Solid Mechanics - Calculating the signboard

-

Upload

ilyia-syafira -

Category

Documents

-

view

180 -

download

30

description

Transcript of Solid Mechanics - Calculating the signboard

Contents

PROBLEM ........................................................................................................................... 2

INTRODUCTION ................................................................................................................ 3

SIGN BOARD IMAGE ..................................................................................................... 8

OBJECTIVES ....................................................................................................................... 9

THEORY AND ANALYSIS ............................................................................................... 10

LIST OF FORMULA .......................................................................................................... 14

MATERIALS ..................................................................................................................... 15

ALUMINIUM ................................................................................................................. 15

STEEL ............................................................................................................................ 17

SIGN BOARD DRAWING (SOLIDWORK) ...................................................................... 20

CALCULATIONS .............................................................................................................. 24

WIND LOAD .................................................................................................................. 24

BOARD LOAD (Aluminium sheet metal) ....................................................................... 25

BRACKET LOAD .......................................................................................................... 25

FREE BODY DIAGRAM ............................................................................................... 26

STRESS ANALYSIS OF POINT A, E AND C ............................................................... 28

STRESS ANALYSIS OF POINT B AND D.................................................................... 29

DISCUSSION ..................................................................................................................... 30

SUGGESTION ................................................................................................................... 32

REFERENCES ................................................................................................................... 33

PROBLEM

Choose any sign in the campus. Determine the state of stress at points A, B, C, D and E as

shown in the figure. Sketch the stress element at each of these points. Loads to be considered

are the weight of road sign and the wind load that acts normal to the surface of the road sign.

The highest recorded wind speed in Malaysia is 150 km/h or 41.7 m/s (source: Malaysian

Meteorological Department)

INTRODUCTION

This report presents a design of road sign board and how it can resist a force that pass

through it. All of the information in this report we obtained through observation, calculation

and analysis. Sign board plays a big role to us especially in finding a way. It makes our job

easier. The purpose of a sign board is to communicate and to convey information such that its

receiver can make cognitive decisions based on the information provided. There are many

types of sign board that we can found. In general, signs can be classified into the following

functions:

a) Information

- Signs giving information about services and facilities

- E.g. maps, directories, instructions for use, etc

b) Direction

- Signs leading to services, facilities, functional spaces and key areas

- E.g. sign posts, directional arrows, etc

c) Identification

- Signs indicating services and facilities

- E.g. room names & numbers, toilet signs, number of floor, etc

d) Safety and Regulatory

- Signs giving warning or safety instructions

- E.g. warning signs, traffic signs, exit signs, rules & regulations, etc.

Traffic signs consist of three basic components:

A blank

Background sheeting

Sign copy

Blanks, usually constructed of plywood, aluminium, or steel, serve as the framework of the

sign. Plywood is the least expensive blank material. It is fairly strong but is susceptible to

weather damage since it is porous. Plywood blanks must be overlaid with a thin layer of

plastic. Aluminium will not rust, but it is very lightweight and must be reinforced with metal

braces along the back. It is the most expensive blank option. Steel is a more economical

alternative to aluminium, it is also more sturdy and does not need reinforcement. Rusting can

be prevented by applying a coat of zinc to the steel blank. Background sheeting and the letter

and symbols for the sign copy are cut from retro-reflective sheeting. This sheeting consists of

tiny glass beads or microprisms embedded in a flexible plastic surface, this construction

allows light from car headlights to be reflected off the sign and back to the driver. Colored

light is reflected from the sign if the sheeting is dyed with a pigment. For instance, to make

“STOP” signs, red dye can be added to the sheeting mixture when it is in a liquid form.

When selecting a material for a particular application, engineers must be confident that it will

be suitable for the loading conditions and environmental challenges it will be subjected to

while in service. The retro-reflective sheeting material is applied to the rigid sign backing,

which can be aluminium, wood or a composite plastic. Understanding and control of a

material’s properties is therefore essential. Thus, the materials with their properties that

commonly used in making sign board is listed below.

Plywood

Plywood is used occasionally for temporary signs because it can be cheaper and is lighter

than aluminium. Fibre glass reinforced plastic materials are used infrequently because of their

handling and recycling issues.

