Session 1 System Curves - Just another WordPress site · Session 1 System Curves. Pumping Systems...

Transcript of Session 1 System Curves - Just another WordPress site · Session 1 System Curves. Pumping Systems...

Mark Markham, P.E.

Gresham, Smith and Partners

September 14, 2017

Session 1

System Curves

Pumping Systems

�Session 1 - Components of a system

curve/hydraulics basic hydraulics/pipe

systems/system curve development

�Session 2 – Pump curves and pump selection

(centrifugal pumps)/duty points/efficiency/duplex &

triplex and series & parallel systems

�Session 3 – Pumping station wet well design - NPSH

and submergence

�Session 4 – Pumping station performance testing -

dry pit/wet pit, submersible, suction lift

Learning Objectives

�Review the elements/components of

pumping systems

�Review the basic hydraulics required to

design a pumping system

�Review basic equations for performing

system head calculations

�Develop a system curve

Terminology

�Pressure – driving force to move fluid

� psi

� feet

� atm

�Head - a measurement of liquid pressure above

a given reference point

� feet

� “Head pressure”

� Express Bernoulli Equation in terms of head (feet)

Pumps and Pumping Stations

�Pumping Systems add energy (provide sufficient pressure) to move fluid through a system at a desired flow rate

�Energy required by the system depends on:� Discharge/Flow rate needed

� Resistance to flow (head/pressure that the pump must overcome)

� Pump efficiency (ratio of power entering fluid to power supplied to the pump)

� Efficiency of the drive (usually an electric motor)

2 2

1 1 2 21 2

2 2pump L

v p v pz H z H

g gγ γ+ + + = + + +

2

2L f minor f i

vH h h h K

g= + = +∑ ∑ ∑ ∑

Elements of a Pumping System

�Convey a fluid that can’t be conveyed by gravity

�System network – pipes, fittings, valves

�Hydraulic Control Points (intake elevations, high

points, discharge elevations)

�Pump

�Motor

�Valves

�Instrumentation

�Controls

Information Needed

�Static Heads

� Min: Min discharge elev. minus max intake elev.

� Max: Max discharge elev. (not high pt.) minus min intake elev.

� Priming Head: Max high pt. minus min intake elev. (RARE)

�Fluid Characteristics

� Water at standard conditions (most of the time)

� Solids content

�System Components

� Pipe sizes, lengths, materials and conditions

� Fittings (elbow, tee, inlet, outlet, other (i.e. condenser, etc.))

� Valves (isolation, check and control)

Pumping System – Static Head� (Total) Static head – difference in head between suction

and discharge sides of pump in the absence of flow;

equals difference in elevation of free surfaces of the fluid

source and destination

�Static suction head – head on suction side of pump in

absence of flow, if pressure at that point is >0

�Static discharge head – head on discharge side of pump

in absence of flow

Total static

head

Static suction

head

Static

discharge

head

Pumping System – Static Head (Lift)

� (Total) Static head – difference in head between suction

and discharge sides of pump in the absence of flow;

equals difference in elevation of free surfaces of the fluid

source and destination

�Static suction lift – negative head on suction side of pump

in absence of flow, if pressure at that point is <0

�Static discharge head – head on discharge side of pump

in absence of flow

Total static

head Static suction

lift

Static

discharge

head

Pumping System – Static Head + Lift

Total static

head (both) Static suction

lift

Static

discharge

head

Static suction

head

Static

discharge

head

Static suction head

Static suction lif

Static discharge head

Static d t

Total static h

ischarge he d

ead

a

= −

= +

Note: Suction and discharge head / lift measured from pump centerline

Terminology

�Friction – force that resist fluid flow

� Pipe diameter & length

� Pipe materials & condition

�Darcy-Weisbach

�Hazen-Williams

� “C” – pipe roughness factor (≈140 new, ≤100 old)

� Typically used at GS&P

�Minor losses

� Valves, Pipe Bends

� “Km” – minor loss coefficient

Friction Head

�Losses dependent on flow rate

� Piping

� Valves/Fittings (“minor losses”)

� Equipment

�“Rule of Thumb” for Pipe velocities

� V > 2.0 fps and < 8 fps for “typical” pipe sizes

� Why – to minimize losses in “typical” systems

� V is not necessarily an indication of the rate of loss. For

example, Loss per 100’ pipe is ≈ 0.2’ in a:

� 24” @ 6,000 gpm (V=4.3 fps)

� 120” @ 425,000 gpm (V=12 fps)

Friction Head - Piping

� Darcy Weisbach

� �� = ��

�

�

�

� Hf = friction loss (ft)

� f = friction factor (Moody Diagram)

� L = pipe length (ft)� V = velocity

(ft/sec)� D = pipe diameter

(ft)� g = gravitational

acceleration = 32.2 ft/sec2

Friction Head - Piping

�Hazen-Williams equation

� �� =�.�

���.����

��.�����.���

� Hf = friction loss (ft)

� V = velocity (ft/sec)

� L = pipe length (ft)

� C = Hazen-Williams’ C-factor

� D = pipe diameter (ft)

Friction Head – Valves/Fittings

�Minor losses use “K”

value

� �� = ��

�

� Hm = minor loss (ft)

� K = resistance coefficient

� V = velocity (ft/sec)

� g = gravitational acceleration

= 32.2 ft/sec2

� Lots of references to find K

values—Cameron,

manufacturers, etc.

