SQRAM Thermal Solution - Microsoft€¦ · chips then form several hot spots. To avoid overheating...

Transcript of SQRAM Thermal Solution - Microsoft€¦ · chips then form several hot spots. To avoid overheating...

SQRAM Thermal Solution for Extreme Temperature Environments

2020. Feb by SQRAM

IoT applications require 24/7 reliable

operation, and can’t afford the risk of

downtime caused by DRAM overheating.

Many IoT applications are deployed in

harsh environments with wide

temperature ranges.

Therefore, it’s important to improve DRAM

heat dissipation as well as to monitor its

operating temperature to avoid overheating

issues.

DRAM Thermal Management for IoT Applications

DRAM thermal management matters

for IoT applications because…

Memory temperature is usually going to be

much higher than other components.

Overheating memory may negatively affect

system performance or even cause downtime.

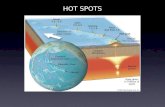

How Does Heat Dissipation by Memory Heatsink Work?

DRAM memory generates heat when operating, and the heat may gather on specific corners of IC

chips then form several hot spots. To avoid overheating problems in the system, it’s important to

evenly spread heat from the hot spots through heatsinks. An aluminum heatsink can evenly

conduct heat from memory ICs and rapidly disperse heat away to system fans or coolers.

Heat transfer by conduction

Heat transfer by conduction & radiation

PCB

Memory

heatsink

System

fan/cooler Aluminum

heatsink 1

Aluminum

heatsink 2

Memory IC

Memory Heatsink Temperature Tests

At room temperature, Tc (case temperature) of all

IC chips were over 50°C, even higher on golden

fingers due to data pin transfer.

In the test, there were two SQRAM memory

modules, one was equipped with a heatsink and

the other one was not. Two thermocouples were

set on each module to detect Tc under different chamber temperatures.

Tc at room temperature

1

2

Thermocouple#1 on the front

Thermocouple#2 on the back

SQRAM memory modules can stably operate in wide temperature range from -40 to 85°C . There were

five levels of ambient temperature (Ta) in the chamber with operating DRAM test board. When Tc was

over 85°C, which exceeded SQRAM operating temperature range, the memory modules still

operated without abnormal symptoms. It was not until Tc reached a extremely high temperature

of 119°C that memory errors occurred.

According to test results in below, the heatsink dispersed heat away and usually lowered the Tc by

about 0.7 to 1°C, which is efficient enough in extremely high temperature environment.

Ta

(°C)

Thermocouple 1

(Tc 1)

Thermocouple 2

(Tc 2)

Memory

Status

25 57.4 57 None Error

55 87.3 87 None Error

60 92.5 92.2 None Error

70 104.4 104.2 None Error

85 119 118.7 Error

Ta

(°C)

Thermocouple 1

(Tc 1)

Thermocouple 2

(Tc 2)

Memory

Status

25 58.1 57.7 None Error

55 88.3 88 None Error

60 93.2 92.8 None Error

70 104.8 104.5 None Error

85 119.7 119.3 Error

With Heatsink Without Heatsink

Memory Heatsink Temperature Tests

Temperature Monitoring by SQRAM Manager 2.0 SQRAM memory modules adopt EEPROM with thermal

sensors to detect memory operation temperature in

ranges from -40 to 95°C. SQRAM Manager can access

temperature data through sensors and delivers it via a user-

friendly interface to help users efficiently monitor SQRAM

memory modules. SQRAM Manager offers these benefits for

temperature monitoring:

• Though operating temperature of each memory module

may differ due to DRAM socket locations on a board,

SQRAM Manager can precisely detect the

temperature of each memory module separately.

• The sensors detect temperature at 5-sec interval to

provide dynamic temperature monitoring.

• Users can set the temperature threshold for

overheating alerts according to their IoT applications.

• Background processing is supported.

System Speed Monitoring by SQRAM Manager 2.0

Besides monitoring memory operating temperature,

monitoring real-time system speed/loading is also

essential to prevent overheating and maintain system

health. SQRAM Manager provides advanced functionality

for users to check system memory loading, real-time

speed, and whole system memory capacity. With this

information, users can know when the system needs to be

fine-tuned to avoid overheating.

• System Memory: total memory capacity of the

platform.

• Speed Grade: memory current operating speed on

the platform. For example, if a motherboard supports

DDR4 2133 but adopts DDR4 2400 memory, the system

speed will be downgraded to 2133 MHz.

• Usage: currently used memory capacity of the

platform

Why Choose SQRAM for Industrial Applications?

˙48hr burn-in test program

˙Mounting hole designs to securely fasten

˙Military shock standard verification

˙Fixed BOM and 3-year longevity

˙Manage up to 8-slot SQRAM memory modules

˙Real-time monitoring of operating temp. & system speed

˙Friendly UI to set overheat alert threshold

˙Background dynamic monitoring

˙Conformal coating/ underfill

˙Anti-sulfur protection

˙SPD security

˙Wide temperature of -40~85 °C

˙Extended temperature of -20~85 °C

˙Optional industrial heatsink

Robust Solution

Customization &

Value-added Service

Wide-temperature

Support

Smart DRAM Management

Software: SQRAM Manager 2.0

SQRAM DDR4 Robust Memory Solutions

Unbuffered SODIMM Rugged DIMM

SQR-SD4N/ SQR-SD4I

4G~32G

0~85℃/-40~85℃

Optional Heatsink Available

SQR-YD4

16G/32G

0~85℃/-40~85℃

• Mounting Hole Design

• ECC Function Available

Superior Performance / Optional Heatsink Available / Monitoring Software

Defense Aerospace Transportation

Learn More about Our Product Offering

• View SQRAM Product Selection

• Download E-Catalog

• Visit SQRAM mini-site

Inquiry / Get Quote

• Contact Your Local Sales Offices

SQRAM Manger Tutorial

Take the Next Steps

Co-Creating the Future of the IoT World

Co-Creating the Future of the IoT World