Simcenter 3D NX Nastran LMS Samtech LMS Test … · Optimization DMAP Programming CADforSimcenter...

Transcript of Simcenter 3D NX Nastran LMS Samtech LMS Test … · Optimization DMAP Programming CADforSimcenter...

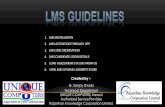

Unrestricted © Siemens AG 20172017.05.19Page 1 Siemens PLM Software

STS

LMS Virtual Lab

LMS SamtechSamcef LMS Test Lab

Simcenter 3D NX Nastran

Unrestricted © Siemens AG 20172017.05.19Page 2 Siemens PLM Software

Simcenter 3D

The learning tracks have been provided to help you plan a productive development path through our courseware.

Learning tracks start from the top and progress downward. Select any course below to open the training content.

Course name MeshingandModeling

Motion Analyst Dynamic Response LaminateComposites

Thermal andFlow

CAD for Simcenter 3D 1

Pre / Post

Motion

Response Dynamics

Laminate Composites

Thermal and Flow Analysis

Advanced Thermal andFlow Analysis

Recommended Optional

For more Simcenter courses see next page:

1. The Essentials for NX Designers training may be taken in place of the NX CAD for Simcenter Training.

Unrestricted © Siemens AG 20172017.05.19Page 3 Siemens PLM Software

Simcenter 3D

For more information on below courses, contact us:

• Advanced Flow• Advanced Thermal Analysis• Design Simulation• Durability Analysis• Electronic System Cooling• Flow Analysis• Pre/Post Processes• Pre/Post Solutions• Space Systems Thermal• Strength Wizard• Stress Wizard• Thermal Analysis• Vibration Wizard• Update Simcenter Advanced Simulation

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 4 Siemens PLM Software

CAD for Simcenter 3D

Duration: 2 daysWho should attent: AnalystsPrerequisites: noneFollow up Training: Simcenter 3D Pre/Post

The NX CAD for Simcenter 3D training is to help everyone who is struggling to get their NX parts prepared for Simulation Analysis (e.g. smoothening or generating the empty volume). In this training you will learn to create, modify and simplify geometry for Simulation Purposes.

Day 1

• Opening and working with parts

• Getting to know the NX interface

• Model History

• Part navigator

• Working with Assemblies

• Show / Hide

• Layers

• Creating datum geometry

• Measurements

• Synchronous Modeling Overview

Day 2

• Using an Idealized Part

• Using Trim Tools

• Simplify Geometry

• Clean up imported parts

• Create Cavity Solids

• Transform thin wall solids into sheets

• View Sections

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 5 Siemens PLM Software

Pre/Post

Duration: 4 daysWho should attent: Design Engineers, AnalystsPrerequisites: CAD for Simcenter orModeling and Assemblies Essentials for NX Designers, Follow up Training: Thermal and Flow Analysis, Nastran,Response Simulation, Laminate Composites, Space ThermalElectrical System Cooling

The Simcenter 3D Pre/Post training (previously known as NX Advanced Simulation) introduces the Simcenter Pre/Post finite element modeling and results visualization product. It is intended for design engineers and analysts who want to learn the details of how to perform finite element analysis using NX.

Students will learn how to generate meshes, define materials, apply boundary conditions, solve, and review analysis results. Students will also learn techniques for setting up and generating structural, dynamic, and thermal analyses, using optimization, and working with large models.

This training will be provided in 2 times 2 days.

Day 1- 4 Objectives

• Introduction to Simcenter Pre/Post

• Basic meshing

• Boundary conditions

• Solving

• Post-processing

• Geometry idealization

• Geometry abstraction

• Geometry repair

• Synchronous modeling

• Boundary conditions techniques

• Boundary conditions types

• Mesh controls and properties

• Mesh display and checking

• Collectors and sets

• Manual node and element generation

• Mesh connections

• Reports

• Analysis quality

• Variables and Result probes

• Introduction to NL analysis

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 6 Siemens PLM Software

Motion

Duration: 3 daysWho should attent: Analysts, Engineers and Designers who want to animate and analyze an assembly of moving partsPrerequisites: Essentials for NX Designers

The Simcenter Motion training (previously known as Motion Simulation) is a CAE software application you can use to animate and analyze both kinematic and dynamic motion simulations in terms of critical design positions, forces, velocities, and accelerations.

Upon successful completion of this course, students will understand how to apply and edit motion simulations, and use motion simulations to analyze, troubleshoot, and optimize a mechanism design.

While this course does include classic engineering topics such as statics, dynamics, kinematics and kinetics, the primary objective of this course is to train users in the use and application of the engineering software package. This course will not serve as a substitute for formal engineering education on these topics.

Day 1 – 3 Objectives

• Combine rigid bodies (links), joints, and motion drivers to create a mechanism and set it into motion

• Manage multiple motion simulations

• Apply forces, torques, springs, dampers, bushings, and contact in a motion simulation

• Query a motion simulation for information and edit both model and simulation features.

