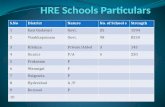

Ship particulars

-

Upload

liyenita-widjaja -

Category

Documents

-

view

214 -

download

6

description

Transcript of Ship particulars

OCIMF SIGTTO

Ship Information Questionnairefor Gas Carriers1st Edition 2000

FORM - C

Oil Companies International Maritime ForumSocitety of International Gas Tanker & Terminal Operators Ltd

BENTE KOSAN

TABLE OF CONTENTS

SECTION A GENERAL INFORMATION Page

A1 Principal Ship Particulars 2 A2 Hull Dimensions 5 A3 Immersions 5 A4 Loaded Particilars 6 A5 Parallel Mid-body Dimensions 6 A6 Bunker Capacities 7 A7 Fuel Consumption Detailes 7 A8 Main Engine Particulars 8 A9 Auxiliary Plant 9 A10 Power/Speed Information 9 A11 Thrusters 10 A12 Fresh Water 10 A13 Ballast Capacities and Pumps 10 A14 Mooring Equipment 11 A15 Navigational Equipment 13 A16 Communications Equipment 15

SECTION B CARGO SYSTEMS

B1 Cargo - General Information 18 B2 Cargo Tanks 18 B3 Cargo Tank Capacities 19 B4 Loading Rates 19 B5 Discharging - General 20 B6 Discharge Performance 21 B7 Unpumpables 21 B8 Vaporising Unpumpables 21 B9 Reliquefaction Plant 22 B10 Cooling Capacity 22 B11 Cargo Temperature Lowering Capability (at sea) 23 B12 Inert Gas 24 B13 Cargo Tank Inerting/De-inerting 25 B14 Gas Freeing to Fresh Air 25 B15 Changing Cargo Grades 25

V

SECTION Page

B16 Deck Tank Capacities 26 B17 Pre-Loading Cooldown 26 B18 Vapouriser 26 B19 Blower 27 B20 Crago Re-Heater 27 B21 Hydrate Control 28 B22 Cargo Measurement 28 B23 Cargo Sampling 29 B24 Cargo Manifold 30 B25 Cargo Manifold Reducers 31 B26 Connections to shore for ESD and Communication System 31 B27 Manifold Derrick/Crane 32 B28 Store Handling 32

VI

SECTION A

GENERAL INFORMATION

1

A1 PRINCIPAL PARTICULARS

1.1. Date Questionnnaire Completed 23-Mar-07

1.2. Name of Vessel BENTE KOSAN1.3. LR/IMO Number 9196333

1.4. Last Previous Name

1.4.1. Date of Name Change

1.5. Second Last Name Change

1.5.1. Date of Name Change -

1.6. Third Last Name Change -

Date of Name Change -

1.7. Fourth Last Name Change -

1.7.1. Date of Change -

1.8. Flag Singapore

1.9. Port of Registry Singapore

1.10. Official Number 392854

1.11. Call Sign S6BE4

1.12. Inmarsat A or B Number

1.13. Vessel's Telephone Number 356 540 010

1.14. Vessel's Fax number 356 540 012

1.15. Vessel's Telex Number 356 540 014

1.16. Vessel's E mail Address [email protected]

1.17. Inmarsat C Number 456 540 010

1.18. Vessel's MMSI Number 565 400 000

1.19. Type of Vessel- Min Tank Temperature(1) Pressurised, 0 deg.C(2) Semi-Pressurised,(3) Refrigerated,

2

Max Tank Pressure1.77 Mpa

OWNERSHIP AND OPERATION

1.20. Registered Owner Lauritzen Kosan A/S

Full Address Sankt Annae Plads 28DK-1291 Copenhagen KDenmark

Office Telephone Number -

Office Fax number -

Office Telex number -

Office E mail Address -

Contact Person -

Contact Person and -Telephone Number After HoursNumber of Years Vessel Owned

1.21. Name of Operator (if Different from AboveUnigas Kosan Ltd.

Full Address 1006 Lippo Centre Tower 2

89 Queensway, AdmiraltyHong Kong

Office Telephone number 852-3102-5577

Office Fax number 852-3102-0577

Office Telex Number 79145 EXCO HX

Office E mail Address [email protected]

