Sodium Fast Reactor - gen-4.org

Transcript of Sodium Fast Reactor - gen-4.org

Sodium Fast Reactor

Philippe DufourSFR SSC Chair

2015 GIF symposiumSession II19 May 2015

Slide 2Tokyo, May 2015

The SFR system was identified during the Generation IV Technology Roadmap as a promising technology to perform the actinide management mission and if enhanced economics for the system could be realized, also the electricity and heat production missions. The main characteristics of the SFR that make it especially suitable for the actinide management mission are:

• Consumption of transuranics in a closed fuel cycle, thus reducing the radiotoxicity and heat load which facilitates waste disposal and geologic isolation.

• Enhanced utilization of uranium resources through efficient management of fissile materials and multi-recycle.

• High level of safety achieved through inherent and passive means that accommodate transients and bounding events with significant safety margins.

Slide 3Tokyo, May 2015

System Research PlanGeneration IV Nuclear Energy Systems

System Research Planfor the Sodium-cooled Fast Reactor

Issued by theGeneration IV International ForumSFR System Steering Committee

Preparing Today for Tomorrow’s Energy Needs

Development Targets and Design RequirementsSFR R&D Projects• System Integration and Assessment (SIA)• Safety and Operations• Advanced Fuel• Component Design and Balance of Plant• Global Actinide Cycle International

Demonstration (GACID)

SFR Design Concepts• Loop Option (JSFR Design Track)• Pool Option (KALIMER-600 & ESFR Design

Tracks)• Small Modular Option (SMFR Design Track)

SRP was updated and released in July 2013

Revision 2

July 12, 2013

Slide 4Tokyo, May 2015

EUR FRA JPN PRC ROK RUF USA

SFR System Arrangement(Signed - 15 Feb 2006)

X X X X X X X

SFR AF PA(Signed - 21 Mar 2007)

X X X P X P X

SFR GACID PA(Signed - Sept 2007)

X X X

SFR CDBOP PA(Signed - 11 Oct 2007)

P X X 2016 X 2016 X

SFR SO PA(Signed - 11 June 2009,Resigned – 15 Nov 2012)

X X X X X X X

SFR SIA PA(Signed - 22 Oct 2014)

X X X X X X X

Status of SFR Arrangements

X=Signatory, D=Under Discussion, P=In Progress

Slide 5Tokyo, May 2015

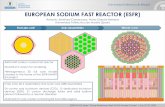

Gen IV SFR System Options and Design Tracks

Loop Pool Small Modular

KALIMERJSFR SMFR

IHXDHX

PHTS pump

Reactor core

Steam Generator

AHX Chimney

PDRC piping

In-vessel core catcher

IHTS piping

IHTS pump

IHXDHX

PHTS pump

Reactor core

Steam Generator

AHX Chimney

PDRC piping

In-vessel core catcher

IHTS piping

IHTS pump

12.03 m

3,186 gal.

PLAN VIEW OF THE CORE

PRIMARYCONTROL RODS

1m TRAVEL DISTANCEOF THE CONTROL RODS

(10'-8")

THERMALSHIELD

(29.5")0.75m

3.25m

Na-COHEAT EXCHANGER

7m

IHX

X-SECTION (FLATTENED FOR CLARITY)

(23')

(Ø 7.5' x 12.6' LONG)

IHX

2

SECTION A - A

Normal s odium level

Normal s odium level

Sodium faulted level

Pump offSodium Level

SODIUM DUMP TANKØ 2.5 m x 3.8 m LONG

CORE BARREL Ø266 / 268 cm(104.7" / 105.5")

SECONDARYCONTROL RODS

CONTROLRODS (7)

PUMPS (2)ON Ø 142.5" B.C.

PLAN VIEW OFIHX AND PUMPS IHX (2)

1.7m EACH2

DRACS (2)0.4m EACH2

Primary Vessel I.D.

Guard Vessel I.D.

