Specification 430:2018 Refurbishing Digital Talking-Book ... · American National Standards...

Transcript of Specification 430:2018 Refurbishing Digital Talking-Book ... · American National Standards...

-

Version 1.1 December 2019

Specification 430:2018 Refurbishing Digital Talking-Book

Cartridges and Containers

-

Page 2 of 17

NLS Spec No. 430 December 2019

Revision History Revision Issue

Date Change Description

Rev. 1.0 8/10/2012 First release Rev. 1.1 9/30/2019 Add language to handle use of cleaning agent,

USB connector contamination, remove lot size, modify for new NLS Logo

Final Approval Head, Engineering Section

(John Brown) Head, Quality Assurance Section

(Margaret Goergen-Rood) Chief, Materials Development Division

(Michael Katzmann) Director

(Karen Keninger)

-

Page 3 of 17

NLS Spec No. 430 December 2019

Table of Contents 1. Scope .................................................................................................................................................................. 4 2. Reference Documents ....................................................................................................................................... 4

2.1 Standards ....................................................................................................................................................... 4 3. Requirements .................................................................................................................................................... 5

3.1 Refurbishment ............................................................................................................................................... 5 3.1.1 Refurbished cartridges .......................................................................................................................... 5 3.1.2 Refurbished containers ......................................................................................................................... 5

3.2 Write protection ............................................................................................................................................ 6 3.2.1 Cartridge write-enabled passcode ......................................................................................................... 6 3.2.2 Cartridge write-protected passcode ....................................................................................................... 6 3.2.3 Security of cartridge passphrases .......................................................................................................... 6 3.2.4 Cartridge file system ............................................................................................................................. 6 3.2.5 Software ................................................................................................................................................ 6

3.3 Monthly totals ............................................................................................................................................... 6 4. Quality Assurance ............................................................................................................................................ 7

4.1 Inspection ...................................................................................................................................................... 7 4.1.1 Incoming inspection for cartridges from NLS network libraries .......................................................... 7 4.1.2 Outgoing inspection .............................................................................................................................. 7 4.1.3 Preparation for delivery ........................................................................................................................ 8

4.2 Contractor’s quality-control plan .................................................................................................................. 8 4.3 Correction of faults by contractor ................................................................................................................. 8 4.4 Contractor’s warranty ................................................................................................................................... 8 4.5 Inspection of contractor by NLS ................................................................................................................... 9

A. Specification Drawings ................................................................................................................................... 10 A.1 Book Cartridge ............................................................................................................................................ 10 A.2 Mailing Container ....................................................................................................................................... 13

B. Cartridge Passphrase ..................................................................................................................................... 16 B.1 Cartridge write-enable ................................................................................................................................. 16 B.2 Cartridge write-protect ................................................................................................................................ 17

-

Page 4 of 17

NLS Spec No. 430 December 2019

1. Scope

This specification covers the requirements for refurbishment of digital talking-book cartridges (“cartridge”) and containers produced for the National Library Service for the Blind and Physically Handicapped (NLS), Library of Congress.

2. Reference Documents

The following documents and publications form a part of this specification. In the event of conflict between the documents and publications referenced herein and the content of this specification, the content of this specification shall be considered a superseding requirement.

2.1 Standards

American National Standards Institute (ANSI) ANSI/ASQ Z1.4-2008 Sampling Procedures and Tables for Inspection by Attributes The document cited above is available from: American Society for Quality Quality Press 611 East Wisconsin Ave. P.O. Box 3005 Milwaukee, WI 53201-3005 www.asq.org/quality-press/index.html Microsoft Microsoft Extensible Firmware Initiative FAT32 File System Specification, Rev 1.03 available at: http://msdn.microsoft.com/en-us/windows/hardware/gg463080

file://nlsserv1/LOCPROF.NLS/phca/My%20Documents/Spec%20and%20Guideline%20Drafts/1204/www.asq.org/quality-press/index.htmlhttp://msdn.microsoft.com/en-us/windows/hardware/gg463080

-

Page 5 of 17

NLS Spec No. 430 December 2019

3. Requirements

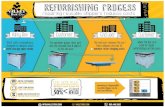

3.1 Refurbishment

NLS network libraries will send digital talking book cartridges and containers for refurbishment. Cartridges and containers will be cleaned, inspected, quantified, and formatted for reuse.