• Apply packaging options to generate feedback in the form of marker and component tracing, critical measurements, and interference checking

• Use spreadsheets and graphing to both animate and analyze a motion simulation

• Use advanced solutions to simulate component flexibility, transfer loads for a finite element analysis, and control an electric motor

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 7 Siemens PLM Software

Response Dynamics

Duration: 3 daysWho should attent: Designers and engineers, who need to characterize dynamic responses including transient, sinusoidal, random and shock spectrumPrerequisites: Simcenter 3D - Pre/Post Processes or Simcenter3D - Pre/PostBasic understanding of finite element analysis principles, statics, solid mechanics and basic dynamics

The Simcenter 3D – Response Dynamics training offers training in the use of Response Simulation for analysis of mechanical components subjected to dynamic loads. In addition the course covers the general theory and methods behind the software and the consideration important to accurate results such as modal sufficiency.

The course also provides opportunities for hands-on practice with NX Response Simulation software. A variety of examples will be used to demonstrate typical approaches for problems with transient, sinusoidal, shock and random excitations. Class participants are invited to submit examples of problems.

Day 1 – 3 Objectives

• Theory of single and multi-degree of freedom systems

• Function creation and manipulation

• Random vibration analysis

• Transient vibration analysis

• Response spectra analysis

• Base excitation methods

• Shock and drop analysis

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 8 Siemens PLM Software

Laminate Composites

Duration: 3 daysWho should attent: Design engineers, AnalystsPrerequisites: Simcenter 3D - Pre/Post Fundamentals or Simcenter 3D - Pre/Post, Working knowledge of NX Modeling, Basic understanding of structural analysis and laminate composite

The Simcenter 3D – Laminate Composites training is a comprehensive presentation of the composite laminates tools integrated in Simcenter Pre/Post.

The course includes laminate simulation processes, draping, failure analysis, optimization, finite element model solution, pre and post-processing, as well as a review of the laminates theory.

The hands-on activities and case studies are presented using Simcenter Laminate Composites and Simcenter Pre/Post.

Day 1 – 3 Objectives

• Overview of Simcenter Laminate Composites

• Zone-based laminate process

• Ply-based laminate process

• Draping

• Materials and micromechanics

• Solution and post-processing

• Laminate theory

• Laminate failure

• Laminate dynamics analysis

• Laminate optimization

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 9 Siemens PLM Software

Thermal and Flow Analysis

Duration: 4 daysWho should attent: Designers, Engineers who use NX to model complex heat transfer for challenging multi-physics applications, Engineers who use NX to model complex fluid flow for challenging multi-physics applications

Prerequisites: Pre/Post

The NX Thermal and Flow Analysis course provides students with comprehensive instruction in the use of the NX Thermal advanced software to model 3D fluid thermal problems. Students will learn the skills necessary to incorporate comprehensive radiation modeling including solar and radiative heating, fully coupled with thermal and fluid flow analysis. Students learn how to apply advanced thermal boundary conditions. The course covers both theoretical and practical aspects of the software.The course also provides students with comprehensive instruction in the use of the NX Flow advanced software to model 3D fluid flow problems. Students learn how to apply advanced flow boundary conditions. The course covers both theoretical and practical aspects of how the software handles different turbulence models and includes a variety of examples and tutorials addressing a wide range of applications.

NX Advanced Thermal Analysis

• Solar heating

• Radiative heating

• Advanced thermo-optical properties

• Advanced thermal coupling types

• Articulating models

• Peltier cooler (TECs)

• Joule heating

• Ablation and charring

• Material libraries

NX Advanced Flow Analysis

• Supersonic flow boundary condition

• Rotating frames of reference

• Rotational and translational periodicity

• Articulating models

• Active fan controller

• Non-Newtonian fluids

• Humidity and scalar fluid mixtures

• Ablation and charring

• Material libraries

• Phase change

• Particle tracking

• Sloshing

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 10 Siemens PLM Software

Advanced Thermal and Flow Analysis

Duration: 4 daysWho should attent: Designers, Engineers who use NX to model complex heat transfer for challenging multi-physics applications, Engineers who use NX to model complex fluid flow for challenging multi-physics applications

Prerequisites: Thermal and Flow Analysis

The NX Thermal and Flow Analysis course provides students with comprehensive instruction in the use of the NX Thermal advanced software to model 3D fluid thermal problems. Students will learn the skills necessary to incorporate comprehensive radiation modeling including solar and radiative heating, fully coupled with thermal and fluid flow analysis. Students learn how to apply advanced thermal boundary conditions. The course covers both theoretical and practical aspects of the software.The course also provides students with comprehensive instruction in the use of the NX Flow advanced software to model 3D fluid flow problems. Students learn how to apply advanced flow boundary conditions. The course covers both theoretical and practical aspects of how the software handles different turbulence models and includes a variety of examples and tutorials addressing a wide range of applications.

NX Advanced Thermal Analysis

• Solar heating

• Radiative heating

• Advanced thermo-optical properties

• Advanced thermal coupling types

• Articulating models

• Peltier cooler (TECs)

• Joule heating

• Ablation and charring

• Material libraries

NX Advanced Flow Analysis

• Supersonic flow boundary condition

• Rotating frames of reference

• Rotational and translational periodicity

• Articulating models

• Active fan controller

• Non-Newtonian fluids

• Humidity and scalar fluid mixtures

• Ablation and charring

• Material libraries

• Phase change

• Particle tracking

• Sloshing

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 11 Siemens PLM Software

NX Nastran

The learning tracks have been provided to help you plan a productive development path through our courseware.