Hot Pool

Cold Pool

PRIMARY VESSEL

(2" THICK)

3.5m(11'-8")

GUARD VESSEL(1" THICK)

1m(39.4")

3

TURBINE/GENERATORBUILDING

ELEVATOR

(Ø 25.5')Ø 7.7m

Na-AirHEAT EXCHANGER (2)

CONTROLBUILDING

0 1 2 3 10METERS4 5

5.08m [16.7FT]

4.57m [15FT]

7m [23FT]

1.89m

[6.2FT]

12.72m [41.7FT]

14.76m [48.4FT]

1.93m [6.3FT]

.61m [2FT]

2.29m [7.5FT]

EXHAUST TO VENT STACK

ESFR

BN-1200 will be presented by Russia as new Gen-IV SFR design track for the next SIA meeting

Slide 6Tokyo, May 2015

System Integration & Assessment Project

Slide 7Tokyo, May 2015

System Integration & Assessment ProjectObjectives

– Integration of the results of R&D Projects– Performance of design and safety studies– Assessment of the SFR System against the goals and criteria set

out in the Gen IV Technology Roadmap

Integration RoleSpecific tasks have been developed and refined– Identify Generation-IV SFR Options

» General system options» Specific design tracks» Contributed trade studies

– Maintain comprehensive list of R&D needs– Review Generation-IV SFR Technical Projects– Unlike the technical Projects, based on synthesis o f results

produced by other Projects

Slide 8Tokyo, May 2015

Safety & Operation Project

Slide 9Tokyo, May 2015

Project Objectives• Analyses and experiments that support safety approa ches and

validate specific safety features• Development and validation of computational tools u seful for such

studies• Acquisition of reactor operation technology, as det ermined largely

from experience and testing in operating SFR plants

S&O Project

France (CEA)

Japan (JAEA)

Korea (KAERI)

US (USDOE)

Members

EURATOM (JRC)

China (CIAE)

RF (Rosatom )

Slide 10Tokyo, May 2015

T°C

T°C

T°C

Zone 1

Zone 2

Zone 3

Zone 4Zone 5

DHR modeling through the PV

Very severe conditions assumed. Blackout with loss of all in vessel DHRS.

A model including convection, conduction and radiat ion was developed

Sensitivity calculations on SS emissivity were perf ormed

Need of fill the space between the main and safety vessels with sodium to reach acceptable temperatures.

TMV°iTMV°eTSV°iTSV°eTRV°

PTh

MVSVRV

P1P2

H

0

T°C

Slide 11Tokyo, May 2015

A report on analytical methods to simulate phenomen a in self-leveling behavior of the debris bed

Development of the debris bed self-leveling model f or IVR confirmation

0sec

30sec

60sec

Proposed model Experiment

Self-leveling behaviorof debris bed

at relocation phase

Slide 12Tokyo, May 2015

SAS4A severe accident model development and prelimi nary analysis

-0.04

-0.02

0.00

0.02

0.04

0.06

0.08

0.10

0 10 20 30

rea

ctiv

ity

($)

time (s)

Net reactivity

1.0

1.1

1.2

1.3

1.4

1.5

0 10 20 30

no

rma

lize

d p

ow

er

time (s)

Normalized power

z(m

)

0 0.002 00

0.2

0.4

0.6

0.8

z(m

)

0 0.0020

0.2

0.4

0.6

0.8

r(m)

z(m

)

0 0.002 0.004 0.0060

0.2

0.4

0.6

0.8 T(K)

1000980960940920900880860840820800780760740720

z(m

)

0 0.002 0.0040

0.2

0.4

0.6

0.8 Margin(K)

550500450400350300250200150100500

-50-100

U, Zr weight fraction Margin to melt

Map of molten fuel Temperature

Slide 13Tokyo, May 2015

Advanced Fuel Project

Slide 14Tokyo, May 2015

Advanced Fuel Project• Objective

– Selection of high burn-up MA bearing fuel(s), cladd ing and wrapper withstanding high neutron doses and tempera tures

• Candidates:– Driver fuels: Oxide, Metal, Nitride & Carbide (sinc e 2008)

Inert Matrix fuels & MA Bearing Blankets (since 200 9)– Core materials: Ferritic/Martensitic & ODS steels

• Scope– Fabrication– Behavior under irradiation

• Signatories (country – implementing agent): France - CEA, USA -DOE, EURATOM - JRC/ITU, Japan - JAEA, Korea -KAERI

Slide 15Tokyo, May 2015

Progress / carbide & nitride fuels Carbothermal reduction process revisited -> Identification of reaction schemes & intermediate

species (Handschuh et al, 2010, Conf. Pu future)

Am bearing fuels synthesis

Fuel element advanced pre-design -> plate

(Carvajal et al., JNM, 2014, accepted)(Rimpault et al., proceedings GLOBAL 2009)