Sheet metal

Sheet metal refers to metal that has a high surface area to volume ratio. Sheet metal is metal

formed by an industrial process into thin, flat pieces. It is one of the fundamental forms used

in metal working and it can be cut and bent into a variety of shapes. Countless everyday

objects are constructed with sheet metal. Thicknesses can vary significantly; extremely thin

thicknesses are considered foil or leaf, and pieces thicker than 6 mm (0.25 in) are considered

plate. Sheet metal is used in the manufacture of cars, trains, aircraft, farm equipment, office

equipment, furniture, house appliances, computers, machine components and beverage cans

to name a few. Therefore, some of the sheet metal operations discussed may not be applicable

to plate. Sheet metal manufacture is mostly performed on a press and parts are formed

between two die. Sheet metal is usually formed cold, however warm or hot working of parts,

(particularly plate), is possible. Generally for sheet metal applications there is essentially no

change, or negligible change, in sheet thickness. Sheet metal manufacturing produces parts

that typically have high strength, good surface and accurate tolerances.

Aluminium

Aluminium is by far the most commonly used material. The aluminium backing can be

reused often, reducing the cost of signing and can be recycled easily to recoup a small portion

of the cost. Aluminium has a unique and unbeatable combination of properties which means

that it is an extremely versatile, highly usable and attractive construction material.

Aluminium is light with a density one third of that of steel. Aluminium is strong with a

tensile strength of 70 to 700MPa depending on the alloy and manufacturing

process. Extrusions of the right alloy and design are as strong as structural steel. The

Young's modulus for aluminium is a third that of steel (E=70,000 MPa). this means that the

moment of inertia has to be three times as great for an aluminium extrusion to achieve the

same deflection as a steel profile. A thin layer of oxide is formed in contact with air, which

provides very good protection against corrosion, even in corrosive environments. This layer

can be further strengthened by surface treatment such as anodising or powder coating.

Aluminium is a good reflector of both light and heat.

Zinc

Zinc is a weak metal with a tensile strength less than half that of mild carbon steel. It is

generally not used in load-bearing applications, although inexpensive mechanical parts can be

die cast from zinc. Pure zinc has low toughness and is generally brittle, but zinc alloys

generally have high impact strength compared to other die casting alloys. Between 212-312

oF, zinc becomes ductile and malleable, but at elevated temperatures reverts to a brittle state.

Again, zinc alloys greatly improve on this property over the pure metal, allowing more

complex fabrication methods to be used. Zinc’s conductivity is moderate for a metal. Its

strong electrochemical properties, however, serve well in the galvanizing process and

alkaline batteries.

Steel

The mechanical properties of steel can be carefully controlled through the selection of an

appropriate chemical composition, processing and heat treatment, which lead to its final

microstructure. The alloys and the heat treatment used in the production of steel result in

different property values and strengths and testing must be performed to determine the final

properties of steel and to ensure adherence to the respective standards. There are many

measurement systems used to define the properties of a given steel. For example, yield

strength, ductility and stiffness are determined using tensile testing. Toughness is measured

by impact testing; and hardness is determined by measuring resistance to the penetration of

the surface by a hard object. Tensile testing is a method of evaluating the structural response

of steel to applied loads, with the results expressed as a relationship between stress and strain.

The relationship between stress and strain is a measure of the elasticity of the material, and

this ratio is referred to as Young's modulus. A high value of Young's modulus is one of

steel’s most differentiating properties; it is in the range 190-210 GPa, which is approximately

three times the value for aluminium.

The physical properties of steel are related to the physics of the material, such as density,

thermal conductivity, elastic modulus, Poison’s ratio etc. Some typical values for physical

properties of steel are:

density ρ = 7.7 ÷ 8.1 [kg/dm3]

elastic modulus E=190÷210 [GPa]

Poisson’s ratio ν = 0.27 ÷ 0.30

Thermal conductivity κ = 11.2 ÷ 48.3 [W/mK]

Thermal expansion α = 9 ÷27 [10-6

/ K]

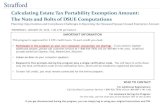

SIGN BOARD IMAGE

It is a road sign board

Located at the foot of the hill

FRONT VIEW

SIDE VIEW BACK VIEW

OBJECTIVES

To determine the maximum load that can be applied to the sign board.

To determine at which point the maximum stress will occur.

