Some results of vacuum stand investigation.. 1. Restoration of turbopump inlet valve V1 tightness...

-

Upload

theodore-lawson -

Category

Documents

-

view

217 -

download

3

Transcript of Some results of vacuum stand investigation.. 1. Restoration of turbopump inlet valve V1 tightness...

Some results of vacuum stand investigation.

1. Restoration of turbopump inlet valve V1 tightness

• The inlet turbopump valve of the first pump station got a leak.

• We sow it in time of working stand in 05.02.2013 (fig 1). The leak was about 3E-10 l∙mbar/s. The leak was appeared after pump station stopping.

• Then the leak was increase up to 2 E-9 l∙mbar/s next working time of the stand in 14.05.2013 (Fig 2).

• We did several times closing of the valve during pumping of the stand in 28.08.2013.

And so we eliminated the valve leak such manner (Fig 3).

Partial pressure measure 04÷05.02.2013

T=125˚C,17-00

T=78˚C,18-00

T=26˚C,8-00

Switch on analyzer time Switch on analyzer timeSwitch off analyzer time

04.02.2013

05.02.2013

Switch off pump station N1(V1closed)

Switch off pump station N1(V1closed)

Switch on pump station N1 (V1closed)

P total=3.3∙10 ¹־ ˚ mbar

Only H2

The valve V1 leak was appeared about 3E-10 l∙mbar/s

Fig 1.

The valve V1 closed at 125ºC

The stand without monitors

Partial pressure measure 14÷15.05.2013

T=123˚C,14-43

Switch on analyzer time

T=61˚C,16-10

Switch off analyzer time

14.05.2013 14.05.2013

Switch off pump station N1 (V1 closed)It is leak of valve V1

T=26˚C,8-03

Switch on analyzer time

P total=2E-9mbar(N2/CO,H2,Ar)

Then the valve V1 leak was increased up to 2 E-9 l∙mbar/s

Valve V1 of pump station N1 is closedat the temperature of 86ºC

Fig 2.

The stand without monitors

Partial pressure measure 27÷28.08.2013

Switch on analyzer time

T=128ºC, 15-23

Switch off analyzer time

T=72ºC, 16-35

Switch on analyzer time

T=21ºC, 08-00

27.08.2013

28.08.2013

P total=1.4E-10mbar Only H2

Close valve V8 of pump station N2

The valve V1 leak was eliminated after several times closing.

Fig 3.

The valve V1 is closed at 128ºC

The temperature of inlet pump flange was increased up to 100ºC

Switch off pump station N1

The stand without monitors

2. Degreasing of pollution level from pump station

• We observed that pump station N1 spread pollutions (the main pollution is water vapour). You can see it on the figure 2.

• For eliminate these pollutions the temperature of the inlet turbopump flange was increased up to 100C. And besides it we decide to close of the pump station valve in the end of heating cycle at the temperature higher than 100ºC.

• After these actions we don’t see pollutions now on the figure 3.

3. Liquidation of pollution from gauges APR 262• We used and use now the vacuum

gauges APR 262 for measure of pure nitrogen pressure after monitors filling. These gauges are heated only up to 80ºC. This gauges temperature is smaller than temperature all other are heated parts. So we see the water vapour (2.9E-10 mbar) on the spectrum Fig 4, and total pressure 1.1E-9 mbar.

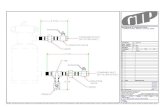

• Now we installed three valves (Fig 5) for closing these gauges in the heating time. The valves are open in the filling time when pressure higher than 100 mbar. After installing valves we have got the spectrum without vapour of water and ultimate rest gas pressure is about 1.5E-10 mbar (Fig 3).

Partial pressure measure 14.08.2007

P total = 1.1E-9 mbar PH2 = 7.4E-10mbarPH2O = 2.9E-10 mbar

Fig 4.

Spectrum of the rest gas in the stand without of monitors

Scheme of the vacuum stand

Fig 5.

ConclusionThe list of the up-date actions

• Restoration of turbopump inlet valve V1 tightness (Fig 1,2,3): -The valve leak was eliminated after several times closing.

• Amount and level of rest gas components penetrated from pump station are degrease (Fig 2,3):

- It made by increasing of the turbopump inlet flange temperature.

• Liquidation of pollution from gauges APR 262 (Fig 3,4,5):

- It made by installing additional valves for closing of the gauges at heating time.

So we got the ultimate rest gas pressure in the stand about 1.5E-10 mbar and the main rest gas is H2.