Servo Magazine - 2007-01

-

Upload

alice-jones -

Category

Documents

-

view

184 -

download

2

description

Transcript of Servo Magazine - 2007-01

Get an HB-25 Two-pack (#29150) for only $79.95 and save $20! The Parallax HB-25 Motor Controller (#29144; $49.95) provides a simple and dependable motor control system for your motorized projects. With an efficiently integrated heat dissipation design, the HB-25 easily manages 12V motors drawing 25A of current! These are sizable motors, as shown in our two example robots which are both controlled by HB-25s.

Motor Size: 0.5 HP Max - No Minimum

Motor Supply: 6.0 vdc min - 16.0 vdc max

Load Current: 25 A Continuous 35 A Surge (13.8 V)

Standby Current: 50 mA @6 V 80 mA @13.8 V (fan on)

PWM Frequency: 9.2 kHz

Pulse Input: 1.0ms Full Reverse, 1.5ms Neutral (off), 2.0ms Full Forward

# of Motors: 1 (or 2 in same direction)

Protection Circuits: Over Voltage, Over Current, Over Temp.

Indicators: Power (green), Fault (red)

Cooling: Forced Air - Ball Bearing Fan

Terminals: Screw Post with 35 A Rating

Weight: 2.5 oz (71 grams)

Size: 1.6” x 1.6” x 1.9”

Mounting: (2) 6-32 screws on .800” centers

Included: (1) 25 A Fuse

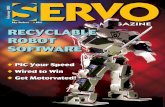

Vol. 5 N

o. 1

SERV

OM

AG

AZIN

EV

INN

IE•

INTEL’S O

PEN CV

•D

IVID

ERS A

ND

TIMER

S•

SOU

ND

GIN

January 2007

Cover.qxd 12/7/2006 1:00 PM Page 84

Perfect holiday gifts for kids of all ages!Perfect holiday gifts for kids of all ages!

WWW.ROBOTSTORE.COM/SRCI-800-374-5764

WWW.ROBOTSTORE.COM/SRCI-800-374-5764

Enthusiasts,Start Dreaming...

Gift Givers,Take Note...

Engineers,We’ve GotIt All!

Enthusiasts,Start Dreaming...

Gift Givers,Take Note...

Engineers,We’ve GotIt All!

Robotic Kits and Components...The World’s MostComplete Offering!

CATALOG I62

I-800-374-5764 WWW.ROBOTSTORE.COM

Call for your free catalog today!

robotic kits

chassis

servos

passives

optos

integrated circuits

semiconductors

muscle wires

connectors

motors

test equipment

software

books

Robotic Kits Components...Robotic Kits Components......there’s something for everyone!Robotic kits help you and your child to experience and learn about perception andcontrol using a variety of sensors and actuators. Challenge yourself with Jameco’sselection of fun and interactive kits! You or your child can assemble the kits andthen enjoy endless hours of discovery.

Check out our unique selection of robotic kits at www.RobotStore.com!. Robot Insects & Animals . Programmable Robots

. Solar Robots . Educational Kits

. Listening, Touching & Seeing Robots . Legged and Wheeled Platforms

. Hackable Robots . OctoBot Survivor Kit

At Jameco’s RobotStore you can get the world’s most complete robotic offering—

all in one place! You’ll find kits for all ages and experience levels, along with gear

boxes, servos and chassis, for those who are ready to take on the extreme.

CoverInside.qxd 12/6/2006 1:12 PM Page 2

SERVO 01.2007 3

Full Page.qxd 12/6/2006 9:56 AM Page 3

Columns Departments

SERVO Magazine (ISSN 1546-0592/CDN Pub Agree#40702530) is published monthly for $24.95 per year by T & L Publications, Inc.,430 Princeland Court, Corona, CA 92879. PERIODICALS POSTAGE PAID AT CORONA, CA AND AT ADDITIONAL ENTRY MAILINGOFFICES. POSTMASTER: Send address changes to SERVO Magazine, P.O. Box 15277, North Hollywood, CA 91615 orStation A, P.O. Box 54,Windsor ON N9A 6J5; [email protected]

06 Mind/Iron

07 Bio-Feedback

23 Robo-Links

24 New Products

67 Events Calendar

72 Robotics Showcase

73 Menagerie

80 SERVO Bookstore

90 Advertiser’s Index

08 Robytes by Jeff EckertStimulating Robot Tidbits

10 Twin Tweaksby Bryce and Evan WoolleyMighty Morphing Bioloid

16 Ask Mr. Roboto by Pete MilesYour Problems Solved Here

20 GeerHead by David GeerRoboGeddon It! Are You Getting It?

74 Programmable Logicby Gerard FonteDividers and Timers

82 Robotics Resources by Gordon McCombShopping the Electronics General Store

86 Appetizer by Lawrence FeirTake Me to Your Leader — Meet Robbie the Robot

87 Then and Now by Tom CarrollShuttle Remote Manipulator System/Canadarm

4 SERVO 01.2007

ENTER WITH CAUTION!26 The Combat Zone

TOC Jan07.qxd 12/7/2006 4:59 PM Page 4

01.2007VOL. 5 NO. 1

SERVO 01.2007 5

34 Exploring Soundginby Gordon McCombRobotics and sound generation are natural playmates. Use this synthesizer to add life to your builds.