THEORY AND ANALYSIS

Mechanical properties:

Strength, hardness, toughness, elasticity, plasticity, brittleness, and ductility and malleability

are mechanical properties used as measurements of how metals behave under a load. These

properties are described in terms of the types of force or stress that the metal must withstand

and how these are resisted. Common types of stress are compression, tension, shear, torsion,

impact, 1-2 or a combination of these stresses, such as fatigue.

Compression stresses develop within a material when forces compress or crush the material.

A column that supports an overhead beam is in compression, and the internal stresses that

develop within the column are compression.

Tension (or tensile) stresses develop when a material is subject to a pulling load; for example,

when using a wire rope to lift a load or when using it as a guy to anchor an antenna. "Tensile

strength" is defined as resistance to longitudinal stress or pull and can be measured in pounds

per square inch of cross section. Shearing stresses occur within a material when external

forces are applied along parallel lines in opposite directions. Shearing forces can separate

material by sliding part of it in one direction and the rest in the opposite direction.

Some materials are equally strong in compression, tension, and shear. However, many

materials show marked differences; for example, cured concrete has a maximum strength of

2,000 psi in compression, but only 400 psi in tension. Carbon steel has a maximum strength

of 56,000 psi in tension and compression but a maximum shear strength of only 42,000 psi;

therefore, when dealing with maximum strength, you should always state the type of loading.

A material that is stressed repeatedly usually fails at a point considerably below its maximum

strength in tension, compression, or shear. For example, a thin steel rod can be broken by

hand by bending it back and forth several times in the same place; however, if the same force

is applied in a steady motion (not bent back and forth), the rod cannot be broken. The

tendency of a material to fail after repeated bending at the same point is known as fatigue.

Table - Mechanical Properties of Metals/Alloys

Strength

Strength is the property that enables a metal to resist deformation under load. The ultimate

strength is the maximum strain a material can withstand. Tensile strength is a measurement of

the resistance to being pulled apart when placed in a tension load.

Fatigue strength is the ability of material to resist various kinds of rapidly changing stresses

and is expressed by the magnitude of alternating stress for a specified number of cycles.

Impact strength is the ability of a metal to resist suddenly applied loads and is measured in

foot-pounds of force.

Hardness

Hardness is the property of a material to resist permanent indentation. Because there are

several methods of measuring hardness, the hardness of a material is always specified in

terms of the particular test that was used to measure this property. Rockwell, Vickers, or

Brinell are some of the methods of testing. Of these tests, Rockwell is the one most

frequently used. The basic principle used in the Rockwell testis that a hard material can

penetrate a softer one. We then measure the amount of penetration and compare it to a scale.

For ferrous metals, which are usually harder than nonferrous metals, a diamond tip is used

and the hardness is indicated by a Rockwell "C" number. On nonferrous metals, that are

softer, a metal ball is used and the hardness is indicated by a Rockwell "B" number. To get an

idea of the property of hardness, compare lead and steel. Lead can be scratched with a

pointed wooden stick but steel cannot because it is harder than lead.

Toughness

Toughness is the property that enables a material to withstand shock and to be deformed

without rupturing. Toughness may be considered as a combination of strength and plasticity.

Table 1-2 shows the order of some of the more common materials for toughness as well as

other properties.

Elasticity

When a material has a load applied to it, the load causes the material to deform. Elasticity is

the ability of a material to return to its original shape after the load is removed. Theoretically,

the elastic limit of a material is the limit to which a material can be loaded and still recover its

original shape after the load is removed.

Plasticity

Plasticity is the ability of a material to deform permanently without breaking or rupturing.

This property is the opposite of strength. By careful alloying of metals, the combination of

plasticity and strength is used to manufacture large structural members. For example, should

a member of a bridge structure become overloaded, plasticity allows the overloaded member

to flow allowing the distribution of the load to other parts of the bridge structure.

Brittleness

Brittleness is the opposite of the property of plasticity. A brittle metal is one that breaks or

shatters before it deforms. White cast iron and glass are good examples of brittle material.

Generally, brittle metals are high in compressive strength but low in tensile strength. As an

example, you would not choose cast iron for fabricating support beams in a bridge.

