Staff Report - nidwater.com · Approve a design-build contract with Gateway Pacific Contractors in...

Transcript of Staff Report - nidwater.com · Approve a design-build contract with Gateway Pacific Contractors in...

Staff Report for the Board of Directors Meeting of June 25, 2014 TO: Board of Directors

FROM: Gary King, Engineering Manager Adrian Schneider, Senior Associate Engineer

DATE: June 18, 2014

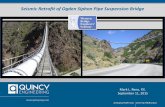

SUBJECT: Siphon Lane Pump Station Design-Build Project ENGINEERING

RECOMMENDATION: Approve a design-build contract with Gateway Pacific Contractors in the amount of $2,497,738, authorize the General Manger to execute the documentation, and approve a budget amendment for the Siphon Lane Pump Station Project formally called the DS Pump Station project as recommended by the Engineering Committee on May 21, 2014 and the Administrative Practices Committee on June 3, 2014. BACKGROUND: During emergency or scheduled shut downs of the conveyance systems upstream of the Cascade Canal such as the South Yuba Canal, the District pumps water from the DS Canal up to the Cascade Canal and the Snow Mountain Ditch. The water is pumped using an existing pipe and siphon (Cascade Extension – Snow Mountain Siphon) and portable rental pumps. In 2013, pumping was required in two separate events. One of the events in 2013 consisted of one month of pumping at a cost to the District in excess of $66,400 for expenses such as fuel, equipment rental, and labor. A significant amount of time is required to set up the pumps and it is dependent on the availability of the pumps. Furthermore, set up in winter weather conditions can take more time. During this time, water deliveries to raw water customers are impacted and treated water facilities will run on storage from conveyance facilities or until facilities are out of water. This situation is improved when the pumps are operating or the Cascade Canal is back in service. A permanent pump station would alleviate the high cost of temporary pump rental and the eliminate time to make it operational. In addition, the permanent pump station would generate less noise than the temporary pumps which is a predominant complaint during these emergency situations. Finally, the pump station will provide the District the necessary operational to adjust during emergency or scheduled repairs and maintenance. On January 10, 2014, staff solicited a request for proposals (RFP) from pre-selected contractors and consultants. The RFP was sent to eight contractors and nine

Nevada Irrigation District

Staffreportboardsiphonlanepumpstation.docx

consultants. On March 7, 2014, four proposals were received by the following contractors: T&S Construction, C&D Construction, Gateway Pacific Contractors, and Hansen Bros. Enterprises. Proposals were evaluated by the Engineering Manager, Operations Manager, Maintenance Manager, and a Senior Engineer and were scored and ranked using screening criteria as outlined in the RFP. Costs were included in the ranking after the initial scoring was compiled. In all categories with the exception of cost, Gateway Pacific scored the highest of the proposals and had the second lowest cost of all four proposals. Gateway Pacific had the overall highest score and recommended for this project. On March 27, 2014, staff discussed the proposal with Gateway Pacific and its subcontractor Bennett Engineering Services. The District requested Gateway to develop options to reduce costs. The District reviewed the proposed cost reduction options and determined that reductions were not sufficient to eliminate those items from the contract. Staff recommends awarding the design-build contract to Gateway Pacific in the amount of $2,497,738. BUDGET: This project was budgeted in 2014 for design and was anticipated to be budgeted for construction in 2015. Failure of the South Yuba Canal in late 2013 emphasized the risks to District operations and the need for a permanent back up facility. Staff has reviewed other budgeted projects for 2014 and determined that this project is a higher priority than some of the projects currently budgeted. Staff recommends delaying the projects outlined in the budget amendment. At the APC meeting, there were concerns on the reductions in the AD/CFD budget. At this time, we do not have any AD/CFDs in development and these funds would not be used this year. The Engineering Department will continue to request $250,000 for the Community Investment Program budget in future years. Attachments: Gateway Pacific’s Proposal dated March 7, 2014 Scoring Results Figure of Siphon Lane Pump Station Area Budget Amendment Pumping cost summary

Staffreportboardsiphonlanepumpstation.docx

APPENDIX A

budgetamendmentdsbcpumpstation.xls 6/18/2014

DATE : 17-Jun-14TO : Board of DirectorsFROM: Remleh Scherzinger, General Manager Initials:

Gary King, Engineering Manager

A budget amendment is hereby requested for the following items:

1) Budgeted capital expenditure line item:Dept Acct # Increase/(Decrease)

a) 10151 6962 Hwy 49 & Christian Life (170,000.00)$ b) 10151 52801 Raw Water Master Plan (150,000.00)$ c) 10151 8348 Cedar Ridge to East Bennett (200,000.00)$ d) 10151 Rattlesnake/BEP (375,000.00)$ e) 10151 AD/CFD Projects (125,000.00)$ f) 10191 52615 Reservior Cleaning ( Loma Rica) (340,000.00)$ g) 10191 2015 Budget (1,190,000.00)$

2) Unbudgeted capital expenditure line item:Department Account # Increase/(Decrease)

a) 10151 6970 Siphon Lane Pump Station 2,550,000.00$

1.a Project to be deferred due to the more critical need of the Pump Station Project1.b Project to be deferred due to more critical need of the Pump Station Project1.c Project to be deferred due to more critical need of the Pump Station Project1.d Rattlesnake project was not envisioned during 2014 and will be delayed till completioof the Alta Sierra/ LOP BEP project1.e. No AD or CFD projects are being worked on since projects are being developedusing the DFWLE program1.f. Reservior cleaning to be deferred due to drought issues1.g. Cash flow is expected to be in 2015.

APPROVALS:Date AGM/FM Initials Approved/Denied

Level I

Level II

Level III

Signature

NEVADA IRRIGATION DISTRICT

BUDGET AMENDMENT REQUEST

Account Name

Account Name

Item Description T&S C&D Gateway Hansen

3 3 4.5 1

4.5 3 4.5 4

4 2 4 4

4 4 5 4

3.9 3.0 4.5 3.34

3 3 4 2

4.5 3 4.5 4.5

3.0 3 4 4

4 4 4 5

3.6 3.3 4.1 3.9

3 1 4 2

4.5 2 4.5 4

3 1 5 4

5 2 5 4

3.9 1.5 4.6 3.5

3 3 4 0

4.5 2 4.5 3.5

3 0 3 3

5 2 5 3

3.9 1.8 4.1 2.4

$3,573,672 $2,286,848 $2,497,738 $3,552,184

3.2 5 4.6 3.2

A 15% of Total Score 0.58 0.45 0.68 0.49B 15% of Total Score 0.54 0.49 0.62 0.58C 15% of Total Score 0.58 0.23 0.69 0.53D 5% of Total Score 0.19 0.09 0.21 0.12E 50% of Total Sore 1.60 2.50 2.29 1.61

T&S C&D Gateway Hansen3.50 3.75 4.48 3.3270% 75% 90% 66%

DS PUMP STATION - PROPOSAL EVALUATION3/18/2014

TOTAL SCORE (0-5)

Consultants

A

Design-Build team capabilities,expertise, related experience,references and size of staff

B

Design-Build team-relatedexperience, references,qualifications, expertise, andpast performance with pump station design

C

Understanding of the necessary components of the pump station & construction of proposed work item task listing Schedule, Proposal Response and thoroughness

D

Present work load and ability to meet the time Schedule requirements indicating staff commitment to this project

E Cost of Project

To: Nevada Irrigation DistrictFrom: Gateway Pacific / Bennett Engineering Team

PROPOSAL

DS Pump Station Design-Build Project

March 7, 2014

Proposal for the Nevada Irrigation District

DS Pump Station Design-Build Project

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT

PROPOSAL

Table of Contents

Design-Build TeamProject ExperienceReferences

Key Personnel

UnderstandingConceptual LayoutSchedule

Availability

Cost Proposal

Resumes

Section A

Section B

Section C

Section D

Section E (Separate, Sealed Envelope)

Appendix

March 7, 2014

Adrian Schneider,Nevada Irrigation District1036 West Main StreetGrass Valley, CA 95945

Re: DS Pump Station Design-Build Project Dear Mr. Schneider and Members of the Selection Committee:

We have assembled a design-build team for the DS Pump Station that has the best experience to provide you with an optimal project—on schedule and within budget. This Gateway Pacific/Bennett Engineering Services (BEN|EN) team is the same design-build team that is successfully completing the Banner-Taylor Reservoir project for the Nevada Irrigation District (NID).