3.1.1 Refurbished cartridges

Refurbished cartridges must meet the following criteria:

a. Label(s) and adhesive residue removed from the housing

b. Clean and free of dust, dirt, debris or other contamination. Any cleaning agent utilized in the refurbishment process shall not leave a visible/tactile residue or a perceptible odor from greater than 0.5 meters

c. Free from significant physical damage (e.g. cracked housings, sharp edges, etc.)

d. USB connector free from physical damage

e. USB connector clean and free of dust, dirt, debris, or other contamination

f. Operates normally and is recognized by a computer

g. Contents of the flash memory erased (see Section 3.2.4)

h. Write-protection reset (see Section 3.2.2)

i. Sorted and grouped according to capacity

Cartridges that cannot be processed to the above criteria shall not be reused. These unusable cartridges shall be retained for review by NLS Quality Assurance Section (QAS). Cartridges determined to be unusable shall be disposed of following the approval of NLS QAS.

3.1.2 Refurbished containers

Refurbished containers must meet the following criteria:

a. Address card removed

b. All labels with the exception of the barcode label removed

c. Clean and free of dust, dirt, debris, or other contamination. Any cleaning agent utilized in the refurbishment process shall not leave a visible/tactile residue or a perceptible odor from greater than 0.5 meters

d. All adhesive residue must be removed

e. Latches work properly; body is free from excessive physical damage

f. Barcode label legible and free from damage; barcode label replaced if missing or damaged (replacement barcodes shall be supplied by NLS).

Containers not meeting the above criteria shall not be reused. These unusable containers shall be retained for review by NLS QAS. Containers determined to be unusable shall be disposed of following the approval of NLS QAS.

-

Page 6 of 17

NLS Spec No. 430 December 2019

3.2 Write protection

3.2.1 Cartridge write-enabled passcode

In order to initialize the contents of the cartridge and to reset the write-protection passphrase, the cartridge shall be write-enabled by applying a passcode as described in Appendix B.1. Cartridges from the NLS network libraries are write protected by a 16-digit, 8-bit binary passcode.

3.2.2 Cartridge write-protected passcode

The cartridge shall be protected to ensure only NLS authorized duplicators have the ability to alter cartridge contents. NLS will supply a hexadecimal representation of a 16-byte sequence that shall be used as the write-protection passcode. The cartridge shall be protected from erasure or writing by applying this passcode as described in Appendix B.2.

3.2.3 Security of cartridge passphrases

The recipient of the cartridge passphrases is responsible for their security. No more than 3 persons within the recipient’s organization shall have access to the NLS passphrases. Prior to obtaining passphrases from the contract monitor, the recipient organization shall provide NLS with a plan to secure the passphrases and its MD5 checksum from compromise. Equipment to be used in cartridge duplication shall not store either the passphrases or the passphrase digest in its unencrypted form.

The passphrases will only be supplied upon the contract monitor’s assessment that its security is assured.

3.2.4 Cartridge file system

The contents of the cartridge shall be erased. The cartridge shall be reformatted as a FAT32 file system. The refurbished cartridge shall be partitioned using the Master Boot Record (MBR) partitioning scheme. The first partition shall be a primary partition and contain a single FAT32 file system according to FAT32 File System Specification, Rev 1.03 (see Section 2.1).

3.2.5 Software

Upon request, NLS will supply software to support write-enabling, formatting, and write-protection of the cartridge. NLS supplied software can be installed on a computer running the Fedora distribution of the Linux operating system. The NLS software is not required for refurbishment. Other software capable of write-enabling, erasing, partitioning, formatting, and write-protecting the cartridge according to the requirements above may be used, subject to approval of NLS QAS.

