Siam Steel Works Company Limited .:. / j)! / )

Transcript of Siam Steel Works Company Limited .:. / j)! / )

I

uslfn aEJ1uaUiaLJ8SAa U1nVl ("( j)! I I

Siam Steel Works Company Limited .:. / / )

rI UKAS ~~

005

I

tJ YU,. ~ri1l~\l

• J

STEEL-WORKS COMPA~N~Y----~

, 0 9001 .);~~ .~.- ..

2526

'VI:; LiJtI'U1J~H'VI"'1 76700268

'VI'U"'i~'VI:;LiJtI'U. 30 ~1'UU1'V1 ('lJl"i:; L~lJ)

i'l'U~h/N~(iJJlru1i vim'vj~nL'vj{1mLL('l:;mJn"iruvi1l Lvi1ln1"i~\l1h.h:;1.h tl1Lvifln"ilJ'l1('lU"i:;'V11'U 111L~tI \ll'Uu"i:;n1lull'1"i\lL'vj~n~'U 1

~\11l SSW

ri'l~\lnl"iN~(iJ 100 LlJ(91~n~'U / l'U

~'U~h\l\ll'U 24,000 lJ2

~l'Ul'U'I"l,rn\ll'U 170 1'1'U

"i:;1JUU~'vjl"il'1rum'l"l• . lu-rm1l\l"i:;uuU~'vjl"il'1rum'l"l ISO 9001• 2000 1l1lnl\11~tI SGS Yarsley

International Certification Service.

- L('l'lJ~ Q 53605 (UKAS)

- L('l'lJ~ NQ 225/00 (NAC)

- lu-rm1l\llJl(iJ"i::l'UN~(iJJlru1i~(iJ~l'vjn"i"ilJ lJ1ln 427 L('l'lJ~ (1) 3793-62/427

1l1lnl\11~udl,rn\ll'UlJl(iJ"i~l'UN~(iJJlru1i1l(iJ~l'vjn"i"ilJ ~ ,

Siam Steel Works Go., Ltd.

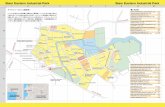

Established 1983 Company Registration No. 76700268 Registered Capital Baht 30.000.000.00 (Fully Paid) Products Steel Water Pipes & Fittings for Water Supply. Wastewater. Irrigation.

Power Plant and Other Steel Fabrication Works Brand Name "SSW" Production Capacity 100 metric tons/day Total Plant Area 24.000 m2

No. Of Employee 170 Quality Management System ISO 9001 2000 Certitified (SGS Yarsley International

Certification Service) - Certificate No. Q53605 (UKAS) - Certificate No. NQ225/00 (NAG)

Product Quality - TIS-427, Certificate No. (1) 3793-62/427 (Thai Industrial Standard Institute)

•••••• 1 'l,I1tJ1LVl~ ~~l~'ULn(1l, 2 'U1!J!JVlll'V'h'll'1 ml(1l!J1Ln!J'HU, 3 'U1!Ja~Ln!J1~ v~1(111~n~. " 4 'U1!Jb"lfl\l "I~!J~~"VlB, 5 'U1!Ja~"lf1!J ti11~1DW\lI'1W1

6 'U1!Jlw~'UVl'S l\llH'UVlU6

7 'U1!J~1L'U1 Ln~a'Ul'U

Mr Vites Siriwattanakate

Mr. Yutthaphong Krityakianrana

Mr Somkiat Amorntrakul

Mr Chaveng Chariyapisuthi

Mr Somchai Nirapathpongporn

Mr. Pairintr Wongwantanee

Mr Samnao Kluanwan

1~8~~~ulunl~~~Ul~~uunl~u~~1~~runlw~u1~~uu~~nl~ti8u~~~u~~~

:J-Jl~~:llu~rumw~lnt'l ISO 9002 L~~tI W'.~. 2541 LLt'l~U~~'VI"1 1~~lLilunl~ U~UU~~~~Ul~~UUU~~l~~rumwmh~liimii~~~u, , l'WtI w.f1.2544 U~~'VI"1 1~~u U~~n1f1ti8um~m~~:J-J1~~:ilU ~rumw ISO 9001 2000 (NAC. UKAS)

Ltt'l~1~~un1~~m~.N~'VI~LU8'W:J-J1~~~1'Wl\J~~llru1i:J-J~n. 427 ~l~~U'vi~'VIn'IJ'Wl~.. ,

