SPECS Product Brochure - SPECS Surface Nano Analysis GmbH

Transcript of SPECS Product Brochure - SPECS Surface Nano Analysis GmbH

Components for Surface Analysis

Tyto™

Applications � Atomic Scale SPM � Nano- & Quantum Devices � Extended and Combined SPM

Precision SPM Head

Features � Modular Design � Three Shielded Contacts to Sensor � Kinematic Sensor and Sample Mount � Direct Sensor Swapping � Extremely Rigid Titanium Casing � Thermally Compensated Design � Capacitive Position Sensor � Rigid and Precise Piezo Motors

Customized Systems and Solutions

Surface Analysis and Preparation Components

Nanostructures and Thin Film Deposition

Surface Science Applications

Modular SPM Head for Advanced Imaging and

Spectroscopy With Various Sensors

The new Tyto scan head from SPECS is a milestone in the

technology of Scanning Probe Microscopy. The modular

design allows for various experimental configurations

and for the usage of different sensors. A kinematic mount

is used for both the sample and sensor and this feature

is combined with accurate position sensors. For the first

time, this enables different sensors to access identical

locations on a sample and to repeat the procedure af-

ter successive sample preparation steps. This opens up

opportunities for new experiments and will advance the

research of surfaces at the nanometer scale.

Innovative Sensor Mount Design

The key feature of the new Tyto scan head is the pat-

ent pending sensor receptor: the Tyto-Claw™. Until now,

the means of mounting SPM sensors on a scan tube

has represented a significant challenge. Ideally, the

mount should be lightweight and non-magnetic with

good electrical, thermal, and mechanical contact, and

it should allow the sensor to be easily changed in UHV.

Solutions with magnetic holding have the drawback

that they are not compatible with magnetic fields and

have poor mechanical anchorage. The keyhole principle

to replace the sensor with a special carrier in the sample

insert is cumbersome as the sample has to be removed

and reinserted. Pushing the sensor under spring clamps

with a wobble stick creates the risk of breaking the scan

tube because of the associated high torque and results

in wear of the metallic springs.

The new Tyto-Claw provides a new and innovative solu-

tion: it has a rigid mount that allows precise kinematic

holding, three shielded electronic contacts and six solid

metal springs for grounding and thermalisation. The

sensor is well shielded from the piezo tube below and

insertion is performed without any friction from metallic

springs or contacts. The Tyto-Claw is completely non-

magnetic, lightweight and easy to replace when neces-

sary. The Tyto-Claw accepts any kind of electrical sensor

including tunneling tip, KolibriSensor, Tuning Fork Sen-

sors, Qplus and Akiyama as well as any piezoelectric or

piezoresistive sensors.

Kinematic Sample and Sensor Mount

The sensor and the sam-

ple are kinematically

mounted on three sap-

phire balls in three radial

grooves (Maxwell geome-

try). This greatly increases

the mechanical stability, avoids rattling the sample or

sensor plate and increases the performance of oscillat-

ing sensors. The biggest advantage for users is the abil-

ity to remove and replace a sample or sensor and to

return to the same spot on the sample within the area of

the scan field. This allows the investigation of the same

atom, molecule or defect following successive sample

preparation steps. In combination with the precise posi-

tion sensors, it also allows imaging of the same spot

on the sample with different sensors, once their relative

offsets are known.

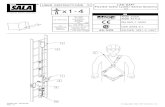

1: The Tyto-Claw is mounted at the end of the scan tube. It features three ruby balls for a precise kinematic mount of the sensor plate, three spring contacts for the signals of the sensor, and solid metal springs for thermal and electrical ground contact

2: The precise Z motor with kinematically guided sapphire tube withdraws the scanner into the sensor exchanger cone.

3: The springs of Tyto-Claws are opened in the sensor exchanger cone.

4: The sensor plate can be placed into the cone with the wobble stick without risk of breaking the Tyto-Claw or the scan tube.

5: The z motor moves forward, the Tyto-Claw grabs the sensor plate which is then pressed onto the three ruby balls.

6: The sensor plate is now firmly mounted on the scan tube. The system is lightweight, non-magnetic, UHV, and low temperature compatible. It allows imaging the same atom after successive tip preparation steps.

Innovation in Surface Spectroscopy and Microscopy Systems2

1

2

3

4

5 6

Position Sensors

Capacitive position sensors allow precise measurement

of the position of the coarse x-y piezo motors within a

few nanometers. This enables the retrieval of previously

imaged spots on a sample by simply recalling the stored

coordinates. This widens the scientific applicability of

SPM as it allows repetitive measurements to be made

on a larger set of spots on a sample.

Minimal Thermal Drift

The Tyto scan head is designed to deliver the lowest

rates of thermal drift. Materials with matching tempera-

ture expansion coefficients are used and the mechanical

path from tip to sample is thermally compensated. This

feature is important for achieving the highest stability

as well as the lowest drift.

Extremely Stable and Rigid

While every SPM is claims to be the most stable, in the

case of the Tyto scan head, every measure (derived from

extensive experience) has been applied to maximise its

mechanical stability and rigidity. The solid non-magnet-

ic titanium casing makes the tip-sample gap stiffer than

ever before.