Learning tracks start from the top and progress downward. Select any course below to open the training content.

Course name StaticAnalysis

StaticAnalysis

Optimization DMAP Programming

CAD for Simcenter 3D 1

Pre / Post

Introduction to FiniteElement Analysis

Advanced Nonlinear

Introduction to DynamicAnalysis

Superelement Analysis

Design Sensitivity andOptimization

Introduction to DMAP

Advanced DynamicAnalysis

DDAM Analysis

Coupled Structure / Acoustics Analysis

Rotor DynamicAnalysis

Recommended Optional

For more NX Nastran courses see next page:

1. The Essentials for NX Designers training may be taken in place of the NX CAD for Simcenter Training.

Unrestricted © Siemens AG 20172017.05.19Page 12 Siemens PLM Software

NX Nastran

Select the Course for more information:

• Aeroelastic Analysis

Unrestricted © Siemens AG 20172017.05.19Page 13 Siemens PLM Software

Introduction to Finite Element Analysis

Duration: 3 daysWho should attent: This course is intended for designers, engineers and finite element analysts who would like to understand how to perform linear static analysis using NX NastranPrerequisites: Pre/Post Fundamentals, Basic understanding of finite element analysis principles, statics, solid mechanics, and basic dynamicsFollow up Training: Introduction to Dynamic Analysis, Superelement Analysis, Introduction to DMAP

The Introduction to Finite Element Analysis with SimcenterPre/Post training is an introductory course for static finite element structural analysis using NX Nastran. The course is designed to teach NX Nastran independent of pre- and post-processors. It is intended for analysts who want to learn the details of how to perform static structural analysis using NX Nastran.

This course does not cover any topics of Simcenter Pre/Post.

Day 1 -3 Objectives

• Introduction to static finite element analysis

• Static solution sequences

• Case control

• Output control

• Common elements, uses and limitations

• Constraint and load types

• Model verification and checking

• Buckling analysis

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 14 Siemens PLM Software

Advanced Nonlinear

Duration: 3 daysWho should attent: Users who will be using NX Nastran Advanced Nonlinear to perform nonlinear analyses to predict structural behavior under steady state and transient conditionsPrerequisites: Pre/Post Fundamentals, An understanding of finite element analysis principles, Familiarity with NX Nastran input file formats

The NX Nastran – Advanced Nonlinear training is a comprehensive presentation of the nonlinear capabilities available in NX Nastran solutions 601 and 701. Nonlinear topics include large displacement, large strain, nonlinear materials (plasticity, hyperelastic), and contact.

The supported elements, materials, and boundary conditions are presented along with the formulations and solution schemes. Tips on solving convergence difficulties are also presented.

The hands-on activities and case studies are presented using Simcenter Pre/Post for the pre- and post- processor.

Day 1 – 3 Objectives:

• Overview of NX Nastran Advanced Nonlinear

• Model definition elements, materials, boundary conditions, contact

• Formulations and solution schemes for SOL 601

• Formulations and solution schemes for SOL 701

• Element formulations

• Modeling contact problems

• Resolving convergence difficulties

• Case studies and hands-on activities

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 15 Siemens PLM Software

Introduction to Dynamic Analysis

Duration: 3 daysWho should attent: Designers, engineers and finite element analysts who will be using NX Nastran to perform dynamic analyses to predict structural behavior under steady state and transient conditionsPrerequisites: Introduction to Finite Element AnalysisFollow up Training: Advanced Dynamic Analysis, Design Sensitivity and Optimization, Aeroelastic Analysis, DDAM Analysis

The Introduction to Dynamic Analysis with Simcenter Pre/Post training introduces the dynamic capabilities available in NX Nastran. It covers the fundamental methods for solving for dynamic response, focusing on modal analysis.

The course covers the linear dynamic response capabilities of NX Nastran, including normal modes analysis, transient and frequency response, residual vectors, and enforced motion. A variety of hands-on workshop exercises supplement the lecture content. The class is focused on NX Nastran and most of the material applies independently of pre- or postprocessor. However, additional material is available for demonstration of use with Simcenter Pre/Post.

Day 1 – 3 Objectives

• Normal Modes Analysis

• Model Mass

• Damping

• Transient Analysis

• Frequency Response Analysis

• Residual Vectors

• Enforced Motion

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 16 Siemens PLM Software

Superelement Analysis

Duration: 2 daysWho should attent: Finite element analysts who need to analyze large system level models composed of multiple components or who work within a team of analysts each responsible for a set of componentsPrerequisites: Introduction to Finite Element Analysis, Basic understanding of finite element analysis principles, statics, solid mechanics, and basic dynamics

The Superelement Analysis with NX training offers training in the use of the superelement analysis capabilities of NX Nastran. Superelements can play a key role in allowing the analyst to solve larger and more complex finite element models with limited computer resources. NX Nastran offers three types of superelements, and these can all be used with most NX Nastran analysis sequences. The different types of superelements each have their advantages and disadvantages, depending on the particular needs of a program. The student will learn to use all three types of superelements through the presentation of lecture materials and the completion of example problems. The class is focused on NX Nastran and most of the material applies independently of pre- or postprocessor. However, additional material is available for demonstration of use with NX.