We believe we are uniquely qualified for this project. Some of these qualities include:

f We have developed a thoughtful approach to completing the project that we believe will be the most cost-effective project for the District.

f We bring together a highly qualified group of professionals who are able to provide the technical expertise this project requires while delivering excellent service to the District. You will see throughout our proposal quotes from current and past clients that attest to the level of service and attention we provide throughout the life of a project. We encourage you to call our references and ask about our work quality and our attention to client needs.

f This is precisely the type and size project that both Gateway Pacific and the BEN|EN design team is set up to complete.

f Both BEN|EN and Gateway Pacific have staff available to begin this project immediately and complete construction on time and within budget.

f As a Placer County firm, our design staff’s location will contribute to our responsiveness and accessibility.

This proposal is valid for 90 days. We acknowledge receipt of Addendum 1. We request no revisions to the District’s Construction Services Agreement. We are available at any time to provide additional information or answer questions you may have. Thank you for your consideration.

Sincerely,Gateway Pacific Contractors, Inc.

Evan Lundin CEO/President

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 1

PROPOSAL

Team Capabilities | Project Experience | References

Section A

Team Capabilities

Gateway Pacific ContractorsGateway Pacific Contractors, Inc. was founded on a cornerstone philosophy of satisfying our clients’ needs by creating a safe workplace, exceptional quality, commitment to schedule, and a fair price. Gateway Pacific is a true general contractor. We self-perform the vast majority of our own projects with our own craftspeople and supervisors. On a typical project this might include the site work, structural concrete, and complete mechanical package among other specialties. This self-performing approach allows us better overall control of our projects, keeps us competitive and offers the broadest base of opportunity for our staff therefore providing the owner with quality assurance.

Established in 1987, Gateway Pacific specializes in the construction of water and wastewater projects on the west coast. Gateway’s project bids range from $1 million to $40 million, and our annual revenues range from

DESIGN-BUILD TEAM LEAD

Gateway Pacific ContractorsEvan Lundin

Project Oversight and Management

SITE/CIVIL DESIGN

Orin Bennett, PESteve Ainsworth, PEStacey Bennett, PEMatt Wheeler, PE

BEN|EN

STRUCTURAL ENGINEERING

Brad Friederichs, SE

VE SOLUTIONS

GATEWAY PACIFIC CONSTRUCTION MANAGEMENT

Gary Bechtel

DESIGN SERVICES CONSTRUCTION SERVICES

ELECTRICAL ENGINEERING

Jeremy Pollet, PE, CAP

CONTROL POINT

PROJECT MANAGERJay Hall

PROJECT SUPERINTENDENTGary Heim

GATEWAY PACIFIC CONTRACTORS

CONSTRUCTION SERVICES

Various Staff

GATEWAY PACIFIC

SUBCONTRACTORS AND SUPPLIERS

See Bid Documents

Project Organization

“The project was completed ahead of schedule and with virtually no net change orders due to the expertise, experience and cooperativeness of the team at Gateway Pacific.”

-Bill Moorhead, P.E., Principal Engineer, Project Manager, City of Anaheim

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 2

$20 million to $40 million. Gateway’s staff size ranges from 40 to 80 workers, including 16 salaried employees.

Most of our projects are improvements and additions to existing treatment plants, pump stations, and reservoirs, where it is imperative to keep the existing facilities online. Many of these projects require construction in residential neighborhoods. Many of our projects have been constructed adjacent to homes and in neighborhood parks.

Bennett Engineering Services (BEN|EN)Providing high quality civil engineering services to cities, counties, special districts, universities, private companies, and other professionals has always been the firm’s focus. BEN|EN takes pride in finding innovative and cost-effective engineering solutions to roadway, water, wastewater, drainage, site improvement, and other important infrastructure projects.

What sets the firm apart is its ability to partner with clients early in project development and retain that partnership through construction.

Orin Bennett started his engineering practice in 1979. Through ownership transitions Bennett Engineering Services, as it is organized today, has been providing service since 1995. The firm’s culture includes a commitment to staff retention. This provides an experienced and highly technical project team. They believe offering dedicated staff and assuring a cohesive team from project inception to completion maximizes client confidence.

The firm is led by talented and highly-experienced, licensed professionals. BEN|EN is a California certified Small Business Enterprise (SBE), #52302.

VE SolutionsBrad Frederichs, SE, has more than 30 years of experience providing structural consulting services. He has assisted both public and private clients with their structural engineering challenges. By providing technological leadership in a responsive manner, he has saved his clients a significant amount in building costs. At the same time, his design services have improved the soundness and safety of those structures. He will be responsible for quality control/quality assurance of the structural building design. He provided the structural design for the HRNPS for Roseville, the Butler Circle Pump Station for Placer County Water Agency (PCWA), and the Bickford Ranch Tank for PCWA.

Control Point Engineering Jeremy Pollet, PE, CAP, will serve as electrical engineer. Jeremy has 15 years of electrical engineering consulting experience specializing in electrical design, process controls and automation, CADA systems, and project management. Jeremy’s industrial sector experience includes water and wastewater treatment plants, pipelines, and pump stations.

In performing their duties, Gateway Pacific Contractors...showed the highest degree of professionalism, skill, and expertise in the construction of a very complex and politically sensitive project. This project was a critical project for the City of Anaheim as a key component in our water system and was situated in a very challenging location that required a great deal of sensitivity to the public and high degree of responsiveness from the contractor. Gateway Pacific performed exceptionally to these demands. The project was completed ahead of schedule and with virtually no net change orders due to the expertise, experience and cooperativeness of the team at Gateway Pacific. - Bill Moorhead, PE, Principal Engineer, City of Anaheim

“As the project manager of the Highland Reserve North Pump Station project, I appreciated Steve Ainsworth’s pursuit of new and innovative solutions to hydraulic problems while staying within a limited project budget.” - Ken Glotzbach, City of Roseville

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 3

Responsibilities

FIRM ROLE RESPONSIBILITY

Gateway Pacific General Contractor Project management and coordination, scheduling, submittals, sitework, concrete work

Bennett Engineering Services

Lead Design Firm Coordinate geotechnical engineering, design site civil, yard piping, and water main

VE Solutions Structural Engineering

Structures

Control Point Engineering

Electrical Engineering

Electrical, Instrumentation

Gateway PacificGateway Pacific will provide project team leadership and serve as the main contact with the District to provide the successful completion of the DS Pump Station design-build project. Gateway Pacific will oversee the entire project coordination including design and construction. Gateway will self-perform all site shoring and concrete work, which entails the major components of the project, thus ensuring the District the utmost quality and efficiency. Gateway will coordinate and manage all submittals, sitework and specialized subcontractors, billings, and ensure the project schedule is met. Gateway’s expertise includes vertical shoring, concrete water retaining structures, installation of mechanical equipment and piping, project oversight and coordination.

Gateway’s success has been achieved in large part due to our attention to financial basics. We have skillfully invested in our own future by concentrating on those areas we know we can perform successfully. In addition, skilled management personnel carefully monitor the progress of every project, regardless of its size. This attention to detail has set Gateway apart from our competition.

The highly specialized projects that Gateway Pacific has managed and constructed have contained elements of virtually every type of mechanical, structural, architectural, and sitework disciplines imaginable. The demands of the projects Gateway has constructed have enabled the company’s employees to develop not only excellent construction skills, but also keen problem solving skills. Gateway envisions its customers’ problems as unique challenges to be solved through teamwork.

Bennett Engineering ServicesBEN|EN staff worked with Gateway Pacific on a successful design-build tank construction project for NID and have provided water facility services for Placer County Water Agency, the City of Roseville, Citrus Heights Water District, and other local agencies.

BEN|EN will take the lead in the engineering for the site work, grading, yard piping, system hydraulics, electrical, structural, and coordination of engineering efforts.

“On the City’s DPPS project, I appreciated Steve’s knowledge of VFD pump operations and his ability to listen to and communicate with our operations staff.” - Jim Mulligan, City of Roseville

“Both projects (San Juan Reservoir and Elkhorn Reservoir) were completed with very few changes orders and no claims. Gateway Pacific’s professional experience and problem-solving attitude contributed greatly to the successful completion of these two projects for the city. I would not hesitate to work with Gateway Pacific again on another project for the city and would highly recommend them to other agencies.” - Dan Sherry, PE, City of Sacramento

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 4

BEN|EN efforts will be managed by Steve Ainsworth who has direct, recent experience working on pump station design and construction projects very similar to the DS Pump Station project.

VE SolutionsVE Solutions has worked with BEN|EN on many projects providing structural engineering on buildings very similar to the DS Pump Station, including the Gold Run and Lincoln Metering and Hydroelectric Station projects for Placer County Water Agency. VE Solutions provides complete, thorough designs that reflect their years of experience. They have assisted both public and private clients with their structural engineering challenges. By providing technological leadership in a responsive manner, they have saved their clients a significant amount in building costs. At the same time, their design services have improved the soundness and safety of those structures.

