (lt)FLATESMUSS (GULV)

Avfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅ

U222305200115002244

MAM U251416200005003333

THE U271405300115000052

U2042410100005002243

000

000

TOTALT813526800222000771612

ANDEL TOT31%50%19%0%0%100%0%0%100%

Gjennomsnitt2.003.251.254.332.000.000.000.500.335.000.000.001.751.174.003.000.00

RØD SKRIFT: Nivå gitt av vanskelig tilgjengelige flater

U+1 etg 2000U+1 etg 20012+3 etg 20002+3 etg 2001Avtalt nivå (min)BeforeAfterIntended, after

Inventar, løst smuss med mer0.271.750.332.623Control0.271.753

Vegg, løst smuss med mer33.53.674.634Intervention0.332.623

Gulv, løst smuss med mer2.633.831.783.693

Gulv, flatesmuss3.092.834.113.883

U. ETG

U+1 etg 2000

U+1 etg 2001

2+3 etg 2000

2+3 etg 2001

Avtalt nivå (min)

Overflater og smusstyper

Kvalitetsnivåer

1. ETG

Before

After

Intended, after

Lokaltyper

Kvalitetsnivå, gjennomsnitt

Visuell rengjøringskvalitet, Inventar

2. ETG

Before

After

Intended, after

Group

Quality levelAverage

Visual cleaning qualityFurniture and fixtures

3 ETG

1. ETG.INVENTAR (lt)VEGG (lt)GULV (lt)FLATESMUSS (GULV)

Avfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅ

1235117207071100152

1303306100005102332

1380213100114002243

1100123300003000053

1173306100005204624

119110210100101004432

1450011304152103432

124010110100101000054

TOTALT121252913031233225015203022

ANDEL TOT41%41%17%0%94%6%25%0%75%

Gjennomsnitt1.501.500.633.631.630.003.880.254.132.750.630.001.882.503.752.750.00

RØDT:Nivå gitt av resultat fra vanskelig tilgjengelige flater

2. ETG.INVENTAR (lt)VEGG (lt)GULV (lt)FLATESMUSS (GULV)

Avfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅ

2191113300005000054

2221012400005002243

2302024300115201335

2312114300005001154

2360213300115000034

2482204300005200244

MF Mursentret0000200005103444

TS Kontrollr2024300224001145

TOTALT10682424004439508133233

ANDEL TOT42%25%33%0%0%100%38%0%62%

Gjennomsnitt1.250.751.003.003.000.000.000.500.504.880.630.001.001.634.004.130.00

3. ETG.INVENTAR (lt)VEGG (lt)GULV (lt)FLATESMUSS (GULV)

Avfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅAvfall&løstStøvFlekkerTOTALTNIVÅ

3231012200115001144

3241214300115003334

3310325200224000044

3341034200624006623

3370224300005103433

3380011400333005533

3600011100224003335

3621102100115000053

TOTALT48112318001612351021222729

ANDEL TOT17%35%48%0%0%133%5%0%95%

Gjennomsnitt0.501.001.382.882.250.000.002.001.504.380.130.002.632.753.383.630.00

Diagram1

ControlControlControl

InterventionInterventionIntervention

Before

After

Intended, after

Group

Dust coverage, %

Dust on surfaces Difficult accessible furniture and fixtures

11.5

13.9

5

9.1

2.9

5

Diagram2

PersonnærtPersonnærtPersonnærtPersonnært

Inventar LTInventar LTInventar LTInventar LT

Inventar VTInventar VTInventar VTInventar VT

GulvGulvGulvGulv

&A

Page &P

Vår 00

Vår 01 ref

Vår 01 int

"Innemiljøkvalitet"