Day 1 – XX Objectives

• Model reduction (static and component mode synthesis)

• Main bulk data superelements

• Partitioned superelements

• External superelements

• Choosing the best type of superelements

• Optimal partitioning of a system model into superelements

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 17 Siemens PLM Software

Design Sensitivity and Optimization

Duration: 2 daysWho should attent: Finite element analysts who need to optimize the performance of their components or systems, or understand what parameters in the system most strongly affect performancePrerequisites: Introduction to Dynamic Analysis with SimcenterPre/Post

The Design Sensitivity and Optimization training offers the theoretical and practical aspects of using the NX Nastran sensitivity and optimization capabilities. Sensitivity and design optimization can be used to automate the improvement of a proposed design. The NX Nastran design sensitivity and optimization solution is extremely flexible and allows the user to vary the model parameters to minimize an objective function, such as overall weight, given constraints on both the static and dynamic response. The class will cover the definition of design variables, constraints and objectives in NX Nastran, as well as the interpretation of results. The student will learn to use NX Nastran sensitivity and optimization through the presentation of lecture materials and the completion of example problems. The class is focused on NX Nastran and most of the material applies independently of pre- or postprocessor. However, additional material is available for demonstration of use with NX.

Day 1 and 2 Objectives

• Understanding structural optimization

• Defining design variables in NX Nastran

• Defining design constraints in NX Nastran

• Defining objective functions in NX Nastran

• Optimization for combinations of static and dynamic loads

• Interpreting design sensitivity and optimization results

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 18 Siemens PLM Software

Introduction to Direct Matrix Abstraction Program (DMAP)

Duration: 2 daysWho should attent: Advanced finite element analysts who need to be able to customize NX Nastran to their exact requirements including acceptance of new inputs, performance of new calculations and generation of new outputsPrerequisites: Introduction to Finite Element Analysis, Basic understanding of finite element analysis principles, statics, solidmechanics, and basic dynamics. Basic linear algebra includingmatrix operations, eigenvalue solutions, etc.

The NX Nastran - Introduction to DMAP training offers training in the NX Nastran Direct Matrix Abstraction Program (DMAP) language. Students will learn to write their own DMAP extensions to enhance the capabilities of NX Nastran. DMAP can be used to enhance the functionality of NX Nastran including computation of different responses, the transfer of non-standard data to and from NX Nastran or to incorporate other userdeveloped algorithms.

The student will learn to use the DMAP language through the presentation of lecture materials and the completion of example problems.

Day 1 and 2 Objectives

• Introduction to DMAP

• DMAP Data Types (Parameters and Datablocks)

• DMAP Syntax (Modules)

• subDMAPs

• Understanding NX Nastran solution sequences

• Altering solution sequences

• Input and Output

• Database

• ISHELL module for user provided routines

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 19 Siemens PLM Software

Advanced Dynamic Analysis

Duration: 2 daysWho should attent: Finite element analysts who will be using NX Nastran to perform dynamic analyses to predict structural behavior under steady state and transient conditions.Prerequisites: Introduction to Dynamic AnalysisFollow up Training: Rotor Dynamic Analysis, Coupled Structure/Acoustic Analysis with Simcenter Pre/Post

The Advanced Dynamic Analysis with NX training continues where the NX Nastran Introduction to Dynamic Analysis course left off in teaching NX Nastran's dynamic analysis capabilities. It covers fundamental methods of dynamic response, including both modal and direct analysis. There is an emphasis on practical applications and enhancing the students' engineering judgment with respect to dynamic response.

This course covers the linear dynamic response capabilities in NX Nastran, including model reduction, random response analysis, shock and response spectra, MFLUID, and nonlinear applied loads. A variety of hands-on workshop exercises supplement the lecture content. The class is focused on NX Nastran and most of the material applies independently of pre-or postprocessor. However, additional material is available for demonstration of use with NX.

Day 1 – XX Objectives

• Model Reduction

• Shock and Response Spectrum

• Random Response

• Extra Points, Transfer Functions, and NOLINs

• Use of MFLUID

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 20 Siemens PLM Software

DDAM Analysis

Duration: 1 daysWho should attent: Finite element analysts who need to perform shock analysis per the Navy’s DDAM procedurePrerequisites: Introduction to Dynamic Analysis, Basic understanding of finite element analysis principles, statics, solid mechanics and basic dynamics

The NX Nastran - DDAM Analysis with NX training offers training in the performance of the Dynamic Design Analysis Method using NX Nastran. DDAM is a U.S. Navy developed analytical procedure for evaluating the design of equipment subject to shock loading. The student will learn to use the NX Nastran DDAM solution (SOL 187) through a presentation of lecture materials and the completion of example problems. The class is focused on NX Nastran and most of the material applies independently of pre- or postprocessor. However, additional material is available for demonstration of use with NX.