Control Point Engineering Jeremy Pollet, PE, CAP, has worked with BEN|EN on many previous projects. He will provide electrical engineering design and construction management for the limited electrical and control facilities.

Engineering Design David Hardin, EIT, Project EngineerJustin George, EIT, Project EngineerCheryl Spatz, EIT, Project EngineerBrandon Michel, CAD Designer

Support StaffJenn Goodwin, Business ManagerAva Roberts, Project AccountantJennifer Ayer, Office ManagerKarman Cates, Marketing Manager

Firm Size

Gateway Pacific Contractors, Inc.

Sacramento OfficeEvan Lundin, PresidentGary Bechtel, Vice President – OperationsJay Hall, Project ManagerTim Gangel, Project ManagerDoug Ormond, Office EngineerChristine Cesa, ControllerJune Roitman, Contract AdministratorEmma Spinks, Payroll Clerk

Job SitesGary Heim, Project SuperintendentRamone Noska, Project SuperintendentGene Gregory, Project SuperintendentTim Brown, Project SuperintendentJeff Wintemute, Project SuperintendentApproximately 40 additional craftsmen. (Laborers, Carpenters, Operators, Finishers, etc.)

Bennett Engineering Services

Project Management and Engineering DesignOrin Bennett, PE, President, Principal EngineerLeo Rubio, PE, Vice President, Project ManagerSteve Ainsworth, PE, Senior Engineer Brian Martin, PE, Senior EngineerSteve Speights, PE, Senior EngineerKit Burton, PE, Senior EngineerTrin Campos, PE, Project DirectorMatt Wheeler, PE, Project DirectorSteve Lamb, PE, Project EngineerStacey Bennett, PE, Project EngineerMike Micheels, QSD/P, Project Manager

VE SolutionsBrad Friederichs, PE

Control Point Jeremy Pollet, PE

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 5

PROPOSALPROPOSAL

Page 5

Gateway Pacific has constructed numerous water, wastewater, storm water and sludge pump stations. The majority of the water storage reservoirs we have constructed, have accompanying pump stations included as part of the contract. Gateway Pacific has furnished and installed self-cleaning screens similar to the Pinewood Pump Station Screens.

Gateway Pacific has constructed pump stations as large as 80 cfs. Several of the pump stations are dual-zone pump stations similar to the requirements of the DS Pump Station. We have installed vertical turbine pumps as large as 20 cfs and high pressure pumps up to 500 psi.

Gateway Pacific has a good relationship with all of the major water pump manufacturers and suppliers. There are many factors that can affect the efficiency of vertical turbine pumps; we have worked closely with the design engineer, pump manufacturer and owners to get the highest efficiency possible.

Pump stations are successfully built by a combination of self-performance capabilities and proven project management skills. Gateway Pacific can self-perform excavation, site utilities, piling, concrete, carpentry, mechanical piping, and the installation of pumping, mechanical, and electrical, and plumbing equipment. We also have extensive experience coordinating with the best manufacturers and electrical engineering firms in the industry to fulfill these requirements.

Team ExperienceThe team of Gateway Pacific Contractors and Bennett Engineering is currently working together on Nevada Irrigation District’s (NID) design-build of the Banner Taylor Tank Replacement Project. This project consists of two pre-stressed concrete reservoirs, foundation improvements, piping; electrical and controls modifications and civil work inside a foot print of the existing earthen reservoir while keeping half of the reservoir in service. It also required that the project be designed and constructed to meet NSF-61 standards for potable water. We had no problems meeting the California Department of Public Health approval of concrete water tanks for use in public potable water systems. We have completed 90 percent of the design and have completed and put in service the first 4.6MG Tank. The second Tank 5.9MG will have the concrete completed in March and be ready to be prestressed. All essential water main piping is complete.

“The excellent design was made even better during construction which saved cost. Gateway was always reasonable in their dealings with the city and we were able to establish a high level of confidence and trust. I do not hesitate to recommend them to anyone considering similar projects. We feel fortunate to have been able to complete two projects with them and hope they keep bidding our projects.” - Kevin Burke, Public Works Supervisor, City of Davis

“Gateway has demonstrated and maintained an excellent approach to problem solving and proactive resolution of not only the usual construction issues and challenges, but to an array of uncommon and unexpected issues and challenges on both projects...I highly recommend Gateway Pacific be considered for...particularly in design-build delivery programs.” - David C. Lee, PE, Senior Vice President, Consolidated CM

Project ExperienceReferences

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 6

The Banner Taylor project is in a residential neighborhood and is only accessible through residential streets and with homes adjacent to the site. Gateway Pacific understands the significance of working in close proximity to homes. Our project superintendent has built a good working relationship with the neighbors and there have been no complaints from them.

Gateway Pacific and Bennett Engineering are also currently working on a design-build 6MG Water Reservoir for the City of Santa Cruz the Bay Street Reservoir Replacement Phase 3 Design-Build Project. We have completed the demolition work and have completed an extensive geological study because of the Karst Geology formation under the tank. We are nearing the completion of that study and believe we have a solution that will save the owner over one million dollars compared to the other proposed solutions from our competitors. On this same site Gateway Pacific and Bennett Engineering redesigned a Water Booster Pump Station for the City of Santa Cruz that had a large footprint and made it difficult to access for maintenance. This resulted in a significant cost saving to the owner and a better solution for the operations staff.

Gateway Pacific and Bennett Engineers were contracted by MICROMIDAS (www.micromidas.com) to help design and build a $3.5 million pilot plant in West Sacramento. The plant transforms corrugated cardboard into paraxylene, a chemical that is used to make plastic bottles. This was a fast track project. The project had ongoing modifications because the system was based on newly formulated process. We were able to work with Micromidas’ chemists and scientists on a daily basis to cost-effectively complete the plant to their tight specifications. The ultimate result was to prove that a large scale plant would work and be cost-effective in making paraxylene, which is normally made from oil.

“Gateway Pacific...was excellent to work with, very professional, organized, produced high quality product, on schedule and on budget.” - David C. Lee, PE, Senior Vice President, Consolidated CM

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 7

Project Description Construct 4MG pre-stressed concrete reservoir and all associated support facilities and utilities.

ff City of Davisff Michael Mitchell ff 530.757.5686 ff $6.2 million | 8/09 - 5/11 ff Ed Gomez, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

East Area Tank and Booster Pump StationDavis, CAGateway Pacific

2011 Project of the Year, Sacramento Chapter, American Public Works Association

Project Description Construct a raw water pump station.

ff Irvine Ranch Water Districtff Steve Bomkamp ff 949.453.5627ff $500,000 | 12/11 – 12/12ff Tim Brown, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Lake Forest Well No. 2Irvine, CAGateway Pacific

Projects and References

Project Description Replace earthen reservoir with one 4.6MG and one 5.9MG prestressed concrete tank and associated piping.

ff Nevada Irrigation Districtff Doug Roderick | Gary Kingff 530.271.6866 | 530.273.6185ff $7.9 million | 7/12 - Presentff Gary Heim, Project Superintendent | Orin Bennett, PE |

Steve Ainsworth, PE (Design Manager) | Stacey Bennett, PE

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Banner-Taylor Reservoir ReplacementNevada City, CAGateway Pacific | BEN|EN

Project Description Construct 6MG prestressed concrete tank for drinking water storage, plus associated facilities and utilities. During the course of the project, the pump station on this project ($1.5 million) was completed on a design-build basis by Gateway Pacific/BEN|EN.

ff City of Santa Cruzff Doug Valbyff 831.420.5212ff $9.9 million | 4/12 - 2/14ff Gene Gregory | Jay Hall | Orin Bennett, PE | Steve Ainsworth,

PE (Design Manager) | Stacey Bennett, PE

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Bay Street Reservoir Replacement - Ph 2 Santa Cruz, CAGateway Pacific | BEN|EN

Project Description Construct chemical process plant to convert corrugated cardboard into paraxylene.

ff Micromidas, Inc.ff John Bissell, CEOff 530.219.9103ff $3.5 million | 2/12 - 1/14ff Ed Gomez | Gary Bechtel | Orin Bennett, PE | Dave Harden,

EIT

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Micromidas Pilot PlantWest Sacramento, CAGateway Pacific | BEN|EN

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 8

Project Description Construct 5MG Prestressed Concrete Reservoir, Transmission Line, Sitework & Irrigation Facilities.