Pumping System – Total Dynamic Head (TDH)

� (Total) Dynamic head = dynamic suction head or lift + dynamic

discharge head – which includes static heads, frictional pipe losses

and minor losses

Total

Dynamic

Head

(TDH)Dynamic

suction lift

Dynamic

discharge

head

Energy Line

Energy Grade Line & Hydraulic Grade Line

Energy Grade Line = Energy Head = Velocity Head + Pressure

Head + Potential (Elevation) Head

Hydraulic Grade Line = Energy Head – Velocity Head = Water

Surface

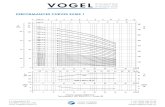

Total System-Head Curve

Total System Head-Curve

Friction Head

(Total Head loss)

Static

Head

TDH

(Total Dynamic Head)

(ft)

Q, Flow

(ft3/s)

System Curve

The relationship

between the head

(pressure)

condition present

in a specific

system (pipe

network,

distribution

system, etc.) for a

specific flow

Determine the static head, total dynamic head (TDH), and total head (friction) loss in the system shown below

Total static head 730 ft 630 ft 100 ft= − =

pd =48 psig

ps =−6 psig

El = 630 ft

El = 640 ft

El = 730 ft

( ){ } 2.31 ftTDH 48 6 psi 124.7 ft

psi

= − − =

( )TDH Static head 124.7 100 ft 24.7 ftLH = − = − =

Example - TDH Calcs with Pressure Gauge Values

A booster pumping station is being designed to transport water from an

aqueduct to a water supply reservoir, as shown below. The maximum design

flow is 25 mgd (38.68 ft3/s). Determine the required TDH, given the following:

� H-W ‘C’ values are 120 on suction side and 145 on discharge side

� Minor loss coefficients are

0.50 for pipe entrance

0.18 for 45o bend in a 48-in pipe

0.30 for 90o bend in a 36-in pipe

0.16 and 0.35 for 30-in and 36-in butterfly valves, respectively

� Minor loss for an expansion is 0.25(v22 − v1

2)/2g

Short 30″ pipe w/30″butterfly valve

El = 6349

to 6357 ft

El = 6127

to 6132 ft

30″ to 48″expansion

4000′of 48″ pipe

w/two 45o bends

8500′of 36″ pipe w/one

90o bend and eight

butterfly valves

Example – TDH Calcs with Losses

Determine pipeline velocities from v =Q/A..

v30= 7.88 ft/s, v36= 5.47 ft/s, v48= 3.08 ft/s

Minor losses, suction side:2

30

2

30

2 2

30 48

2o 48

,minor

Entrance: 0.50 0.49 ft2

Butterfly valve: 0.16 0.16 ft2

Expansion: 0.25 0.21 ft2

Two 45 bends: 2* 0.18 0.05 ft2

0.91 ft

L

L

L

L

L

vh

g

vh

g

v vh

g

vh

g

h

= =

= =

−= =

= =

=∑

Example – TDH Calcs with Losses

Minor losses, discharge side:

2

36

2o 36

,minor

8 Butterfly valves: 8* 0.35 1.30 ft2

One 90 bend: 0.30 0.14 ft2

1.90 ft

L

L

L

vh

g

vh

g

h

= =

= =

=∑

Example – TDH Calcs with Losses

1.85

2.630.43f

Qh L

CD

=

( )( )( )

1.85

, 2.63

38.74000 2.76 ft

0.43 120 48 /12f suctionh

= =

Pipe friction losses (don’t use a conservative C):1.85

2.630.43

fh QS

L CD

= =

( )( ) ( )

1.85

, 2.63

38.78500 16.77 ft

0.43 145 36 /12f dischargeh

= =

Example – TDH Calcs with Losses

Loss of velocity head at exit:2

36Exit: 0.46 ft2

L

vh

g= =

( )Static head 6357 6127 ft 230 ft= − =

Total static head under worst-case scenario (lowest water level in

aqueduct, highest in reservoir):

[ ] [ ]( )

, ,TDH

230 0.91 1.90 2.76 16.77 0.46 ft

252.8 ft

static L minor f L exitH h h h= + + +

= + + + + +

=

∑ ∑Total dynamic head required:

Example – TDH Calcs with Losses

System Curve Development

�We’ve calculated TDH and head losses for a single flow condition

�A system curve represents a range of TDH and flow conditions

�DON’T use a conservative approach to calculate a system curve for a “new” system (use C ≈ 140). Try to be as accurate as possible.

�Only use C ≤ 100 as a check.

�To simplify system curve calcs, can either: � Sum K values for each pipe size

� Convert various pipe sizes, fitting and valves to one pipe size and lenght

Calculate System Curve

Summary

�Definition of a System Curve: � A graphical representation of a piping system’s energy

requirement response to a range of flows.

�References:� Crane Technical Paper No. 410 (Crane Valves)

� Cameron Hydraulic Data (Ingersoll-Rand)

� Hydraulic Handbook (Fairbanks Morse)

� Hydraulic Institute Engineering Data Book (HI)

� Handbook of Hydraulic Resistance (Idelchik)

� Component manufacturers (ℎ = ��

�)

�Programs:� AFT Fathom v9 (Applied Flow Technology)

� Flow of Fluids (Crane)

Next Steps

So we have a system curve – what next?

�Select a pump to meet the requirements of the

system

�Do you need to develop a composite system curve?

� Intermediate high point condition

�Bracket our system conditions (best case/worst case,

high head/low head/variable head, range of pipe

conditions/appropriate selection of C factor)

Questions/Discussion