Ductility and Malleability

Ductility is the property that enables a material to stretch, bend, or twist without cracking or

breaking. This property makes it possible for a material to be drawn out into a thin wire. In

comparison, malleability is the property that enables a material to deform by compressive

forces without developing defects. A malleable material is one that can be stamped,

hammered, forged, pressed, or rolled into thin sheets.

LIST OF FORMULA

i. Flexure formula :

ii. Shear stress :

iii. Normal stress :

iv. Wind force, FWIND : Wk x width x height (Based on BS code 6399)

MATERIALS

For this sign board chosen, materials used are aluminium and steel A-36. Aluminium is used

in form of sheet metal while steel A-36 is used for the sign board support.

ALUMINIUM

Background

Aluminium is the world’s most abundant metal and the third most common element

comprising 8% of the earth’s crust. The versatility of aluminium makes it the most widely

used metal after steel.

Applications of Aluminium

Pure aluminium is soft, ductile, corrosion resistant, and has a high electrical conductivity. It is

widely used for foil and conductor cables, but alloying with other elements is necessary to

provide the higher strengths needed for other applications. Aluminium is one of the lightest

engineering metals, having strength to weight ratio superior to steel.

By utilising various combinations of its advantageous properties such as strength, lightness,

corrosion resistance, recyclability and formability, aluminium is being employed in an ever-

increasing number of applications. This array of products ranges from structural materials

through to thin packaging foils.

Alloy Designations

Aluminium is most commonly alloyed with copper, zinc, magnesium, silicon, manganese and

lithium. Small additions of chromium, titanium, zirconium, lead, bismuth and nickel are also

made and iron is invariably present in small quantities.

There are over 300 wrought alloys with 50 in common use. They are normally identified by a

four figure system which originated in the USA and is now universally accepted. Table 1

describes the system for wrought alloys. Cast alloys have similar designations and use a five

digit system.

Physical Properties of Aluminium

Density of Aluminium

Aluminium has a density around one third that of steel or copper making it one of the lightest

commercially available metals. The resultant high strength to weight ratio makes it an

important structural material allowing increased payloads or fuel savings for transport

industries in particular.

Strength of Aluminium

Pure aluminium doesn’t have a high tensile strength. However, the addition of alloying

elements like manganese, silicon, copper and magnesium can increase the strength properties

of aluminium and produce an alloy with properties tailored to particular applications.

Aluminium is well suited to cold environments. It has the advantage over steel in that its’

tensile strength increases with decreasing temperature while retaining its toughness. Steel on

the other hand becomes brittle at low temperatures.

Corrosion Resistance of Aluminium

When exposed to air, a layer of aluminium oxide forms almost instantaneously on the surface

of aluminium. This layer has excellent resistance to corrosion. It is fairly resistant to most

acids but less resistant to alkalis.

Thermal Conductivity of Aluminium

The thermal conductivity of aluminium is about three times greater than that of steel. This

makes aluminium an important material for both cooling and heating applications such as

heat-exchangers. Combined with it being non-toxic this property means aluminium is used

extensively in cooking utensils and kitchenware.

Electrical Conductivity of Aluminium

Along with copper, aluminium has an electrical conductivity high enough for use as an

electrical conductor. Although the conductivity of the commonly used conducting alloy

(1350) is only around 62% of annealed copper, it is only one third the weights and can

therefore conduct twice as much as electricity when compared with copper of the same

weight.

Reflectivity of Aluminium

From UV to infra-red, aluminium is an excellent reflector of radiant energy. Visible light

reflectivity of around 80% means it is widely used in light fixtures. The same properties of

reflectivity makes aluminium ideal as an insulating material to protect against the sun’s rays

in summer, while insulating against heat loss in winter.

STEEL

Background

Steel is an alloy of iron and a small amount of carbon. Carbon is the primary alloying

element, and its content in the steel is between 0.002% and 2.1% by weight. Too little carbon

content leaves (pure) iron quite soft, ductile, and weak. Carbon contents higher than those of

steel make an alloy commonly called pig iron that is brittle and not malleable. Additional

elements may be present in steel: manganese, phosphorus, sulphur, silicon, and traces of

oxygen, nitrogen and aluminium. Alloy steel is steel to which additional alloying elements

have been intentionally added to modify the characteristics of steel. Common alloying

elements include: manganese, nickel, chromium, molybdenum, boron, titanium, vanadium

and niobium.