Overflate

Støvdekkeprosent

1.7078947368

0.9266666667

0.935

1

3.6605263158

1.8

1.33

1.5

10.4176470588

15.1214285714

3.065

5

4.1638888889

6.8642857143

5.13

3

Ark1

4. ETASJE407477413478420429433437445452GjennomsnittStd. avvik

Personnært0.000.00

Inventar LT0.000.00

Inventar VT0.000.00

Gulv0.000.00

Gjennomsnitt alle:0.00

3. ETASJE323324331334337338360361343365GjennomsnittStd. avvik

Personnært0.23.41.20.91.31.30.81.30.101.050.97

Inventar LT0.81.21.50.74.102.68.600.92.042.61

Inventar VT0.70.80.53.52.70.11.140.33.11.681.48

Gulv5.72.54.74.65.942.61056.85.182.17

Gjennomsnitt alle:2.49

2. ETASJE219225227228231234236248SAVNGjennomsnittStd. avvik

Personnært00.70.81.30021.51.10.80.820.68

Inventar LT0.70.1011.101.11.10.50.60.620.46

Inventar VT2.50.88.31.462.62.99.44.36.34.452.93

Gulv2.96.202.66.15.75.44.76.910.35.082.79

Gjennomsnitt alle:2.74

1. ETASJE109110114115121127130141145146GjennomsnittStd. avvik

Personnært1.10.32.20.70.71.52.91.80.41.31.290.83

Inventar LT1.11.52.91.31.721.61.13.32.51.900.76

Inventar VT4.511.410.6155.811.310.216.122.411.811.915.11

Gulv2.85.14.45.34.88.96.44.816.996.844.03

Gjennomsnitt alle:5.49

U.ETASJEU19U20U21U22U24U25U27GjennomsnittStd. avvik

Personnært2.300.5000.500.470.84

Inventar LT00.30.2002.94.91.191.95

Inventar VT23.120.44.811.517.632.530.720.099.91

Gulv5.18.854.57.8118.47.232.43

Gjennomsnitt alle:7.24

Vår 00Vår 01 refVår 01 int"Innemiljøkvalitet"

Personnært1.70.90.91

Inventar LT3.71.81.31.5

Inventar VT10.415.13.15

Gulv4.26.95.13

Inventar LT

FørEtterAvtalt nivå

Kontrollokaler4.71.71.5

Intervensjonslokaler2.11.31.5

Inventar VT

BeforeAfterIntended, after

Control11.513.95

Intervention9.12.95

&LMÅLING AV STØVDEKKE - FASE 3

Ark1

Før

Etter

Avtalt nivå

Lokaltyper

Støvdekke-%

Støvavsetninger, lett tilgjengelig inventar

Ark2

Before

After

Intended, after

Lokaltyper

Støvdekke-%

Støvavsetninger, vanskelig tilgjengelig inventar

Ark3

Before

After

Intended, after

Group

Dust coverage, %

Dust on surfaces Difficult accessible furniture and fixtures

Diagram1

ControlControl

InterventionIntervention

Before

After

Group

Sick leave in % of day's work

Short time sickness absence

0.0243076923

0.0305059524

0.0368718406

0.0229260935

Ark1

SYKEFRAVÆR 2000

Antall dagsverkAntall sykedager1-3 dg.4-16 dg.LangtidLuftveisplagerDiffuse plagerInnemiljørelatertAntall svar

U + 1. Etg3250157394078381138

2.+3. Etg.3363216824292577952

NBI 2. Etg.13227447270267018

Kontrollrådet28672507009

NBR 3. Etg175513533109224925

SYKEFRAVÆR 2001

Antall dagsverkAntall sykedager1-3 dg.4-16 dgLangtidLuftveisplagerDiffuse plagerInnemiljørelatert

U + 1. Etg2688136275553140533

2.+3. Etg.331526441351893901548

NBI 2. Etg.14211152013832501530

Kontrollrådet2942200

NBR 3. Etg16001471922106140018

Sykedager % før og etter

U+1etg 2000U+1 etg 20012+3 etg 20002+3 etg 2001

Totalt sykefravær4.8 %5.1 %6.4 %8.0 %

1-3 dg1.2 %1.0 %2.4 %1.2 %

4-16 dg1.2 %2.0 %1.2 %1.1 %

Langtid2.4 %2.0 %2.7 %5.7 %

Innemiljørelaterte forekomster i forhold til antall dagsverk (omregnet til 100 personer i begge grupper)