Contact Person Mr Jeremy Lee

Contact Person and 852-3102-5577Telephone Number After Hours

1.22. Number of Years As Vessel Operator

1.23. Total Number of Vessel Operatedby this Operator

3

BUILDER

1.24 Builder Murakami Hide Shipbuilding Co.,Ltd.

1.25 Name of Yard Vessel built at Japan

1.26 Hull Number S.No.502

1.27 Date Keel Laid 21st May.1998

1.28 Date Launched 27th Sept.1998

1.29 Date Delivered 08th Dec.1998

1.30. Date of Completion of Major Hull Changes(if any) N/A

1.31 If Changes were made, what changeswere made and at which Yardwere they carried out N/A

CLASSIFICATION

1.32 Classification Society Class NK

1.33 Class Notation NS* (18 kgf/cm3, 0 deg. C, Type II PG)and MNS*

1.34 If Classification Society Changed,Name of Previous Society -

1.35 If Classification Society Changed,Date of Changed -

1.36 Was Ship built in Accordance With the Following Regulations:- Approval Received

IMO

USCG

RINA

Other (………………..)

1.37 IMO CertificationCertificate of Fitness -IGC

A328

A329

Letter of Compliance

Issued By

1.38. Unattended Machinery Space Certificate N/A

4

YES NO YES NO

NO NO YES NO

NO YES

YES NO

YES NO

YES NO

YES NO

YES

YES YES YES

YES

YES

TONNAGES

1.39. Net Registered Tonnage 1,062

1.40. Gross Tonnage 3,540

1.41. Suez Canal Tonnage 3,155.86

1.42. Panama Canal Tonnage 3,032.00

A2 HULL DIMENSIONS

2.1. Length Overall 99.92 m

2.2. Length Between Perpendiculars 92.87 m

2.3. Distance Bow to Bridge 75.20 m

2.4. Diatance Bridge Front to Mid-Point Manifold 30.00 m

2.5. Distance Bow to Mid-point Manifold 45.20 m

2.6. Extreme Breadth 16.20 m

2.7. Extreme Depth 7.20 m

2.8. Summer Draught 4.814 m

2.9. Corresponding Deadweight 2,854.42 tonnes

2.10. Light Displacement 2,350.42 tonnes

2.11. Loaded Displacement 5,204.84 tonnes

2.12. Cargo Tank Cubic Capacity (100% full) 4,021.579 m3

2.13. Distance from Keel to Highest Point 33.45 m

2.14. Air Draught (with normal ballast) 29.20 m

A3 IMMERSION

3.1. TPC - at Normal Ballast Draught 11.8 tonnes @ 3.8 m.draught

- at Loaded Draught (Summer) 12.1 tonnes @ 4.814 m.draught

5

A4 LOADED PARTICULARS

Complete the folloing table:

Cargo: N-Butane Propane Butadiene VCM Ballast4.1. only

4.2. Density:- -

4.3. Cargo tonnes

4.4. Bunkers - FO tonnes

4.5. - DO tonnes

4.6. Fresh Water tonnes

4.7. Stores/Spares tonnes

4.8. Lub oil tonnes

4.9. Ballast tonnes

4.10. Deadweight tonnes

4.11. Draught Forward

4.12. Aft

4.13. Mean

Remarks : The above figures shall be extracted from Stability Information Booklet. Actual loadable cargo quantity to be refered to Damage Stability Booklet.

A5 PARALLEL MID-BODY DIMENSION

To aft PP 54.72 m 45.20 m

33.46 m 29.20m

LOADED DRAFT (4.814 m)BALLAST DRAFT (4.32 m)

