SMC 4133 AUTOMOTIVE STRUCTURES

-

Upload

afrodite-ballas -

Category

Documents

-

view

223 -

download

9

description

Transcript of SMC 4133 AUTOMOTIVE STRUCTURES

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

- The main function of the body structure is to protect occupants in a collision- There are many standard crash tests and performance levels- For the USA, these standards are contained in Federal Motor Vehicle Safety Standards (FMVSS)- They are FMVSS 208 (front), 214 (side), 301 (rear) and 216 (roof)

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

• The insurance industry & consumer groups have their own test standard toevaluate vehicles beyond government standards • For instance, the New Car Assessment Program (NCAP)• It is based on the probability of injury; measured with a star rating where the five stars indicate lower probability of injury and vice-versa

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSFRONT BARRIER• Is a condition of a moving vehicle crashes onto a rigid barrier at a front end• Let’s model the frontal impact with a point mass

t = 0 t = 0, dx/dt = V0 t = 0, x = 0

dx/dt = 0

Resulting behavior of the point mass model

The crush efficiency factor is used to consider non-uniform crash force properties

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSExample 1Consider a vehicle of mass 1580kg impacting a rigid barrier at 55 km/h and average crush load of 300 kN. Calculate crash acceleration, deformation and time.

Acceleration = -300000/1580 = 189.87 m/s^2 = -19.4g

time = 1580 x 55/(3.6 x 300000) = 0.0805s

Deformation = -300000 x (0.0805^2)/(2 x 1580) + (55/3.6) x 0.0805 = 0.614m

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSThe crush efficiency factor is used to consider non-uniform crash force properties

• When crush factor approaching 1, it indicates the lower the head injury

• When designing the collapsed structureof the motor compartment, it is desirableto have a square wave shape

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSProcedure for establishing Front body structural requirements: 1.Maximum allowable cabin decelerations based on occupant injury2.Consistent structural efficiency and crush space3.Average and maximum allowable crush forces 4.Total crush forces to be used in the structural elements

Crush force:10% - hood & fender20% - lower cradle50% - mid-rail20% - top of fender

The front end elements are sized to ensure that the cabin zone won’t be intrudedAll materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSExample 2

a) Determine the required crush space. The structure will be 80% efficient and the allowable maximum deceleration is 20g. The impact speed is 48km/h.

b) Compute the average total crush force with a vehicle mass of 1200kg and impact speed of 35 km/h.

Solution:a) Crush space = (48/3.6)^2/(2*20*9.81*0.8) = 0.57m

b) Crush force = 0.5*1200*(48/3.6)^2/0.57 = 187N

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

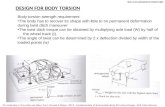

DESIGN FOR CRASHWORTHINESSBeam sizing

• A thin-walled square section is subjected to an axial compressive load• As the compressive load is gradually increased, the elastic buckling load is reached and the walls buckle• As the load increases further and past the ultimate load, the walls section cripple and the load drops

Beam section can be determined

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSExample 3

Each of motor compartment side rail must generate 25% of the crush force F=300kN. A 100mm square section is used. Find the required thickness for yield stress of 207 MPa.

Solution:Pm = 0.25*300000 = 75000NPm = 386*t^1.86*100^0.14*207^0.57 = 75000t^1.86 = 4.88 t = 2.34mm

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

• Motor compartment packaging typically require flange location & section shapes

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSLimit load analysis

• Is the ultimate load-carrying ability for the structure• Is used to determine the failure load that cause to initiation of permanent deformation

Plastic hinge model

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

Model with small deflection

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSVehicle pitch during impact

- Some vehicles rotate/pitch upon crash with a fixed barrier- It can increase the possibility of neck injuries- To reduce pitching, crushable beam is introduced

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSExample 4

Fup = 100000* 100/(400) = 25kN

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

Side impact-Plays an important role in sizing vehicle structure-FMVSS requires a minimum injury performance while NCAP uses star scale-The injury criterion is TTI index where the larger values indicate a more severe injury-TTI < 57 in desirable

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESSKinematic and load path analysis

Final velocity Acceleration & time

Distance traveled

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

Side – impact model

Time at which the occupant hit the door

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.

SMC 4133 AUTOMOTIVE STRUCTURES

DESIGN FOR CRASHWORTHINESS

Rear impact- To minimize fuel system from leakage

Final speed Final speed Work of deformation

Equivalent impact velocity

Average rear crush force

All materials in this slide are taken from Donald E Malen. 2011. Fundamentals of Automobile Body Structure Design, SAE International.