ff Irvine Ranch Water Districtff James Loomis ff 707.449.5346ff $8.2 million | 6/05 – 4/07ff Gene Gregory, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

McMurtry ReservoirVacaville, CAGateway Pacific

Project Description Construct 3.5MG domestic water reservoir, 2.2MG reclaimed water reservoir and domestic and reclaimed water booster pump stations.

ff Irvine Ranch Water Districtff Bill Stewart ff 949.453-5610 ff $10 million | 7/05 – 7/07ff Tim Gangel, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

PA 6 Zone 4&C Reservoir, Zone 4-6 BPS, Zone C-D BPSIrvine, CAGateway Pacific

Project Description Construction of the Chico WPCP increasing the nitrification treatment capacity to 12 MGD.

ff City of Davisff Quene Hansen ff 530.879.6909ff $38.5 million | 10/07 – 12/10ff Jay Hall, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Water Pollution Control Plant 12MGD ExpansionChico, CAGateway Pacific

Project Description Construct 3MG water storage reservoir on steel piles, booster pump station, control building and landscaping.

ff Irvine Ranch Water Districtff Warren Peterson ff 916.808.1910ff $6.3 million | 5/06 – 1/08ff Gene Gregory, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Elkhorn ReservoirSacramento, CAGateway Pacific

Project Description Destruction of existing well 78 and drilling and equipping the new well 78.

ff Irvine Ranch Water Districtff Jacob Moeder ff 949.453.5554 ff $2.8 million | 2/11 – 7/12ff Tim Brown, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Well 78 Replacement ProjectIrvine, CAGateway Pacific

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 9

Project Description Construction of 3 recycled water pump stations, 3 prestressed concrete recycled water storage reservoirs/improvements to the existing tertiary treatment facilities.

ff City of Coronaff Bill Weinstock , Parsons ff 949.453.5586ff $18.1 million | 1/04 – 3/07ff Jeff Wintemute, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Citywide Recycled Water Facilities, Project “A”, Contract 3Corona, CAGateway Pacific

f ASCE 1999 Award of Excellence, 33.0MG Twin Oaks Reservoir, San Marcos, CA

f ASCE 2004 Award of Merit, Gano Reservoir & Pipeline project Rancho Bernardo, CA

f APWA 2005 Project of the Year, Otay Water Treatment Plant Expansion, San Diego, CA

f APWA 2009 Project of the Year, Stoneridge Water Storage Facility, Roseville, CA

f APWA 2011 Project of the Year, East Area Tank and Booster Pump Station

Gateway Pacific Industry Recognition

Project Description Construct Hydropneumatic Water Pump Station.

ff Corky McMillin Construction Services, Inc.ff Gary Silverman, PBS&J ff 858.514.1037ff $1.6 million | 8/04 – 1/06ff Tim Gangel, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Rolling Hills Hydropneumatic Water Pump StationChula Vista, CAGateway Pacific

Project Description Construction of a 100-foot diameter Secondary Clarifier, Return activated sludge pump station, and site improvements.

ff Irvine Ranch Water Districtff Kelly Lew ff 949.453.5586ff $8.8 million | 8/06 – 12/08ff Jeff Wintemute, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Michelson Water Reclamation PlantIrvine, CAGateway Pacific

Project Description Demo existing structures and construct new site structures and improvements.

ff City of Willowsff Kent Perkes ff 530.934.7041 ff $7.8 million | 6/05- 2/07 ff Gary Heim, Project Superintendent

ClientReferenceContact InfoConst. Cost/DatesKey Staff

Willows WWTP Improvement ProjectWillows, CAGateway Pacific

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 10

Project Description While with the Las Vegas Valley Water District, Steve Ainsworth was engineering manager for the design and construction management of the Oakey Boulevard Reservoir and pumping station for the Las Vegas Valley Water District. The project consists of a three-million-gallon, prestressed, post-tensioned, circular, concrete reservoir with 3,000 feet of 72-inch diameter steel water transmission pipeline and a water pump station with seven 900 hp vertical turbine pumps.

ff Las Vegas Valley Water Districtff Alan Walter, Chief Engineer (Retired)ff 989.728.5171ff $700,000 ff Engineering Manager: Steve Ainsworth

ClientReferenceContact InfoConst. Cost/Key Staff

Oakey Blvd Reservoir and Pumping StationLas Vegas, NVBEN|EN

Project Description While with the Las Vegas Valley Water District, Steve Ainsworth was assistant design engineer and construction engineer for the design of drilling and equipping of Water Well 1A for the Las Vegas Valley Water District. This well is located within a residential development and was designed with special consideration for sound attenuation and heat dissipation. The well provides 2,200 gpm from a vertical turbine pump set at a depth of 600 feet. The well site included chlorine injection and a pressurized 20 minute contact tank.

ff Las Vegas Valley Water Districtff Alan Walter, Chief Engineer (Retired)ff 989.728.5171ff $700,000 ff Assistant Design Engineer and Construction Engineer: Steve

Ainsworth

ClientReferenceContact InfoConst. CostKey Staff

Well 1ALas Vegas, NVBEN|EN

Project Similarities f Large Vertical Turbine Pumps f Surge Control f Flow Control f Cooling Issues

Project Similarities f Large Vertical Turbine Pumps f Sound Attenuation f Residential Neighborhood

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 11

Project Description While with the Las Vegas Valley Water District, Steve Ainsworth was assistant design engineer and construction engineer for the design of drilling and equipping of Water Well 7A for the Las Vegas Valley Water District. The well was equipped with a 600 hp engine-driven pump, a right angle gear drive, and a 600 hp electric motor on top of the gen drive. The well provides 2200 gpm from a vertical turbine pump set at a depth of 600 feet.

ff Las Vegas Valley Water Districtff Alan Walter, Chief Engineer (Retired)ff 989.728.5171ff $700,000 ff Assistant Design Engineer and Construction Engineer: Steve

Ainsworth

ClientReferenceContact InfoConst. CostKey Staff

Well 7ALas Vegas, NVBEN|EN

Project Similarities f Large Vertical Turbine Pumps f Engine-Driven Pump f Right-Angle Gear Drive f Concrete Masonry Unit Building Housing Engine f Cooling Issues

PROJECT EXPERIENCE

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 12

BEN|EN

Butler Circle Pump Station

ClientReferenceContact Info

Project Similarities f Diesel Engine f Air Quality Permitting f Concrete Masonry Unit Building

f Close proximity to neighbors

Project Description: BEN|EN analyzed the PCWA Water Model, to determine the most appropriate means of adding PCWA facilities to provide service to the project with four pressure zones (one of which is a pumped closed zone). The pre-design effort included a report on projected demands, engineering calculations and use of PipeOpt for pipe sizing, and meetings with PCWA operations staff to define the specific requirements for the system. As a part of this process, BEN|EN proposed the use of packaged pumping stations, saving 20% on the construction costs and months on the construction time.

The project included a concrete masonry unit building with roof hatches for pump removal, pump controls, startup, SCADA, and back-up power via a Tier III diesel gen-set. Services included air quality permitting for the diesel gen-set. Construction was 90% completed as of July 2008. Final construction is currently on hold due to funding.

Challenges | Solutions: Low cost requirements combineed with fast construction. The issues were resolved by designing a factory-built station.

f Placer County, CA f $450,000 f 2005-2007

f Orin Bennett, PE | Steve Ainsworth, PE (Project Manager) | Stacey Bennett, PE | VE Solutions: Brad Friederichs, SE

f Factory Packaged Pump Station | PipeOpt Analysis f Civil Engineering | Technical Reports | Design | SWPPP | Construction Management

f Placer County Water Agency (PCWA) f Ross Hooper, Assoc Engineer - PCWA f 530.823.4886 | [email protected]

Key Staff

Key FeaturesServices

LocationConst. CostDates

PROJECT EXPERIENCE

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 13

BEN|EN

Highland Reserve North Pump Station

ClientReferenceContact Info

Project Similarities f Confined Footprint f 3 Pumps f Control Valves

Project Description: The project included integration of a new pump station into the City’s extended period H2OMAP water modeling for pumping system analysis and the engineering design and construction management of a pre-packaged pump station with three VFD operated pumps. The HRNPS project was originally conceived by the City as a built-in-place pump station. BEN|EN designed a packaged pump station and building, meeting the City of Roseville design standards. The project was publically bid listing the three pre-approved package pump station suppliers and saved the City over $200,000 in construction costs. In addition to cost savings, construction quality was improved and construction time was reduced. The project included integration of the pump station telemetry with the City SCADA system.