Classification of Steel

There are five major classifications of steels: carbon steel, alloy steel, high-strength low-alloy

steel, stainless steel and tool steel. Carbon steels are the most common, containing various

amounts of carbon; produce everything from machines to bedsprings to bobby pins. Alloy

steels have definite amounts of vanadium, molybdenum, manganese, silicon and cooper.

Alloy steels produce gears, carving knives and even roller skates. Stainless steels have

chromium, nickel amongst other alloy elements which sustains their colour and reaction to

rust. Stainless steel products include pipes, space capsules, surgical equipment to kitchen

equipment. Last but not least, tool steels have tungsten, molybdenum amongst other alloy

elements. These elements create the strength and ability of the tool steel products, which

include parts for manufacturing operations as well as machinery.

The varying amounts of carbon, amongst other elements in each of the types of steel create a

variety in densities or specific gravities. (Specific gravity or relative density is the ratio of a

material's density to that of water.)

Stainless steels are the densest, coming in at 8000 kg/m3. Though the densities vary, the

density of steel is about 7700 kg/m3. The density of steel are measured

in g/cm3, kg/m3, kg/L and lb. /f3, with kg/m3 being the more commonly used measurement.

A good way to remember the density of steel is to remember that titanium has about half the

density of steel and aluminium is about one-third.

Applications of Steel

Iron and steel are used widely in the construction of roads, railways, other infrastructure,

appliances, and buildings. Most large modern structures, such as stadiums and skyscrapers,

bridges, and airports, are supported by a steel skeleton. Even those with a concrete structure

employ steel for reinforcing. In addition, it sees widespread use in major appliances and cars.

Despite growth in usage of aluminium, it is still the main material for car bodies. Steel is used

in a variety of other construction materials, such as bolts, nails, and screws.

Other common applications include shipbuilding, pipelines, mining, offshore construction,

aerospace, white goods (e.g. washing machines), heavy equipment such as bulldozers, office

furniture, steel wool, tools, and armour in the form of personal vests or vehicle armour (better

known as rolled homogeneous armour in this role). Steel was the metal of choice for sculptor

Jim Gary and a frequent choice for sculpture by many other modern sculptors.

Physical Properties of Steel

The physical properties of an alloy depend on the percentage composition of the

constituent elements and the manufacturing process. The properties of steel are totally

different from its component elements - iron and carbon. One of its major properties is the

ability to cool down rapidly from an extremely hot temperature after being subjected to water

or oil. And a particular amount of carbon can be dissolved in iron at a specific temperature.

The physical properties of steel include high strength, low weight, durability, ductility

and resistance to corrosion. Steel, as we all know, offers great strength though it is light in

weight. In fact, the ratio of strength to weight for steel is the lowest than any other building

material available to us. The term ductility means steel can be molded easily to form any

desired shape.

Unlike the constituent element iron, steel does not corrode easily, on being exposed to

moisture and water. The dimensional stability of steel is a desired property; it is found that

the dimension of steel remains unchanged even after many years, or after being subjected to

extreme environmental conditions. Steel is a good conductor of electricity, i.e., electricity can

pass through steel.

Steel grades are classified by many standard organizations, based on the composition

and the physical properties of the metal. The deciding factor for the grade of steel is basically

its chemical composition and the supplied condition. The higher the carbon content, the

harder and stronger is the steel metal. On the contrary, high quality steel containing less

carbon is more ductile.

Earlier forms of steel consisted of more carbon, as compared to the present day steel.

Today, the steel manufacturing process is such that less carbon is added and the metal is

cooled down immediately, so as to retain the desirable physical properties. Rapid cooling (or

quenching) of steel also alters the grain structure.

There are other types of steel such as galvanized steel and stainless steel (corrosion-

resistant steel). Galvanized steel is coated with zinc to protect it from corrosion, whereas

stainless steel contains about 10 percent chromium in its composition.

The major advantage of steel is the ability to recycle it effectively, without destroying

or losing any of its physical properties in the recycling process. Steel is very important in our

day-to-day life; starting from cookware to scientific instruments like scalpel, steel is used in

making several items. Steel is one of the most versatile and sustainable construction

materials. Due to its cost-effectiveness and strength, it is used in engineering works and

infrastructure developments such as roads, railways, bridges, buildings and stadiums. Indeed,

the technological and economic progress gained momentum with the growth and

development of steel industries, further promoting the industrial growth.

