sharp LC70LE600U

description

Transcript of sharp LC70LE600U

SERVICE MANUALLC-60/70LE600U

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace these parts with specified ones for maintaining thesafety and performance of the set.

This document has been published to be used forafter sales service only.The contents are subject to change without notice.

SAFETY PRECAUTIONIMPORTANT SERVICE SAFETY PRE-CAUTION............................................................iPRECAUTIONS A PRENDRE LORS DE LA REPARATION............................................... iiPRECAUTIONS FOR USING LEAD-FREE SOLDER ........................................................... iii

OUTLINEMAJOR SERVICE PARTS ................................ iv

CHAPTER 1. SPECIFICATIONS[1] SPECIFICATIONS ......................................... 1-1

CHAPTER 2. OPERATION MANUAL[1] PARTS NAMES.............................................. 2-1[2] OPERATION MANUAL .................................. 2-2

CHAPTER 3. DIMENSIONS[1] DIMENSIONS ................................................ 3-1

CHAPTER 4. REMOVING OF MAJOR PARTS[1] REMOVING OF MAJOR PARTS

(LC-60LE600U) .............................................4-1[2] REMOVING OF MAJOR PARTS

(LC-70LE600U) .............................................4-7

CHAPTER 5. ADJUSTMENT[1] ADJUSTMENT PROCEDURE ......................5-1

CHAPTER 6. TROUBLESHOOTING TABLE[1] TROUBLESHOOTING TABLE ......................6-1

CHAPTER 7. MAJOR IC INFORMATIONS[1] MAJOR IC INFORMATIONS .........................7-1

CHAPTER 8. OVERALL WIRING/SYSTEM BLOCK DIAGRAM[1] OVERALL WIRING DIAGRAM......................8-1[2] SYSTEM BLOCK DIAGRAM.........................8-2

Parts Guide

TopPage

CONTENTS

No. S72X460LE600U

LC-60LE600ULC-70LE600UMODELS

In the interests of user-safety (Required by safety regulations in some countries) the set should be restored to its orig-inal condition and only parts identical to those specified should be used.

LCD COLOR TELEVISION

LC-60/70LE600U

LC-60LE600U Service ManualSAFETY PRECAUTION

IMPORTANT SERVICE SAFETY PRECAUTION

WARNING1. For continued safety, no modification of any circuit should be

attempted.

2. Disconnect AC power before servicing.

BEFORE RETURNING THE RECEIVER (Fire &Shock Hazard)Before returning the receiver to the user, perform the followingsafety checks:

3. Inspect all lead dress to make certain that leads are not pinched,and check that hardware is not lodged between the chassis andother metal parts in the receiver.

4. Inspect all protective devices such as non-metallic control knobs,insulation materials, cabinet backs, adjustment and compartmentcovers or shields, isolation resistor-capacitor networks, mechanicalinsulators, etc.

5. To be sure that no shock hazard exists, check for leakage currentin the following manner.

• Plug the AC cord directly into a 120 volt AC outlet.

• Using two clip leads, connect a 1.5k ohm, 10 watt resistor paral-leled by a 0.15µF capacitor in series with all exposed metal cabinetparts and a known earth ground, such as electrical conduit or elec-trical ground connected to an earth ground.

• Use an AC voltmeter having with 5000 ohm per volt, or higher, sen-sitivity or measure the AC voltage drop across the resistor.

• Connect the resistor connection to all exposed metal parts having areturn to the chassis (antenna, metal cabinet, screw heads, knobsand control shafts, escutcheon, etc.) and measure the AC voltagedrop across the resistor.

All checks must be repeated with the AC cord plug connectionreversed. (If necessary, a nonpolarized adaptor plug must be usedonly for the purpose of completing these checks.)

Any reading of 0.75 Vrms (this corresponds to 0.5 mA rms AC.) ormore is excessive and indicates a potential shock hazard whichmust be corrected before returning the monitor to the owner.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

SAFETY NOTICEMany electrical and mechanical parts in LCD color television havespecial safety-related characteristics.

These characteristics are often not evident from visual inspection, norcan protection afforded by them be necessarily increased by usingreplacement components rated for higher voltage, wattage, etc.

Replacement parts which have these special safety characteristics areidentified in this manual; electrical components having such featuresare identified by " " and shaded areas in the Replacement Parts Listand Schematic Diagrams.

For continued protection, replacement parts must be identical to thoseused in the original circuit.

The use of a substitute replacement parts which do not have the samesafety characteristics as the factory recommended replacement partsshown in this service manual, may create shock, fire or other hazards.

///////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Service work should be performed only by qualified service technicians who are thoroughly familiar with all safety checks and the servicing guidelines which follow:

CAUTION : FOR CONTINUED PROTECTIONAGAINST A RISK OF FIRE REPLACE ONLY WITHSAME TYPE FUSE.

F7001 (250V 5A) :

DVM

AC SCALE

1.5k ohm10W

TO EXPOSEDMETAL PARTS

CONNECT TOKNOWN EARTHGROUND

0.15 µF

TEST PROBE

i

LC-60/70LE600U

PRECAUTIONS A PRENDRE LORS DE LA REPARATIONDe nombreuses pièces, électriques et mécaniques, dans les télévi-seur ACL présentent des caractéristiques spéciales relatives à la sé-curité, qui ne sont souvent pas évidentes à vue. Le degré de protec-tion ne peut pas être nécessairement augmentée en utilisant despièces de remplacement étalonnées pour haute tension, puissance,etc.Les pièces de remplacement qui présentent ces caractéristiques sontidentifiées dans ce manuel; les pièces électriques qui présentent cesparticularités sont identifiées par la marque " " et hachurées dans laliste des pièces de remplacement et les diagrammes schématiques.

Pour assurer la protection, ces pièces doivent être identiques à cellesutilisées dans le circuit d'origine. L'utilisation de pièces qui n'ont pasles mêmes caractéristiques que les pièces recommandées par l'usine,indiquées dans ce manuel, peut provoquer des électrocutions, incen-dies, radiations X ou autres accidents.

AVERTISSEMENT1.

2.

3.

4.

5.

•

•

•

•

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

/////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////////

Ne peut effectuer la réparation qu' un technicien spécialisé qui s'est parfaitement accoutumé à toute vérification de sécurité et auxconseils suivants.

N'entreprendre aucune modification de tout circuit. C'est danger-eux.

Débrancher le récepteur avant toute réparation.

Inspecter tous les faisceaux de câbles pour s'assurer que les filsne soient pas pincés ou qu'un outil ne soit pas placé entre le châs-sis et les autres pièces métalliques du récepteur.

Inspecter tous les dispositifs de protection comme les boutons decommande non-métalliques, les isolants, le dos du coffret, les cou-vercles ou blindages de réglage et de compartiment, les réseauxde résistancecapacité, les isolateurs mécaniques, etc.

S'assurer qu'il n'y ait pas de danger d'électrocution en vérifiant lafuite de courant, de la facon suivante:

Brancher le cordon d'alimentation directem-ent à une prise de cou-rant de 120V. (Ne pas utiliser de transformateur d'isolation pourcet essai).

A l'aide de deux fils à pinces, brancher une résistance de 1.5 kΩ10 watts en parallèle avec un condensateur de 0.15µF en sérieavec toutes les pièces métalliques exposées du coffret et une terreconnue comme une conduite électrique ou une prise de terrebranchée à la terre.

Utiliser un voltmètre CA d'une sensibilité d'au moins 5000Ω/V pourmesurer la chute de tension en travers de la résistance.

Toucher avec la sonde d'essai les pièces métalliques exposées quiprésentent une voie de retour au châssis (antenne, coffret métalli-que, tête des vis, arbres de commande et des boutons, écusson,etc.) et mesurer la chute de tension CA en-travers de la résistance.Toutes les vérifications doivent être refaites après avoir inversé lafiche du cordon d'alimentation. (Si nécessaire, une prised'adpatation non polarisée peut être utilisée dans le but de termin-er ces vérifications.)La tension de pointe mesurèe ne doit pas dépasser 0.75V (corre-spondante au courant CA de pointe de 0.5mA).Dans le cas contraire, il y a une possibilité de choc électrique quidoit être supprimée avant de rendre le récepteur au client.

PRECAUTION: POUR LA PROTECTION CON-TINUE CONTRE LES RISQUES D'INCENDIE,REMPLACER LE FUSIBLE

VERIFICATIONS CONTRE L'INCEN-DIE ET LECHOC ELECTRIQUE

Avant de rendre le récepteur à l'utilisateur, effectuer les vérifica-tions suivantes.

DVMECHELLE CA

1.5k ohm10W

0.15 µFSONDE D'ESSAI

AUX PIECESMETALLIQUESEXPOSEES

BRANCHER A UNETERRE CONNUE

AVIS POUR LA SECURITE

F7001 (250V 5A) :

ii

LC-60/70LE600U

PRECAUTIONS FOR USING LEAD-FREE SOLDEREmploying lead-free solder• “PWBs” of this model employs lead-free solder. The LF symbol indicates lead-free solder, and is attached on the PWBs and service manuals. The

alphabetical character following LF shows the type of lead-free solder.

Example:

Using lead-free wire solder• When fixing the PWB soldered with the lead-free solder, apply lead-free wire solder. Repairing with conventional lead wire solder may cause dam-

age or accident due to cracks.

As the melting point of lead-free solder (Sn-Ag-Cu) is higher than the lead wire solder by 40 °C, we recommend you to use a dedicated solderingbit, if you are not familiar with how to obtain lead-free wire solder or soldering bit, contact our service station or service branch in your area.