32.00 m 23.4 m16.50 m 18.33 m

LOA 99.92 m MANIFOLD

6

A6 BUNKER CAPACITIES

6.1 M.E.. Fuel Oil - Grade HFO180-R.W.No.1 1500sec

- Capacity@ 98% 473 m3

6.2 Diesel Oil - Grade MDO

Capacity@ 98% 162 m3

A7 FUEL CONSUMPTION DETAILS

7.1 At Sea (Normal Service Speed) - HFO-180 tonnes/day

- MDO tonnes/day7.2 At Sea (Normal Service Speed)

while conditioning cargo - HFO-180 tonnes/day

(for N2 Gen') - MDO tonnes/day

7.3 In Port,Loading - HFO-180 tonnes/day

- MDO tonnes/day

7.4 In Port, Discharging - HFO-180 tonnes/day

- MDO tonnes/day

7.5 In Port, Idle - HFO-180 tonnes/day

- MDO tonnes/day

(See also Consumption Graph on the following Page)

7

SPEED CONSUMPTION GRAPH

60

50

Consumption(tonnes/day) 40

30

20

11 12 13 14 15 16 17 18 19SPEED (Knots)

In the graph above, enter curves for both Loaded and Ballast conditions.(if necessary, amended consumption and speed scales to suit)

A8 MAIN ENGINE PARTICULARS

8.1 Main Engine Make and Type Akasaka Diesel LimitedA41

8.2 No.of Units 1 set

8.3 Maximum Continuous Rating (MCR) per Engine 3300PS @ 230 RPM

8.4 Total Available Power 2063 kw

8.5 Normal Service Power 2063 kw

8

A9 AUXILIARY PLANT9.1 Make and Type of Auxiliary Generators Yanmar S165-DT

9.2 No. of Units 2 sets

9.3 Maximum Generator Output per unit 1,200 RPM 309 kilowatts

RPM kilowatts

RPM kilowatts

9.4 Shaft Generator kilowatts

9.5 Total Available Powe 445 Volts 60 Hz 618 kilowatts

9.6 Emergency Generat 2,400 RPM 100 Volts 60 Hz 9.9 kilowatts

9.7 Emergency Fire PumpType Engine driven contrifugalDelivery Pressure 30 m3/h x 50mMotive Power Engine drivenif Electrical, Indicate Power Required in Kw

9.8 Steering GearType Electro-Hydraulic

Indicate Power Required in Kw

to Steer the Vessel with One Pump Unit 5.5 kw

A10 POWER/SPEED INFORMATION

10.1 Trial Data BHP

10.2 MCR RPM

Speed knots

Draught m

10.2 Normal Service Speed BHP KW

MCR RPM

Speed knots

Draught m

9

A11 THRUSTERS

11.1 Make and Type

11.2 No. Installed

11.3 Location and Rated Bollard Pull or Kw output / /

A12 FRESH WATER

12.1 Capacity of Distilled Tanks tonnes

12.2 Capacity of Domestic Tanks 149 tonnes

12.3 Daily Consum - Distilled tonnes

- Domestic about 6 tonnes

12.4 Daily Evaporator Output 10 tonnes

A13 BALLAST CAPACITIES AND PUMPS

Complete the following table:

Tank Capacity (m3 Number13.1 Fore Peak13.2 Wing or Side Tanks 13.3 Double Bottoms 13.4 Aft Peak13.5 Other (Deep Tank.)

13.6 TotalRemarks : Hopper Ballast Tanks to be entry in Wing Tanks column.

13.7 Ballast Pump Make and Type Centrifugal

13.8 No.of Pumps

13.9 Total Capacity m3/hr

13.10. Location Engine room

13.11. Control Location Engine room / Engine control room

10

each 210

0

1431.06

2

104.54790.20536.32

A14 MOORING EQUIPMENT

14.1 ROPES AND WIRESOn the diagram below indicate the position of Which Mounted Wires (W) and Ropes (R)together with Open (O) and Closed (C) Fairleads. Indicate also the position of mooring Bitts (B).