Non Destructive Examinations of a (U 0.5Pu0.25Am0.15Np0.10)N fuel rodlet, Na bonded,

irradiated in ATR (17at%, 270W.cm-1) within the ser ies AFC-1 -> satisfactory results

consistent with predicted behavior

Slide 16Tokyo, May 2015

Progress / metal fuels

• Fuel slug fabrication:– gravity-casting & pressurized injection casting (Lee et al., proceedings FR-13):

» U-Zr-Mn & U-10Zr-RE-Mn (RE: 1-10%, Mn :0 & 5%)

» retention of Mn (Am surrogate)

– Implementation of the Glovebox Advanced Casting System at INL

->Pu & Am bearing fuels, 3 slugs/batch, Φ: 4,5mm & 250mm long

with a re-usable mold (Fielding et al., FR-13)

• Irradiations:

– SMIRP-1: PIE on UZr & UCeZr slugs irradiated (2.7at%) in HANARO (Lee et al., FR13)

-> satisfactory behavior & Cr layer at fuel/cladding interface to prevent FFCI performed well, despite some cracks in the Cr layer

Slide 17Tokyo, May 2015

Progress / core materials

• F/M & ODS steels– HT9 cladding tube manufacturing processes

-> melting, forging, machining, hot-extrudingdrawing & pilgering, annealings …

– Welding : Electro-Magnetic Pulse Technology -> joining of tubing and end caps for T91

and ODS

– Metallic Fuel / Cladding Chemical Interaction mitigation: » investigation of cladding liner materials & liner deposition processes

– barriers : Cr, V, Cr2O3, …– methods : CVD, electroplating, …

– ODS fuel pin irradiation in JOYO under preparation

Slide 18Tokyo, May 2015

Component Design & BOP Project

Slide 19Tokyo, May 2015

CD & BOP Project Subjects for 2012 -2016

(1) In-Service Inspection & Instrumentation (ISI) t echnology• Ultrasonic inspection in sodium using different app roaches and technologies, codes

and standards (CEA, Euratom , JAEA, KAERI) (2) Repair experience

• Phénix, Monju, (CEA, JAEA)

(3) Leak Before Break (LBB) Assessment technology • Creep, fatigue, and creep-fatigue crack initiation & growth evaluation for Mod. 9Cr-1Mo

(Grade 91) steel, Na leak detection by laser spectr oscopy (JAEA, KAERI)

(4) Supercritical CO 2 Brayton Cycle Energy Conversion• S-CO2 compressor tests, S-CO 2 cycle demonstration tests, Compact heat exchanger

tests, Material oxidation tests in S-CO 2, Sodium -CO2 reaction tests, S-CO 2 SFR plant dynamic analyses and control strategy development, Computer code analysis, S-CO 2SFR design study, Validation of S-CO 2 plant dynamic analyses with S-CO 2 loop data, Sodium plugging tests (CEA, DOE, Euratom , JAEA, KAERI)

(5) Steam Generator design and associated safety & instrumentation (since 2011)• Na/water reaction, thermal-hydraulics, thermal perf ormance, DWT structural evaluation

and heat exchange performance, DWT-SG fabrication (CEA, JAEA, KAERI)

Slide 20Tokyo, May 2015

study of the supercritical CO 2 cycle

S-CO2 Brayton Cycle Energy Conversion

� CFD simulations of the small scale S-CO 2 compressor have shown good agreement with the experiment data

� Calculations were carried out with the ANL Plant Dy namics Code that performs system level transient analysis for S-CO2 cycles coupled to SAS4A/SASYS-1