Soldering• As the melting point of lead-free solder (Sn-Ag-Cu) is about 220 °C which is higher than the conventional lead solder by 40 °C, and as it has poor

solder wettability, you may be apt to keep the soldering bit in contact with the PWB for extended period of time. However, Since the land may bepeeled off or the maximum heat-resistance temperature of parts may be exceeded, remove the bit from the PWB as soon as you confirm thesteady soldering condition.

Lead-free solder contains more tin, and the end of the soldering bit may be easily corroded. Make sure to turn on and off the power of the bit asrequired.

If a different type of solder stays on the tip of the soldering bit, it is alloyed with lead-free solder. Clean the bit after every use of it.

When the tip of the soldering bit is blackened during use, file it with steel wool or fine sandpaper.

• Be careful when replacing parts with polarity indication on the PWB silk.

Lead-free wire solder for servicing

Indicates lead-free solder of tin, silver and copper. Indicates lead-free solder of tin, silver and copper.

PARTS CODE PRICE RANK

PART DELIVERY DESCRIPTION

ZHNDAi123250E BL J φ0.3mm 250g (1roll)ZHNDAi126500E BK J φ0.6mm 500g (1roll)ZHNDAi12801KE BM J φ1.0mm 1kg (1roll)

iii

LC-60/70LE600U

iv

LC-60LE600U Service Manual

OUTLINE

MAJOR SERVICE PARTS

PWB Unit

OTHER Unit

IC For Exclusive Use Of The Service

Service Jigs

Ref No. Parts No. DescriptionN DKEYMF905FM04 MAIN UnitN DUNTKG015FM01 R/C, OPC UnitN DUNTKG014FM01 ICON UnitN DUNTKF800FM53 KEY Unit

N RUNTKB057WJQZ POWER/LED DRIVER Unit (RUNTKB057WJQZ is completely interchangeable with RUNTKA932WJQZ.) (LC-60LE600U)

N RUNTKA933WJQZ POWER/DRIVER Unit (LC-70LE600U)N DUNTKF908FM04 LCD CONTROL Unit

Ref No. Parts No. DescriptionN R1LK600D3GV0BZ 60" LCD Panel Module Unit (LK600D3GV0BZ)

N R1LK695D3GW8BD 70" LCD Panel Module Unit (LK695D3GW8BD)

Ref No. Parts No. Description Q'tyIC508 RH-iXD397WJQZS IC S-24CS02AFJ-TB-G (RGB) 1

IC1503 RH-iXD394WJQZS IC S-24CS02AFJ-TB-G (HDMI1) 1IC1504 RH-iXD396WJQZS IC S-24CS02AFJ-TB-G (HDMI3) 1IC1505 RH-iXD395WJQZS IC S-24CS02AFJ-TB-G (HDMI2) 1

Ref No. Parts No. Description Q'tyN QCNW-C222WJQZ Connecting Cord L=1000mm 80pins, LCD Control Unit to LCD Panel Unit 2N QCNW-F676WJQZ Connecting Cord L=1000mm 41pins, MAIN Unit to LCD Control Unit (LW) 1N QCNW-N033WJZZ Connecting Cord L=1000mm, 24-12/4pins, Main to LCD Control Unit (PD) 1

LC-60/70LE600U

1 – 1

LC-60LE600U Service Manual CHAPTER 1. SPECIFICATIONS

[1] SPECIFICATIONS

LC-60/70LE600U

LC-60LE600U Service Manual CHAPTER 2. OPERATION MANUAL[1] PARTS NAMES

2 – 1

LC-60/70LE600U

[2] OPERATION MANUAL2 – 2

LC-60/70LE600U

2 – 3

LC-60/70LE600U

2 – 4

LC-60/70LE600U

2 – 5

LC-60/70LE600U

3 – 1

LC-60LE600U Service Manual CHAPTER 3. DIMENSIONS

[1] DIMENSIONS

LC-60/70LE600U

LC-60LE600U Service Manual CHAPTER 4. REMOVING OF MAJOR PARTS[1] REMOVING OF MAJOR PARTS (LC-60LE600U)

1. Removing of Stand Unit and Rear Cabinet.1. Remove the 4 lock screws and detach the Stand Unit .

2. Remove the 1 lock screw and detach the AC Cord Cover .

3. Disconnect AC wire and detach the AC Cord .

4. Remove the 4 VESA Covers , 10 lock screws , 2 lock screws and 16 lock screws and detach the Rear Cabinet .

[Precaution when removing the rear cabinet]

If the rear cabinet is removed with the set upright, the speakers may fall; it results in connector disconnection. Therefore, never remove the rear cab-inet with the set upright.

Be sure to remove the rear cabinet with the screen side down.

[Precaution when mounting the rear cabinet]

Put the speakers in place with the screen side down, and attach the rear cabinet.

Since the speakers are fixed by the rear cabinet, they cannot be fixed without the rear cabinet.

2Stand Unit

Rear Cabinet10

4AC Cord Cover 5 AC Cord

VESA Cover

8

9

7

6

3

1

[AC]

[AC]

8

Screws for fixing Speakerand Rear Cabinet

4 – 1

LC-60/70LE600U

[Precautions when fixing the Rear Cabinet]When fixing the Rear Cabinet, be careful not to catch the backlight LED harness, speaker harness and other harnesses in it.

• The hooks on the external wall of the Rear Cabinet are fitted in the Front Cabinet Ass’y. After putting the Rear Cabinet in place, fit the hookssecurely; then tighten the screws.

(Work method of Rear Cabinet fixation)

(Front Cabinet Ass’y/Rear Cabinet fingernail fixation place)

Rear Cabinet

(Mat parts)

Front Cabinet Ass'y

(Luster parts)

There is a gap without the fingernail fitting in completely only when covering

with Rear Cabinet.

It becomes the factor of a gap increase of Front Cabinet Ass'y/Rear Cabinet

and the Rear Cabinet misregistration.

Please tighten the screw after Rear Cabinet is firmly pushed, and the

fingernail is confirmed.

17 places

4 – 2

LC-60/70LE600U

2. Removing of Speaker (L/R), KEY Unit and Bottom Cover.1. Detach the Bottom Cover2. Disconnect the SP wire.

3. Detach the Speaker (L) , Speaker (R) .

4. Disconnect the RC wire.

5. Detach the KEY Unit Ass’y .

6. Disconnect the KM wire.

7. Remove the 2 lock screws and detach the Key Button from Key Button Cover .

8. Detach the KEY Unit from Key Button .

2Speaker (L)3Speaker (R)

MAIN Unit

[SP] [RC]

[KM]

[SP]

7 5

4

8

6Key Button

KEY Unit

KEY Unit Ass'y

Key ButtonCover

4 – 3

LC-60/70LE600U

3. Removing of Connectors1. Disconnect the following connectors from the MAIN Unit. (PD, LW, Cl)2. Disconnect the following connectors from the POWER/LED DRIVE Unit. (PD, LA)

3. Disconnect the following connectors from the LCD CONTROL Unit. (LW, PL)

MAIN UnitPOWER/LED DRIVE Unit

LCD CONTROL Unit

MAIN Unit[PD]

[CI]

[LW]

[PD]

[LA]

[LA]

[LW]

[PL]

4 – 4

LC-60/70LE600U

4. Removing of 60” LCD Panel Module Unit, LCD CONTROL Unit, MAIN Unit, POWER/LED DRIVE Unit.1. Remove the 21 Hooks and detach the 60” LCD Panel Module Unit .2. Remove the 2 FFC , 2 Ferrite Cores and 4 lock screws and detach the LCD CONTROL Unit .

3. Remove the 4 lock screws and detach the MAIN Unit and Term Angle side .

4. Remove the 2 lock screws and detach the Earth Angle .

5. Remove the 6 lock screws and detach the POWER Unit and AC Cord Barrier .

6. Remove the 12 lock screws and detach the 2 Stand FIX Angles Ass’y .

7. Remove the 16 lock screws and detach the 4 VESA Angles Ass’y .

8 Term Angle Side

10EarthAngle

9

6

7

6

MAIN Unit

4 – 5

LC-60/70LE600U

5. Removing of R/C OPC Unit, ICON Unit.1. Detach the R/C OPC Unit .2. Disconnect the RA wire.

3. Detach the ICON Unit .

4. Disconnect the CI wire.

Front Cabinet Ass'y

[CI]

2ICON Unit

[RA]

1R/C OPC Unit

4 – 6

LC-60/70LE600U

[2] REMOVING OF MAJOR PARTS (LC-70LE600U)1. Removing of Rear Cabinet.1. Remove the 1 lock screw and detach the AC Cord Cover .

2. Disconnect AC wire and detach the AC Cord .

3. Remove the 4 VESA Covers , 9 lock screws and 19 lock screws and detach the Rear Cabinet .

[Precautions when mounting and removing the rear cabinet]

If the rear cabinet is removed with the set upright, the speakers may fall; it results in connector disconnection. Therefore, never remove the rear cab-inet with the set upright.

Be sure to remove the rear cabinet with the screen side down.

(8)

(8)

(8)

(8)

(8)

(8)

(8) (8)

(8)

(8)

(8)

(8)

(8) (8)

(8)

(8)

(8)

(7) (7) (7) (7) (7)

(7)

(7)(7)

(8)(8)

(6)(6)

(6) (6)

Tighten together with theRear Cabinet Ass'y.

4 – 7

LC-60/70LE600U

[Precautions for assembly](Front Cabinet Ass’y/Rear Cabinet Ass’y fingernail fixation place)

Push

Push Push

Push

Push

Push Push Push

CAUTION

Set it so that there may not be a clearance between Front Cabinet Ass'y and Rear Cabinet Ass'y.