(O) (C) (C) (C) (O) (C)

(O) (O)

(O) (R) (R) (O)

(C) (R) (R) (C)

(O) (R) (R) (O)

(O) (R) (R) (O)

(O) (C) (C) (C) (O) (C)

Mooring Wire (On Drums) Mooring Wire Tails

No. Dia Length MBL No. Type Dia Length MBL

Forecastle

For'd Main Deck

Aft Main Deck

Poop

Mooring Ropes (On Drums)

No. Type Dia Length MBL

Forcastle 4 55

For'd Main Deck

Aft Main Deck

Poop 4 55

Other Mooring Lines

No. Type Dia Length MBL

Mooring Wires not on Drums

Mooring Ropes not on Drums PE 359

Emergency Towing Wires (Fire Wires)

11

359

359

48

24

PE

PE

200

200

2

2

200

50

14.2 MOORING WINCHES

No. Serving Split Motive Heaving Brake HaulingSingle or Drums Power Power Capacity Speed Double (Yes/No)(eg Steam (tonnes) (tonnes) (m/min) Drums Hydraulic)

Forecastle 2 Double No 5 15 15

For'd Main Deck

Aft Main Deck

Poop 2 Double No 5 15 15

14.3 ANCHORS AND WINDLASSES

Windlass Motive Power (eg. Steam, Hydraulic) HydraulicHauling Power tonnes

Breke Holding Power tonnes

Anchor Type

Weight tonnes

Is Spare Carried

Cable Diameter 46 mm

No. of Shackles Port 9

No. of Shackles Starboard 8

14.4 TOWING EQUIPMENT

Is Ship fitted with a Towing Bracket Aft

If Yes, state SWL tonnes

Is Towing Chain provided

Dimensions of Towing Wire - Diameter 34 mm

- Length 190 m

14.5 WINDAGE

Windage on Ballast Draught - End-on m2

- Lateral m2

12

760.00

820.00

Hydraulic

Hydraulic

9

53.7

Hall's patent anchor

YE NO

YES NO

YES NO

A15 NAVIGATIONAL EQUIPMENTIs the following equipment fitted:-

15.1. Magnetic Commpass

15.2. Off Course Alarm - Magnetic

15.3. Gyro Compass

Specify Number 1

15.4. Off Course Alarm - Gyro

15.5. Bridge Repeaters

Specify Number 4

15.6. Radar 3cm

15.7. Radar 10cm

15.8. Are Radars Gyro Satbilished

15.9. Radar Plotting Equipment

15.10. ARPA

15.11. ECDIS (Electric Display and Information System)

15.12. Depth Echo Sounder with Recorder

15.13. Depth Echo Sounder without Recorder

15.14. Speed/Distance Indicator

15.15. Doppler Log

15.16. Speed of Approach Doppler

15.17. Rudder Angle Indicator

15.18. Rudder Angle Indicator on Each Bridge Wing

15.19. R.P.M. Indicator

15.20. R.P.M. Indicator on Each Bridge Wing

15.21. Controllable Propeller Pitch Indicator

15.22. Thruster(s) Indicator

15.23. Rate of Turn Indicator

13

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

NO

y YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

15.24. Radio Direction Finder

15.25. NAVITEX Receiver

15.26. G.P.S

15.27. Transit SATNAV

15.28. DECCA Navigator

15.29. Omega

15.30. Loran C

15.31. Weather Fax

15.32. Sextant(s)

15.33. Signal Lamp ALDIS

15.34. Anemometer

15.35. Engine Order Recorder

15.36. Course Recorder

15.37. Are steering motor controls and engine controls fitted on bridge wings

15.38. Is Bridge Equipped with a "Dead Man" Alarm Equipment

15.39. What chart outfit coverage is provided

Worldwide

Limited

If limited Please Indicate Area Covered South East Asia

15.40. Formal Chart Correction System in use

15.41. Electronic Chart System in use.

15.21. Controllable Propeller Pitch Indicator

15.22. Thruster(s) Indicator

15.23. Rate of Turn Indicator

14

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YS NO

YES NO

YES NO

YES NO

A16 COMMUNICATIONS EQUIPMENTIs the following equipment fitted:-

16.1. Main Transmitted Including Radio TelephoneDistress Frequency

16.2. Main Receiver Including Radio Telephone DistressFrequency

16.3. Radio Telephone Distress Frequency Watch Receiver

16.4. Main Radio Antenna

16.5. Reserve Radio Antenna

16.6. Are the Main and Recerve Installations ElectricallySeparate and Electrically Independent of each other