Experiment data CFD simulation

Shaft speed, rpm 12000

Mass flow rate, kg/s 4.008 ± 0.007 4.008

Inlet temperature, oC 35.35 ± 0.5 35.35

Inlet pressure, bar 82.71 ± 0.20 82.71

Outlet temperature, oC 38.35 ± 0.5 38.98

Outlet pressure, bar 91.34 ± 0.20 91.31

-20%

0%

20%

40%

60%

80%

100%

120%

140%

160%

180%

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000 4400 4800 5200

W,

FRA

CTIO

N O

F N

OM

INA

L G

EN

ER

ATO

R P

OW

ER

TIME, s

TURBINE AND COMPRESSORS WORK AND GENERATOR OUTPUT

W_Turb

W_Comp1

W_Comp2

W_gen

W_grid

0.0

0.2

0.4

0.6

0.8

1.0

1.2

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000 4400 4800 5200

NO

RM

ALIZ

ED

PO

WER

OR

FLO

W

TIME, s

CORE POWER AND FLOW

POWER DECAY POWER PEAK CHANNEL FLOW

300

350

400

450

500

550

600

650

700

750

0 400 800 1200 1600 2000 2400 2800 3200 3600 4000 4400 4800 5200

TEM

PER

AT

UR

E,

oC

TIME, s

PEAK CORE TEMPERATURES

PEAK FUEL PEAK CLAD

PEAK COOLANT INLET

Slide 21Tokyo, May 2015

S-CO2 Brayton Cycle Energy ConversionCorrosion behavior of metallic materials in SC-CO 2

� Fruitfull collaboration between CEA and JAEA for more comprehensive understanding of corrosion mechanisms in SC-CO 2 (2012-2014).

� More than 350 corrodes samples, 11 steel grades, 5 temperatures (400 to 600C), up to 8000h exposure.

JAEA facility CEA facility

� Fast oxidation and carburization of 9-12Cr steels : s uccessful modeling of oxide growth rate and carburization rate.

� Much slower oxide growth (more than 100 times slowe r than 9-12Cr) and almost no carburization of 18-25Cr steels. Increasing %Cr d ecreases the degradation of the steel.

� No strong influence of CO 2 pressure on the corrosion behavior was observed.� At T > 400C, the use of austenitic steels are recom mended.

Slide 22Tokyo, May 2015

S-CO2 Brayton Cycle Energy ConversionPreparation of a Sodium -CO2 interaction test facility

�The fabrication of test facility for wastage and pl ugging issues is supposed to be finished by Mar. 2014 and main experiments wi ll be carried out in FY2014.- Wastage test : Damage propagation on the pressure b oundary in Na-CO 2 HXs - Plugging test : Channel plugging in Na-CO 2 HXs

CO2 injection with

controllable flowrate

Lchannel (< 1.0 m)

Test section schematic:

Plugging test channel

Sodium flow

A-A’

<Plugging Test (Section II)>

<Wastage Test (Section I)>

< Impinging angle: 90 o >

< Impinging angle: 45 o >

< Construction of test loop (Photo of Mar. 3, 2014) >

Slide 23Tokyo, May 2015

Steam GeneratorsPreparation of a basic heat transfer test facility for Double Wall Tubes

and G91 tube inspection technology

- Combined SG tube inspection sensorRFECT + Magnetic sensor testing

- Preliminary test of magnetic sensor testing system has been carried out.

- Construction of a basic heat transfer test facility for DWT has been finished.

Basic heat transfer test facility for DWTBasic heat transfer test facility for DWTBasic heat transfer test facility for DWTBasic heat transfer test facility for DWT (5.3 x 4.6 x 11.8 m)

RFECT exciter coilRFECT exciter coilRFECT exciter coilRFECT exciter coil RFECT pickup coilRFECT pickup coilRFECT pickup coilRFECT pickup coil

Magnetic sensorMagnetic sensorMagnetic sensorMagnetic sensor

Magnetic sourceMagnetic sourceMagnetic sourceMagnetic source

Combined SG tube inspection sensor (design example)Combined SG tube inspection sensor (design example)Combined SG tube inspection sensor (design example)Combined SG tube inspection sensor (design example)

20%20%20%20% 40%40%40%40% 60%60%60%60%

Magnetic sensor testing system and preliminary test resultsMagnetic sensor testing system and preliminary test resultsMagnetic sensor testing system and preliminary test resultsMagnetic sensor testing system and preliminary test results

20%20%20%20% 40%40%40%40% 60%60%60%60%

Outer circum. notch

Outer groove

Slide 24Tokyo, May 2015

Steam GeneratorsTrial fabrication of main parts of double-walled-tu be steam generator

Dies

Double-wall-tube drawing process

(Double-walled tube, tube-sheet, tube to tube-sheet junction)

Tube and tube-sheet welding test

Welder

Welding zoneInner tube

Outer tube

Slide 25Tokyo, May 2015

Steam Generators

25

Sodium/water reaction control technology using nano -size particles in sodium

Sodium combustionNa/water reaction (Computer analysis)

� The technology is to reduce the chemical reactivity of liquid sodium using nano-particle.