Luftveisplager3.1 %3.3 %1.6 %2.5 %

Diffuse plager0.1 %0.4 %0.0 %0.0 %

Innemiljø årsak i fohold til antall dager rapportert innemiljørelatert fravær

U+1etg 2000U+1 etg 20012+3 etg 20002+3 etg 2001

Andel innemiljø mulig årsak2.6 %35.7 %14.1 %38.5 %

BeforeAfter

Control2.4 %3.1 %

Intervention3.7 %2.3 %

&LOVERSIKT OVER SYKEFRAVÆR

Steinar Klubben Nilsen: Hele 2. Etg., ikke bare NBI

Ark1

U+1etg 2000

2+3 etg 2000

U+1 etg 2001

2+3 etg 2001

Typer sykefravær

Fravær i % av antall dagsverk

Ark2

U+1etg 2000

2+3 etg 2000

U+1 etg 2001

2+3 etg 2001

Relativ forekomst

Ark3

Andel innemiljø mulig årsak

Before

After

Lokaltyper

Fravær i % av antall dagsverk

Sykefravær innenfor areidsgiverperioden

Before

After

Group

Sick leave in % of day's work

Short time sickness absence

-

SINTEF Building and Infrastructure 8

BEST PRACTICE CLEANING PROJECT DESIGN

STEP 1 (2002): Analyze “present situation” for cleaning services in the Defence’s

buildings (20 % of the total area) Compare with other buildings Establish a set of benchmarks and goals which can be measured

STEP 2 (2002-2003): Develop a new cleaning concept with the tools and systems needed

for planning, skills upgrading, purchasing equipment and materials, and following up

STEP 3 (2003-2005): Upgrade cleaner skills and introduce the new cleaning system in all

buildings Evaluate effects

-

SINTEF Building and Infrastructure 9

BPR - RESULTS Summary – ”Win-win”

Cleaning costs were reduced by NOK 77 mill. (2005, from 300 mill.)

Quality requirements were fullfilled in 79 % of the buildings

Average dust load on surfaces was reduced by 32 %

Consumption of cleaning chemicals was reduced from 100 tons to 54 tons/year (70 % with ecolabel)

Consumption of dustbin bags was reduced from 20 tons to 2,6 tons

Sick leave was reduced from 20 % to 12 % (2005)

High score in evaluation of courses and employee and costomer satisfaction

Awarded the Norwegian environment prize “The Glass Bear 2006”

Reductions

29

32

46

86

40

0 10 20 30 40 50 60 70 80 90 100

Costs (2005)

Dust load

Chemical load

Plastics waste

Sick leave (2005)

%

Diagram6

Costs (2005)

Dust load

Chemical load

Plastics waste

Sick leave (2005)

%

Reductions

29

32

46

86

40

Ark1

Costs (2005)Dust loadChemical loadPlastics wasteSick leave (2005)

2932468640

2002200420052008 estimate

195153137118

2002200320042005200620072008 estimate

195153137118

BeforeAfter

Cleaning chem. consumpt.12065

Proportion Swan (%)1870

Plastic bags15121

BeforeAfter

Cleaning chem. consumpt.23

Proportion Swan15

Plastic bags25

Ark1

% reduction

Ark2

%

Reductions

Ark3

Year

NOK pr sq. m and year

Costs

Cleaning chem. consumpt.

Proportion Swan (%)

Plastic bags

mg pr. cleaned sq.m and year

Environmental factors

Cleaning chem. consumpt.

Proportion Swan

Plastic bags

-

SINTEF Building and Infrastructure 10

Sertifisering i henhold til INSTA 800 Standarden ble gjort "sertifiserbar"

ved revisjonen i 2010 – 2011 Der er etablert ordninger for

sertifisering i Danmark, Norge og Finland

SINTEF Certification har fra 2012 utstedt personsertifikater til hele det nordiske markedet

Personsertifikater utstedes for Kunnskapsnivå 3 og Kunnskapsnivå 4 i hht standardens Tillegg B

470 sertifikater har så langt blitt utstedt av SINTEF Certification: 311 til det norske markedet 158 til det danske markedet 1 til det finske markedet