There is a gap without the fingernail fitting

in completely only when covering with Rear Cabinet Ass'y.

The fingernail is surely fixed when Rear cabinet Ass'y is

firmly pushed, and the gap disappears.

19 places

4 – 8

LC-60/70LE600U

2. Removing of Speaker (L/R) and KEY Unit.1. Disconnect the SP wire.2. Remove the 2 lock screws and detach the Speaker (L) , Speaker (R) .

3. Disconnect the RC wire.

4. Detach the KEY Button Cover Ass’y .

5. Disconnect the KM wire.

6. Remove the 2 lock screws and detach the Key Button from Key Button Cover .

7. Detach the KEY Unit from Key Button .

8. Remove the 4 Hooks and detach the 2 Bottom Cover .

[SP] [RC]

4 – 9

LC-60/70LE600U

3. Removing of Connectors1. Disconnect the following connectors from the MAIN Unit. (PD, LW, Cl)2. Disconnect the following connectors from the POWER/DRIVER Unit. (PD, LA)

3. Disconnect the following connectors from the LCD CONTROL Unit. (LV, PL)

MAIN Unit[PD]

[CI]

[LW]

4 – 10

LC-60/70LE600U

4. Removing of 70” LCD Panel Module Unit, LCD CONTROL Unit, MAIN Unit, POWER/DRIVER Unit.1. Remove the 24 Hooks and detach the 70” LCD Panel Module Unit .2. Remove the 2 Connecting Cords , 4 lock screws and detach the LCD CONTROL Unit .

3. Remove the 2 look screws and detach the 2 Spacers .

4. Remove the 6 lock screws and detach the POWER/DRIVER Unit .

5. Remove the 4 lock screws and detach the MAIN Unit and Terminal Angle side .

6. Remove the 2 lock screws and detach the Eath Angle .

7. Remove the 12 lock screws and detach the 2 Stand Fix Angle Ass’y .

8. Remove the 16 lock screws and detach the 4 VESA Angle Ass’y .

14Terminal Angle Side

11Eath Angle

10

12

13

12

MAIN Unit

4 – 11

LC-60/70LE600U

5. Removing of R/C OPC Unit, ICON Unit, Wi-Fi Unit.1. Detach the R/C OPC Unit .2. Disconnect the RA wire.

3. Detach the ICON Unit .

4. Disconnect the CI wire.

4 – 12

LC-60/70LE600U

LC-60LE600U Service Manual CHAPTER 5. ADJUSTMENT[1] ADJUSTMENT PROCEDUREThe adjustment values are set to the optimum conditions at the factory before shipping. If a value should become improper or an adjustment isrequired due to part replacement, make an adjustment according to the following procedure.

1. After replacement of any PWB unit and/or IC for repair, please note the following.• When replacing the following units, make sure to prepare the new units loaded with updated software.

2. Upgrading of microprocessor softwareCAUTION: Never “POWER OFF” the unit when software upgrade is ongoing.

Otherwise the system may be damaged beyond recovery.

2.1. Software version upgradeThe model employs the following software.

• Main software

The main software can be upgraded by using a general-purpose USB Memory.

The followings are the procedures for upgrading.

2.2. Main software version upgrade

2.2.1 Get ready before you start• USB Memory of 128MB or higher capacity.

• PC running on Windows 98/98SE/ME/2000/XP operating system.

• USB Memory reader/writer or PC with a USB port.

• The file system of a USB memory is FAT. (FAT32 is not applied)

• Use the USB memory without other functions. (Lock and memory reader...etc)

2.2.2 PreparationsTo upgrade the main software, it is necessary to get ready the USB Memory for version upgrade before you start.

Follow the steps below and create the USB Memory for version upgrade.

1. Copy the file JAS_DTV_US_P102_Vx.xxF_AP.BIN for version upgrade to the root directory (folder) of the USB Memory.

NOTE: In the USB Memory drive, do not store other folders or unrelated files, or more than one file for version upgrade.

Now the USB Memory for version upgrade is ready.

2.2.3 How to upgrade the software1. Unplug the AC cord.

2. Insert the USB Memory for version upgrade (prepared as above) into the service socket located Right side of Main Board terminals, upper HDMI3terminal.

3. Plug in the AC cord with power button pressed down after 5 seconds, releases the power button.

4. After a few seconds, Center Icon illumination will blink on and off.

No display on the LCD screen. (Black screen)

5. Upon completion of the upgrade process, Center Icon illumination will blink on and off quickly.

NOTE: If the Center Icon illumination doesn't come to blink on and off quickly within 70 seconds (ex. the unit was automatically rebooted on the way),the upgrade is failure.

• In the case of a failure, repeat the upgrade process. If the process repeatedly fails, it is likely that the hardware need fixing.

6. Unplug the AC cord and remove the USB Memory for version upgrade.

7. Now the software version upgrade is complete.

NOTE: When you are done with the software version upgrade, start the set, go to the top page of the adjustment process screen and check the mainsoftware version information.

MAIN Unit: DKEYMF905FM04

5 – 1

LC-60/70LE600U

3. Entering and exiting the adjustment process mode1) Before entering the adjustment process mode, the AV position RESET in the video adjustment menu.2) While holding down the “VOL (–)” and “INPUT” keys at a time, plug in the AC cord of the main unit to turn on the power.

The letter “<K>” appears on the screen.

3) Next, hold down the “VOL (–)” and “CH ( )” keys at a time.

(The “VOL (–)” and “CH ( )” keys should be pressed and held until the display appears.)

Multiple lines of white characters appearing on the display indicate that the unit is now in the adjustment process mode.

When you fail to enter the adjustment process mode (the display is the same as normal startup), retry the procedure.

4) To exit the adjustment process mode after the adjustment is done, unplug the AC cord from the outlet to make a forced shutdown. (When thepower was turned off with the remote controller, once unplug the AC cord and plug it again. In this case, wait 10 seconds or so before plugging.)

CAUTION: Use due care in handling the information described here lest your users should know how to enter the adjustment process mode. If thesettings are tampered in this mode, unrecoverable system damage may result.

4. Remote controller key operation in adjustment process mode

*Input mode is switched automatically when relevant adjustment is started so far as the necessary input signal is available.

5. List of adjustment process mode menu

Remote controller key Main unit key FunctionCH ( / ) CH ( / ) Moving an item (line) by one (UP/DOWN)VOL (+/–) VOL (+/–) Changing a selected item setting (+1/ –1)Cursor (UP/DOWN) ————— Turing a page (PREVIOUS/NEXT)Cursor (LEFT/RIGHT) ————— Changing a selected line setting (+10/ –10)INPUT ————— Input switching (toggle switching)ENTER ————— Executing a function

Page Line Item Description Remarks1 1 Main Version Main software version BL: boot loader version

2 Check Sum Flash check sum3 PANEL Version4 TEMP SENSOR5 NORMAL STANDBY CAUSE Normal standby cause6 ERROR STANDBY CAUSE Error standby cause

2 1 Factory Init Initialization to factory settings2 Inch Setting Inch size3 Public Mode Public mode Not available4 Operation Acutime Accumulated operation time5 RESET Reset

3 1 RF-AGC ADJ Not available2 TUNER ADJ Not available3 PAL ADJ Not available4 RF AGC Not available5 TUNER Level Not available6 CVBS Level Not available7 VIF Not available8 VIDEO AGC Not available

4 1 COMP SD ADJ Component 15K picture level adjustment2 Y OFFSET3 Cb OFFSET4 Cr OFFSET5 Y GAIN6 Cb GAIN7 Cr GAIN8 RESET ADJUSTMENT Reset

5 1 COMP HD ADJ Component 33K picture level adjustment2 Y OFFSET3 Pb OFFSET4 Pr OFFSET5 Y GAIN6 Pb GAIN7 Pr GAIN8 RESET ADJUSTMENT Reset

5 – 2

LC-60/70LE600U

6 1 RGB ADJ Analog RGB picture level adjustment2 G OFFSET3 B OFFSET4 R OFFSET5 G GAIN6 B GAIN7 R GAIN8 RESET ADJUSTMENT Reset

7 1 IN POINT LOW_D Adjustment point1 at Dynamic mode2 IN POINT HIGH_D Adjustment point2 at Dynamic mode3 R LEVEL LOW_D WB adjustment Point 1, R adjustment value at Dynamic mode4 G LEVEL LOW_D WB adjustment Point 1, G adjustment value at Dynamic mode5 B LEVEL LOW_D WB adjustment Point 1, B adjustment value at Dynamic mode6 R LEVEL HIGH_D WB adjustment Point 2, R adjustment value at Dynamic mode7 G LEVEL HIGH_D WB adjustment Point 2, G adjustment value at Dynamic mode8 B LEVEL HIGH_D WB adjustment Point 2, B adjustment value at Dynamic mode9 R LEVEL MAX_D WB adjustment Point Max., R adjustment value at Dynamic mode

10 G LEVEL MAX_D WB adjustment Point Max., G adjustment value at Dynamic mode11 B LEVEL MAX_D WB adjustment Point Max., B adjustment value at Dynamic mode

8 1 IN POINT LOW Adjustment point12 IN POINT HIGH Adjustment point23 R LEVEL LOW WB adjustment Point 1, R adjustment value4 G LEVEL LOW WB adjustment Point 1, G adjustment value5 B LEVEL LOW WB adjustment Point 1, B adjustment value6 R LEVEL HIGH WB adjustment Point 2, R adjustment value7 G LEVEL HIGH WB adjustment Point 2, G adjustment value8 B LEVEL HIGH WB adjustment Point 2, B adjustment value9 R LEVEL MAX WB adjustment Point Max., R adjustment value

10 G LEVEL MAX WB adjustment Point Max., G adjustment value11 B LEVEL MAX WB adjustment Point Max., B adjustment value12 ADJ DATA STORE Execute13 RESET ADJUSTMENT Reset

9 1 EEP CLEAR Clear all setting data of flash memory2 AUTO INSTALLATION SW3 STANDBY CAUSE RESET Reset STANDBY CAUSE4 DESTINATION Destination of factory Initialization5 L ERR RESET Number of termination due to lamp error and Reset6 L ERR STOP Stop the detection of amp error detection7 TEMP CAUTION Threshold level of temperature caution8 TEMP SHUTDOWN Threshold level of temperature protection

10 1 VCOM ADJ Not available2 TEST PATTERN Test pattern3 DIMMER DIMMER setting (64)

Page Line Item Description Remarks

5 – 3

LC-60/70LE600U

6. Writing the microprocessor software6.1. Writing the main microprocessor software and monitor microprocessor software (Main PWB: QPWBXF905WJZZ)

7. Signal adjustment

7.1. LCD section adjustment [LCD module adjustment]

7.2. Image adjustment

7.2.1 Device check

Before adjustment, check that the adjustment jig and signal source are set for Sharp LCD US.