Challenges | Solutions: The City of Roseville had collected impact fees from developers to construct a pump station to serve Zone 4. For interim service, water was provided by PCWA. When the development was completed, the City was to construct the pump station and cease purchasing water from PCWA. However, it was discovered that the fees had been too low and not enough funds were collected to construct the pump station. The factory-built “packaged” pump station design greatly reduced construction costs and time, yet maintained quality.

f Roseville, CA f $497,500 f 2005-2007

Key StaffKey FeaturesServices

f Orin Bennett, PE | Steve Ainsworth, PE (Project Manager) | VE Solutions: Brad Freiderichs, SE f Packaged Pump Station f Water Modeling | Planning | Engineering Report | Civil Design | Pre-Qualification of Suppliers |

Bidding | Construction Management

f City of Roseville f Cathy Lee, Senior Engineer f 916.746.1703 | [email protected]

LocationConst. CostDates

PROJECT EXPERIENCE

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 14

Project Similarities f Variable Flows f Flow Solutions

Project Description: The existing control strategy had become unstable for the station that pumps to Roseville’s closed pressure Zone 2 during the transi-tion from summer to winter demands. BEN|EN performed troubleshooting for the Water System Operations staff for the Zone 2 DPPS pumps, to analyze the cause of abnormal operation of two VFD controlled pumps, and to determine a course of action to remedy the problem.

BEN|EN interviewed the station operations and maintenance staff to get an overall assessment of the problems, reviewed the SCADA-reported operating conditions, pump shop drawings and system control strategies, and the station’s pump curves. We then recommended several levels of modifications to the op-erations strategy. Based on pump curves obtained from the original pump tests, engineering calculations were made to provide a pump station system curve to display the pressure/flow characteristics of the VFD-driven pumps at a range of speeds. This system curve was then used to analyze the problems with the existing control strategy. Three system-fix options were prepared, requiring small to large budgets and requiring oversight ranging from manual to fully automatic, respectively.

Challenges | Solutions: This effort involved extensive analysis to find the cause of abnormal operation of two VFD-controlled pumps, and to determine a course of action to remedy the problem. The Zone 2 DPPS has since successfully made the transition from summer to winter demands.

VFD Pump Curve

Zone 2 Dual Purpose Pump StationBEN|EN

ClientReferenceContact Info

f Roseville, CA f $14,000 f 2006-2007

Key StaffKey FeaturesServices

f Orin Bennett, PE | Steve Ainsworth, PE (Project Manager) | Stacey Bennett, PE f Water Systems Analysis f Water System Modeling | Control System Troubleshooting | Control Strategy Review

f City of Roseville f Jim Mulligan f 916.774.5668 | [email protected]

LocationContract CostDates

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 15

Project Description Designed the electrical facilities for 4 lift stations. Projects included contract drawings and specifications and the electrical scope included the PG&E metering section, standby generator with automatic transfer switch, pump control panel, power distribution panel, and associated generator building electrical and lighting infrastructure.

ff City of Auburn ff Bernie Schroederff 530.823.4211 | [email protected] Jeremy Pollett, PE, CAP

ClientReferenceContact InfoKey Staff

Vintage Oaks Lift StationAuburn, CAControl Point Engineering

Project Description Designed, installed, programmed, and integrated a non-proprietary, state-of-the-art SCADA System for the City’s Water Wells, Sewage Lift Stations, and Storm Drain Stations. Hardware consisted of Allen-Bradley’s MicroLogix PLC Platform and Motorola Canopy Ethernet Radios that were installed on the top of the City’s 125 ft water tower.

ff City of Davis Public Worksff Dianna Jensen, Principal Civil Engineer ff 530.757.5686 | [email protected] Jeremy Pollett, PE, CAP

ClientReferenceContact InfoKey Staff

SCADA Pilot ProjectDavis, CAControl Point Engineering

Project Description Developed and maintained SCADA graphics and auto-dialer systems, performed field tests, assisted in electrical and SCADA system start-ups, and reviewed/evaluated other consultants work.

ff City of Woodland ff Mark Hierholzer, Chief Plant Operatorff 530.406.5112 | [email protected] Jeremy Pollett, PE, CAP

ClientReferenceContact InfoKey Staff

Control Systems Replacement Wastewater Treatment Plant Woodland, CAControl Point Engineering

Project Description Designed the electrical facilities for two canal check/flow control structures. Project included contract drawings and specifications and the electrical scope included automated control panels, power distribution panels, radio telemetry, and associated area lighting.

ff Arvin-Edison Water District ff John Duffy, P.E. ff 661.616.5900 | [email protected] Jeremy Pollett, PE, CAP

ClientReferenceContact InfoKey Staff

Canal Check StructuresBakersfield, CAControl Point Engineering

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 16

PROPOSAL

Key Personnel

Section B

Key PersonnelResumes for all of the teams key personnel can be found in the Appendix. Brief descriptions of each key team member and their responsibilities for this project follow:

Evan Lundin, President/Lead Estimator | Gateway PacificEvan holds a BS in Construction Management from Kansas State University. Founder of Gateway Pacific Contractors. Has been involved in all of Gateway Pacific’s projects from design and estimating to construction. On this project Evan will take the lead in design and estimating of the project, He will stay up to date with the project and if any problems arise, will be available to consult.

Gary Bechtel, Operations Manager, Owner | Gateway PacificGary holds a BS in Civil Engineering from Lehigh University and has been with Gateway Pacific since 1985 gaining experience in construction as Project Engineer, Project Superintendent, Project Manager and Vice President, Operations manager. Gary also serves as Gateway Pacific’s safety manager and scheduling manager participating in the development of each project’s CPM schedule. On this project for NID, Gary will oversee the project management with Jay Hall.

Jay Hall, Project Manager/Estimator | Gateway PacificJay holds a BS in Civil Engineering from UOP and joined Gateway Pacific in 2000 as a Project Superintendent, Project Manager and Estimator. Jay brings vast expertise in earthwork, shoring and underground piping to the Gateway team. Jay serves as our SWPPP Manager (QSP certified) coordinating and monitoring the erosion control measures on our projects. Jay will take the lead on this project with NID coordinating the field work with our project field superintendent.

Doug Ormond, Project Engineer | Gateway PacificDoug holds a BS degree in Construction Management from BYU and has been with Gateway Pacific for 20 years. Doug handles all project documentation

with the Design Engineer/Construction Manager including Requests for Information, Clarifications and Submittals. Our entire submittal process is streamlined due to Doug’s detailed review of all submittal documents/manufacturer data prior to submittal to design engineer helping with coordination of timely deliveries and field installation of project components. Doug is experienced with many forms of project management software however in house, Gateway Pacific utilizes Timberline Project Management.

Gary Heim, Project Field Superintendent | Gateway PacificGary has been a Superintendent for Gateway Pacific for over 25 years. He has been involved in many of our Concrete Water Reservoirs. He will be involved in the Design Phase and the Estimate to review constructability of the project. He will be fully in charge at the site for Safety, Schedule, Quality, and Cost.

Orin Bennett, PE, Principal Engineer | BEN|ENOrin will serve as Principal Engineer and will assure staffing availability throughout the project, and the accuracy of deliverables. Orin has more than 40 years of civil engineering experience, including extensive experience with water reservoir and site work design. He leads the company serving mostly local public agencies including Nevada Irrigation District, Placer County, City of Lincoln, City of Auburn, City of Sacramento, Placer County Water Agency, and others. Orin has designed, managed, and directed water projects throughout his career. He is very familiar with the design challenges of water facility improvement projects.

Steve Ainsworth, PE, Senior Engineer | BEN|ENSteve will ensure the soundness and constructability of the design. Steve has more than 36 years of civil engineering experience in design and construction management of water system projects, including water main replacements, water reservoirs, both electric and engine-driven pump stations, in-conduit hydroelectric generation systems, storage facilities, cost-benefit analysis, water system modeling, and related engineering activities. Throughout his career, Steve has specialized in engineering for water systems. He

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 17

has published and presented papers on pipeline size optimization to minimize cost and maximize energy. Steve is also experienced with public presentations, agency negotiations, cost estimating, and consultant management. With extensive experience in permit acquisition and compliance with federal, state and local policies, he is experienced in negotiating with agency and elected officials to obtain the best possible project conditions. He has developed successful methods for gaining active support from surrounding property owners, and other organized groups.