16.7. 2182kHZ Bridge Auto Alarm

16.8. Alarm Signal Generating Device

16.9. VHF Radio(s)

Specify Number 2-sets

16.10. Portable VHF/UHF Radios

Specify Type and Number 4-sets

Are Sets Intrindically Safe

16.11. Inmarsat Satellite System B & C

Specify System Type A,B or C

16.12. Is the Ship Equipped as per GMDSS requirements

If yes, which area of operation is vessel certified to operate in A1 + A2 + A3

16.13. EPIRB

16.14. SARTS

16.15. Emergency Lifeboat Tansmitter

16.16. At least Three Survival Craft Two-Way Radio Telephone Apparatus

16.17. Full Set of Publications.

15

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

16

SECTION B

CARGO SYSTEM

17

B1 CARGO - GENERAL INFORMATION

1.1. List Products Which the Ship is Certified to Propylene, Propane, Butane,Carry Butadiene, VCM, B/P Mix,

Butylenes, Isoprene

Transport and Carriage Conditions

1.2. Minimum Allowable Tank Temperature ℃

1.3. Maximum Permissible Tank Pressure

1.4. List Grades which can be Loaded orDischarged Simultaneously

1.5. List Grades which can be TransportedSimultaneously

1.6. Number of Products that can be Conditioned N/Aby Reliquefaction Simultaneously

1.7. State Natural Tank Segregations N/A(NB. Separation must be by the removalof spools or the insertion of blanks)

B2 CARGO TANKS Independent Type - "C"

2.1. Type and materials of Cargo Tanks Carbon Manganese Steel

2.2. Maximum Allowable Relief Valve Setting

2.3. Safety Valve Set Pressure - if Variable GiveFilled Tanks

2.4. Maximum Vacuum

2.5. Maximum Cargo Density kg/m3

2.6. Maximum Rate of Cool - Down N/A ℃

2.7. State any Limitations Regarding Partially No cargo tanks should be loaded more than 98%Filled Tanks liquid full at reference temperature.

2.8. State Allowable Combinations of Filled and Empty Tanks

18

1.77 Mpa

0.69 Mpa

0.948

0

18

One (1) Grade

One (1) Grade

B3 CARGO TANK CAPACITY

Complete the Following Table (for example)

Capacity m3 N- Butane Propane VCM Propylene Butadiene Butylene Tank ( 100% ) Tonnes ℃ Tonnes ℃ Tonnes ℃ Tonnes ℃ Tonnes ℃ Tonnes ℃

1 1017.0 868.0 1695.0 917.0 45 1103.0 1058.0

2 1017.0 868.0 1695.0 917.0 45 1103.0 1058.0

Totals 4021.579 2034.0 1736.0 3390.0 1834.0 2206.0 2116.0 S.G 0.519 0.443 0.865 0.468 0.563 0.540

Remarks : Actual loadable quantity to be refered to Damage Stability Booklet. The specific gravity of cargo at the highest temperature which the cargo

may reach upon the termination of loading, during the transport, or at thedischarging under the ambient design temperature condition, should bedepending on the ship's service route.

B4 LOADING RATES4.1. From Refrigereted Storege:

Rate (tonnes/hr) With Vapour Without Vapour Return Return

4.2. Butane

4.3. Propane

4.4. Ammonia

4.5.

4.6.

4.7. (To be entry in case of Re-Heater installed.)

4.8. From Pressure Storage:Rate (tonnes/hr)

With Vapour Without Vapour Return Return

4.9. Butane 0-30℃ 360 250

4.10. Propane 0℃ 320 220

4.11. 10℃ 300 210

4.12. 20℃ 300 210

4.13. 30℃ 280 200

4.14. Special Remarks: 19

60

60

49

49

63

63

MARVS (1.77 MPa)

2012.247

2009.332

68

68

Product

Product

54

54

00 0 0

B5 DISCHARGING - GENERAL

Cargo Pumps

5.1. Type of Pumps Fixed deepwell pumps

5.2. Number Per Tank 1 set

5.3. Rate (per Pump) 300/250 m3/hr

5.4. Delivery Head 110 / 120 mlc

5.5. Maximum Density kg/m3

Booster Pump

5.6. Type of Pump

5.7. Number Per Tank

5.8. Rate (per pump) m3/hr

5.9. Delivery Head mlc

5.10. Maximum Density kg/m3

Pumping Curves

Insert in the space below copies of Pumping Curves for Cargo Pumps and Booster pumps:

CARGO COMPRESSOR

5.11 Type Water cooled Stage Double Acting Oilless Compressor

5.12 Number 2 set

5.13 Capacity (per unit) 460 m3/hr

5.14 Are they oil free? Yes

20

0.948

B6 DISCHARGE PERFORMANCE

Full Cargo Discharge Times (using all main pumps):

6.1 Fully Refrigerated:

Manifold Hours* Back Pressure With Vapour Without Vapour

Return Return

6.2 1 kP/cm2

6.3 5 kP/cm2

6.4 10 kP/cm2

* Indicate difference when manifold strainers are installed

6.5 Pressurized:

Mainfold Hours Back Pressure With Vaopur Without Vapour

Return Return

6.6 1 kP/cm2

6.7 5 kP/cm2 Depending on

6.8 10 kP/cm2 Shore Condition

B7 UNPUMPABLES

Tank No. 1 2 3 4 5 6 7 8 Totals m3

7.1 Liquid 0 0 0 0 0 0 0 0 0

B8 VAPOURISING UNPUMPABLES

8.1 Process usedTime to Vapourise Liquid Unpumpables Remaining After Full Cargo Discharge:

8.2 - Propane hrs

- Butane hrs

- Ammonia hrs

- …………… hrs

- ……………. hrs

- ……………. hrs

21

B9 RELIQUEFACTION PLANT

9.1. Plant Design Condition - Air Temperature ℃

- Sea Temperature ℃

Plant Type

9.3. Single Stage/Direct

9.4. Two Stage/Direct

9.5. Simple Cascade

9.7. Coolant Type

Compressors

9.8. Type and Makers Name

9.9. Number

9.10. Capacity (per unit) m3/hr

9.11. Are they Oil-Free

B10 COOLING CAPACITY

State Cooling Capacity (in kj/hr) for -

10.1. Propane @ -42 ℃ Kcal/hr

10.2. @ -20 ℃ Kcal/hr

10.3. Butane @ -5 ℃ Kcal/hr

10.4. @ -5 ℃ Kcal/hr

10.5. @ ℃ Kcal/hr

10.6. @ ℃ Kcal/hr

22

YES NO

YES NO

YES NO

YES NO

B11 CARGO TEMPERATURE LOWERING CAPABILITY (AT SEA WITH SEA TEMPERATU + 15 ℃ )

Time taken to lower the temp. of:

11.1. Propane from . . . ℃ - 42 ℃ hrs

11.2. - 5 ℃ to - 42 ℃ hrs

11.3. - 38 ℃ to - 42 ℃ hrs

11.4. + 20 ℃ to - 1 ℃ hrs

11.5. + 10 ℃ to - 1 ℃ hrs

11.6. Butane from + 20 ℃ to - ℃ hrs

11.7. + 10 ℃ to - ℃ hrs

11.8. + 10 ℃ to - ℃ hrs

11.9. from to hrs

11.10. from to hrs

11.11. from to hrs

11.12. from to hrs

23

B12 INERT GAS

Main I.G. Plant

12.1. Type of System Nitrogen Generator

12.2. Capacity 118 m3/hr @ 99.5% purity

12.3. Type of Fuel Used -

12.4. Composition of I.G.(O2 - Co2 - Co - Nox - N2)

12.5. Lowest Dewpoint Achievable Minus 65 DEG.C ℃

12.6. Used For Cargo Grade Changes

Auxiliary I.G. or Nitrogen Plant

12.7. Type of System

12.8. Capacity m3/hr

12.9. Composition of I.G.(O2 - Co2 - Co - Nox - N2)

12.10. Lowest Dewpoint Achievable ℃

12.11. Used For

Nitrogen Nitrogen for Tank padding to be mentioned in this section.