3.3 Monthly totals

Records of the number of cartridges and containers received from individual network libraries and their source shall be maintained. Reports listing the total number of cartridges and mailing containers received from each network library in a calendar month shall be provided to NLS on the first day of the following month

-

Page 7 of 17

NLS Spec No. 430 December 2019

4. Quality Assurance

4.1 Inspection

4.1.1 Incoming inspection for cartridges from NLS network libraries

The contractor is required to perform an inspection of each cartridge received from NLS network libraries. The inspection shall consist of the following requirements from NLS Drawing Number 4824591013 Housing, Cartridge or this specification:

• Hardware interface:

o USB plug shall be free of physical damage and fit properly into the NLS digital player

• Housing text: A visual inspection of the cartridge text is required to ensure it is clear and legible. All markings shall be black. The following text shall be inspected:

o PROPERTY OF THE U.S. GOVERNMENT

o Further reproduction or distribution in other than a specialized format is prohibited

o • Housing barcode: The housing barcode shall be readable by a barcode scanner and appear

clear to a visual inspection.

• Housing color: A visual inspection is required to ensure color is white (see note 23 in drawing 4824591013 Appendix A.1).

• Housing shall be free of significant physical damage. Cartridge shall fit properly into the NLS digital player; housing shall not be cracked and shall be free of sharp edges.

• Electrical interface:

o Verify cartridge is recognized by a computer and identified as an LoC.NLS Talking Book USB Device (not generic device)

o Cartridge write-enabled passcode: Verification of the cartridge write-enabled passcode supplied to the contractor per Section 3.2.1 and Appendix B.1.

The contractor shall provide monthly notification to NLS QAS on cartridges that fail incoming inspection. Failed cartridges shall be retained for review by NLS QAS. Failed cartridges may be disposed of following approval by NLS QAS.

4.1.2 Outgoing inspection

The contractor is required to use an outgoing lot-inspection sampling plan of the finished products for the following requirements from this specification. Acceptable Quality Level (AQL) shall be level II “normal” 0.65%.

The cartridge inspection shall test the following requirements:

Cartridge is properly write protected

Cartridge can be write-enabled by applying the write-enable passcode and ensuring it is writeable. Any failure to write enable a cartridge must be reported immediately to the NLS QAS, via e-mail at [email protected], and shipments halted. If the cartridge is successfully write-enabled, then the cartridge must be write-protected and included with the shipment.

Label and adhesive residue is cleared from the housing. Residual adhesive shall be less than that which would hold a label sized sheet of 20 lb. paper inverted

Cartridge must be free from significant physical damage; cartridge must fit into the machine dock, housing shall not be cracked and shall have no sharp edges, etc.

-

Page 8 of 17

NLS Spec No. 430 December 2019

Cartridge is clean and free of dust, dirt, debris, or other contamination. Any cleaning agent utilized in the refurbishment process shall not leave a visible/tactile residue or a perceptible odor from greater than 0.5 meters

USB connector is free from physical damage

USB connector is clean and free of dust, dirt, debris, or other contamination

Cartridge operates and is recognized by a computer and identified as an LoC.NLS Taking Book USB Device (not generic device)

Cartridge is formatted as a FAT32 file system and contains no files

The container inspection shall include the following:

Address card is removed

The barcode label is the only label present

All adhesive residue is cleared from the container. Residual adhesive shall be less than that which would hold a label sized sheet of 20 lb. paper inverted

Container is clean and free of dust, dirt, debris or other contamination. Any cleaning agent utilized in the refurbishment process shall not leave a visible/tactile residue or a perceptible odor from greater than 0.5 meters

Container must latch properly and be free from excessive physical damage

Container barcode is present, legible, and free from damage.

4.1.3 Preparation for delivery

Cartridges shall be sorted and grouped by capacity (see note 7 on drawing 4824591013 AppendixA.1) No mixing of capacities shall be allowed. Cartridges and containers shall be boxed and palletized for shipment, protected from moisture and static damage. The nature of the packaging shall be such that the cartridges and containers are easily accessible for use in production. Pallets shall not be more than 5 feet in height and the individual boxes shall not extend past the edge of the pallet. Packaging and method of shipment shall be subject to approval by NLS QAS.