“As the project manager for the Cascade Dechlorination project, Steve provided innovative solutions for several engineering hydraulic constraints encountered during design. I appreciated the outside of the box thinking” - Bryan Buchanan, City of Roseville

“As the project manager for the Highland Reserve North Pump Station project construction, Steve provided innovative solutions to financial and water system constraints that resulted in a successful project that was completed within a tight budget” - Cathy Lee, City of Roseville

Matthew J. Wheeler, PE, Project Engineer | BEN|ENMatthew Wheeler has more than 16 years of experience in engineering consulting. His experience includes water distribution system design and analysis; stormwater and wastewater collection system design and analysis; master plan reviews and updates; grading, utility, and erosion control design; district engineering; project management; capital improvement plan recommendation and design; presentations to city councils, boards of directors, planning commissions, and the public; expert witness; and negotiations with State and regional water quality control boards for wastewater and stormwater discharge permits.

Matthew’s district engineering experience includes development plan review; water master plan and system model update; wastewater treatment and disposal system evaluation; strategic planning

assistance; cost estimating; and constructability analysis. He has also successfully negotiated project conditions and acceptance with the Army Corps of Engineers, Department of Fish and Game, Regional Water Quality Control Board(s), State Water Resources Control Board, county building departments and planning commissions on behalf of clients.

Stacey Bennett, PE, Project Engineer | BEN|ENStacey Bennett will serve as Project Engineer, and will provide design and coordinate with electrical and structural subconsultants to produce a cohesive design. Stacey has more than nine years engineering experience including drainage analysis and design, water and wastewater design, and commercial development. Responsibilities include research, conceptual analysis, planning, design calculations, and technical studies. Technical skills include proficiency in AutoCAD, water modeling software and Visual Basic. She also has experience with construction management services.

Brad Freiderichs, PE, SE, Structural Engineer | VE SolutionsBrad Freiderichs will serve as Structural Engineer, and will review the Geotechnical Report and provide structural and seismic engineering analysis and design. Brad has 35 years experience as a structural engineer, designing wastewater, water treatment, commercial, industrial, agricultural, retail and residential structures. His expertise is in cast-in-place concrete, prestressed concrete, steel framing, wood framing and masonry construction. His specialty is in producing completely detailed, contractor friendly, value-oriented construction documents resulting in projects that bid well with few change orders.

Jeremy J. Pollet, PE, CAP, Electrical Engineer | Control PointJeremy has 15 years of electrical engineering consulting experience specializing in electrical design, process controls and automation, CADA systems, and project management. Jeremy’s industrial sector experience includes water and wastewater treatment plants, pipelines, pump stations, electric power generation, cogeneration, discrete manufacturing, food processing, oil and gas production and refining.

More detailed information appears in the resumes in the Appendix.

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 18

PROPOSAL

Understanding | Conceptual Layout | Schedule

Section C

Project UnderstandingNevada Irrigation District currently operates the DS pump station using skid mounted diesel powered pumps. The pump station pumps water from NID’s DS Canal to two locations, Cascade Canal and Snow Mountain Ditch.

Cascade Canal is about 365 feet higher than the DS Canal. Water is pumped to Cascade Canal through an existing, buried, 1,580-foot-long, 16-inch ductile iron pipe. The existing pipe is in good condition and can be used with the proposed design. The District desires to pump 15 cubic feet per second (CFS) to Cascade Canal during normal operation. In the case of a failure of one pump at the DS Pump Station, the District desires to pump a minimum of 7 CFS to the Cascade Canal.

Snow Mountain Ditch is about 135 feet higher than the DS Canal. An existing, buried, 2,830-foot-long, 16-inch ductile iron pipe is used to transport water to Snow Mountain Ditch. The existing pipe is in good condition and can be used with the proposed design. The District desires to pump 4 CFS to the Snow Mountain Ditch during normal operation. In the case of a failure of one pump, the District would like to pump a minimum of 2 CFS.

The district is open to both variable speed pumps and constant speed pumps. The DS Pump Station location currently does not have utility electrical power. The nearest single phase power is 1,380 feet away and the nearest three phase power is 7,700 feet away. If utility electrical power is required for the proposed design, the cost of the electrical line extension is to be included in the design-build bid amount. The design submitted in the proposal will not require utility electrical power to the site.

The site is also near a residential area and will require sound attenuation to allow a maximum sound of 45 dB at a distance of 100 feet from the new pump station.

Project DesignThe Gateway Pacific/Bennett Engineering team has prepared a conceptual design for this project that includes efficient and cost effective solutions that meet the District’s requirements. The team proposes to use three (3) diesel powered, engine driven pumps. A solar-powered trickle charge will allow the batteries to provide power to start the pump engines. Over-sized alternators on each engine will provide power to the building lighting, controls, screen motors, weir motor (if provided), etc. A small propane heater will provide heat to avoid freezing. The pumps and engines will be housed in a split face block building with a wood truss, standing seam roof with removable sections to allow the pumps to be pulled for repair.

Sound attenuation components similar to the District’s Pinewood Pump Station will be included. Large double doors for engine removal and repair will be included.

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 19

Water from the DS Canal will be diverted into the pump station using a tilting weir gate. An International Water Screen self-cleaning trash rack will screen the water before entering a concrete wet well below the pump station.

The site will be fenced with chain link with a gate on either side of the site to allow access beyond the pump station site for maintenance. The site will include a crushed rock drive and parking/maintenance area.

With the use of engine-driven pumps with control valves, the need for surge suppression is not anticipated. The control valves will also act as a check valve with adjustable closing speed to provide surge control due to pump failure. Design will include a surge analysis to evaluate the proposed method for surge control. If necessary, during final design, additional surge control will be provided. Added surge control will be an additional cost. See the site plan drawings on the following page.

Pump System

NOMINAL FLOW (CFS) MINIMUM FLOW (CFS) ONE PUMP OPERATING

HEAD (FEET)

DISTANCE (FEET)

REQUIRED PROVIDED REQUIRED PROVIDED

Cascade Canal 15 (1) 15.5 (2) 7 (1) 10 (3) 365 1,580

Snow Mountain Ditch 4 (1) 4 (2) 2 (1) 3 (3) 135 2,830

(1) Per Addendum No. 1

(2) 19.5 CFS divided between Cascade and Snow Mountain as needed

(3) 13 divided between Cascade and Snow Mountain as needed

The design proposal includes three (3) 6.5 CFS (each) diesel engine driven pumps. During normal operation the pump station will deliver 19.5 CFS total, which can be distributed to the Cascade Canal and Snow Mountain Ditch as the District desires using a flow control valve on the Cascade Canal pipeline. This arrangement can provide a total flow that exceeds the design requirements. If less flow is desired, the engine driven pumps can be throttled down or the pipeline valve can be partially closed to decrease the flow. Upon failure of one pump, a total of 13 CFS can be provided (distributed to each canal as the District desires using the flow control valve).

The pump station will be designed with a flow control valve (FCV) on the Snow Mountain discharge, which will provide a set flow to Snow Mountain Ditch. This piping arrangement will allow gravity flow from Cascade Canal to Snow Mountain Ditch. The flow though the FCV will be adjustable and the flow rate can be estimated based upon the stem position of the FCV. Flow measurement beyond that estimated by the stem position of the FCV is not provided. If desired by the District, flow measurement to either or both canals can be added at additional cost. Butterfly valves and check valves will be incorporated for each pump. Butterfly valves will be included on the discharge to each canal.

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 20

Replace with Conceptual Layout

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 22

Future ExpansionIf power becomes available at the site, the proposed design will lend itself to a future installation of electric motors on top of the right-angle gear drives. The existing engines can then operate as emergency back-up pump drives in the event of power failure, eliminating the need for a large back-up generator.

Engine Drive Pump Selection Advantages f A large back-up generator is not required. If electric motors are

used, and the generator fails, a back-up unit should be provided. If two smaller generators are used, synchronizing them is not trivial.

f The design allows for future installation of electric motors on top of the angle gear drives. The existing engines then can be used for back-up.

f Engines are located in the concrete masonry unit building providing sound control

f Surge potential is less due to the engine shut-down dynamics f Fuel tanks can be interconnected, providing long run times and

staggered out-of-fuel failure f If only a portion of flow is required to be transported, only one

or two of the pumps could be running and/or the diesel engines can be throttled down, which will save fuel and reduce cost. With electric motors and a gen-set, the generator must run at all times during any pumping scheme.

Header/Manifold and Piping The design includes a 18-inch header pipe that connects to the two 16-inch conveyance pipes. At the high flows (19.5 CFS), the 18-inch pipe will have a velocity up to 11 fps.