Day 1 Objectives

• Introduction to DDAM theory

• Shock spectra calculations per NRL memorandum 1396

• Mode selection criteria

• Closely spaced modes

• Methods for stress summation including the NRLSUM

• Running and interpreting DDAM solutions in Nastran

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 21 Siemens PLM Software

Coupled Structure/Acoustic Analysis

Duration: 1 dayWho should attent: Engineers and finite element analysts who will be using NX Nastran to perform analysis of fluid or coupled fluid-structural systems to predict responses under steady state and transient conditions.Prerequisites: Advanced Dynamic Analysis, Basic understanding of finite element analysis principles, Working knowledge of Nastran and Simcenter Pre/Post

The NX Nastran - Coupled Structure/Acoustic Analysis with Simcenter Pre/Post training introduces the acoustics and structural-acoustics coupled analysis capabilities of NX Nastran. It covers the solution of acoustic systems, the solution of coupled structural-acoustic systems, the implementation of acoustic boundary conditions, and the modeling of absorbers, barriers, and infinite boundaries. Examples and workshops give the student practical hands-on experience.The class is focused on NX Nastran and all of the material applies independently of pre- or postprocessor. The workshops and examples are deck centric (i.e. the decks will be prepared with a text editor), though where appropriate Simcenter Pre/Post will be used for preprocessing of the model and visualization of results.

Day 1

• Solution of acoustic modes

• Acoustic boundary conditions

• Frequency and transient response of acoustic systems

• Modeling sound absorption, barriers, and infinite boundaries

• Coupled structural/acoustic systems

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 22 Siemens PLM Software

Rotor Dynamic Analysis

Duration: 1 dayWho should attent: Engineers and finite element analysts who will be using NX Nastran to perform analysis of rotating systems to predict critical frequencies and dynamic responsePrerequisites: Advanced Dynamic Analysis

The NX Nastran - Rotor Dynamic Analysis with NX training introduces the rotor dynamics analysis capabilities of NX Nastran. It covers the solution of rotor dynamic problems in both rotating and fixed coordinates, including complex eigenvalues (Campbell diagrams), synchronous and asynchronous frequency response and synchronous and asynchronous time response. Examples and workshops give the student practical hands-on experience. The class is focused on NX Nastran and all of the material applies independently of pre- or postprocessor. Where appropriate NX is used for pre-processing and visualization of results.

Day 1

• Understanding rotor dynamics in rotating and fixed coordinates

• Complex modes, critical frequencies and Campbell Diagrams

• Synchronous and Asynchronous Frequency Response

• Synchronous and Asynchronous Transient Response

• Frequency Dependent and Nonlinear Simulation

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 23 Siemens PLM Software

Aeroelastic Analysis

Duration: 1 dayWho should attent: Engineers and finite element analysts who will be using NX Nastran to perform aeroelastic analysis to determine aircraft, missile, or launch vehicle loads, performance, or stabilityPrerequisites: Introduction to Finite Element Analysis with Femap for pre/post, Introduction to Dynamic Analysis with Femap for pre/post, Basic understanding of finite element analysis principles, statics, solid mechanics, and dynamics.

The NX Nastran – Aeroelastic Analysis training introduces the aeroelasticity capabilities available in NX Nastran. A review of aeroelastic theory and the fundamentals of setting up and running aeroelasticity solutions are covered. There is an emphasis on the practical applications of the software and enhancing the student’s engineering judgment with respect to aeroelastic analysis of aircraft.The course covers the aeroelastic capabilities of NX Nastran, including aerodynamic panel model theories, connection of aerodynamic models to structural models, static trim analysis, dynamic maneuver and gust analysis, and flutter analysis. The class is focused on NX Nastran and most of the material applies independently of pre- or post-processor. Additional material is available for use with Femap.

Day 1

• Aerodynamic theories

• Aerodynamic panel modeling

• Aerodynamic model corrections

• Static aeroelasticity

• Dynamic aeroelasticity

• Flutter

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 24 Siemens PLM Software

LMS Samtech Samcef

Select the Course for more information:

• Structural Composite Damage Modeling

Unrestricted © Siemens AG 20172017.05.19Page 25 Siemens PLM Software

Structural Composite Damage Modeling

Duration: 2 daysWho should attent: Mechanical engineers and FEA analystsPrerequisites: Pre / Post

LMS Samtech Samcef Composites can be used to study the highly nonlinear behavior of composite materials and structures, increase structural efficiency and reliability plus minimize weight.

This LMS Samtech Samcef – Structural Composite Damage Modeling training will teach users how to perform advanced nonlinear analysis of various types of composites within the NX advanced simulation environment.

Day 1 – 2 Objectives

• Review finite element library for composites

• Material definition for composites & laminates

• Nonlinear implicit solver for static and dynamic analyses of composites

• Specific progressive damage models for ply failure and delamination and their coupling

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 26 Siemens PLM Software

LMS Test.Lab

Select the Course for more information:

• Rotating Machinery Testing• Rotating Machinery Testing - Advanced• Structures - Modal Testing and Analysis• Structures - Modal Testing and Analysis - Advanced• Transfer Path Analysis

Unrestricted © Siemens AG 20172017.05.19Page 27 Siemens PLM Software

Rotating Machinery Testing

Duration: 2 daysWho should attent: Engineers and technicians who need to learn how to use LMS Test.Lab for Rotating Machinery analysis or want to learn about its capabilities. We recommend a basic understanding of Noise and Vibration measurements on rotating machinery.Prerequisites: Basic knowledge on NVH Testing and AnalysisFollow up Training: Rotating Machinery – Advanced, Transfer Path Analysis

You will learn how to use LMS Test.Lab for the acquisition and analysis of rotating machinery harmonics through real-life exercises.

