Small-Scale Hydropower Optimization ME/EE Senior Design Project 2004/2005 Customer: John Law...

-

date post

21-Dec-2015 -

Category

Documents

-

view

214 -

download

0

Transcript of Small-Scale Hydropower Optimization ME/EE Senior Design Project 2004/2005 Customer: John Law...

Small-Scale Hydropower Small-Scale Hydropower OptimizationOptimization

Small-Scale Hydropower Small-Scale Hydropower OptimizationOptimization

ME/EE Senior Design Project 2004/2005ME/EE Senior Design Project 2004/2005

Customer: John LawCustomer: John Law

Mentors: Ralph Budwig (ME), Brian Johnson (EE)Mentors: Ralph Budwig (ME), Brian Johnson (EE)

Phillip ArpkePhillip ArpkeKelly JobesKelly Jobes

Jamin JuhaszJamin JuhaszKarl KrohmerKarl KrohmerJill NieborskyJill Nieborsky

Problem DefinitionProblem DefinitionProblem DefinitionProblem Definition

Optimize Small-scale Hydropower System For Optimize Small-scale Hydropower System For Residential HeatingResidential Heating

The Generator Is Capable Of Providing 3.7 kW The Generator Is Capable Of Providing 3.7 kW Power Power

Last Spring During Maximum Flow, The Last Spring During Maximum Flow, The Generator Provided Only 1 kW Of PowerGenerator Provided Only 1 kW Of Power

ConstraintsConstraintsConstraintsConstraints Site Vs. Lab ConditionsSite Vs. Lab Conditions

Site: 9 cfs and 40 ft/sSite: 9 cfs and 40 ft/s Lab: 1 cfs and 16 ft/sLab: 1 cfs and 16 ft/s

Inherited FeaturesInherited Features Three-phase Three-phase

Generator Sunk CostGenerator Sunk Cost 12-inch Penstock 12-inch Penstock

Pipe To 6-inch RoundPipe To 6-inch Round On/Off Operation On/Off Operation

With Maximum FlowWith Maximum Flow

Project MilestonesProject MilestonesProject MilestonesProject Milestones

Lab Tests Of Initial Lab Tests Of Initial SystemSystem RPMRPM Static TorqueStatic Torque Power OutputPower Output

System DesignSystem Design Hydro LabHydro Lab Randall CreekRandall Creek

Performance VerificationPerformance Verification LabLab FieldField

Cross-flow Turbine Cross-flow Turbine BackgroundBackground

Cross-flow Turbine Cross-flow Turbine BackgroundBackground

Banki TurbineBanki Turbine Top Water EntryTop Water Entry Falling ActionFalling Action =80%=80%

Design ImprovementsDesign ImprovementsDesign ImprovementsDesign Improvements

Increased Power OutputIncreased Power Output Nozzle RedesignNozzle Redesign Reduced Water Drag In Reduced Water Drag In

“Hot Spot”“Hot Spot” Viewing WindowViewing Window

Old Configuration

New Configuration

Nozzle Design (Lab)Nozzle Design (Lab)Nozzle Design (Lab)Nozzle Design (Lab)

Design Based On Fluid Velocity (16 ft/s)Design Based On Fluid Velocity (16 ft/s) 15.75 in15.75 in22 Cross-sectional Area Cross-sectional Area Hydraulic Area Constant From Round To Hydraulic Area Constant From Round To

Square Square

Nozzle Design (Field)Nozzle Design (Field)Nozzle Design (Field)Nozzle Design (Field) Design Based On Flow Rate (9.63 ftDesign Based On Flow Rate (9.63 ft33/s)/s) 31.875 in31.875 in22 Cross-sectional Area Cross-sectional Area Hydraulic Area Constant From Round To Hydraulic Area Constant From Round To

SquareSquare

Housing DesignHousing DesignHousing DesignHousing Design

Eliminated Water Drag In “Hot Spot”Eliminated Water Drag In “Hot Spot” Plexiglas Top For Viewing Flow Plexiglas Top For Viewing Flow

PatternPattern

Electrical SchematicElectrical SchematicElectrical SchematicElectrical Schematic Three ComponentsThree Components

Resistive Heating Load (12 Resistive Heating Load (12 ΩΩ)) Capacitor Bank (135 µF)Capacitor Bank (135 µF) Induction GeneratorInduction Generator

ManufacturingManufacturingManufacturingManufacturing

Welding Test Nozzle Installing the Runner

Fitting Circular Flange to Lab Nozzle

Bridgeport CNC Machine

TestingTestingTestingTesting

Measured Generator and Turbine RPMMeasured Generator and Turbine RPMWith No-load, Shunt Capacitors Only, and With No-load, Shunt Capacitors Only, and 12 12 ΩΩ Load With Shunt Capacitance Load With Shunt Capacitance

Measured Power Output For Three CasesMeasured Power Output For Three Cases Measured Static TorqueMeasured Static Torque

TurbineGeneratorElectrical Box

Water Supply

Laboratory ResultsLaboratory ResultsLaboratory ResultsLaboratory Results

RPM TestsRPM Tests Turbine Turbine GeneratoGeneratorr % Improvement% Improvement

Free-Spin RPM Test 409 RPM 81

No Load RPM Test297.5

RPM1785

RPM 20

Capacitors w/o Load 201 RPM

1171 RPM 13

w/Capacitors w/Load 218 RPM

1271 RPM 12

Static Torque Static Torque TestTest Force (lb)Force (lb)

% % ImprovemenImprovementt

2-ft Arm 15.5 34

3-ft Arm 10.25 32Electrical Power Electrical Power

(Watts)(Watts) % Improvement% Improvement

141.4 53

Field PerformanceField PerformanceField PerformanceField Performance

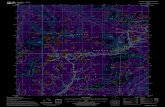

Diversion Setup

Diversion Canal

Installed Turbine