Spec Book Blast Page 073010 - Dlubak Specialty Glass ...

Transcript of Spec Book Blast Page 073010 - Dlubak Specialty Glass ...

The design of a blast window system involves very detailed areas of design. First the peak pressure must be determined from the size of the charge and the set back distance from that charge. Then a positive phase duration must be known to determine the impulse of the blast wave. Finally a performance condition must be specified to determine the expected performance level. With this information a computer model can be constructed to determine the specific thickness or layers of material needed to contain the blast within the specified performance criteria . See the chart below for performance conditions. (GSA Test Protocol: GSA-TS01-2003).

It is important to note that a blast resistant window operates as a system. It involves not only the glass itself, but also the framing system, anchoring system and even the structure of the building. A frame that is not designed for blast or that is not anchored properly may not hold the glazing during a blast situation causing unnecessary failure and possible injury. A qualified blast engineer should be consulted for the design of each project.

3A 3B

4

5Occupied Space

Window Assembly

Window Performance Condition & Glass Fragmentation Diagram

1

2

3.3 ft

10 ft

2 ft

5

4

3B

3A

2

1 Safe NoneGlazing does not break. No visible

damage to glazing or frame

Description of Window GlazingResponse

HazardLevel

ProtectionLevel

PerformanceCondition

Glazing cracks but is retained by theframe. Dusting or very small fragments

near sill or on floor acceptable.

Glazing cracks fragments enter spaceand land on floor no further than 3.3 ft.

from window.

Glazing cracks fragments enter spaceand land on floor no further than 10 ft.

from window.

Glazing cracks fragments enter space,land on floor and impact a vertical

witness panel at a distance of no morethan 10 ft. from the window at a heightno greater than 2 ft. above the floor.

Glazing cracks and window system fails catastrophically. Fragments enter space,

impacting a vertical witness panel at adistance of no more than 10 ft. from the

window at a height greater than 2 ft. above the floor.

Very high None

High Very Low

High Low

High

Medium Medium

Low

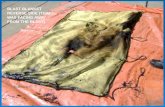

As the threat of terrorist attacks with explosive devices increases we have become much more aware of the need to secure buildings against blast. Windows have become a particular focus, as we have learned that many of the injuries sustained in a blast are the result of flying glass. Standard window designs of monolithic glass will shatter in a blast situation, propelling thousands of razor sharp fragments into the occupied space, resulting in serious injury or even death. These injuries can be minimized or even prevented with the use of laminated glass products for blast mitigation.

Laminated products substantially reduce injuries because the glass fragments are adhered to the interlayer material preventing them from being propelled into the occupied space. Laminated products can also increase protection from other flying debris such as rocks, because the elastic interlayer material helps prevent objects from penetrating. Other materials such as polycarbonates or other plastics can be incorporated into the laminate for additional impact resistance. See below for some of the blast laminates that Dlubak offers.

Blast Design

Glass/Polycarbonate Laminates

Insulating Units Available(ASTM E 2190 Certified)

Custom Designs Available for Government,Military and Commercial Applications

Air Force Research Lab, Tyndall

FBI Birmingham, Al

Tempered Glass Laminates(Cost effective & Maximum Durability)

DuPont SentryGlas® & Spall Shield®(Dupont’s Ionoplast Interlayer Technology)

Kathmandu, Nepal USAID AnnexQuito, Ecuador NEC

Laminates

BLASTRESISTANT

073010

520 Chestnut St.Blairsville, PA 15717www.dlubakglass.com

724-459-9540800-336-0562

Fax:724-459-0866