Day 1 – 2 Objectives

• Review of Digital Signal Processing (DSP)

• LMS Test.Lab Desktop: Data visualization

• Review of signature & order analysis theory

• LMS Test.Lab Signature Testing

• Post-Processing

• Time Signal Editing & Throughput Processing

• Advanced & Automated reporting

• Structural Analysis

• Geometry

• Operational Deflection Shapes & Time Animation

• Offline RPM Extraction

• PWM application

• Exercises included for each topic

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 28 Siemens PLM Software

Rotating Machinery Testing - Advanced

Duration: 1 dayWho should attent: Engineers and technicians who need to learn how to use LMS Test.Lab for angle domain processing, real time octaves and torsional vibration analysis. The knowledge of LMS Test.Lab Signature Testing and Signature Throughput Processing is assumed.Prerequisites: Basic knowledge on NVH Testing and Analysis applied on rotating elements and Rotating Machinery Testing trainingFollow up Training: Transfer Path Analysis for automotive

This product training will explain the principals behind and the software use of LMS Test.Lab for angle domain processing of rotating components, using Real Time Octaves and performing Torsional Vibration analysis.

Day 1 Objectives

• Specific/Advanced Techniques:

• Angle Domain analysis

• Real Time Octaves

• Torsional Vibration Analysis

• Exercises included for each topic

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 29 Siemens PLM Software

Structures - Modal Testing and Analysis

Duration: 3 daysWho should attent: Engineers and technicians that need to learn how to use LMS Test.Lab for experimental modal analysis or that want to learn about its capabilities. Prerequisites: Basic knowledge on NVH Testing and Analysis

Learn how to use LMS Test.Lab for experimental modal analysis (EMA) as well as some more advanced analysis techniques.

In this product training, you will become familiar with the basics of how to operate LMS Test.Lab and how to use it for Experimental Modal Analysis (EMA). We will use an industrial example to walk you through the LMS Test.Lab Structures family. We will also introduce you to more advanced techniques such as how to extract modal parameters from data acquired under operating conditions and challenging boundary conditions. We will conclude by explaining how to use modal parameters in computations to adjust a structures’ dynamic behavior.

Day 1 – 3 Objectives

• Review of theory of Experimental Modal Analysis

• Review of Digital Signal Processing (DSP) techniques for data acquisition

• LMS Test.Lab Desktop: Data visualization

• LMS Test.Lab Spectral Testing + Source Control

• LMS Test.Lab Modal Impact

• LMS Test.Lab Geometry

• LMS Test.Lab Modal Analysis

• LMS Test.Lab Multi-Run Modal Analysis

• LMS Test.Lab Modification Prediction

• LMS Test.Lab Rigid Body Calculator

• LMS Test.Lab Desktop: Printing and Plotting…

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 30 Siemens PLM Software

Structures - Modal Testing and Analysis - Advanced

Duration: 1 dayWho should attent: The course is intended for engineers and technicians that need to learn how to use LMS Test.Lab for experimental modal analysis or that want to learn about its capabilities. We recommend a basic knowledge of vibration measurements, structural dynamics and a basic understanding of digital signal processing.Prerequisites: Basic knowledge on NVH Testing and Analysis and Structures – Modal testing and Analysis

Learn about advanced modal techniques like operational modal analysis , MIMO FRF, MIMO Stepped /Swept Sine and Normal Mode Testing.

In this product training we will introduce you to more advanced techniques such as how to extract modal parameters from data acquired under operating conditions and challenging boundary conditions. Also the multiple-input multiple-output techniques and normal mode testing will be treated.

Day 1 Objectives

• LMS Test.Lab Operational Modal Analysis (OMA)

• LMS Test.Lab MIMO FRF Testing

• LMS Test.Lab MIMO Swept & Stepped Sine Testing

• LMS Test.Lab Normal Mode Testing…

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 31 Siemens PLM Software

Transfer Path Analysis

Duration: 2 daysWho should attent: The course is intended for engineers and technicians that need to learn how to use LMS Test.Lab for Transfer Path Analysis. We recommend a basic knowledge of structural measurements and modal analysis. The required measurements will be provided and discussed, but will not be acquired during the class.Prerequisites: Knowledge on NVH Testing in Automotive context and Rotating Machinery

In this training Single Reference and Multiple Reference Transfer Path Analysis will be explained as well as new techniques for Operational Transfer Path Analysis. To become familiar using LMS Test.Lab for single and multi reference transfer path analysis, load calculation, principal component analysis and contribution analysis. The required measurements will be provided and discussed, but will not be acquired during the class. LMS Test.Lab Signature Testing, Spectral Testing, and Modal Impact could be used for these measurements.