Signal generator level adjustment check (Adjust to the standard value level.)

7.2.2 Process mode

Adjustment item Adjustment conditions Adjustment procedure1 Writing the software Checker process

Checking the file versionChecking the USB memory

1) Connect the USB memory to J501 (TL514-517).2) Set the PWB correctly and apply the specified voltage to it; then write the soft-

ware on it.3) After confirming the completion of the writing operation, turn off the power.4) File name

JAS_DTV_US_P102_Vx.xxF_AP.BIN(x.xxx software version)

CAUTION: When the USB memory is not inserted or reading error occurs, nothing is written.

Adjustment item Adjustment conditions Adjustment procedure1 Opposite bias adjustment

(LCD module adjustment item)

Adjustment in the center position of the panel

1) Enter the process mode using the process adjustment remote control.2) Select [VCOM ADJ] using the Channel / keys on the remote control.3) Press the Enter key to check that the pattern for adjustment is displayed.4) Make adjustment so that the flicker located in the center of the screen is mini-

mized using the Volume +/- keys on the remote control.5) If the optimum condition is obtained in step 4, press the Enter key to turn off the

pattern.

CAUTION: * Make adjustment with no ANT signal (since the brightness is changed by the active backlight).

[Adjustment position]

• 15K component signal: Y level: 0.714Vp-p± 0.02Vp-p (Pedestal to white)PB/PR level: 0.7Vp-p ± 0.02Vp-p

• 33K component signal: Y level: 0.7Vp-p ± 0.02Vp-p (Pedestal to white)PB/PR level: 0.7Vp-p ± 0.02Vp-p

• Analog RGB: RGB level: 0.7Vp-p ± 0.02Vp-p (Pedestal to white)

Adjustment point Adjustment conditions Adjustment procedureProcess mode Enter the process adjustment mode using the process adjustment remote control.

1/2 1/2

1/2

1/2

5 – 4

LC-60/70LE600U

7.2.3 Component 15K signal adjustment7.2.4 Component 33K signal adjustment

7.2.5 Analog RGB signal adjustment

Adjustment point Adjustment conditions Adjustment procedure1 Setting 480i signal

100% Full Field Color Bar• Send the 100% color bar signal to the component input.

2 Automatic adjustment exe-cution

Point the cursor to [COMP SD ADJ] and press the [Enter] key.The adjustment is complete when [OK] is displayed.

Adjustment point Adjustment conditions Adjustment procedure1 Setting 1080i signal

100% Full Field Color Bar• Send the 100% color bar signal to the component input.

2 Automatic adjustment exe-cution

Point the cursor to [COMP HD ADJ] and press the [Enter] key.The adjustment is complete when [OK] is displayed.

Adjustment point Adjustment conditions Adjustment procedure1 Setting XGA signal

100% Checkerd Pattern

Please Make Sure SYNC is OFF

• Send the 100% checker signal to the analog RGB input.Be sure to set to SYNC=OFF.

2 Automatic adjustment exe-cution

Point the cursor to [RGB ADJ] and press the [Enter] key.The adjustment is complete when [OK] is displayed.

100% white 0% black

480i

100% color bar

Color saturation: 100%

100% white 0% black

1080i

100% color bar

Color saturation: 100%

5 – 5

LC-60/70LE600U

8. White balance adjustment8.1. White balance adjustment

Adjustment point Adjustment conditions Adjustment procedure1 Setting 1) Set the unit to the following conditions.

AV MODE: [DYNAMIC]Backlight: +16Active Contrast: OFFAging Time: Min. 60 minutes

2) Connect the unit with the white balance adjustment jig.2 Automatic adjustment

execution[Command]Process modeKRSW0001KKT10037

SettingKY0F0000OSDS0001SBSL0016

Multi-point adjustment modeFACT0001MSET0000

Point 2WBI20200MG2G****MG2B****MG2R****

Point 1WBI10040MG1G****MG1B****MG1R****

Point 2(Doubling)WCI20200MH2G****MH2B****MH2R****

Point 1(Doubling)WCI10040MH1G****MH1B****MH1R****

MAX valueMGMR****MGMG****MGMB****

MAX value(Doubling)MHMR****MHMG****MHMB****

WritingMSET0003FACT0000

[Adjustment procedure]1) Send the “monitor adjustment process” code using the remote control.2) Set the point 2 to the specified gradation, specify the strongest color as the fixed

color, and adjust the RGB so that it becomes the standard value through negative adjustment.

3) Set the point 1 to the specified gradation, set the G correction value (640 x G value of point 2/3200) and adjust the RB so that it becomes the standard value.

4) Calculate the MAX RGB values. (For entry, see 11 below.)

5) Calculate the tilt between the MAX point and the point 2.

6) Calculate the correction value for doubling the point 2.

7) Calculate the RGB values after doubling the point 2.

8) Calculate the tilt between the point 2 and the point 1.

9) Calculate the correction value for doubling the point 1.

10)Calculate the RGB values after doubling the point 1.

11)Enter the MAX RGB values.12)Enter the RGB values after doubling the MAX values.

13)Write the adjustment values using the MSET0003 command and turn off the AC power.

Gmax = Gmax_d = 4080 Ghigh / 3200Rmax = Rmax_d = Gmax + Rhigh - Ghigh

Bmax = Bmax_d = Gmax + Bhigh - Ghigh

(4080 when Rmax, Gmax and Bmax exceed 4080 by calculating them)

Rahigh = (Rmax - Rhigh) / (4080 - 3200)

Gahigh = (Gmax - Ghigh) / (4080 - 3200)

Bahigh = (Bmax - Bhigh) / (4080 - 3200)

Rhigh = Rahigh (3510 - 3200)

Ghigh = Gahigh (3510 - 3200)

Bhigh = Bahigh (3510 - 3200)

Rhigh_d = Rhigh + Rhigh

Ghigh_d = Ghigh + Ghigh

Bhigh_d = Bhigh + Bhigh

Ralow = (Rhigh - Rlow) / (3200 - 640)

Galow = (Ghigh - Glow) / (3200 - 640)

Balow = (Bhigh - Blow) / (3200 - 640)

Rlow = Ralow (717 - 640)

Glow = Galow (717 - 640)

Blow = Balow (717 - 640)

Rlow_d = Rlow + Rlow

Glow_d = Glow + Glow

Blow_d = Blow + Blow

Rmax_d = Rmax

Gmax_d = Gmax

Bmax_d = Bmax

5 – 6

LC-60/70LE600U

9. Key writing

9.1. EDID writing (Main PWB: QPWBXF905WJZZ)

9.2. DIMMER setting (Main PWB: QPWBXF905WJZZ)

Adjustment point Adjustment conditions Adjustment procedure[Adjustment value]* According to the “Standard settings” submitted by the Technical Department

[LC-60LE600U] teaching set

[Adjustment standard value]Measuring instrument: [Minolta CA-210] Technical measuring instrument

Level Reference value Adjustment spec Inspection spec

Point 2 3200X=0.272

±0.0020 ±0.0040y=0.277

Point 1 640X=0.272

±0.0080 ±0.0160y=0.277

Adjustment point Adjustment conditions Adjustment procedure1 HDMI EDID writing

(Main PWB)Inspection modeFile version check

1) Write the EDID date for HDMI on IC1503/IC1504/IC1505 mounted on the main PWB using the checker.

IC1503 (HDMI1) TL1522 ⋅⋅⋅ I2C SDA TL1519 ⋅⋅⋅ I2C SCL TL1507 ⋅⋅⋅ 5V TL1510 ⋅⋅⋅ GND TL1516 ⋅⋅⋅ write protection (H: WP, L: write enable)

IC1505 (HDMI2) TL1524 ⋅⋅⋅ I2C SDA TL1521 ⋅⋅⋅ I2C SCL TL1509 ⋅⋅⋅ 5V TL1512 ⋅⋅⋅ GND TL1518 ⋅⋅⋅ write protection (H: WP, L: write enable)

IC1504 (HDMI3) TL1523 ⋅⋅⋅ I2C SDA TL1520 ⋅⋅⋅ I2C SCL TL1508 ⋅⋅⋅ 5V TL1511 ⋅⋅⋅ GND TL1517 ⋅⋅⋅ write protection (H: WP, L: write enable)

2) Write the data before being inspected by the checker.2 Analog RGB EDID

writing(Main PWB)

Inspection modeFile version check

1) Write the EDID date for analog RGB on IC508 mounted on the main PWB using the checker.