U~~'VI ~m:J-J~~t'lLl~{~tf <Sln~ 1~111L81~~UUU~~1~mlll~\lil'W~rum~~lnf'l

ISO 9001 :2000 :J-Jl1'iidJ'WLL'Wl'VI1~l'Wnl~~I1lJUln1~~lLilU~lU "~f'l~~~uflrum~ lUnl~l\J~1Il ,nnn1~111L81~~UUmlll~~lu~rum~~lnt'l,1:J-Jl1'ii'Vhl~U~~'Vl"1 ~l:J-Jl~n Lvi:J-Ju~~~'VI5m~1'Wn1~LL'li~i'W1'W~f'l';If'ln1~

J' v :"1 A

~~UUmlll~:il'W~rum~ ISO 9001 :2000 1.,1 'WULu'W~~UUm~l~~rum~~~~~

"lJ~~U~~'Vl"1 l(i18wt!n~lU'VlnflU~~ 1~~Un1~N n~m:J-J 1~i'Jflru~:J-JU~ f1l;:J-J1~f'l~~~'W , , 'U

l1n'B::;~~~~'U ,

~~~~~m8'IJ~"'VIn.ff'WIIl~'W1'Wn~::;Ul'Wn1~l\J~~ ~~n1~m~f'lCi~~rum~~~~~ 'li~~:J-J;8fi~nl~l\J~~vi~ fi~Jl LLt'l::;~un~ruvi~'li"i'Jflrum~ L'11~O~1~ LL~::; Ljj8~~~8, , U~::;~'VI5mW

l'W~::;w..i1~ nd::;Ul'Wn1~l\J~1Il U~~'Vl"1 ~~1~i'Jn1~IIl~l~~~U Lvi~~lu~:J-J~rumwmh~ ~(i1n:J-J oR~~l:J-J1uCi~ nl~IIl~1~~~U'IJ'W1M:i~ n1~1Il~1~ ~~Uf1l1:J-J~'W~ LLJ'WL~~n~18 ~::;~UOf'lIll~lhilfl nl~ml~~~m~m'11~:J-J~181',,~ X-Ray LLf'l::;nl~r;)~~~ nl~'Vl~~~U~ll:J-J~l:J-Jl~(llunl~~ULt~~r;)'WJl n1~ml~~~U~ll:J-J~'Wl~L~~~U ~lmL~L~~n n1~~~l~~~u~ml::;n1~n~Ln1::;'IJ~~~lL~~~U1Ilt'l~(i1~'Wn1~~~l~~~U

~ll:J-JLU'Wi:l'Wl'W'IJ~~~lLfl~~U~lm~~~~Holiday Detector

u~n~ln,1U~~'Vl ~m:J-J~~f'ln~{fl~if~N~L~~:J-Jn1~~I1lJ'Wl1w;h'Wflll:J-JUt'l~(i11l8 1Un1~'Vh~l'W LLt'l::;1'W~1'W ~'lJm~f1luV'i1u nu nl~~m"l~~ LL l(i1 ~~:J-J Lvi ~~t! n~l'W 'IJ~~U~~'VI"1 LLt'l::;lff~fl:J-J l~EJ~l:J-J \U~~~:J-J'1 n~ l(i18U~~'Vl"1 L~~Ll\'Wfi~flll:J-J6'il~bJ,JL'VIi'h,1 LLt'l::; O~ LU'Wflll:J-J1U ~~'lI~U'IJ~~~t!n~l'W'Vl ,nfl'W

• 4 I

• .

llma rk of Qua'i"1.

Continual improvement of the company's overall performance is

a permanent objective of the company. The achievement of the

internationally recognised ISO 9002 . 1994 quality system certification in

1999 and ISO 9001 . 2000 in 2002 respectively is a clear indication of the

company's commitment towards continual improvement. The company also

achieved locally recognised TIS - 427 "Steel Pipes" product certification.

assessed by Thai Industrial Standard Institute.

Siam Steel Works implemented ISO 9001 :2000 as the basis on which

to further develop its operations and production quality. In adopting this

internationally recognised system of quality assurance. Siam Steel works

aims to gain a competitive edge in the world market.

The ISO 9001 :2000 quality system is now the company's primary

quality management system. and all employees have been trained to achieve

superior qualifications. knowledge and skills.

The aim of every stage of the production process is to achieve total

quality performance. That means producing top-quality pipes and fittings.

During the production process. inspections are applied to ensure quality

control. That includes dimensional inspections, hydrostatic pressure tests.

ultrasonic flaw detector tests. dye-penetrant tests. holiday detector tests.