We are proposing to utilize the existing piping system to each canal. The velocities in the pipes are as follows:

Flow 2 CFS

4 CFS

7 CFS

15 CFS

18 CFS

19.5 CFS

Velocity in existing 16” 1.4 fps 2.9 fps 5.0 fps 10.7 fps 12 fps 14.0 fps

Velocity in 18” 1.1 fps 2.3 fps 4.0 fps 8.5 fps 10.2 fps 11.0 fps

Velocity in existing 8” 5.7 fps 11.5 fps n/a n/a n/a n/a

Schedule We believe that the timeline proposed (six months for design and four months for construction) is feasible. Following approval of the proposed design parameters, all long-lead items will be ordered. This includes the engines, pumps, and right-angle gear drives. As design proceeds, additional items will be ordered so that all materials can be at the site as needed for construction.

We have prepared an anticipated schedule for this project to meet the timeline requested. See the following page.

ActID

Description OrigDur

EarlyStart

EarlyFinish

2014

24MAR

2015

03APR

10MAY

17JUN

24JUL

31AUG

07SEP

14OCT

21NOV

28DEC

05JAN

12FEB

19MAR

26APR

02 09 16 23 30 07 14 21 28 04 11 18 25 01 08 15 22 29 06 13 20 27 03 10 17 24 01 08 15 22 29 05 12 19 26 02 09 16 23 02 09 16 23 30 06 1

1000 Submit RFP 1 07MAR14 07MAR14

1010 NID - RFP Evaluation & Contract Award 40 10MAR14 02MAY14

1020 NID Issue NTP 10 05MAY14 16MAY14

1030 Project Kick-Off Meeting 10 19MAY14 30MAY14

2010 Engineering Design - TASK 1 5 02JUN14 06JUN14

2020 Engineering Design - TASK 2 Piping Layout 10 09JUN14 20JUN14

2025 Engineering Design - TASK 2B Hydraulic 15 23JUN14 11JUL14

2030 Engineering Design - TASK 3A -Pump 10 14JUL14 25JUL14

2035 Engineering Design - TASK 3B - Prelim Design 15 14JUL14 01AUG14

3000 Procure Pumps / Motors 120 28JUL14 09JAN15

2040 Engineering Design - TASK 4 - 50% Plans 25 04AUG14 05SEP14

2045 NID Review/Approval of 50% Plans 5 08SEP14 12SEP14

5010 Site Survey, Layout, Pot Holing 10 08SEP14 19SEP14

2050 Engineering Design - TASK 5 - 90% Plans 20 15SEP14 10OCT14

3010 Procure Valves 80 15SEP14 02JAN15

3020 Procure Piping 60 15SEP14 05DEC14

3030 Procure Screens 80 15SEP14 02JAN15

2055 NID/Design Team Review of 90% Plans 10 13OCT14 24OCT14

4000 Issue Subcontracts (Masonry, Roofing, Fencing) 20 13OCT14 07NOV14

5000 Construction - TASK 7 110 15OCT14 17MAR15

2060 Engineering Design -TASK 6 100% Plans/as 15 18MAR15 07APR15

Project name NID DS PS D-B

© Primavera Systems, Inc.

Gateway Pacific Contr / Bennett Engr

NID DS Pump Station D-B

Early bar

Critical bar

Date Revision Checked Approved07MAR14 RFP Submittal

PROPOSAL

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 24

SoundDue to the maximum allowed sound level of 45 dB, at 100 feet from the pump station, the design for the pump station building will incorporate acoustical panels for sound attenuation. The engines will include a silencer on the exhaust. The exhaust will be mounted and routed on the ceiling. The engine intake louvers will also include sound attenuation.

ControlsA float switch will be located in the wet well and will monitor the water level. The level signal will be used to stop the pumps in the event of low suction head. The control panel will be mounted on a wall.

Start UpPrior to starting the pump engine, the engine batteries will provide power to the screen motors to remove debris that may have accumulated. The batteries will also power the weir gate in the canal. The weir gate will be tilted to back up water in the canal and to allow water to flow to the pump station wet well. Once the operator concludes water is flowing freely into the station, the pump engines can be started, one at a time to operate in a normal operation. 12V solar power will be provided to trickle charge the batteries. Lighting in the building and the 12V or 24V screen and weir gate motors will be powered by the batteries. The battery system will be provided with a plug for a portable generator to provide power and battery charging if the need arises.

Operations and MaintenanceThe O&M for this facility will include (but is not limited to) the following:

Pump Seal Lubrication f Because these pumps may not run for extended periods,

consideration must be given to providing additional lubrication to the pump seals

Fuel f Diesel fuel becomes stale if it sits for extended periods. It may be

necessary to drain the diesel fuel or run the diesel dry. The design will take this into account.

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 25

PROPOSAL

Availability | Ability to Meet TIme Schedule

Section D

The project team members were selected because of our successful partnering history and their availability to commit to this very important projects for the District. Subconsultant firms who specialize in single-focus engineering specialties have a vested interest in providing the best value and service to our clients. Their commitment is demonstrated by their consistent flexibility and responsiveness to our clients and projects.

Although Gateway Pacific Contractors has several experienced Superintendents qualified to complete this project, we have slated Gary Heim as our superintendent to construct the DS Pump Station. Mr. Heim is successfully completing the $7.9 million Banner-Taylor Reservoir Replacement Project for NID this summer and will be available to move directly

into the DS Pump Station project. Our construction projects are supported by a seasoned office staff of engineers and administrators as well as experienced project management. If additional experienced field supervision is required for the DS Pump Station project, we have also just completed a $2.6 million concrete water storage tank project in Tacoma, Washington, freeing up another superintendent who has been with Gateway Pacific for more than 20 years.

The District desires a project team that is committed to the project, despite other demands made on staff. The District can rest easy knowing that the proposed project team is highly committed to seeing this project through to completion. The project team has recently completed or is close to completion of several projects, as you can see listed in the chart below.

Projects in Progress GPC BEN|EN Contract Amount

Date of Expected Completion

Bay Street Reservoir Replacement - Phase 3 | City of Santa Cruz n n $7,199,140 June 2015

Banner-Taylor Reservoir Replacement Project | Nevada Irrigation District

n n $7,932,477 June 2014

Vickery Avenue Reservoir Replacement | San Jose Water Company n $13,321,148 November 2015

Soscol Water Recycling Facility-Phase 1 | Napa Sanitation District n $11,996,116 June 2014

Water Pollution Control Plant Digester Cover Replacement | City of Chico

n $1,103,012 April 2014

Recycled Water System Expansion Water Reclamation Plant and Pump Station | City of San Clemente

n $7,579,932 August 2014

Poplar/Park Main Replacement | Citrus Heights Water District n $56,500* October 2014

City Engineering 2014 | City of Biggs n $30,000* Annual Renewal

6th Street Bridge Replacement | City of Biggs n $291,200* August 2014

Wastewater Treatment Plant | City of Biggs n $141,400* August 2014

NZPS Tank Recoating Specifications | City of Roseville n $7,500* May 2014

Zone 4 to Zone 1 Pump Stations | City of Roseville n $250,000* August 2014

Gold Run, Phase V & VI | PCWA n $276,218* December 2015

Colfax WTP Baffle Wall Replacement | PCWA n $4,650* May 2014

Small Diversion Upgrades | PCWA n $620,000* October 2016

Lincoln Metering Station | PCWA n $397,903* December 2014

Clover Valley Reservoir | PCWA n $367,900* March 2015

*Design Only

Gateway Pacific Contractors | DS PUMP STATION DESIGN-BUILD PROJECT Page 26

PROPOSAL

Evan LundinGary A. BechtelJay E. HallGary HeimDoug Ormond

Orin Bennett, PESteven Ainsworth, PEMatthew J. Wheeler, PEStacey Bennett, PE

Brad Friederichs, SE

Jeremy Pollet, PE, CAP

Included in this Appendix are the following key staff resumes:

Key Staff Resumes

Gateway Pacific Contractors

Bennett Engineering Services

VE Solutions

Control Point

Gateway Pacific | RESUME

TEAM RESUME

Work Experience

1985 – Present CEO/President Gateway Pacific Contractors, Inc., Sacramento, California. Gateway Pacific is a general contractor specializing in heavy construction, water and wastewater treatment and storage plants.

1982 – 1985 Project Manager/Superintendent, Olson Construction Company, Denver, CO

Partial List of Projects

Bay Street Reservoir Replacement Project - Phase 3, Santa Cruz, $7,199,140. Design and construct one new 6MG pre-stressed concrete AWWA D110 Type 1 water tank, site improvements, and demolish four steel 1.5MG tanks.

Vickery Avenue Reservoir Replacement, Saratoga, CA, $13,321,148. The project includes the removal of an existing earthen reservoir, construction of a temporary cofferdam, construction of one 2MG and one 5.8MG AWWA D110 Type 1 pre-stressed concrete tank.