427 sertifikater er fortsatt gyldige 43 sertifikater er under utarbeidelse

-

SINTEF Building and Infrastructure 11

Experiences – Tools for planning and control Several suppliers offer INSTA-supporting tools: Datec; Jonathan Clean/Clean Pilot (planning and control) KBD-gruppen; RenData 800 (planning and control) Renplan 2000 (planning and control (2005-version of INSTA 800) Plania (planning) Data-know-how (planning and control) Digital pen; control, for registration of data from inspections and

automatic calclulation of results

Some interest groups have developed "standard" quality profiles: NHO Service/Digital pen (employers' federation) Forum for sykehusrenhold (hospitals) Norsk kommunalteknisk forening (association of local governments) SINTEF Building and Infrastructure/Norwegian Institute of Technology

(consultants)

-

SINTEF Building and Infrastructure 12

Revisjon av INSTA 800 i 2016 - 2017 Det ble avholdt et felles nordisk standardiseringsmøte i København 17.

desember 2015. Der ble det besluttet å starte arbeidet med revisjon av INSTA 800

Det tas sikte på å ha et forslag til revidert standard klart sommeren 2017, og utgi en versjon 4 av standarden i løpet av 2017 (kan komme noe senere i norsk versjon grunnet oversettelsesarbeid)

Arbeidet ledes av Dansk Standard (sekretariat)

Målet er å gjøre standarden mer brukervennlig

Det er etablert speilkomiteer i Norge, Sverige, Finland og Danmark

Speilkomiteene møtes i forkant av de nordiske møtene, og tar stilling til innspill fra de øvrige nordiske landene samt diskuterer forbedringer som den norske gruppen vil spille inn til den nordiske komiteen

-

SINTEF Building and Infrastructure 13

Norsk speilkomite for revisjonsarbeidetSECRETARIAT: Hege Thorkildsen, Standard Norge

CLEANING COMPANIES: Nils Finstad, Eurest Unny Ingvaldsen, Toma

CLEANING CONSULTANTS: Ann-Kristin Mork, Teknologisk Institutt Karin Bergsetn Lied, KBD-gruppen Lena Furuberg, Bygg & Facility Consult AS Per Arne Løvstad, Ren-Consult AS

TRADE ORGANISATIONS: Tore Barlo, NHO Service

EMPLOYER ORGANISATIONS: Mette Sætervold, Fagforbundet/St. Olavs

hospital Brede Edvardsen, Arbeidsmandsforbundet

CUSTOMERS/CLIENTS: Edith Stakvik, Forsvaret Gunda Djupvik, NAV

TECHNICAL SCHOOLS/UNIVERSITIES: Nora Klungseth, NTNU

RESEARCH INSTITUTES/CERTIFICATION BODIES: Steinar K. Nilsen (L), SINTEF

CLEANING TECHNICAL ORGANISATIONS: Inger E. Dahl, NFSR

SUPPLIERS: Bjørn Olav Erland, DATEC AS

-

SINTEF Building and Infrastructure 14

MEETINGS

Meetings will be held before each Nordic meetings.

First meeting: Tuesday 16th of February

Planned meetings: April (21st) August (31st)

No working groups have been established so far.

-

SINTEF Building and Infrastructure 15

I de påfølgende lysark er innspill til det nordiske arbeidet gitt fra norsk gruppe listet opp

For spesielt interesserte:

-

SINTEF Building and Infrastructure 16

INSTA 800 – Need for revision (input to the meeting 17.12.2015)

2 Normative references: Needs updating (revised standards, new FM-standards),

3.2 (or a new sub-clause under clause 5): Make clear (by examples) how soiling (group 1) on complex furniture (e.g. office chairs, hospital beds) can be divided into "accumulationsof soiling"

3.2 (or a new sub-clause under clause 5, see above): Make clear (by examples) howsoiling on long, narrow, continuous surfaces (skirting boards etc.) can be divided into"accumulations of soiling"

6.1.2: Make clear how soiling group 2 shall be evaluated, for a given inspection unit and object group; evaluate soiling-% on LT and VT separately based on the area of LT and VT respectively? Or: evaluate soling-% on LT and VT based on the total area of the surface?

6.1.4: Instrumental methods are more accurate than visual methods . It must be madeclear that when both visual inspection and instrumental methods are used, resultsobtained with instrumental methods shall take precedence over visual results whenevaluating the result for the sample (accepted/not accepted).