magnetic thickness tests. tensile tests. radiographic tests. adhesion tests

and bend tests.

In addition. Siam Steel Works promotes ongoing efforts to improve

occupational safety and health. while preserving a clean environment for

all employees and society at large. The company regards the issue of

occupational safety. health and the environment as the responsibility of all

its employees.

b'7i,mellil1U~MmJUlil:; b~Ubn~tn Spiral Welding

b'VI~nihu Steel Coil

'"r

" ,b'VIt'lnmJU

Steel Plate

....- -UUVlEJUnlSWaVlUa:nlSAJUAUAf1.JnlW, ,

Quality Control Diagram

Raw Material

Inspected by QA

1 Passed

Storage

Forming

1

~ 1

Hydrostatic Pressure Test

1-----,

ReJecled

Reiect~

-~ Passed 1

Rejected

Surface Preparation SA 2.5

1 Relecl~ In~

I Passed 1 Internal COa~ing / Lining

~--~ Passed 1

External Coating

Inspected by QC

Passed 1

Rejected

Piping Products

1 Passed

Storage ~

1 QA / Delivery

_6

UUVI£lun1swaVi PlIJIlPimsuusLll>UnlJmSIAa£luiiiJ 'Vimi,nil~alil~lnb'l'lanb'l'liltJ1'iiri'liIbb~U'l'I~eJ'iiillilii1U lvwl:j iUliIeJulunl~~alil~~~eJlud

b'VI~nb'VIiltll'l5illilbbWU/'l5illilihu - .ffml.ldJu'Viml1 - b'7imJmtllu

((~iltln1lb'7immUUellil1u~M)- b'7iEl:lJ£lvlt1UEln (~iltln1lb'7iEl:lJbbUU ellil1WrM) - .ffUll.1l.1t'llt1v1El - n1lli11l"!flElU~ltlelt'llill11 'l5ill'l bbt'l:;

v v

biln'l5bl1J - n11V1li1flElUbbl\1~mh - n1lblil1t1:lJ~h - n1lbl'l~Elu~h

mtllu - n1lbl'l~Elu~hmtluEln - n1lli1ll"!flElUWalilnru1i.frufllilVllti,

Production Process - From Rolling to Coating Steel pipes are made from either steel plates or coils:

Steel Plate/Steel Coil - Pipe Forming - Inside Welding (by an automatic submerged arc welding process) Outside Welding (by an automatic submerged arc welding process) - Pipe End Preparation - Ultrasonic/X-Ray Testing - Hydro static Testing - Surface Preparation - Inside Coating - Outside Coating - Final Inspection of End-Product

INSPECTION ITfM INSPECTION & TfSnNG

1. RAW MAfERIAL " ULTRASONIC T.HICKNESS GAUGE

STEEL PLATE AND COIL - VERNIER CALIPER. STEEL TAPE

2 fORMING;;:- - -~------~ ~~R~-;;;R CAL;~-;;~~';;E --~J - H~DROSTATIC PRESSURE TEST • MULTI WELDING GAUGE

RADIOGRAPHIC INSPECTION (X-Ray) - HYDROSTATIC TEST MACHINE (Opllonalj - SMART 200 X RAY UNIT (60-200 kVA.

____ _ __ I ~_ 1-49 ffi_ffi_) ~_

3. SURFACE PREPARATION & COATING0 - ADHESION TESTER I - VERNIER CALIPER I'

- SA 25 FILM STANDARD

.. ELECTROMAGNETIC TfliCKNESS GAUGE j' - WET FILM THICKNESS GAUGE

HOLIDAY DETECTOR (ELCOMETER)

4 P~O~UC':FI~"A;_IN~~EC':!ON--~-i - VERNIERC;~IPER~':EEL':~PE ...._

i .. eUeCTROMAGNETIC THICKNESS GAUGE - HOLIDAY DETECTOR

bl'l~Elu~hmtllu Inside Coating / lining

n1lblil1t1:lJ~h

Surface Preparation

'i

bl'l~Elu~hmtluEln

Outside Coating

~-

liIll"! flElU-nU ~ liIVll tI

Product & Final Inspection