Soscol Water Recycling Facility-Phase 1 Recycled Water Expansion, Napa, CA, $11,801,116. Modify and construct filters, pump stations, equalization basin, dissolved air flotation clarifier, chlorine contact basins, chemical facilities and appurtenances.

Water Pollution Control Plant Digester Cover Replacement and Misc Improvement Project, Chico, CA, $1,305,960. Replace a floating digester cover, replace digester gas piping and waste gas flare, install a heat exchanger and digester gas flow meter, and replacement of digester recirculation pump.

Recycled Water System Expansion Water Reclamation Plant and Pump Station–Proj #18201A, San Clemente, $7,579,932. Construct, modify and add to yard structures, tertiary filters, chlorine contact basins, chemical bldg, filter control bldg, recycled water effluent pump station and integration of SCADA system at Bldg J.

Project Oversight and Management

8055 Freeport BoulevardSacramento, CA 95832T [email protected]

Education

f Kansas State University, B.S. Construction Management, 1976

Evan Lundin, CEO and President

Evan Lundin, CEO and President

Gateway Pacific | RESUME

Green River Filtration Facility-Prestressed Concrete Tanks (Subcontract), Ravensdale, WA, $2,694,414. Upgrades to existing drinking water treatment facilities to provide a filtration system with initial design capacity of 150MGD and an ultimate capacity of 168 MGD.

Anza Reservoir No. 2 [Project D1574], Temecula, CA, $2,694,414. Construct 3.0 MG prestressed concrete reservoir and associated site work.

Banner Taylor Reservoir Restoration Project, Nevada City, CA, $7,932,477. Replace storage tank with one 4.6MG and one 5.9MG prestressed concrete tank.

Bay Street Reservoir Replacement Project – Phase 2, Santa Cruz, CA, $9,661,440. Construct 6MG prestressed concrete tank for drinking water storage plus associated, facilities and utilities.

Lake Forest Well No. 2, Lake Forest, CA, $583,544. Well equipping and disinfection facilities

Pala Mesa Tank Phase 2, Fallbrook, CA, $4,625,249. Construct 6MG prestressed concrete reservoir.

NSD Recycled Water Facility, Novato, CA, $5,614,764. Demo and reconstruction of existing treatment plant

Well 78 Replacement Project, Irvine, CA, $2,820,099. Destruction of existing Well 78 and drilling and equipping the new Well 78

Digester No. 1 Rehabilitation, Antioch, CA, $1,055,111. Rehabilitation of existing digester

Bowman Water Treatment Plant Tube Settler Replacement Project, Antioch, CA, $102,224. Remove and replace tube settler modules in existing filters at Bowman WTP

Bowman Water Treatment Plant Residuals Handling Improvements, Auburn, CA, $4,129,186. Construct new drying beds, equalization basin, polymer building and associated piping, electrical and earthwork.

San Joaquin Marsh Campus Perimeter Walls, Irvine, CA, $451,243. Construct masonry flood protection walls and specialized food control gates at perimeter of wildlife sanctuary.

Evans Reservoir Replacement Project, Riverside, CA, $13,113,553. Demolish existing reservoir and construct 16MG concrete reservoir, large di-ameter pipeline.

Grant Line Channel Restoration Project, Elk Grove, CA, $758,288. Regrading and repair of existing drainage channel.

Reed Reservoir Replacement Project, Escondido, CA, $6,109,186. Demolish existing reservoir and construct two 2.5MG prestressed concrete, reservoirs.

East Area Tank and Booster Pump Station, Davis, CA, $6,178,161. Construct 4MG prestressed concrete reservoir and all associated support facili-ties and utilities

Water Pollution Control Plant Outfall Replacement Project, Chico, CA, $4,267,427. Replacement of 84” sewer outfall into the Sacramento River.

Northeast Water Storage Reservoir Replacement, Rocklin, CA, $5,207,198. Replace 6MG concrete reservoir with 10MG prestressed concrete reservoir.

Nohl Canyon Water Storage Tank Project, Anaheim, CA, $15,934,002. Replace 60MG earthen reservoir with 10MG prestressed concrete reservoir.

Primary Treatment Expansion Project, Fairfield, CA, $13,820,968. Modifications to existing grit chamber influent channels, construction of two new, influent channels fitted with Parshall flumes, construction of new primary clarifier, new foul air treatment facility.

Water Pollution Control Plant 12MGD Expansion, Chico, CA, $40,383,122. Construction to the Chico WPCP, increasing the nitrification treatment capacity to, 12 MGD., Stoneridge Joint Use Water Storage Facility, Roseville, CA, $4,196,374. Construct a 3MG prestressed concrete reservoir.

Rancho Bernardo Reservoir Rehabilitation, San Diego, CA, $7,154,497. Rehabilitation of current concrete reservoir, structural repairs, shear wall columns and beam retrofit, installation of new liner, installation of aluminum roof.

PA 6 Zone 4&C Reservoir, Zone 4-6 BPS, Zone C-D BPS, Irvine, CA, $9,899,601. 3.5MG Domestic Water Reservoir, 2.2MG Reclaimed Water Reservoir, Domes-tic and Reclaimed Water Booster Pump Stations

Randall-Bold Water Treatment Plant Sedimentation Basins, Oakley, CA, $11,990,893. 2 Sedimentation Basins, Utility relocations, Site Improvements

Willows Waste Water Treatment Plant Improvement Project, Willows, CA, $7,785,354. Demolish existing

Evan Lundin, CEO and President

Gateway Pacific | RESUME

structures, Construct new site structures and improvements

Terminal Reservoir 3, San Juan Capistrano, CA, $10,527,276. 6MG Prestressed Concrete Reservoir, Install Chloramine Generator System

Citywide Recycled Water Facilities, Corona, CA , $15,431,258. 3 Recycled Water Pump Stations, 3 Prestressed Concrete Reservoirs

Gano Reservoir and Unit X Pipelines, Rancho Bernardo, CA, $7,515,915. 6.5MG Reservoir, Pipelines, Valuts & Utility / Road Improvements

Otay Water Treatment Plant, San Diego, CA, $12,694,781. Relocate valves and piping, Construct 6.9MG Prestressed concrete circular tanks

Talega Reservoir & Pump Station, San Clemente, CA, $6,879,997.00. Domestic/Nondomestic Reservoir, Domestic Pump Station

South Yuba Master Drainage Plan, Phase 2A, Olivehurst Interceptor, Marysville, CA, $587,941. Storm drainage canal, detention basin attached to the canal.

Oceanside Mission Basin Facility Expansion, Oceanside, CA, $7,902,899.00. Desalting Facility Expansion, (Groundwater Purification)

Dual-Purpose Pump Station/10MG Water Storage Tank, Roseville, CA, $6,887,469. Dual purpose pump station and 10 MG circular prestessed concrete tank.

Twin Oaks Reservoir-Phase II, Reservoir Improvements, San Marcos, CA, $16,021,934. 33 MG Circular prestressed tank, buried.

Primary Plant Headworks & Cannery Segregation, Modesto, CA, $12,473,010. Construction of first-phase pretreatment (headworks) facility for domestic wastewater.

Mojave Siphon Power Plant - Completion, Hesperia, CA, $7,595,261. Hydro-electric Power Plant and 125 KVA substation.

Railroad Tunnel Ventilation, Denver, CO, $8,000,000. Demo of existing portal structure over railroad tracks while maintaining train traffic of 20 trains per day. Furnish and installation of three 3,000hp electrical fans.

Salmon Fish Hatchery, U.S. Corp of Engineers, Stanley, ID, $ 10,000,000. Complete salmon hatchery.

Design/Build Office Building, Denver, CO, $13,000,000. High-rise office building, 1977 – 1982 Project Manager/Estimator/Superintendent,, EBY Construction Company, Wichita, KS

Foundation for Coal Power Plant, Iaton, MO, $10,000,000. Intake structure and substation.

Foundation for Coat Power Plant, Garden City, KS, $15,000,000. Included substation, coal unloading structure, railroad bridge.

Gateway Pacific | RESUME

TEAM RESUME

Gary Bechtel is an engineering and construction management industry veteran having served in multiple senior level positions over a distinguished 30 year career. Bechtel’s career includes a broad and diversified project portfolio including an $800 million Liquefied Natural Gas (LNG) Plant in Indonesia and a $5.5 billion U.S. Nuclear Power Plant while with Bechtel International as well as $500M in successful wastewater and water treatment, storage and transmission projects for Gateway Pacific Contractors, Inc. where he served as COO since 1998.

Project Experience