IC508 TL503 ⋅⋅⋅ I2C SDA TL502 ⋅⋅⋅ I2C SCL TL567 ⋅⋅⋅ 5V TL560 ⋅⋅⋅ GND TL568 ⋅⋅⋅ write protection (H: WP, L: write enable)

2) Write the data before being inspected by the checker.

Adjustment point Adjustment conditions Adjustment procedure1 Setting [Command]

Process modeKRSW0001KKT10037

SettingFACT0001LDIM00**

1) Type in the left commands, and enter the duty value into ** of LDIM00**.

LC-60LE600U:LDIM0065

5 – 7

LC-60/70LE600U

10. Factory settingAfter completing the factory setting, pull out the AC cord to complete the setting.CAUTION: Do not turn on the power after completing the factory setting. If the power is turned on, configure the factory setting again.

11. Software version1. Main microcomputer

2. EDID data

3. (Reference: File name in the Technical Department)

• For HDMI

IC1503 (HDMI1): 60LE630U_hdmi_fullhd_port1_v1.bin

IC1505 (HDMI2): 60LE630U_hdmi_fullhd_port2_v1.bin

IC1504 (HDMI3): 60LE630U_hdmi_fullhd_port3_v1.bin

• For Analog RGB

IC508: 60LE630U_dsub_fullhd_256.v1.bin

12. Writing the inch onto EEPROM60/70LE600U

1. Enter the adjustment process mode.

2. Point the cursor to [Inch Settuing] (Page 2/10).

3. Select "60" or "70", and press [Enter] key.

4. "OK" is displayed.

5. Turn off power

6. Turn on power

Adjustment point Adjustment conditions Adjustment procedure1 Factory setting Complete the setting by

pulling out the AC cord.• Place the cursor over the item “Factory Init” and press the ENTER key.• Adjustment is complete when the green screen is displayed.• Turn off the AC power.

Be sure to check that US is displayed in the item “Factory Init”.The following items are initialized when configuring the factory setting.1) User set value2) Channel data (broadcasting frequency, etc.)3) Operating time4) Password setting value5) V-CHIP block setting value

5 – 8

LC-60/70LE600U

LC-60LE600U Service Manual CHAPTER 6. TROUBLESHOOTING TABLE[1] TROUBLESHOOTING TABLE

No video (1)

COMPOSITE: No external input video [VIDEO]

Is VIDEO selected on the input select menu screen?

YES

NOSelect VIDEO on the input select menu screen forthe right input signal.

Does the VIDEO V1_PLUG detection function?Check the line between pin (7) of input terminal (J508) and terminal on IC3301 side of R530.

Is there the COMPOSITE signal input at terminal on IC3301 side of C3312?

YES

NOCheck the line between pin (6) of J508 and terminal on IC3301 side of C3312.

Are the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin),LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin),LVDS_O_D3P/N (16/17pin), LVDS_E_D0P/N (39/40pin),LVDS_E_D1P/N (37/38pin), LVDS_E_D2P/N (35/ 36pin),LVDS_E_CLKP/N (32/33pin), LVDS_E_D3P/N (30/31pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

6 – 1

LC-60/70LE600U

No video (2)

COMPONENT: No external input video [COMPONENT]

Is COMPONENT selected on the input select menu screen?

YES

NOSelect COMPONENT on the input select menu screen for the right input signal.

Does the COMPONENT Y2_PLUG detection function?Check the line between pin (7) of input terminal (J502) and ter-minal on IC3301 side of R502.

Are there the COMPONENT video signal input at terminals on IC3301 side of C3321 (Y), C3323 (Pb), C3324 (Pr)?

YES

NOCheck the line between the input terminals of J502 and IC3301.

J508 pin (3) (Y), pin (5) (Pb), pin (7) (Pr)IC3301 C3321 (Y), C3323 (Pb), C3324 (Pr)

Are the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin),LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin),LVDS_O_D3P/N (16/17pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

6 – 2

LC-60/70LE600U

No video (3)

No video at UHF/VHF broadcast signal reception No video at digital broadcast signal reception

Is the specified TV signal selected on the input select menu screen?

Is there the analog video signal output (CVBS) at pin (9) of tuner (TU1101)?

Are there the video signal outputs (DIF-/+) at pins (10) and (11) of tuner (TU1101)?

YES

NO

YES

NOCheck TU1101 and its peripheral circuits.(TU_I2C_DAT: pin (4), TU_I2C_CLK: pin (5) of TU1101, etc.)

Check TU1101 and its peripheral circuits.(TU_I2C_DAT: pin (4), TU_I2C_CLK: pin (5) of TU1101, etc.)

Is there the analog video signal input at the terminal on IC3301 side of R3334?

Are there the video signal inputs at the terminals on IC3301 side of R3340 (DIFP) and R3344 (DIFN)?

YES

NO

YES

NOCheck the line between IC3301 and TU1101, and their peripheral circuits.

Check the line between IC3301 and TU1101, and their peripheral circuits.

Are the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin), LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin), LVDS_O_D3P/N (16/17pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

No video (4)

PC: No external input video [PC IN]

Is PC IN selected on the input select menu screen?

YES

NOSelect PC IN on the input select menu screen for the right input signal.

Is IC508 (EEPROM) accessed by I2C, with con-nected, to read the DDC_I2C data?Check the DDC line and its peripheral circuits.(IC508 and its peripherals)

Are there the video signal inputs at the terminals on IC3301 side of C3302 (R), C3303 (G), and C3304 (B)?Are there the VSYNC/HSYNC signal inputs at the terminals on IC3301 side of R621 and R620?

NO Check the line between SC502 and IC3301.

YESAre the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin), LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin), LVDS_O_D3P/N (16/17pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

6 – 3

LC-60/70LE600U

<HDMI input> No video (5)-1

HDMI: No external input video [HDMI1] HDMI: No external input video [HDMI2]

Is HDMI1 selected on the input select menu screen? Is HDMI2 selected on the input select menu screen?

YES

NO

YES

NOSelect HDMI1 on the input select menu screen for the right input signal.

Select HDMI2 on the input select menu screen for the right input signal.

Does the HOT PLUG detection function? Does the HOT PLUG detection function?Does the DDC5V signal come from pin (16) of SC1501 to the ter-minal on IC3301 side of Q1508?

Does the DDC5V signal come from pin (16) of SC1503 to the terminal on IC3301 side of Q1510?

YES

NO

YES

NOCheck the line between the input terminals of SC1501 and IC3301.

Check the line between the input terminals of SC1503 and IC3301.

Check IC3301 and its peripheral circuits. Check IC3301 and its peripheral circuits.

Does the HPD signal come from pin (5) of Q1501 to pin (19) of SC1501?

Does the HPD signal come from pin (5) of Q1503 to pin (19) of SC1503?

YES

NO

YES

NOCheck the line between the pin (5) of Q1501 and the pin (19) of SC1501.

Check the line between the pin (5) of Q1503 and the pin (19) of SC1503.

Check IC3301 and its peripheral circuits. Check IC3301 and its peripheral circuits.

Is IC3301 accessed by I2C, with HDMI connected, to read DDC_I2C data?

Is IC3301 accessed by I2C, with HDMI connected, to read DDC_I2C data?

YES

NO

YES

NOCheck the HDMI_DDC line and its peripheral circuits.(Q1511 and IC1503 etc.)

Check the HDMI_DDC line and its peripheral circuits.(Q1513 and IC1505 etc.)

Are there the TMDS signal inputs at the terminals on IC3301 side of R3369/R3370 (CLK-/+), R3374/R3381 (D0-/+), R3384/R3385 (D1-/+), R3387/R3388 (D2-/+)?

Are there the TMDS signal inputs at the terminals on IC3301 side of R3347/R3348 (CLK-/+), R3349/R3350 (D0-/+), R3351/R3360 (D1-/+), R3364/R3368 (D2-/+)?

YES

NO

YES

NOCheck the line between SC1501 and IC3301. Check the line between SC1503 and IC3301.

Are the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin), LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin), LVDS_O_D3P/N (16/17pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

6 – 4

LC-60/70LE600U

<HDMI input> No video (5)-2

HDMI: No external input video [HDMI3]

Is HDMI3 selected on the input select menu screen?

YES

NOSelect HDMI3 on the input select menu screen for the right input signal.

Does the HOT PLUG detection function?Does the DDC5V signal come from pin (16) of SC1502 to the terminal on IC3301 side of Q1509?

YES

NOCheck the line between the input terminals of SC1502 and IC3301.Check IC3301 and its peripheral circuits.

Does the HPD signal come from pin (5) of Q1502 to pin (19) of SC1502?

YES

NOCheck the line between the pin (5) of Q1502 and the pin (19) of SC1502. Check IC3301 and its peripheral circuits.

Is IC3301 accessed by I2C, with HDMI connected, to read DDC_I2C data?

YES

NOCheck the HDMI_DDC line and its peripheral circuits.(Q1512 and IC1504 etc.)

Are there the TMDS signal inputs at the terminals on IC3301 side of R3389/R3390 (CLK-/+), R3391/R3392 (D0-/+), R3393/R3394 (D1-/+), R3395/R3396 (D2-/+)?

YES

NOCheck the line between SC1502 and IC3301.