.ffUll.1'ViEl v

Roll Bending

b'7iEl:lJbbM:lJ

Tack Welding

b'7iEl:lJliI:;b~Umtllu

Inside Welding

d " b'lJEl:lJliI:;b'lJUmtlUEln

Outside Welding

....--- .ffml.ll.lt'llt1'ViEl

v

Pipe End Preparation

.,..."...~-~ 't!

liIll"!flEl1J1EltJb'7iEl:lJ

UItrasonicIX-Ray

Testing ~

VlliIflElUbbl\1~mI1

Hydrostatic Testing

v

_ __ r

W2lVlnrun

rimVlantVlutJJUElIJ us8n CltJlUClMcHJElSflcf ,5lnVl 1vlSumswaliluuvnuullilSjJlU1US:vTut.Js:lnFllla:lUs:vTuCllna vTIJviEl1t.Jd

Steel pipes are manufactured to the following national and international standards:

.. t,. •

AWWA C200: Steel Water Pipes 6 Inches and Larger

2: API 5L. API Line Pipes

3: ASTM A53: Welded Steel Pipes

4: ASTM A139: Electric Arc Welded Steel Pipes

5: ASTM A252: Welded Steel Pipes

6: ANSI: American National Standards Institute

7: USASI: United States of America Standards Institute

.. ... . l' BS 534: Steel Pipe, and Specials for Water and Sewage

2: BS 3601: Steel Tubes for Pressure Purposes

• •• •

•• •

.- ....

1: JIS G3457: Electric Arc Welded Carbon Steel Pipes

l' 01 N 1626: Welded Unalloyed Steel Tubes

2: DIN 2458: Welded Steel Tubes

ISO 134: Steel Tubes for General Purpose

2: ISO 2547' Welded Plain End Unalloyed Steel Tubes

3: ISO 559: Steel Tubes for Water and Sewage

... .. .. . 1: TIS 427: Electrically Welded Steel Water Pipes

vifldl'Vl-rU11\11lii~'U

vimh'l1-rU11\11tiiJlbb~:::1tii~'U

AWWA C210

AWWA C216

AWWA C209

AWWA C20S

AWWA C214

AWWA C213

Underground fittings. connections and

Underground fittings. connections and

Underwater or underground steel pipes

·-1

Underground steel pipes

special sections

All steel pipes and fittings

All steel pipes and fittings

special sections

AWWA C216

AWWA C214

AWWA C209

AWWA C213

AWWA C20S

AWWA C210

Tape Coating Systems - Cold Application

Fusion-Bonded Epoxy Coatings

Cement-Mortar Lining

Tape Coatings - Cold Application

Heat-Shrinkable Polyolefin

Liquid Epoxy Coating

Whether pipes are used for water supply, irrigation, sewage,

or wastewater projects, protective coatings are crucial to protect

them from corrosion due to aggressive environments such as the

low resistivity of soil, variations in water flow or ground pollution.

The following are the various linings and coating options

available Therefore, Siam Steel Works Co.. Ltd.'s steel pipes and

fittings, are durable and long-lasting.

vifl~\lJl1lJr,h<v:::'l11hJ1"1i~1'Vl-rUnl'l1.h:::1.11 nWlJ~1.h:::'Vnu nl'lU1Ut'1

Jlb~tJ n1'lbA~BU~l11udj'U~\I~~l~b\!d~h.lmh\ld\ldl'Vl-rUnl'l'UB\ltl'UviB

'nnnl'ltlt'1n~B'U flwt1B\lm'illnL'li111::: bt It'1~mJ t'li'U ~'U~:nAl1:l-J liil'U'Vl1'U1V'Jvh~1 nl'l1'VlWlIfl\lJl 1Il~flt'1'il'U:l-J~ml:::1'U~'U nl'ltl'l~flU~l 'llUt'11111\1 '1 '1JB\lviB~\lJlu~::;~1.Jn'lruvifl~~~lIl~'Ult'1tJ U~H'Vl liWllJ

