Stainless Steel Submersible Pumps€¦ · The Lubi J & W series Stainless steel submersible pumps...

Transcript of Stainless Steel Submersible Pumps€¦ · The Lubi J & W series Stainless steel submersible pumps...

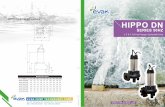

Stainless Steel Submersible Pumps

50 HzPumping Solution

ISO 9001 Company

J & W STAINLESS STEEL SUBMERSIBLE BORE WELL PUMPS

INTRODUCTION MOTOR

:::::::

::::::

Submersible rewindable motor1 phase - 0.37 to 4 kW, 3 phase - 0.37 to 185 kW2900 rpmIP 68F (Oil Filled motors)1 phase 220 V, 230 V3 phase 380 V, 400 V, 415 V 50 Hz+45°C6.5 - 8S1 / ContinuousClockwise as seen from the pump coupling side.300 metres (4")250 metres (6")200 metres(8")200 metres (10")

Motor type Ratings

Rated speed Enclosure classInsulation class Nominal voltages(Tolerance +6% / -10%)Supply frequencyAmbient temperatureWater pHDuty / RatingDirection of rotationMaximum submerged depth

PUMPED LIQUIDS

DESIGN FEATURES

APPLICATIONS

The Lubi J & W series Stainless steel submersible pumps are designed for 4" (DN 100 mm), 6" (DN 150 mm), 8" (DN 200mm) and 10" (DN 250 mm) bore well pumps applications.

They are available from 0.37 to 4 kW for single phase and from 0.37 to 185 kW for three phase power supply.

These pumps are constructed completely out of stainless steel AISI 304 (AISI 316 are also available on request).

Pumps are designed and sized for connection to the motor according to NEMA standards up to 8" motor joining.

All pumps are equipped with built-in non-return valve.

These pumps are available in two basic impellers design.

Radial flow impellers 4" pumps: W1A, W2A, W3A, W5A 6" pumps: J6, J9, J12, J17, J17A, J20, J24, J13H, J16H, J18H

Mixed flow impellers 4" pumps: W8A, W14A 6" pumps: W10, W15, W17, W30, W46, W60 8" pumps: W77, W95 10" pumps: W125, W160, W215.

Connection: Screwed pipe connection with BSP thread as standard. (NPT thread pipe connection are available on request).

Water supply

Irrigation

Civil

Industrial

Fire fighting

Flow range

Head range

Liquid temperature

Installation depth

Maximum sand content

:

:

:

:

:

Max. 18.8 m³/h (for 4" pump)Max. 78 m³/h (for 6" pump)Max. 123.8 m³/h (for 8" pump)Max. 280 m³/h (for 10" pump)

Max. 547 metres (for 4" pump)Max. 750 metres (for 6" pump)Max. 423 metres (for 8" pump)Max. 505 metres (for 10" pump)

0°C to +45°C

350 metres

50 g/m³

OPERATING CONDITIONS

FEATURES AND BENEFITS

All pumps feature complete fabricated stainless steel AISI 304 construction.

All pumps are equipped with water lubricated rubber wear rings and bush bearings to work well with sand, found in well water.

These pumps offers higher pumping efficiency due to state-of- the-art computerized hydraulic design and usage of stainless steel sheet metal which offers a very low co-efficient of friction. This significantly reduces energy consumption.

These pump can withstand harsh, abrasive and corrosive environment due to their construction in high grade AISI 304 stainless steel.

All pumps are equipped with reliable non-return valve to prevent back flow and reduces water hammer when the pump is stopped.

Pumps are designed for pumping clear and cold water that is free of air and gasses, thin, non-aggressive and non-explosive liquids without solid particles or fibers.

Decreased pump performance and life expectancy can occur if the water is not cold and clear or contains air and/or gasses.

The maximum sand content of the water must not exceed 50 g/m³. Higher sand content will increase the risk of blockage and reduce the pump life.

When pumping liquids with a density higher than that of water, motors with correspondingly higher outputs must be used.

Bearings with sand channels

Non-return valve

Stop ring

Inlet strainer

All pumps are equipped with a reliable non-return valve which prevents back flow in connection with pump stoppage.

Furthermore, the short closing time of the non-return valve means that the risk of destructive water hammer is reduced to a minimum.

The valve casing is designed for optimum hydraulic properties, to minimize the pressure loss across the valve and thus contributes to the high efficiency of the pump.

The inlet strainer prevents particles over a certain size from entering the pump.

The stop ring prevents damage to the pump during transport and in case of up-thrust in connection with start-up.

The stop ring, which is designed as a thrust bearing, limits axial movements of the pump shaft.