4.2 Contractor’s quality-control plan

The contractor is required to provide written documentation showing that the contractor's methods of quality control incorporate those established by this specification under Section 4.1. The contractor shall submit this document to the NLS/BPH Quality Assurance Section at the beginning of each new contract or at any time required by NLS.

4.3 Correction of faults by contractor

Should NLS determine that a significant fault or faults have been found in production units, then correction of the fault or faults in previously produced units and production inspections or controls for prevention shall be instituted without additional charge to NLS.

4.4 Contractor’s warranty

The contractor shall agree to unconditionally warrant each refurbished product for a period of 1 year. The warranty shall include only the materials supplied by and work performed by the contractor. The contractor will not be responsible for defects or damage of GFE cartridges and containers unless the damage was caused by the contractor. Refurbished cartridges and containers produced by the contractor that are not in conformance with this specification will be returned to the contractor and shall be refurbished for reuse at the contractor's expense.

-

Page 9 of 17

NLS Spec No. 430 December 2019

A monthly report on unusable cartridges shall be forwarded to the NLS QAS. This report should be sent to [email protected], and is due by the 7th of the following month. The monthly report document shall be submitted for approval as part of the written documentation described in Section 4.2.

4.5 Inspection of contractor by NLS

The National Library Service for the Blind and Physically Handicapped, Library of Congress, reserves the right to inspect any process or tests being performed. The Library representative shall have the authority to select, at random, a sample of the cartridges for testing to the specified requirements at any time during the course of the contract without additional charge to NLS. The National Library Service for the Blind and Physically Handicapped, Library of Congress, reserves the right to reject any production lot represented by a sample that has been tested and rejected.

4.6 Lot Samples

For each lot subsequent to the initial production lot, the contractor shall send randomly-selected samples to NLS for inspection. The quantity of samples required will be dependent upon lot size and will be specified by NLS at time of contract award. The contractor’s inspection reports shall accompany the samples. NLS inspection of deliverables shall employ the statistical lot sampling methods of ANSI Standard Z1.4-2003. Sampling shall be in accordance with ANSI/ASQC Z1.4-2003 Normal Inspection Level II and lots shall have an Acceptable Quality Level (AQL) of 0.65. Any Lot that fails to pass the inspection shall be rejected. A rejected lot shall be returned to the contractor for a 100% inspection/evaluation to determine the total number of defective units. All deficient units shall be repaired or replaced. Upon repair or replacement of deficient units the lot shall be re-submitted to NLS. All re-inspection, repair, and replacement work performed by the contractor shall be done at no additional cost.

mailto:[email protected]

-

Page 10 of 17

NLS Spec No. 430 December 2019

Appendices A. Specification Drawings

A.1 Book Cartridge

-

Page 11 of 17

NLS Spec No. 430 December 2019

-

Page 12 of 17

NLS Spec No. 430 December 2019

-

Page 13 of 17

NLS Spec No. 430 December 2019

A.2 Mailing Container

-

Page 14 of 17

NLS Spec No. 430 December 2019

-

Page 15 of 17

NLS Spec No. 430 December 2019

-

Page 16 of 17

NLS Spec No. 430 December 2019

B. Cartridge Passphrase

B.1 Cartridge write-enable

The cartridge is implemented as a mass storage class device using USB Bulk Only Transport and the SCSI Transparent Command Set. A vendor-specific SCSI command is used to write enable the cartridge.

The write-enable SCSI command block is 6 bytes long and contains an operation code byte (10h) and a passcode parameter length.

To enable a device for writing, once a “Set Passcode” command has been executed at any time since manufacture, the “Write-Enable” command shall be executed with the last passcode set each time power is applied to the device. The passcode is the 16-byte, 8-bit sequence represented by the hexadecimal passphrase supplied by NLS for cartridges provided as GFE. The passcode shall be contained in the parameter list and be 16 bytes.