~~~ b1fl{A~ <Jltlt'1 'liltJ1o;,vim'Vlt'il{:I'l(li-run1'l1.JniJfl\l~\I~t'1 :iJA11:l-J'Vl'U'Vl1'U

bb('l::::iJmtJnl'l1"1i\ll'U~tJl1'Ul'U <J ,, -j,

s:uun1S IAaaUW:>lj UAPi1U1

(lauuhu~uflncl1\l

n1fJUElfl)

Outside Diameter of Pipe and Fillings

(mm)

(A~lUfJl~U1AS~lU~El\l

riElUU~Uua:lVi~u)

Standard Length of Underground and

Above-ground Pipe (m)

(mlUfJl~U1AS~lU

~El\lriEllJaElfl)

Standard Length of Sleeve Pipe

(m)

(A~lUVlU1Wa\lriEl) Wall Thickness

(rialjj~u)

Underground Pipe and Sleeve Pipe

(mm)

(riElUUfiu)

Above-ground Pipe (mm)

114.30 600 300 2.65 450 168.30 6.00 300 345 550 219.10 6.00 300 450 5.50 273.00 6.00 300 4.80 6.00 32390 6.00 3.00 6.00 6.00 355.60 600 300 6.00 6.00 40640 900 300 6.00 7.90 45720 9.00 300 6.00 7.90 508.00 9.00 3.00 6.00 7.90 558.80 9.00 300 6.00 790 60960 9.00 3.00 6.00 1110 66040 9.00 300 6.00 11.10 711.20 900 300 6.00 11.10 762.00 9.00 300 6.00 11.10 81280 9.00 3.00 7.90 1270 86360 900 300 7.90 1270 91440 300 7.90 12.70 965.20 9.00 300 7.90 12.70

101600 9.00 300 9.50 12.70 1066.80 9.00 300 9.50 12.70 1117.60 9.00 300 950 12.70 116840 9.00 3.00 9.50 1270 121920 9.00 3.00 1110 1590 1320.80 9.00 300 1270 1910 1371.60 9.00 300 12.70 19.10 142240 9.00 300 12.70 19.10 1524.00 9.00 300 12.70 19.10 162000 9.00 3.00 1270 19.10 1820.00 600 300 15.90 2540 2020.00 6.00 3.00 19.10 Max.56.00 2120.00 6.00 3.00 19.10 Max.56.00 232000 6.00 300 Max.56.00 Max.56.00 242000 6.00 300 Max.56.00 Max.56.00 2520.00 6.00 300 Max 56.00 Max.56.00 2620.00 6.00 300 Max 56.00 Max.56.00 2820.00 6.00 300 Max.56.00 Max.56.00 302000 6.00 300 Max.56.00 Max.56.00 3220.00 6.00 300 Max.56.00 Max.56.00 3420.00 6.00 3.00 Max.56.00 Max.56.00 3620.00 6.00 300 Max56.00 Max.56.00

8unsruri8 Pipe Fittings, JO'ints and Appurtenances ,

'i:;UU'Vitl<ll btJ'U~'i:;(lftl'lHi'iitllllmb('l:; A pipeline system is composed of pipes, fittings, joints and appurtenances

connected by end to end. Siam Steel Works manufactures tll.ln'iru'VitlUl'1tl~l'1 bvim'iim.Jliim~mblii('l:;'Vitl'U, steel fittings of different varieties that are suitable for

b'iil~':ltJn'U "tJl).J"lIi';H1tlfV'l~ tJ.J~IIl'iiElliimb('l:; the requirements and applications of contractors,

tll.ln'iru'Vim'l('lltJ1l.1bbUU .z1'1b'Vl).Jl:;").Jnu, " network operators and pipe-laying contractors. V'l11).J(lftl'lnl'iHi'll'U1'Ubblll('l:;lV'l'i'lnl'i A standard range includes elbows, tees, tapers, and 'iU bbUU).J1III 'i'i l'U'lJEl'l"liEl IiiEl \\('1:; tll.ln'iru'Vitl flange-slip joints. for a complete network, both for 'U.... 'I 'V

1~\\ri 'Vitll~'1 "1).JV11'1 ojjEl('l~ 'Vimr'U d'J'U~'U potable water, sewage, and irrigation.

Schedule of WaLL Thickness for Steel Water Pipes and Fittings

ualtJnEllJVlalnVlaltJ§UlIUUlVilaEln ~lJviEllUd

1. l.I('11tH1tJU"'h'l'iil'1

2. l.I('11tH1tJUbb('l:;l.I('11tH0m

3. 'jIl'Wl'il'U

4.1.I1m:;..J'I

5. ~'U1

Various types of pipe end are also available: 1. Plain ends for mechanical coupling joints 2. Plain ends and bevelled ends for butt

welded joints 3. Flanged ends for flange joints 4. Spherical spigot and socket ends for sleeve

welded joints 5. Others as required

9_Note 1: The special size and dimensions could be specified by purchaser Note 2: Scheduie of wall thickness shown is based on a designed working pressure 100 m w.c. or PN 10

".O<DIO.or,.. ..,..,""',..~ ..._,_ S< ...._~...._, -.:.:._"

n. ' ...... \ho.l... 0 01

~ - ...., ,.~, ~~ .... .O<l'""_l OSOtool

........... xo,.....-- - _=.::::-,..;-....::. ~..:-

SGSV.nley l"I&lOIIltto..~IC.ntflUlrio"S""""'1

)9Moo6~.A9)C.