SIGN BOARD DRAWING (SOLIDWORK)

TOP VIEW

FRONT VIEW

BACK VIEW

ISOMETRIC VIEW

CALCULATIONS

WIND LOAD

Given from question, wind speed = 150 km/h. To calculate wind load from given speed, BS

code 6399 is referred.

Basic speed, V = 250 km/h = 41.67 m/s

Topological factor, s1 = 1.10

Height above ground factor, s2 = 1.01

Life of a structure factor, s3 = 1.00

Design wind speed, Vs = V x s1 x s2 x s3

= 41.67 x 1.10 x 1.01 x 1.00

= 46.30 kN/m2

Q = 0.613 Vs2

= 0.613 (46.30)2

= 1.314 kN/m2

Take Cp1 = 0.7 and Cp2 = -0.25

Wind pressure, Wk = Q (Cp1 – Cp2)

= (1.314)(0.7 – (-0.25))

= 1.2483 kN/m2

Wind force, FWIND = Wk x width x height

= (1.2483)(0.905)(0.465)

FWIND = 0.525 N

BOARD LOAD (Aluminium sheet metal)

ρal = 2800 kg/m3

Val = 0.905 x 0.465 x 0.0005

= 2.104 x 10-4

mal = 2800kg/m3 x 2.104x10

-4

= 0.589 kg

Find FPLATE

= 0.589kg x 9.81m/s2

FPLATE = 5.77 N

BRACKET LOAD

To find FBRACKET ;

ρSTEEL = 7850 kg/m3

VSTEEL = V1 + V2 + V3

V1 = V3 = 0.14 x 0.055 x 0.005

= 3.85x10-5

V2 = 0.14 x 0.005 x 0.025

= 1.75x10-5

VTOTAL = 2(3.85x10-5

) + 1.75x10-5

= 9.48 x 10-5

mSTEEL = 7850 kg/m

3 x 9.48x10

-5

= 0.7442 kg

Find FBRACKET

= 0.742kg x 9.81 m/s2

FBRACKET = 7.30 N

0.905 m

0.465 m

0.05cm

5.5cm

14cm

1 3

0.05cm

X c

m

N V Mo

7.30 N

7.30 N

5.77 N

FREE BODY DIAGRAM x-axis

y-axis

From the free body diagram;

+ ↑∑ FY = 0;

= FWIND + V

= -0.525 (0.465) - V

V = 244 N ↑

→∑ FX = 0;

= FPLATE + (2 x FBRACKET) + N

= 5.77 + (2 x 7.3) - N

N = 20.37 N ←

∑ MO = 0; (counter-clockwise positive)

= FWIND + FBRACKET1 + FBRACKET2 + FPLATE + MO

= (525)(0.465)(χ–0.2325) –(7.3)(0.0275) – (7.3)(0.0275) – (5.77)(0.028) + MO

MO = 396.75 N.m (clockwise)

+

STRESS ANALYSIS OF POINT A, E AND C

Since point A, E and C lies on Neutral Axis (NA), there are no bending moment occurred on

the points.

And σA = σC = σE ;

( )

=

[ ( ) ] [ ( ) ]

= 11 919.25 Pa » 11.92 kPa

= ( )( )

( ) ( )

= 273 066.5 Pa

= 0.273MPa

𝑄 ∑ȳ′𝐴′ 4𝑟𝑜3𝜋

𝜋𝑟𝑜

2 −

4𝑟𝑖3𝜋

𝜋𝑟𝑖

2

𝐼 1

4𝜋(𝑟𝑜

− 𝑟𝑖 )

= ( )

𝜋

𝜋( )

−

( )

𝜋

𝜋( )

= 1.7906x10-5

m3

=

𝜋 (0 038 − 0 03 )

= 1.00x10-6

m4

σA = 11.92 kPa

τA = 0.273

MPa

A E C

NA

A, E & C STRESS ELEMENT

Y-AXIS VIEW

STRESS ANALYSIS OF POINT B AND D

At point B and point D, the shear stress is zero.

And since both point located at the farthest location,

The normal stress and bending moment are maximum.