Higher Voltages for Stiffer Piezos

The high voltage devices in Nanonis Control Systems are

able to operate at voltages up to ±400 V. This is a big ad-

vantage for the mechanical stability of the piezo scanner

since the wall of the piezo tube can be made thicker and

stronger while continuing to provide a large scan range.

Ultra Precise Piezo Motors

The Nanonis high voltage and high current Piezo Motor

Driver (PMD) allows the construction of more rigid pi-

ezo motors with a stronger driving force, and finer step

size. The innovative and truly kinematical sliding bear-

ing made from sapphire results in a strong holding force,

good repeatability and a longer lifetime. The net result

is finally a sharper image at the atomic level and a better

efficiency in coarse positioning.

High Performance Cabling

Up to 30 cables are linked to the advanced Tyto scan

head. All of them are copper coaxial cables for lowest

crosstalk. The copper shields also serve as thermal links

to ensure the whole head and all its components espe-

cially sample and sensor are in thermal equilibrium.

Four Evaporation Ports

Four openings in the body

of the Tyto scan head al-

low for in-situ evaporation

onto the sample at an angle

of 30 degrees from the sam-

ple normal.

Laser Ports

For simultaneous optical ex-

periments, the Tyto scan head

has two specular ports at an

angle of 36 degrees from the

sample normal with the pos-

sibility to mount extensions

such as lenses or mirrors.

Once the laser is adjusted to

the tip, the sample can be

moved with the x-y motor

to access different locations

without the need to re-ad-

just the laser.

Visual Inspection From All Sides

A large front opening and

windows situated on each

side of the body and at the

back allow for broad visual

inspection of the sample

and sensor in-situ under an

angle of 70 to 80 degrees

from the sample normal.

Electronic Contacts to the Sample

Various sample receptors can be installed in the Tyto

scan head, with four or twelve electronic contacts to

the sample. Optional extra features include a calibrated

Cernox temperature sensor located directly under the

sample plate, and a small heater to control the sample

temperature to within 1 mK.

Innovation in Surface Spectroscopy and Microscopy Systems 3

SPECS Tyto Scan Head Specifications

Body Material Titanium (non magnetic)

Total Weight ~300 g

Diameter 50 mm

Operating Temperature 0.5 K – 400 K

Bake out Temperature 120 °C

UHV compatibility < 1 x 10-10 mbar

Scanner

Scanner Tube with five electrodes

Maximum Voltage ± 400 V

XY Scan Range 300K/4K ~22 µm/~4 µm

Z Scan Range 300K/4K ~2.3 µm/~0.42 µm

Coarse Positioning Piezo Motors

Sliding contact bearing Kinematic Sapphire-Sapphire contacts

Operating voltage ± 400 V

Maximum peak current 20 A

XY Motor

XY Coarse Positioning (Sample)

Orthogonal guided Inertial shear piezo motors

Travel Range ± 2.5 mm

Final position switches Four opening contacts

Z Motor

Z Coarse Positioning (Sensor)

Inertial piezo motor with concentric piezo tube

Travel Range 20 mm

XY Encoder (Optional)

Encoder Type Differential Capacitive Sensor

Sensor Resolution 5 nm

Repeatability 100 nm

JT-Tyto-Kolibri-Nanonis

The Tyto scan head fits perfectly into the JT-SPM plat-

form, a Joule Thomson cryostat with temperatures down

to 1K and magnetic fields up to 3 Tesla. It runs best with

the KolibriSensor and the Nanonis Control System. A su-

perior combination in every respect.

Ease of Maintenance

Due to the modular design, exchanging functional parts

of the Tyto scan head is straightforward whenever a dif-

ferent experimental configuration is required or a part

needs to be replaced. Standard parts for the scan head

are premanufactured and are readily available off the

shelf from SPECS. The up-time of the scan head can thus

be maximised and scientific output increased.

Highest Performance STM and ncAFM

The new and advanced features of the Tyto scan head

do not compromise traditional STM or NC-AFM perform-

ance. Rather, our long-standing experience with SPM

technology has resulted in a precision scan head with

the highest stability and best signal quality, which will

produce STM and ncAFM images of a quality never seen

before.

Tyto Starter Kit

In order to speed up the starting process, SPECS offers

the air station for mounting the Tyto scan head. With a

spring suspension and the standard SPECS SPM connec-

tor, it allows operation of the scan head in air in order to

gain experience. The Tyto head can be mounted subse-

quently in one of the SPECS SPM platforms, such as the

JT-SPM, for example.

SPECS Surface Nano Analysis GmbHVoltastrasse 513355 BerlinGermany

Tel. +49 30 46 78 24-0Fax +49 30 46 42 08-3Email [email protected] www.specs.com ISO 9001 Certificate

Your Local Representative:

Technical alterations reserved. The information in this document is provided with greatest care but SPECS does not assume any liability arising from the application or use of the information or product described here. SPECS is a registered trademarks of SPECS GmbH.

Other product and company names mentioned herein are trademarks or trade names of their respective companies.Printed in September 2010

Innovation in Surface Spectroscopy and Microscopy Systems