Are the LVDS signal outputs at the LVDS of SC2601?LVDS_O_D0P/N (25/26pin), LVDS_O_D1P/N (23/24pin), LVDS_O_D2P/N (21/22pin), LVDS_O_CLKP/N (18/19pin), LVDS_O_D3P/N (16/17pin)

NO Check IC3301 and its peripheral circuits.

YESCheck the panel module.

6 – 5

LC-60/70LE600U

No audio (1)

VIDEO No audio COMPONENT No audio

Is VIDEO selected on the input select menu screen? Is COMPONENT selected on the input select menu screen?

YES

NO

YES

NORefer to “: No external input video [VIDEO]”. Refer to “: No external input video [COMPONENT]”.

Is the audio output selected for “VARIABLE” on the menu screen? Is the audio output selected for “VARIABLE” on the menu screen?

YES

NO

YES

NOSet the audio output to “FIXED”. Set the audio output to “FIXED”.

Does the audio signal come from pins (5) (L) and (4) (R) of input terminal (J508) to the terminal on IC3301 side of C3329 (L) and C3330 (R)?

Does the audio signal come from pins (2) (L) and (4) (R) of input terminal (J504) to the terminal on IC3301 side of C3331 (L) and C3332 (R)?

YES

NO

YES

NOCheck the line between J508 and IC3301. Check the line between J504 and IC3301.

Does the I2S audio signal come from terminals on IC3301 side of R3413 (I2S_MCLK), R3414 (I2S_SCLK), R3415 (I2S_LRCLK), and R3416 (I2S_DAT) to pins (5) (MCK), (7) (SCLK), (8) (LRCLK), and (5) (SDATA) of IC2704 (AMP)?

YES

NOCheck IC3301 and its peripheral circuits.Check the line between IC3301 and IC2704.(N_AMP_RST, SP_MUTE etc.)

Is the audio output from IC2704 as specified? NO Check IC2704 and its peripheral circuits.

YESCheck the connector (P2701), speakers and their peripheral circuits.

6 – 6

LC-60/70LE600U

No audio (2)

[PC analog audio input] PC IN No audio [HDMI analog audio input] HDMI1 No audio

Is PC IN selected on the input select menu screen? Is HDMI1 selected on the input select menu screen?

YES

NO

YES

NORefer to “: No external input video [PC IN]”. Refer to “: No external input video [HDMI1]”.

Is the audio output selected for “VARIABLE” on the menu screen? Is the audio output selected for “VARIABLE” on the menu screen?

YES

NO

YES

NOSet the audio output to “FIXED”. Set the audio output to “FIXED”.

Is the “PC Audio Select” selected for “PC IN” on the menu screen? Is the “PC Audio Select” selected for “HDMI1” on the menu screen?

YES

NO

YES

NOSet the “PC Audio Select” to “PC IN”. Set the “PC Audio Select” to “HDMI1”.

Is the HDMI audio output selected for “Digital” on the menu screen?

YES

NOSet the HDMI audio output to “Analog”.

Does the audio signal come from pins (2) (L) and (3) (R) of input terminal (J506) to the terminal on IC3301 side of C3327 (L) and C3328 (R)?

NO Check the line between J506 and IC3301.

YESDoes the I2S audio signal come from terminals on IC3301 side of R3413 (I2S_MCLK), R3414 (I2S_SCLK), R3415 (I2S_LRCLK), and R3416 (I2S_DAT) to pins (5) (MCK), (7) (SCLK), (8) (LRCLK), and (5) (SDATA) of IC2704 (AMP)?

NO Check IC3301 and its peripheral circuits.Check the line between IC3301 and IC2704.(N_AMP_RST, SP_MUTE etc.)

YESIs the audio output from IC2704 as specified? NO Check IC2704 and its peripheral circuits.

YESCheck the connector (P2701), speakers and their peripheral circuits.

6 – 7

LC-60/70LE600U

No audio (3)

No audio at UHF/VHF broadcast signal reception No audio at digital broadcast signal reception

Is TV selected on the input select menu screen? Is TV selected on the input select menu screen?

YES

NO

YES

NORefer to “No video at UHF/VHF broadcast signal reception”.

Refer to “No video at digital broadcast signal reception”.

Is the audio output selected for “VARIABLE” on the menu screen? If no video appears, refer to “No video at digital broadcast signal reception”.

YES

NOSet the audio output to “FIXED”.

Is there the SIF signal output at pin (8) of tuner (TU1101)? Is the audio output selected for “VARIABLE” on the menu screen?

YES

NO

YES

NOCheck TU1101 and its peripheral circuits.(TU_I2C_DAT: pin (4), TU_I2C_CLK: pin (5) of TU1101, etc.)

Set the audio output to “FIXED”.

Is there the SIF signal input at the terminal on IC3301 side of C3335 (SIFP)?

YES

NOCheck the line between IC3301 and TU1101, and their peripheral circuits.

Does the I2S audio signal come from terminals on IC3301 side of R3413 (I2S_MCLK), R3414 (I2S_SCLK), R3415 (I2S_LRCLK), and R3416 (I2S_DAT) to pins (5) (MCK), (7) (SCLK), (8) (LRCLK), and (5) (SDATA) of IC2704 (AMP)?

NO Check IC3301 and its peripheral circuits.Check the line between IC3301 and IC2704.(N_AMP_RST, SP_MUTE etc.)

YESIs the audio output from IC2704 as specified? NO Check IC2704 and its peripheral circuits.

YESCheck the connector (P2701), speakers and their peripheral circuits.

6 – 8

LC-60/70LE600U

No audio (4)

HDMI1 No audio (HDMI connected)HDMI2 No audio (HDMI connected)HDMI3 No audio (HDMI connected)

[HDMI1]Is HDMI1 selected on the input select menu screen?[HDMI2]Is HDMI2 selected on the input select menu screen?[HDMI3]Is HDMI3 selected on the input select menu screen?

YES

NORefer to “: No external input video [HDMI1/2/3]”.

[HDMI1]If no video appears, refer to “No external input video (HDMI) [HDMI1]”.[HDMI2]If no video appears, refer to “No external input video (HDMI) [HDMI2]”.[HDMI3]If no video appears, refer to “No external input video (HDMI) [HDMI3]”.

Is the audio output selected for “VARIABLE” on the menu screen?

YES

NOSet the audio output to “FIXED”.

Does the I2S audio signal come from terminals on IC3301 side of R3413 (I2S_MCLK), R3414 (I2S_SCLK), R3415 (I2S_LRCLK), and R3416 (I2S_DAT) to pins (5) (MCK), (7) (SCLK), (8) (LRCLK), and (5) (SDATA) of IC2704 (AMP)?

YES

NOCheck IC3301 and its peripheral circuits.Check the line between IC3301 and IC2704. (N_AMP_RST, SP_MUTE etc.)

Is the audio output from IC2704 as specified?

YES

NOCheck IC2704 and its peripheral circuits.

Check the connector (P2701), speakers and their peripheral circuits.

6 – 9

LC-60/70LE600U

No audio signal at Digital Audio Output terminal (Analog sound heard)

No HDMI1/2/3 audio No audio at digital broadcast signal reception

If no video appears, refer to “No external input video (HDMI) [HDMI1/2/3]”.

If no video appears, refer to “No video at digital broadcast signal reception”.

Is there the SPDIF signal output (OPT_OUT) at terminal on IC3301 side of R3345?

NO Check the IC3301 and its peripheral circuits.

YESIs there the SPDIF signal input at pin (1) of D516 (OPTICAL OUTPUT)? NO Check the line between D516 and IC3301.

YES

No optical output under the following conditions as per HDMI requirements.* Audio contents protected.* Audio frequency beyond 48kHz.* Audio bit length beyond 16bits.

Check the speakers and the optical cable.

No monitor audio output

Is the audio output from the monitor set at “VARIABLE” or “FIXED” on the menu screen?

NO Check the IC3301 and its peripheral circuits.

YESAre there the analog audio signal outputs at the terminals on IC3301 side of R3332 (L) and R3333 (R)?

NO Check the IC3301 and its peripheral circuits.

YESDoes the audio signal come from R3332 (L) and R3333 (R) to pins (5) (L) and (4) (R) of IC2703 (monitor audio output AMP)?

NO Check IC3301 and each signals lines/its peripheral circuits.

YESDoes the audio signal come from pins (7) (L) and (1) (R) of IC2703 to pins (2) (L) and (4) (R) of J507?

NO Check the line between IC2703 and J507 and there peripheral circuits.

YES

Check the L_MUTE line and its peripheral circuits.(Q2702/Q2701, etc.)

Check the connector (J507) and their peripheral circuits, and speakers and the Cable.

6 – 10

LC-60/70LE600U

1) Center Icon illumination

LED flashing timing chart for error notification.

Error type Center Icon illumination operation (1 cycle) Pins are microprocessor pins.Lamp errorFlashes once: Fast

[Center Icon illumination] H: On

L: Off

Judged by the ERR_PNL port. Confirmed after 10 consecutive detections at 500 ms intervals (detected only when the backlight is on).[Released]• Execute AC_ON with [INPUT] and [VOL-DOWN] on the unit

down. Then execute the function of “L ERR RESET” in the adjustment process mode menu.

• Continuous illumination for 15 minutes.

NOTE: After five detection counts, the lamp cannot be activated.Temperature errorFlashes 4 times

[Center Icon illumination] H: On

L: Off

Judged by monitoring temperature with the temperature sensor. When the panel temperature is 63°C or more, caution is dis-played. If the panel temperature is 65°C or more, error standby is activated.[Released]Reduce the value of TEMP CAUTION (temperature caution threshold) and TEMP SHUTDOWN (temperature protection threshold) in the adjustment process mode menu.