-

SINTEF Building and Infrastructure 17

INSTA 800 – Need for revision(input to the meeting 17.12.2015)

7.2.1.1 (Contract): Add a bullet point; quality frequencies for all room types/inspection units (+ define quality frequency; how often the quality requirements for the inspection unit (room) shall be met)

7.2.2, 4th section: Must be re-written. AQL is not 4 for small lot sizes (up to 25), and AQL in table 6b is 2,5.

7.2.2, 7th section: It must be made clear (by examples) what this means. Which conditions have to be met in order to ensure that "the cleaning is uniform and in accordance with the same instructions"? Same cleaning methods? (dry methods/wet methods) Same cleaning principles? (machines/manual methods) Same kind of rooms? (offices/wetrooms) Same building? Same building type? Same level of maintenance? Same kind of flooring? (carpets/hard floors) ???

7.2.2.1: Total control is mentionned, but it is not described when it should be used. Need for explanation/examples, add new sub-clause?

-

SINTEF Building and Infrastructure 18

INSTA 800 – Need for revision(input to the meeting 17.12.2015)

Table 5: This table was revised in 2010 and is now not in accordance with ISO 2859, buta mixture of 3 different tables. AQL 4 should be used for all lot sizes due to:

Use of a "self-constructed" table may conflict with the requirements in EN 13549 Small lot sizes are often comprised of rooms which require a high hygienic and cleaning standard (toilets,

sanitary rooms, operating theatres, laboratories, clean-rooms). AQL up to 10 % is unacceptable for such rooms.

There are some minor mis-prints in Annex A and Annex D

Annex D: should be "Normative" (it is not mandatory to use the methods, but when theyare used the methods described should be followed)

D.1 Measuring dust/D.1.6.1: Measurements frequency is "once a quarter" for all othermethods. Should be quarterly for this method as well, as it is an important method for ensuring good indoor air quality.

D.2 Hygiene conditions: ATP-measurements are now widely used in all the Nordic countries, and it should be considered to include this method in the standard

D.4 Gloss/D.4.7: The assessment method is complicated and should be re-considered

-

SINTEF Building and Infrastructure 19

INSTA 800 – Need for revision(input to the meeting 02.03.2016)

3. Define "cleaning" Define "walking around" Define "damage or lack of maintenance…" Define "not accessible surfaces" if accepted as new surface category Define "totaql sampling" Define "simpel random sampling"

4. Contradiction: The standard says 6 quality levels. Only 5 are described. Delete level 05. Add notes to table 2 for surfaces that are difficult to place in the right surface

category/inspection unit (doors, joints)5.1 Add a new group of surfaces: Not accessible5 Add a new clause giving information about accumulations; how to evaluate long narrow

surfaces6. Add a note describing how dirt in grooves shall be evaluated as part of a tiled floor7. Add "Damages" to the sentence mentioning "lack of maintenance"7. Set an upper limit for time used for inspection of an inspection unit7. Add a note telling that upper limit for cleaning shall be described in the contract7. Give recommendations regarding how to save inspection time by correct

stratification/selection 7. Add a reference to Annex C regarding performance of simple random sampling

-

SINTEF Building and Infrastructure 20

INSTA 800 – Need for revision(input to the meeting 02.03.2016)

Annex A: Correct referencesAnnex A: Make following up actions mandatory ("shall" instead of "can")Annex D: Delete D.5 and D.6 (and maybe D.2 as well??)Annex F: Improve the assessment form

Standard Morgen – Økt seriøsitet i renholdsbransjen��INSTA 800 – Erfaringer og revisjonsarbeidHistorySalesUsersExperiences in generalExperiences – Published research Lysbildenummer 7BEST PRACTICE CLEANING �PROJECT DESIGNBPR - RESULTS �Summary – ”Win-win”Sertifisering i henhold til INSTA 800Experiences – Tools for planning and control Revisjon av INSTA 800 i 2016 - 2017 Norsk speilkomite for revisjonsarbeidetMEETINGSFor spesielt interesserte:INSTA 800 – Need for revision �(input to the meeting 17.12.2015)INSTA 800 – Need for revision�(input to the meeting 17.12.2015)INSTA 800 – Need for revision�(input to the meeting 17.12.2015)INSTA 800 – Need for revision�(input to the meeting 02.03.2016)INSTA 800 – Need for revision�(input to the meeting 02.03.2016)