� The sodium chemical reactivity can be suppressed by an atomic interaction between nano-particle and sodium atom.

Reaction jetHeat transfer tube

Slide 26Tokyo, May 2015

In-service InspectionRecent progress in under-sodium viewing technology with waveguide

sensor: Development and applicability verification of a rem ote inspection module

Remote Inspection Module (4 Ch. WG sensors)Remote Inspection Module (4 Ch. WG sensors)Remote Inspection Module (4 Ch. WG sensors)Remote Inspection Module (4 Ch. WG sensors)

10 m

Upper drivingUpper drivingUpper drivingUpper driving

devicedevicedevicedevice

LowerLowerLowerLowerguidingguidingguidingguidingstructurestructurestructurestructure

- Remote inspection module employing 4Ch. 10 m long waveguide sensors was developed for ISI of reactor internals in an SFR.

- Several verification tests were carried out and the applicability of the remote inspection module to ISI of reactor internals was successfully demonstrated.

ObstaclesObstaclesObstaclesObstaclesObstaclesObstaclesObstaclesObstacles

ObstaclesObstaclesObstaclesObstacles

Ranging inspection resultsRanging inspection resultsRanging inspection resultsRanging inspection results

Viewing inspection resultsViewing inspection resultsViewing inspection resultsViewing inspection results

Identification inspection resultsIdentification inspection resultsIdentification inspection resultsIdentification inspection results

Slide 27Tokyo, May 2015

In-service InspectionRecent Developments of Ultrasonic Sensors for NDE i n liquid sodium

� New TUSHT (High Temperature Ultrasonic Transducers) were manufactured and performance tests were realized� These sensors were immerged in sodium up to 600 °°°°C

� New multielement EMAT (Electromagnetic transducer) – 8 phased array

< TUHST tested on DOLMEN Na facility at CEA >

• Optimization of the sensor to limit the piezoelement crystalchemical reduction

• Potential use in SONAR for in sodium telemetryapplication

• Demonstration of operation at 180°C• Ability to deflect the wave direction• New design to optimise the sensor

(enhance deflection, size reduction of focal spot)

Slide 28Tokyo, May 2015

GACID Project

Slide 29Tokyo, May 2015

Overview of GACID Conceptual Scheme

MA raw material preparationMonju

Fuel pin fabri-cation

Irradiation test

MA-bearing MOX fuel pellets

�Objective: to demonstrate, using Joyo and Monju, that FR’s can transmute MA’s (Np/Am/Cm) and thereby reduce the concerns of HL radioactive wastes and proliferation risks.

�A phased approach in three steps.�Material properties and irradiation

behavior are also studied and investigated.

Step-1Np/Am pin irrad. test Joyo

Step-3Np/Am/Cmbundle irrad. test

Monju (Final Goal)

Test fuel fabrication

Step-2Np/Am/Cm pin irrad. test

Monju

Planning

MonjuJoyo�The Project is being conducted by

CEA, USDOE and JAEA as a GIF/SFR Project, covering the initial 5 years since Sep. 27, 2007.

GACID overall schedule

1

Slide 30Tokyo, May 2015

Summary

Slide 31Tokyo, May 2015

• System Research Plan has been updated in order to i ncorporate changes in Project Plans and design concepts

• Various collaborative activities are being conducte d in the areas of advanced fuels, transmutation of MAs, component des ign and BOP, and safety and operation within the SFR Technical R&D P roject Arrangements

• Procedures of resigning SFR Technical R&D Project A rrangements is under way

• Signing SFR SIA PA will permit to integrate and ass ess the results of R&D work conducted under SFR Technical R&D Project Arrangements

Slide 32Tokyo, May 2015

Thank youfor your attention !

Slide 33Tokyo, May 2015

Primary Roles of SIA Project and Relation to Techni cal Projects

Concept DeveloperConcept Developer

System Steering Committee

Technical PMBs (AF, GACID, CDBOP and SO)

SIA Project

Concept Developer

Entire set of R&Ds

Integrate R&D results

Design Concept Study

Self-assessment

(JSFR, ESFR, KALIMER, SMFR)

• Maintain and refine SFR system options in SRP

• Contribute trade studies in support of system specification

• Specify R&D needs in technical PMBs• Review PPs to ensure the needs are met

• Assess & Integrate R&D results

Contribution as BPI/Voluntary

SRPWP 1

WP 3

WP 2