Example hexadecimal representation of 16 byte passphrase: ”9E107D9D372BB6826BD81D3542A419D6”

Vendor Specific SCSI command 0x10

Bit Byte 7 6 5 4 3 2 1 0

0 Operation Code (10h)

1 Reserved (0)

2 Not Used (0)

3 Not Used (0)

4 Parameter List Length (10h)

5 Control (0)

Parameter List Bit Byte 7 6 5 4 3 2 1 0

0 Byte 0 of passcode (0x9E)

1 Byte 1 of passcode (0x10)

2 Byte 2 of passcode (0x7D)

3 Byte 3 of passcode (0x9D)

4 Byte 4 of passcode (0x37)

5 Byte 5 of passcode (0x2B)

6 Byte 6 of passcode (0xB6) 7 Byte 7 of passcode (0x82) 8 Byte 8 of passcode (0x6B) 9 Byte 9 of passcode (0xD8) 10 Byte 10 of passcode (0x1D) 11 Byte 11 of passcode (0x35) 12 Byte 12 of passcode (0x42) 13 Byte 13 of passcode (0xA4) 14 Byte 14 of passcode (0x19) 15 Byte 15 of passcode (0xD6)

-

Page 17 of 17

NLS Spec No. 430 December 2019

B.2 Cartridge write-protect

The cartridge is implemented as a mass storage class device using USB Bulk Only Transport and the SCSI Transparent Command Set. A vendor-specific SCSI command is used to write-enable the cartridge.

The write-protect SCSI command block is 6 bytes long and contains an operation code byte (11h) and a passcode parameter length.

To protect a device against writing, the “Write-Protect” command shall be executed with the 16-byte passcode. The passcode is the 16-byte, 8-bit sequence represented by the hexadecimal passphrase supplied by NLS. The passcode shall be contained in the parameter list and be 16 bytes.

Example hexadecimal representation of 16-byte passphrase: “076827E5E002E0A4CFCB990EF3E8CDB3”

Vendor Specific SCSI command 0x11 Bit Byte 7 6 5 4 3 2 1 0

0 Operation Code (11h)

1 Reserved (0)

2 Not Used (0)

3 Not Used (0)

4 Parameter List Length (10h)

5 Control (0)

Parameter List

Bit Byte 7 6 5 4 3 2 1 0

0 Byte 0 of passcode (0x07)

1 Byte 1 of passcode (0x68)

2 Byte 2 of passcode (0x27)

3 Byte 3 of passcode (0xE5)

4 Byte 4 of passcode (0xE0)

5 Byte 5 of passcode (0x02)

6 Byte 6 of passcode (0xE0) 7 Byte 7 of passcode (0xA4) 8 Byte 8 of passcode (OxCF) 9 Byte 9 of passcode (0xCB)

10 Byte 10 of passcode (0x99) 11 Byte 11 of passcode (0x0E) 12 Byte 12 of passcode (0xF3) 13 Byte 13 of passcode (0xE8) 14 Byte 14 of passcode (0xCD) 15 Byte 15 of passcode (0xB3)

Specification 430:2018 Refurbishing Digital Talking-Book Cartridges and ContainersRevision HistoryFinal ApprovalTable of Contents1. Scope2. Reference Documents2.1 Standards

3. Requirements3.1 Refurbishment3.1.1 Refurbished cartridges3.1.2 Refurbished containers

3.2 Write protection3.2.1 Cartridge write-enabled passcode3.2.2 Cartridge write-protected passcode3.2.3 Security of cartridge passphrases3.2.4 Cartridge file system3.2.5 Software

3.3 Monthly totals

4. Quality Assurance4.1 Inspection4.1.1 Incoming inspection for cartridges from NLS network libraries4.1.2 Outgoing inspection4.1.3 Preparation for delivery

4.2 Contractor’s quality-control plan4.3 Correction of faults by contractor4.4 Contractor’s warranty4.5 Inspection of contractor by NLS4.6 Lot Samples

AppendicesA. Specification DrawingsA.1 Book CartridgeA.2 Mailing ContainerB. Cartridge PassphraseB.1 Cartridge write-enableB.2 Cartridge write-protect