Error TypePanel power errorFlash 2 times

H: On

L: Off

Judged panel power supply by the DET_POW_port.Conformed after 2 consecutive detections at 16mS intervals.

400ms 1600ms

6 – 11

LC-60LE600U

7 – 1

LC-60LE600U Service Manual CHAPTER 7. MAJOR IC INFORMATIONS

[1] MAJOR IC INFORMATIONS

1. MAJOR IC INFORMATIONS

1.1. IC3301 (RH-IXD253WJQZQ)This LSI is FULL HIGH-DEFINITION 1080P DIGITAL TV SYSTEM-ON-A-CHIP.

It combines a transport de-multiplexer, a high definition video decoder, an AC3 audio decoder, a dual-link LVDS transmitter, and a NTSC/PAL/SECAM TV decoder with a 3D comb filter (NTSC/PAL).

It supports Full-HD MPEG2 video decoder standards, and Hardware JPEG.

Audio support includes a BTSC and a Dolby AC3/MPEG-2 Layer 1, 2, audio decoder.

A SPDIF output and a pair of analog outputs (L-R) are provided.

Integrated peripherals include a USB 2.0, UART, and GPIO controllers.

1.2. IC3501 (RH-IXD361WJQZQ)This is 512M-bit (32M x 16bit) DDR2-800 synchronous DRAM.

1.3. IC8401 (RH-IXD265WJN4Q)The 32M-bit SPI flash memory device stores the main CPU program.

1.4. IC8403 (RH-IXD110WJQZY)This is 8k-bit EEPROM device including the cryptography key data.

1.5. IC1503, IC1504, IC1505, IC508 (VHIS24CS02J-1Y)This is 2k-bit EEPROM device including the EDID data.

1.6. IC2704 (VHIYDA164EZ-1Y)The Class-D type digital audio power amplifier YDA164CZ gives maximum continuous output of 10 W/ch.

1.7. IC2703 (VHiAK4201EU-1Y) This IC is audio amplifier for line-out.

LC-60/70LE600U

1918161514 17

8 – 1

LC-60LE600U Service ManualCHAPTER 8. OVERALL WIRING/SYSTEM BLOCK DIAGRAM

[1] OVERALL WIRING DIAGRAM

1 2 3 1097654 8

J

A

B

C

D

E

F

G

H

I

1311 12

LC-60/70LE600U

1918161514 17

8 – 2

[2] SYSTEM BLOCK DIAGRAM

1 2 3 1097654 8

J

A

B

C

D

E

F

G

H

I

1311 12

LC-60/70LE600U

PartsGuidePARTS GUIDE

CONTENTS

No. S72X460LE600U

LC-60LE600ULC-70LE600UMODELS

LCD COLOR TELEVISION

[1] PRINTED WIRING BOARD ASSEMBLIES

[2] LCD PANEL MODULE UNIT

[3] CABINET AND MECHANICAL PARTS (LC-60LE600U)

[4] CABINET AND MECHANICAL PARTS (LC-70LE600U)

[5] SUPPLIED ACCESSORIES/PACKING PARTS (LC-60LE600U)

[6] SUPPLIED ACCESSORIES/PACKING PARTS (LC-70LE600U)

[7] SERVICE JIG (USE FOR SERVICING)

Parts marked with " " are important for maintaining the safety of the set. Be sure to replace theseparts with specified ones for maintaining the safety and performance of the set.

This document has been published to be usedfor after sales service only.The contents are subject to change without notice.

LC-60/70LE600UPRICE NEW PART

NO. PARTS CODE RANK MARK DELIVERY DESCRIPTION[1] PRINTED WIRING BOARD ASSEMBLIESN DKEYMF905FM04 BN N X MAIN UnitN DUNTKF908FM04 BN X LCD CONTROL UnitN DUNTKF800FM53 AE X KEY UnitN DUNTKG014FM01 AE X ICON UnitN DUNTKG015FM01 AF N X R/C OPC Unit

! N RUNTKB057WJQZ BR N XPOWER/LED DRIVE Unit (RUNTKB057WJQZ is completely interchangeable withRUNTKA932WJQZ.) (LC-60LE600U)

! N RUNTKA933WJQZ BM X POWER/DRIVER Unit (LC-70LE600U)

[2] LCD PANEL MODULE UNITN R1LK600D3GV0BZ DS N X 60" LCD PANEL MODULE Unit (LK600D3GV0BZ) (LC-60LE600U)N R1LK695D3GW8BD ET X 70" LCD PANEL MODULE Unit (LK695D3GW8BD) (LC-70LE600U)

2

LC-60/70LE600U

[3] CABINET AND MECHANICAL PARTS (LC-60LE600U)

A

B

B

B

B

A

C

E

F

h

ca

k

n

n

p

q

m

d

ICON Unit

R/C OPC Unit

60"LCD Panel Module Unit

KEY Unit

LCD CONTROL Unit

POWER/LED DRIVE Unit

C

1-8

1-1

1

3-3 3-2

36

3-1

24

3126

1-7

1-2

1-3

j

8

32

33

38

623 15

36

17

2

36

16

30

29 30

29

7

536

36

7

p

q

D

E

F

12

34

22

1-4 1-5

1-6

1-5

1-5

14

20

20

18

36

4-2

4-1

36

4-2

4-14

4

36

4-2

4-14

36

4-2

4-14

9

5-1

5-2

5

5-1

5-2

17

3

37

13

16

28

11

16

25

1019

21

2735

MAIN Unit

c

h

a

d

F

j

m

k

3

LC-60/70LE600U

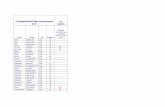

NO. PARTS CODE PRICE RANK

NEW MARK

PART DELIVERY DESCRIPTION

[3] CABINET AND MECHANICAL PARTS (LC-60LE600U)1 CCABAC860WJ35 BB N X Front Cabinet Ass'y

1-1 Not Available - - Front Cabinet1-2 Not Available - - Center ICON Cover1-3 Not Available - - R/C LED Decoration1-4 LHLDWA124WJKZ AC J WireHolder1-5 LHLDWA175WJUZ AC J WireHolder, x41-6 LHLDWA289WJKZ AC J WireHolder1-7 PSHEPB181WJKZ AB X ICON DIF. Sheet1-8 TLABZD330WJZZ AB N X Dolby Ene Label2 GCABBC003WJ3A BE X Rear Cabinet3 DCOVAE060WE01 AG N X KEY Unit Ass'y

3-1 Not Available - - KEY Button Cover3-2 JBTN-A912WJ3A AB X KEY Button3-3 XEBS830P08000 AA J Screw, x24 CANGKD484WJ31 AE X VESA Angle Ass'y, x4

4-1 Not Available - N - VESA Angle4-2 Not Available - - VESA Shaft5 CANGKD611WJ31 AF X Stand FIX Angle Ass'y, x2

5-1 Not Available - N - Stand FIX Angle5-2 Not Available - - Himeron, x26 GCOVAD981WJ3A AC X AC Cord Cover7 GCOVAE320WJ3A AE X Bottom Cover, x28 HiNDPE693WJSA AB N X Model Label9 HiNDPE695WJZZ AC N X Energy Guide Label10 LANGKD341WJFW AC X Term Angle Side11 LANGKD342WJFW AC X Earth Angle12 LHLDWA074WJKZ AD J WireHolder13 LHLDWA175WJUZ AC J WireHolder14 LHLDWA289WJKZ AC J WireHolder15 LHLDWA318WJKZ AD J Cable Tie16 LX-BZA207WJF7 AA J Screw, x817 LX-BZA473WJN1 AC J Screw, x218 NSFTZA459WJF7 AC J Tray Shaft, x619 PMLT-A681WJQZ AC X Gasket (TUNER)20 PSPANA044WJKZ AB J Spacer, x5 (POWER)21 PSPAZC730WJKZ AD X Gasket22 PZETKA595WJKZ AD X AC Cord Barrier

! 23 QACCDA084WJPZ AH X AC Cord24 QCNW-M108WJZZ AG N X Connecting Cord (SP)25 QCNW-M507WJZZ AG X Connecting Cord (RC)26 QCNW-M508WJZZ AD X Connecting Cord (CI)27 QCNW-M955WJZZ AK N X Connecting Cord (PDPL)28 QCNW-M956WJQZ AQ N X Connecting Cord (LW)29 QCNWN2731TPZZ AF J FFC 80PIN, x230 RCORFA061WJZZ AG J Ferrite Core, x231 RSP-ZA597WJZZ AQ N X Speaker UNIT (L)32 RSP-ZA598WJZZ AQ N X Speaker UNIT (R)33 TLABNB037WJZZ AA X Back Serial Label34 Not Available - N - Side Serial Label35 XBPS830P06000 AA J Screw, x236 XBPS830P06WS0 AA J Screw, x5137 XEBS830P12000 AA J Screw, x1038 GCOVAC576WJKZ AC X VESA Cover, x4

4

LC-60/70LE600U

[4] CABINET AND MECHANICAL PARTS (LC-70LE600U)