1l.·,l",I~ ....... r!u""il ~._ucoo

053605

~V ..le-.fo<...... l.HnI..

S"!'...d"y

Slam Steel Works Co., lId

F"totl><l "".. """,4'4: fhtr _"".0",.101" ',-..' r:...-;o•• ,." ..,••ICe-

•..........-_,,.,.... ""~l ,.. _eo tl'. Cr'U'-='~

..-.It'" >tlVl>'S::>ljl;Ol~'_._·",~",

bo c~~.....0<1 b-~ _'...... , .....;-.,.......

ASSESSMENT SCHEDULE

Q53606

".".... ·_•••I.."'rt'" 1...:...:.-1 ........:

...i_Co~':')]

h/tl\{tylf'

1l.·~eHlIlllIll""'I"'n\lHl,."llnI~f\.,"nnll ."'..'~"._I-'r."'~t....iol""" ..._,.. K~"'''''

_~._t~_' . .......~I

..I.,~,~,~,

II 1 • ,.;.,.~: .... ~.It-Jrr; ·.....l~........-. u-...o;,tJ ,- .... " '.~;;, .,l",...;n:o ••J l I.~ i.M .-,,.';0. •• 1,,,, 0\ , •• .., ...

.V(l225/QO

U9I\O\'cmbcr"2001

Tim/land

""... ll>ocullll..... k~'" ",1 1..,.4..0••• A. ,,,,•••

I>_.t....:.'_'5@

l "r.<l ,,«lpl_rd'..~ .. ......,..I<",,«,~

l;.. ~,,""l•....,...., •• '''~lo"_._ ••. """,.

I ... ~"",>II_ ll\l·

lilt ,'<,,_,,-10.-.._............_,. >.kJMt.-_ ........,.._ .....~"

1.".,-.."' .. ·,-.... '~~ ..OjJI'" d

SWill Str!cI Work,' Co., Lid.

..... """io., ~~............_ ... Jlt1I ,<>!ISO.'

--,~_.......l·......-,.>,..-..

r.,,,

ASSESSMENT SCH£DUL~

NQ215iOO

r_.I ••l;,"" ~oI)I_r'_«'I..-..... ....,rJwlJr,~, '~~')1 :'I7.It~._, ... lW__ ~_ ,..:·_'"

!file us,;" IBluauiimsn ~Itin SIAM INTEGUrr CQ"LTD.

SIAM SYNDICATE TRADING CO., LTD. 2nd-4th Floor. SST Building. 999 Moo 6. Navamin Road. Klongkum,

Bungkum. Bangkok 10240, Thailand

Tel.: (662) 733-6080-99 Fax: (662) 375-8160-1

E-mail: [email protected]

Website: www.sst.co.th

SST HOLDING CO., LTD. 4th Floor, SST Building. 999 Moo 6. Navamin Road. Klongkum.

Bungkum, Bangkok 10240, Thailand

Tel.: (662) 733-6080 Fax: (662) 375-8160

SIAM INUGRATE CO., LTD. SST Building, 999 Moo 6. Navamin Road. Klongkum. Bungkum,

Bangkok 10240, Thailand

Tel.: (662) 733-6080-99 Fax: (662) 375-8160-1

SIAM NAVACO CO., LTD. 59-61 Charoennakorn Road. Soi 45. Banglumpulang,

Klongsan. Bangkok 10600. Thailand Tel.: (662) 437-0476-8, 862-6032-40 Fax: (662) 438-0980, 437-8794

E-mail: [email protected]

SIAM ASIA METAL CO., LTD. 18/1 Moo 9. Sukhapiban 1 Road, Bangkhunthian. Bangkok 10150. Thailand Tel.: (662) 899-4151-55, 416-0046. 415-4650-1 Fax: (662) 415-4590

- '--... .. ..;. ..

>

Plant: SIAM STEEL WORKS COMPANY LIMITED

76 Moo 6, Rama 2 Rd" T, Bangkaew. A. Muang Samut Songkhram 75000. Thailand Tel.: 01-645-6304 Fax: 01-215-8184

Sales office: SIAM SYNDICATE TRADING COMPANY LIMITED

SST Building, 999 Moo 6. Navamin Rd" Klongkum. Bungkum. Bangkok 10240, Thailand, Tel.: (662) 733-6080-99 Fax: (662) 375-8160-1 E-mail: [email protected] Website: www.sst.co.th