12.12. Liquid Storage Capacity m3

12.13. Daily Boil-Off Loss m3

12.14. Maximum Supply Pressure kP/cm2

12.15. Supply Capacity m3/hr

12.16. Used For

12.17. HP Nitrogen Nm3

24

B13 CARGO TANK INERTING/DE-INERTING(Experienced Data)

13.1. Time taken From Fresh Air to Under 5% O2 at -25 ℃ hrsDewpoint

Time Taken From Cargo Vapour to Fully Inert at - 25 ℃ Dewpoint when:

13.2. - I.G. Density less than Product hrs

- I.G. Density greater than Product hrs

B14 GAS FREEING TO FRESH AIR(Experienced Data)

14.1. Plant Used By Cargo Compressor

14.2. Time Taken from Fully inert Condition to FullyBreathable Fresh Air hrs

B15 CHANGING CARGO GRADES (Experienced Data)

In the table below, show the number of hours needed to change grades from the removal of unpumpables to tanks fit to load. Also indicate quantity of inert gas consumed during the operation:

To Propane Butane Ammonia VCMFrom Time I.G.Used Time I.G.Used Time I.G.Used Time I.G.Used

(hours) (m3) (hours) (m3) (hours) (m3) (hours) (m3)

Propane

Butane

Ammonia

VCM

Note any operation that cannot be carried out at sea

* Restrictions may apply.

( To be mentioned in case of Not installed Inert Gas /Nitrogen Generator)

25

62

170

30

B16 DECK TANK CAPACITIES

16.1 Propane Capacity m3

16.2 Butane Capacity m3

16.3 Ammonia Capacity m3

16.4 Maximum Allowable Relief Valve Setting kP/cm2

16.5 Lowest Permissible Temperature ℃

16.6 Materials

B17 PRE-LOADING COOLDOWNIn the table below,show time and quantity of coolant required to cooldown cargo tanks from ambient temperature and fully gassed up state sufficient to allow loading to commence.

Quantity of Time (hours)Product Coolant With Vapour Without Vapour

Required (m3) Return Line Return Line

17.1 Propane

17.2 Butane

17.3 Ammonia

17.4 VCM

B18 VAPORISER

18.1 Type of Vaporiser

18.2 Number Fitted

18.3 Capacity (per unit) - Propane m3/hr Vapour

18.4 Liquid Supply Rate m3/hr Liquid

18.5 Delivery Temperature ℃

18.6 Capacity (per unit) - Ammonia m3/hr Vapour

18.7 Liquid Supply Rate m3/hr Liquid

18.8 Delivery Temperature ℃

18.9 Capacity (per unit) - Nitrogen m3/hr Vapour

18.10. Liquid Supply Rate m3/hr Liquid

18.11. Delivery Temperature ℃

26

B19 BLOWER

19.1 Type of Blower

19.2 Rated Capacity m3/hr

19.3 Delivery Pressure kP/cm2

B20 CARGO RE-HEATER

20.1 Type of Re-Heater None

20.2 Number Fitted

20.3 Heating Medium

Discharge retes with sea water at 15℃ to raiseproduct temperature:

20.4 - for V.C.M from 14 ℃ to 0 ℃ m3/hr

20.5 - for PROPYLENE from 48 ℃ to 0 ℃ m3/hr

20.6 Cargo Heater Curve:

Seawater Density: Back Pressure :

28

26

24

22

20Sea WaterTemperaure 18

℃ 16

14

12

10

Loading Rate tonnes/hrAmmonia/Propane Dischar @ - 10 ℃

( In case of Pressurized Vessel to be changed to "LOADING")27

450250 300 350 40050 100 150 200

B21 HYDRATE CONTROL21.1. Type of Depressant with Freezing Point Temperature ℃

21.2. Quantity of Depressant Carried Litters

21.3. Means of Injection

Any other system used

B22 CARGO MEASUREMENTLevel Gauges

22.1. Are level gauges Loacal or Remote

22.2. Manufacturer Musashino Co., Ltd.

22.3. Type M-LMZ

22.4. Rated Accuracy 1 cm

22.5. Certifiying Authority Class/Owner/Service Comp

Temperature Gauges22.6. Manufacturer Hyoda Gauge Mfg. Co., Ltd.