Day 1 Objectives

• Some theory behind Transfer Path Analysis

• LMS Test.Lab Single Reference Transfer Path Analysis

• Load Identification methods

• LMS Test.Lab Principal Component Analysis

• LMS Test.Lab Multi Reference Transfer Path Analysis

• LMS Test.Lab Operational Transfer Path Analysis

• LMS Test.Lab OPAX

• LMS Test.Lab Operational Transfer Path Analysis

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 32 Siemens PLM Software

LMS Virtual.Lab

Select the Course for more information:

• Acoustics (BEM)• Acoustics (FEM)• Correlation and Updating• Durability• Motion• Motion Advanced• Noise and Vibration• Ray Tracing Applications

Unrestricted © Siemens AG 20172017.05.19Page 33 Siemens PLM Software

Acoustics (BEM)

Duration: 4 daysWho should attent: This course is intended for new users of LMS Virtual.Lab that need to learn both the product and application and managers who want to get an overview of the state-of the-art acoustic prediction techniques.Prerequisites: A general understanding of Finite Element Methods and Boundary Element Methods is essential to get the most out of this training.Follow up Training: Ray Tracing Applications

In the LMS Virtual.Lab – Acoustics (BEM) training you will be trained on every aspect of the acoustic calculation process.

We will introduce you to the basic theory of Boundary Element Methods (BEM). You will learn to use LMS Virtual.Lab to ready a mesh for an acoustical simulation. We will teach how to set up an analysis for interior acoustics, calculate noise radiation, and include fluid-structure interaction in your simulation.

Day 1 – 4 Objectives

• LMS Virtual.Lab Desktop

• CAE interfaces to LMS Virtual.Lab

• LMS Virtual.Lab Mesh based design

• Mesh Morphing

• Cavity Meshing

• Mesh Coarsening

• Visualization of mesh quality

• LMS Virtual.Lab Acoustic Analysis

• Harmonic BEM Solver

• Transient BEM Solver

• Fast Multi-Pole BEM Solver

• Acoustic Transfer Vector (ATV) Solver

• Vibro-acoustic Solver

• Automatically Matched Layer (AML)

• Visualization of results and post-processing

• Advanced Processing

• ATV based Response

• Vibro-Acoustic Transfer Vector (VATV)

• Panel Contribution Analysis

• Order Cut Sound Synthesis

• Exercises included for all topics

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 34 Siemens PLM Software

Acoustics (FEM)

Duration: 4 daysWho should attent: This course is intended for new users of LMS Virtual.Lab that need to learn both the product and application and managers who want to get an overview of the state-of the-art acoustic prediction techniques.Prerequisites: A general understanding of Finite Element Methods is essential to get the most out of this training.Follow up Training: Ray Tracing Applications

In the LMS Virtual.Lab – Acoustics (FEM) training you will be trained on every aspect of the acoustic calculation process.

We will introduce you to the basic theory of Finite Element Methods (FEM). You will learn to use LMS Virtual.Lab to ready a mesh for an acoustical simulation.

We will teach how to set up an analysis for interior acoustics, calculate noise radiation, and include fluid-structure interaction in your simulation.

Day 1 – 4 Objectives

• LMS Virtual.Lab Desktop

• CAE interfaces to LMS Virtual.Lab

• LMS Virtual.Lab Mesh based design

• Mesh Morphing

• Cavity Meshing

• Mesh Coarsening

• Visualization of mesh quality

• LMS Virtual.Lab Acoustic Analysis

• Harmonic FEM Solver

• Fast Multi-Pole BEM Solver

• Acoustic Transfer Vector (ATV) Solver

• Vibro-acoustic Solver

• Automatically Matched Layer (AML)

• Visualization of results and post-processing

• Advanced Processing

• ATV based Response

• Vibro-Acoustic Transfer Vector (VATV)

• Panel Contribution Analysis

• Order Cut Sound Synthesis

• Exercises included for all topics

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 35 Siemens PLM Software

Correlation and Updating

Duration: 2 daysWho should attent: New users of LMS Virtual.Lab that need to learn both the product and the applicationPrerequisites: A background in Finite Element Methods and Experimental Modal Analysis is essential to getting the most out of this course. Familiarity with operating MSC Nastran is an advantage.

In the LMS Virtual.Lab – Correlation and Updating training you will learn how to correlate modal models obtained through Finite Element techniques and models obtained from Experimental Modal Analysis.

We will show you how to predict the sensitivity of the dynamic characteristics for changes in the properties of the structural model and how to use these sensitivities in an updating analysis. Furthermore you will learn how to design a setup for Experimental Modal Analysis using a Finite Element model.

Day 1 – 2 Objectives

• LMS Virtual.Lab Desktop

• CAE interfaces to LMS Virtual.Lab

• LMS Virtual.Lab Correlation

• Correlation Analysis

• MSC Nastran SOL200 Sensitivity

• SOL200 Updating

• Pre-test analysis

• Visualization of results and post-processing

• Exercises

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 36 Siemens PLM Software

Durability

Duration: 2 daysWho should attent: This course is intended for new users. We recommend that you are familiar with fatigue calculation methods.Prerequisites: A general understanding of fatigue calculation methods is recommended, Previous experience with CAD or CAE is an asset.

The LMS Virtual.Lab - Durability training will teach you the basics of Fatigue Life Prediction methods (Stress-Life and Strain-Life Approach) and the Numerical Life Prediction based on FEM Results.

You will learn how to set up a durability analysis and evaluate your results using the specific post-processing features of LMS Virtual.Lab Durability.