σB

( )

[ ( ) ] [ ( ) ] −

( )( )

( )

= 11 919.25 - 15 076 500

= 15.065 MPa

( )

[ ( ) ] [ ( ) ]

( )( )

( )

= 11 919.25 + 15 076 500

= 15.09 MPa

15.065 MPa

B

D

B STRESS ELEMENT

Y-AXIS VIEW

15.065 MPa

D STRESS ELEMENT

Y-AXIS VIEW

DISCUSSION

Shear failure of reinforced concrete beam, more properly called “diagonal tension

failure”, is difficult to predict accurately. Although the experiment research has been carried

out so many years with the help of sophisticated computational tool, shear failure is still not

fully understood. If a beam without properly designed for shear reinforcement is overloaded

to failure, shear collapse is likely to occur.

All points along the length of the beam, where shear and bending moment are not

zero, and at locations other than extreme fibre or neutral axis, are subject to both shearing

stresses and bending stresses. The combination of these stresses produces maximum normal

and shearing stresses in a specific plane inclined with respect to the axis of the beam.

By assuming that the hollow cylinder uses steel A-36 because of the rusting happens

on the pole and the physical properties that can be seen, in which its yield strength for both

compression and tension is 250 MPa, it is shown that from the result, this design will not face

any failure.

From the calculation made, it shows that the structure will not face failure since the

maximum stress applied on the structure is 15.09 MPa (at point B and point D) with normal

stress acting on the hollow cylinder is only 11.92 kPa. These stresses did not exceed the yield

strength of the steel A-36.

However, in beam design, there is one term of failure called buckling. In

science, buckling is a mathematical instability, leading to a failure mode. Theoretically,

buckling is caused by a bifurcation in the solution to the equations of static equilibrium. At a

certain stage under an increasing load, further load is able to be sustained in one of two states

of equilibrium: an undeformed state or a laterally-deformed state.

Since this pole is considered as free-standing, vertical column, self-buckling might

happen if the height of the column exceeds critical height. For steel A-36 with outer radius

and inner radius are 0.038m and 0.03m respectively, the critical height is 46m, while the

height of the signboard pole is only 1.86m. Thus, self-buckling also will not occur.

= ( )

( )( )

( )( ) ( )

= 46m

One thing that a design should have is a safety factor. Safety factor is a term describing the

structural capacity of a system beyond the expected loads or actual loads. Essentially, how

much stronger the system is than it usually needs to be for an intended load. Safety factors are

often calculated using detailed analysis because comprehensive testing is impractical on

many projects, such as bridges and buildings, but the structure's ability to carry load must be

determined to a reasonable accuracy. Many systems are purposefully built much stronger

than needed for normal usage to allow for emergency situations, unexpected loads, misuse, or

degradation.

=

= 16.6

It shows that this design is way too safe since it is bigger than 1 or 100%.

SUGGESTION

This design is far too safe for the load applied and acting on it. Since we already know

the normal stress, shear stress and bending moment of this particular design, we can reduce

the cost to produce this design by reducing some components in this design. However, the

reductions need to be calculated again to get a specific value.

In order to save production cost, we can reduce the diameter of the pole used for this

particular design. Not only the diameter, but the thickness of the pole can also be reduced. By

reducing the thickness and diameter of this design, the weight of the steel pole is reduced thus

lower its production cost.

We can also use another type of metal for the pole that its yield strength is more than

16MPa. Since the stress on the load is too small, we can use fibre-reinforced plastic (FRP) as

a replacement of this steel pole. However, the outer and inner diameter of FRP pole must be

more or equal to the previous diameter. The height also should not exceed the height

recorded.

REFERENCES

Person:

Mohd Haniff bin Hasanuddin; Civil Engineer, Ministry of Defence.

Book:

British Standard code 6399

Mechanics of Materials (seventh edition); Hibbeler; Pearson-Prentice Hall; 2008

Fundamental of Reinforced Concrete (fifth edition); Phil M Ferguson, John E Breen, James

O. Jirsa; 1988

Website:

http://en.wikipedia.org/wiki/Signage

http://thelibraryofmanufacturing.com/sheetmetal_basics.html

http://www.hydro.com/en/Subsites/Extrusion-Ltd/Aluminium/Aluminium-properties/

http://www.keytometals.com/page.aspx?ID=SteelProperties

http://www.madehow.com/Volume-2/Road-Sign.html

http://www.trafficsigns.com/materials.html