The stationary part of the stop ring is secured in the upper intermediate chamber. The rotating part is fitted above the split cone.

All bearings are water-lubricated and have a squared shape enabling sand particles, if any, to leave the pump together with the pumped liquid.

Bowl / DiffuserImpellerNeck ringShaftCoupleDelivery casingSuction caseBearing bushStrainerConnector

12345678910

AISI 304AISI 304

NBRAISI 431AISI 304AISI 304AISI 304

NBRAISI 304

-

AISI 304AISI 304

NBRAISI 431AISI 304AISI 304AISI 304

NBRAISI 304

-

Stainless steelStainless steel

NBRStainless steelStainless steelStainless steelStainless steel

NBRStainless steelStainless steel

AISI 304AISI 304

NBRAISI 316AISI 316AISI 304AISI 304

NBRAISI 304

-

AISI 304AISI 304

NBRAISI 431AISI 316AISI 304AISI 304

NBRAISI 304AISI 304

AISI 304AISI 304

NBRAISI 431AISI 316AISI 304AISI 304

NBRAISI 304

-

8" PUMPCOMPONENTPOS.

10" PUMPMATERIAL

4" PUMP 6" PUMP

"W" TYPE "W" TYPE "W" TYPE "W" TYPE"J" TYPE

4" PUMP 10" PUMP

6

1

3

2

4

8

7

5

9

W25, W160, W215

6

1

3

2

4

8

7

5

9

W77, W95

8" PUMP

6" PUMP

SECTIONAL DRAWING & MATERIALS

J & W STAINLESS STEEL SUBMERSIBLE BORE WELL PUMPS

J6, J9, J12, J17, J17A, J20, J24

W10, W15, W17, W30, W46, W60

J13H, J16H, J18H

6

7

5

9

8

2

1

4

3

6

10

8

4

7

5

9

3

2

1

W1A, W2A, W3A, W5A W14AW8A

6

2

7

5

3

4

1

8

9

6

2

7

5

3

4

1

8

9

J & W

PERFORMANCE RANGE

STAINLESS STEEL SUBMERSIBLE BORE WELL PUMPS

4" Pump

6" Pump

8" Pump

10" Pump

2 4 6 8

1

10

100

1000

2

3

5

20

30

50

200

300

500

0

0 100 150 200 250 300 350 400 450 500 550

10

100

1000

5

20

30

50

200

300

500

2000

3000

0 6 12 18 24 30

0 25 50 75 100 125 150

600 650

10

36

Hm

Hft

l/sec

l/minQ

m³/h

USgpmJ

6

J17

J1

8H

J1

7A

J2

0

J2

4

J1

3H

J16H

J 50 Hz

J1

2

J9

1 102 3 5 20 30 500.50.3

10

100

5

20

30

50

200

300

500

10 100 100020 30 50 200 300 500 2000 3000

100

1000

20

30

50

200

300

500

2000

3000

1 10 1002 3 5 20 30 50 200

10 10020 30 50 200 300 50053

1000

Hm

Hft

l/sec

l/minQ

m³/h

USgpm

W1

A

W2

A

W3

A

W5

A

W8

A

W1

4A

W1

7

W3

0

W4

6

W6

0

W7

7

W9

5

W1

25

W1

60

W2

15

W50 Hz

W1

0

W15

LUBI INDUSTRIES LLPNear Kalyan Mills, Naroda Road, Ahmedabad-380 025, INDIA.Phone : +91 - 79 - 30610100, Fax No. :+91 - 79 - 30610300.Sales Enquiries: [email protected], [email protected] Improvement is a continuous process at ‘LUBI’. The data given in this publication is therefore subject to revision.

02.00.151015.0047 Toll Free Service Hotline for India : 1800 419 3055 / 1800 3000 3055

![Type Series Booklet ILN, ILNC · 2020-04-09 · Type series booklet CTI-2600/02 [05-2011] ILN, ILNC ILN, ILNC Series DN discharge nozzle [mm] DN Impeller [mm] Impeller Hydraulics](https://static.fdocuments.in/doc/165x107/5f7657580471dd7a2470e955/type-series-booklet-iln-ilnc-2020-04-09-type-series-booklet-cti-260002-05-2011.jpg)

![EN SuperBetsy Mobile Pump SystemsDescription SB100-DS SB150-EM SB150-EH DN Suction flange (PN10) [mm] DN Discharge flange (PN10) [mm] DN100, PN10 DN100, PN10 DN150, PN10 DN150, …](https://static.fdocuments.in/doc/165x107/6063becdbc70967b2f2a7a36/en-superbetsy-mobile-pump-systems-description-sb100-ds-sb150-em-sb150-eh-dn-suction.jpg)