22.7. Type S5.5-GT-M

22.8. Rated Accuracy ± 0.1℃

22.9. Certifiying Authority Class/Owner/Service Comp

Pressure Gauges22.10. Manufacturer Nagano Keiki

22.11. Type Bourdon's tube

22.12. Rated Accuracy

22.13. Certifiying Authority Class/Owner/Service Comp

Oxygen Analyser (portable)22.14. Manufacturer Riken Keiki

22.15. Type OX-62B

Lowest Level Measurable 0

Fixed Gas Analyser22.16. Manufacturer Tokai seiki Co., Ltd.

22.17. Type TS-303-PS

22.18. AreCargo Tank Calibration Table Available

22.19. Measuring Compaany

22.20. Certifiying Authority

22.21. Calibration Calculated to cm cm 1 mm

22.22. Tables Established to cm 1 cm mm

22.23. Trim and List Corrections Available

22.24. Temperature Correction Available

22.25. Float Gauge Tape Corrections Available

28

LOCAL REMOTE

YES NO

YES NO

YES NO

YES NO

YES NO

B23 CARGO SAMPLING

23.1. In the table below, indicate whether samples may be obtained from the levels specified:

Cargo Tank: - 1 2 3 4 5 6 7 8 Sample Level

Top

Middle

Bottom 0 0

23.2. Can samples be drawn from - Tank Vapour Outlet

- Manifold Liquid Line

- Manifold Vapour Line

- Pump Discharge Line

23.3. State Connection Type and Size 3/8" coupling

29

YES NO

YES NO

YES NO

YES NO

B24 CARGO MANIFOLD

Complete the following table:

BOW m STERN 54.72 m

A B C D E F G

2 m 1.5 m

m m

m m

Notes 1. Indicate liquid, vapour and Nitrogene lines2. Indicate pipe groupingd for separate system3. Indicate fuel oil connections4. Indicate flange rating5. Show any cross manifolding arrangements6. Indicate distances from centerline of manifold7. Indicate if manifold strainers can be installed if yes specify type and mesh

Pipe Duty Rating Size Raised (R) or Frange Flat (F) Face

ABC Vapor ANSI #300 5" RD Liquid ANSI #300 8" RE Vapor ANSI #300 5" RFGH

b

a

a Height above uppermost continuous deck 0.93 m

c b Distance from ship's side 2.60 m

d c Height above load W/L 2.42 m

LOAD W/L draft4.814 m d Height above light W/L 4.83 m

LIGHT W/L dra 2.41m c = To be entry Summer L/L Condition.d = To be entry Light Condition.

30

45.20

B25 CARGO MANIFOLD REDUCERS

State number of reducers carried on board and theirflange rating and size:

25.1. ANSI Class 300 8 x 6,5,4,8

5 x 6,4 3,2

25.2. ANSI Class 300 to Class 150 8 x 8,6,5,4,3

5 x 6,4,3,2

25.3. ANSI Class 300 to JIS 20kg/cm2

JIS20kg/cm2 to ANSI 300Lbs

BLIND FLANGE ANSI 300Lbs

B26 CONNECTIONS TO SHORE FOR ESD AND COMMUNICATIONS SYSTEM

26.1. Is ESD connection to Shore available

If yes which of the following systems are fitted: -

Pneumatic

Electrical

Fibre Optic

26.2. Type of Plug Used: -

Pneumatic

Electrical Intrincically Safe Type.

Fibre Optic

26.3. Is Hose or Cables Available on Board

Specify Length

Pneumatic

Electrical 30m

Fibre Optic

26.4. Is Connection Available for Telephone Line

26.5. Are Connections Available on Both Side of Vessel

31

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

YES NO

B27 MANIFOLD DERRICK/CRANE

27.1. I s Manifold Derrick Provided

27.2. I s Manifold Crane Provided

27.3. I s Lifting Equipment Same Port and Starboard

If No, give detailes Porable cargo hose rollers available

27.4. State SWL at maximum Outreach STBD : 4ton/6M

PORT : 0.9ton

B28 STORES HANDLING

28.1. Stores Crane/Derrick Location and SWL Navigation Deck

tonnes

32

0.9

YES

YES

NO

NO

YES NO