A

B

B

B

B

A

C

E

F

h

c

k

n

n

p

q

m

d

ICON Unit

R/C OPC Unit

70"LCD Panel Module Unit

KEY Unit

LCD CONTROL Unit

POWER/DRIVE Unit

C

1-8

1-1

1

1-5

1-5

1-4

6-3 6-2

41

6-1

28

36

33

1-7

1-2

1-3

j

11

18

38

9

10

26

42

42

241

17

35

34 35

34

5

41

41

5

41

15

18

37

p

1-6

q

D

E

F

24

14

39

41

16

4-2

4

4-1

41

4-2

4

4-1

41

4-2

4

4-1

41

4-2

4

4-1

22

12

33-1

3-2

33-1

3-2

6

21

43

17

17

1319

20

27

MAIN Unit

a

d

32

jk

30

c

a

5

LC-60/70LE600U

NO. PARTS CODE PRICE RANK

NEW MARK

PART DELIVERY DESCRIPTION

[4] CABINET AND MECHANICAL PARTS (LC-70LE600U)1 CCABAC859WJ35 BD N X Front Cabinet Ass'y

1-1 Not Available - - Front Cabinet1-2 Not Available - - ICON Cover1-3 Not Available - - R/C LED Decoration1-4 LHLDWA124WJKZ AC X Wire Holder, x21-5 LHLDWA175WJUZ AC X Wire Holder, x41-6 LHLDWA289WJKZ AC X Wire Holder1-7 PSHEPB181WJKZ AB X Sheet1-8 TLABZD330WJZZ AB N X License Label2 GCABBC151WJ3A BL N X Rear Cabinet3 CANGKD611WJ31 AF X Stand Fix Angle Ass'y, x2

3-1 Not Available - N - Stand Fix Angle3-2 Not Available - - Himeron4 CANGKD483WJ31 AE X VESA Angle Ass'y, x4

4-1 Not Available - N - VESA Angle4-2 NSFTZA460WJFN BC X VESA Shaft5 GCOVAE335WJ3A AF X Bottom Cover, x26 DCOVAE162WE01 AK N X KEY Button Cover Ass'y

6-1 Not Available - - KEY Button Cover6-2 JBTN-A912WJ3A AB X KEY Button6-3 XEBS830P08000 AA X Screw, x29 GCOVAC576WJKZ AC X VESA Cover, x410 GCOVAE163WJ3A AE X AC Cord Cover11 HINDPE692WJSA AB N X Model Label12 HINDPE694WJZZ AC N X Energy guide Lable13 LANGKD704WJ3W AD N X Terminal Angle (Side)14 LHLDWA289WJKZ AC X Wire Holder15 LHLDWA176WJUZ AC X Wire Holder16 LHLDWA318WJKZ AD X Cable Tie17 LX-BZA207WJF7 AA X Screw, x918 LX-EZA069WJF7 AB X Screw, x219 PMLT-A681WJQZ AC X Gasket20 PSPAZC730WJKZ AD X Gasket21 LANGKD342WJFW AC X Earth Angle22 PSPAKA510WJKZ AA N X Spacer24 PSPAZC823WJ3Z AB N X Spacer, x2

! 26 QACCDA084WJPZ AH X AC Cord27 QCNW-M960WJZZ AL N X Connecting Cord (PD)28 QCNW-M962WJZZ AE N X Connecting Cord (SP)30 QCNW-M961WJPZ AS N X Connecting Cord (LV)32 QCNW-M502WJZZ AG X Connecting Cord (RC)33 QCNW-M503WJZZ AC X Connecting Cord (CI)34 QCNWN2731TPZZ AF X Connecting Cord (FFC), x235 RCORFA061WJZZ AG X Ferrite Core, x236 RSP-ZA597WJZZ AQ X Speaker (L)37 RSP-ZA598WJZZ AQ X Speaker (R)38 TLABNB037WJZZ AA X Serial Label (Back)39 Not Available - N - Serial Label (Side)41 XBPS830P06WS0 AA X Screw, x5542 XEBS830P12000 AA X Screw, x943 XBPS830P06000 AA X Screw, x2

6

LC-60/70LE600U

[5] SUPPLIED ACCESSORIES/PACKING PARTS (LC-60LE600U)

Remote control unitX10

“AA” size batteryX11

Stand Screw Ass'yX3 Operation manual

X6 X7 X8Connection guide

X9

Enpuete CardX4

extend WarrantyX5

Stand Base Ass'yX1

Stand Support Ass'yX2

S6

S6

S6

S2

S1

S7

S7S7

X3

X11S9

X10

X2S5

X6X5X4

X7X8X9

S8

X1S4

S3

S10

7

LC-60/70LE600U

NO. PARTS CODE PRICE RANK

NEW MARK

PART DELIVERY DESCRIPTION

[5] SUPPLIED ACCESSORIES/PACKING PARTS (LC-60LE600U)X1 CDAi-A778WJ31 AZ X Stand Base Ass'yX2 CANGKD276WJ01 AK X Support Ass'y, x2X3 CSAKKA011WJ01 AF X Screw Ass'yX4 TCADEA290WJZZ AA N X Enpuete CardX5 TGAN-A845WJN1 AB X Extend WarrantyX6 TiNS-F576WJZZ AB N X Operation Manual (English)X7 TiNS-F577WJZZ AB N X Operation Manual (F)X8 TiNS-F578WJZZ AB N X Operation Manual (S)X9 TMAN-A048WJZZ AB N X Conection GuideX10 RRMCGA667WJSA AH X R/C HuitongX11 Not Available - - "AA" Size Battery, x2S1 SPAKCG640WJZZ - - Packing Case Bottom (NOT REPLACEMENT ITEM)S2 SPAKCG916WJZZ - N - Packing Case Main (NOT REPLACEMENT ITEM)S3 SPAKPB427WJZZ - - Polyethylene Bag (NOT REPLACEMENT ITEM)S4 SPAKPB722WJZZ - N - Miror Mat (Base) (NOT REPLACEMENT ITEM)S5 SPAKPB723WJZZ - N - Miror Mat (Support) (NOT REPLACEMENT ITEM)S6 SPAKXD566WJZZ - - Packing Form (TOP) (NOT REPLACEMENT ITEM)S7 SPAKXD567WJZZ - - Packing Form (BOTTOM) (NOT REPLACEMENT ITEM)S8 SSAKA0101GJZZ - - Polyethylene Bag (NOT REPLACEMENT ITEM)S9 SSAKKA011WJZZ - N - Polyethylene Bag (NOT REPLACEMENT ITEM)S10 TLABKA009WJZZ - - Case No. Label (NOT REPLACEMENT ITEM)

8

LC-60/70LE600U

[6] SUPPLIED ACCESSORIES/PACKING PARTS (LC-70LE600U)

FRONT

Remote control unitX8

“AA” size batteryX9

Stand Screw Ass'yX3 Operation manual

X6Connection guide

X7X10 X11

Ennquete CardX4

Guarantee CardX5

Stand Base Ass'yX1

Stand Support Ass'yX2

S6

S6

S6

S1

S2

S7

S7S7

X3

X9S9

X8

X2S5

X4X5X6X7X10X11

S8

X1S4

S3

S10

S7

S7

9

LC-60/70LE600U

NO. PARTS CODE PRICE RANK

NEW MARK

PART DELIVERY DESCRIPTION

[6] SUPPLIED ACCESSORIES/PACKING PARTS (LC-70LE600U)X1 CDAI-A778WJ31 AZ X Stand Base Ass'yX2 CANGKD276WJ01 AK X Stand Support Ass'y, x2X3 CSAKKA011WJ01 AF X Stand Screw Ass'yX4 TCADEA290WJZZ AA N X Ennquete CardX5 TGAN-A845WJN1 AB X Guarantee CardX6 TINS-F576WJZZ AB N X Operation Guide (E)X7 TMAN-A048WJZZ AB N X Conection GuideX8 RRMCGA667WJSA AH X Remote ControlX9 Not Available - - AAA size battery, x2X10 TINS-F577WJZZ AB N X Operation Guide (F)X11 TINS-F578WJZZ AB N X Operation Guide (S)S1 SPAKCG915WJZZ - N - Packing Case (NOT REPLACEMENT ITEM)S2 SPAKCG641WJZZ - - Packing Case (Bottom) (NOT REPLACEMENT ITEM)S3 SPAKPB733WJZZ - - Polyethylene Bag (NOT REPLACEMENT ITEM)S4 SPAKPB722WJZZ - N - Packing Add. (Base) (NOT REPLACEMENT ITEM)S5 SPAKPB723WJZZ - N - Packing Add. (Support) (NOT REPLACEMENT ITEM)S6 SPAKXD568WJZZ - - Packing Add. (Top) (NOT REPLACEMENT ITEM)S7 SPAKXD569WJZZ - - Packing Form (Bottom) (NOT REPLACEMENT ITEM)S8 SSAKA0101GJZZ - - Polyethylene Bag (NOT REPLACEMENT ITEM)S9 SSAKKA011WJZZ - N - Polyethylene Bag (NOT REPLACEMENT ITEM)S10 TLABKA009WJZZ - -

[7] SERVICE JIG (USE FOR SERVICING)N QCNW-C222WJQZ AW J Connecting Cord L=1000mm 80pins, LCD Control to LCD Panel, x2N QCNW-F676WJQZ BH J Connecting Cord L=1000mm 41pins, Main to LCD Control (LW)N QCNW-N033WJZZ AZ J Connecting Cord L=1000mm 24-12/4pins, Power-Main/LCD Control (PD)

10

LC-60/70LE600U

LC-60/70LE600U

COPYRIGHT © 2012 BY SHARP CORPORATION

ALL RIGHTS RESERVED.

No Part of this publication may be reproduced,stored in a retrieval system, or transmitted inany from or by any means, electronic, mechanical,photocopying, recording, or otherwise, withoutprior written permission of the publisher.

SHARP CORPORATIONAV Systems GroupCS Promotion CenterYaita,Tochigi 329-2193, Japan

Jul. 2012SH. DS