Day 1 – 2 Objectives

• LMS Virtual.Lab Environment

• LMS Virtual.Lab Durability Workbench

• Theoretical Background of non-FEM fatigue life calculations

• Basics of Stress Life Approach

• Basics of Strain Life Approach

• Numerical Life Prediction based on FEM Results

• LMS Virtual.Lab Component Fatigue

• Local Analyses

• Result Visualization and Reporting

• Exercises included for all topics

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 37 Siemens PLM Software

Motion

Duration: 3 daysWho should attent: This course is intended for new users of LMS Virtual.Lab Motion who need to learn both the product and the application. A general understanding of structural dynamics is recommended. Previous experience with CAD is an asset.Prerequisites: A general understanding of structural dynamics is recommended and Previous experience with CAD is an asset.Follow up Training: Motion Advanced

In the LMS Virtual.Lab - Motion training you will learn the basics of the NX modeling architecture to create Parts and Products for mechanical simulation with LMS Virtual.Lab Motion.

We will teach you how to quickly assemble, analyze and optimize the real world behavior of dynamic mechanical systems on your desktop. You will learn how to define parameterized mechanical system models for more advanced design studies.

Day 1 – 3 Objectives

• LMS Virtual.Lab Desktop

• CAD and CAE interfaces to LMS Virtual.Lab

• LMS Virtual.Lab Motion

• Pre -Processing

• Part and geometry creation

• Constraints and drivers

• Forces

• Motion Solvers

• Introduction to Flexible Bodies

• Post-processing

• Animation of multi-body models

• Visualization of resulting functions

• Contact Force modeling

• Expressions

• Parameterization, Design Tables, and Configurations

• Simple Control Systems

• Exercises included for all topics

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 38 Siemens PLM Software

Motion Advanced

Duration: 2 daysWho should attent: This course is for users who wish to model mechanical systems with greater fidelity and increased efficiency. The sessions on advanced elements and modeling techniques will provide modeling solutions to many complex physical phenomena. The sessions on automation, parameterization, and optimization will help the user work more efficiently and gain more knowledge from the analyses.Prerequisites: Motion

In the LMS Virtual.Lab – Motion Advanced training you will learn about the advanced capabilities of LMS Virtual.Lab Motion in order to create multi-body models and handle complex types of forces. You will learn how to incorporate finite element models into your own multi-body simulation. We will guide you through the interfacing of LMS Virtual.Lab Motion with external solvers and data sources. We will also show you how to automate processes in LMS Virtual.Lab and apply optimization calculations. Depending on the input from the attendants, further specific topics and techniques will be reviewed.

Day 1 – 2 Objectives

• Solver topics (Integrator options, troubleshooting, etc)

• Utilizing CAD Geometry

• Sub mechanisms

• Control Plant packages (Amesim, Matlab, Easy5)

• Animation features and post-processing

• Flexible body modeling with Stress Recovery

• User Defined Subroutines

• Optional topics (based upon attendants interest)

• Exporting Loads for Durability and NVH

• Cable and Gear systems

• Tracked Vehicle Systems

• Suspension and Full Vehicle modeling

• Tire/Road Interaction

• Scripting and Journaling

• LMS Virtual.Lab Optimization

• Exercises

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 39 Siemens PLM Software

Noise and Vibration

Duration: 3 daysWho should attent: New users of Virtual.Lab that need to learn both the product and the application and managers that want to get an overview of the state-of-the-art in advanced applications for structural dynamics.Prerequisites: A general understanding of finite element methods and structural dynamics is desirable.

The LMS Virtual.Lab – Noise & Vibration training will teach you how to use LMS Virtual.Lab in the context of structural dynamics.

You will learn how to predict structural responses using modal models obtained with Finite Element techniques or Experimental Modal Analysis and/or frequency response functions. We will guide you through the assembly of a global dynamic model from component models. You will also be introduced to the concepts of Transfer Path Analysis and you will learn how to drive MSC Nastran.

Day 1 – 3 Objectives

• LMS Virtual.Lab Desktop

• CAE interfaces to LMS Virtual.Lab

• LMS Virtual.Lab Noise and Vibration

• LMS Virtual.Lab Analysis Applications

• Noise and Vibration Solvers

• NVH System Synthesis Solver

• Advanced Processing

• Load Identification Analysis

• Path and Modal Contribution Analysis

• Modification Prediction

• LMS Virtual.Lab Structures

• Mesh Based Design

• Connection Modeling

• Assembly

• MSC Nastran analysis driver

• Exercises included for all topics

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]

Unrestricted © Siemens AG 20172017.05.19Page 40 Siemens PLM Software

Ray Tracing Applications

Duration: 2 daysWho should attent: This course is intended for users interested in using VL Ray Acoustics to perform acoustic simulation in high frequency range. This is the frequency range where both FEM/BEM technologies fail to deliver accurate results.Prerequisites: Acoustics (FEM), Acoustics (BEM), A basic understanding of the LMS Virtual.Lab infrastructure is required to attend this training.

The hypothesis behind this method assumes at high frequencies sound approximately travels as rays from source to receiver bouncing off different absorptive surfaces enroute. This allows us to treat the sound rays in the same way as light rays in geometrical optics -> geometrical acoustics is the result.

Day 1 – 2 Objectives

• Introduction to Ray Acoustics

• Theory

• Modeling

• Numerical Methods

• Auralization

• Application Overview and Highlights

• Examples

More information?

Siemens PLM Software T: +31 (0) 73 - 680 2500 E: [email protected]