39 DARwInby Karl Muecke, Patrick Cox, and Dennis HongPart 2: Parts, wires, and motors.

44 Hacking Rogerby Monty ReedRoger Robot makes a perfect platform for beginning hackers.

52 Robot Safetyby Bryan BergeronA discussion of robot design, construction, and operating practicesthat can improve the survivability of your robots and minimize the safetyrisks to you and bystanders.

57 Beginner’s Robotics on$50 a Monthby Paul PawelskiPart 2: Building the CIRC bot.

62 Seeing With OpenCV by Robin HewittPart 1: An Introduction to OpenCV — Intel’s free, open-source computer vision library. Learn where to get it, how to set it up on your computer, and work with the OpenCV interfaces.

68 ROBOGames Prepby Dave CalkinsThis month: Tetsujin.

Features & Projects

Page 20

TOC Jan07.qxd 12/7/2006 5:05 PM Page 5

Published Monthly By T & L Publications, Inc.

430 Princeland CourtCorona, CA 92879-1300

(951) 371-8497FAX (951) 371-3052

Product Order Line 1-800-783-4624www.servomagazine.com

SubscriptionsInside US 1-877-525-2539

Outside US 1-818-487-4545P.O. Box 15277

North Hollywood, CA 91615

PUBLISHERLarry Lemieux

ASSOCIATE PUBLISHER/VP OF SALES/MARKETING

Robin [email protected]

CONTRIBUTING EDITORSJeff Eckert Tom CarrollGordon McComb David GeerPete Miles Kevin BerryDave Calkins Bryan BergeronKarl Muecke Patrick CoxDennis Hong R. Steven RainwaterPaul Pawelski Robin HewittMonty Reed Lawrence FeirMichael Simpson Gerard FonteBryce Woolley Evan WoolleyAaron Taggart Brian BensonAdam Wrigley Bradley Hanstad

CIRCULATION DIRECTORTracy Kerley

WEB CONTENT/STOREMichael Kaudze

PRODUCTION/GRAPHICSShannon Lemieux

ADMINISTRATIVE ASSISTANTDebbie Stauffacher

Copyright 2007 by T & L Publications, Inc.

All Rights Reserved

All advertising is subject to publisher’s approval.We are not responsible for mistakes, misprints,or typographical errors. SERVO Magazineassumes no responsibility for the availability orcondition of advertised items or for the honestyof the advertiser.The publisher makes no claimsfor the legality of any item advertised in SERVO.This is the sole responsibility of the advertiser.Advertisers and their agencies agree toindemnify and protect the publisher from anyand all claims, action, or expense arising fromadvertising placed in SERVO. Please send alleditorial correspondence, UPS, overnight mail,and artwork to: 430 Princeland Court,Corona, CA 92879.

Last year, I built a walker robotfor the Robot Fest. I christened thisrobot “Face Walker.” It was featuredin the August, September, andOctober issues of SERVO Magazine.My goal was to create a robot thatwould catch the attention of thespectators and hold their interestwhile I gave my presentation. I had a nice little speech all planned.What I had not planned on was the“freak factor.”

What actually happened was thatthe spectators were so enthralled bythe look of Face Walker, that theydidn’t hear a word I said. Manyindividuals left only to return withfriends or family members. What is it that made the Face Walker so awe-inspiring? The Face Walker hadwhat I now call the freak factor.

I had a chance to review videosthat were taken of the spectatorswhile they were watching the FaceWalker in action. Almost all of themwere watching the face. The facewould animate and make noises asthe robot would move. Individualssaw this walker robot thingy thatlooked something like a spider, but asit turned to face them, it would winkor say something. Immediately theywould smile and point. It is when westart to add human characteristics tomachines that we start to evokeemotions, which can range fromamazement to outright fear.

So, I created a really cool robot,but what can it do? This is the kind of question I often get when showing walker robots. The powerrequirements for a fully articulatedwalker are massive. In many cases,you have 12-24 servos that are all

energized at once. The Face Walker always had to

have three legs in contact with theground at any one time to supportthe total weight of the robot. Evenwhen standing still, a walker will uselarge amounts of power. This is nottrue with a wheel-based robot.

The 7.2V 3,000 mAh batterypack would power the Face Walkerbase for about five minutes before itneeded an hour charge. On awheeled robot of the same weight,you get over an hour of run time onthe same battery. This makes walkersvery inefficient for most tasks.However, when it comes to educationor studying the human condition, youcan’t beat a walker.

In order to top last year’s RobotFest, I have started early on my nextrobot exhibit. This robot will be abiped walker with 19 servoscontrolling various limbs, as well asthe neck. Let’s call him Kronos.Kronos is still in the experimentalstage but while he is in the sitting position, I added a randommovement generator and createdsome routines to simulate breathing.The bot’s chest would simply move inrhythm and the head would turnslightly at random intervals.

This was freaky enough, but Iwanted to take it a step further andadded some random fidgetmovements. He started moving hisarms or would change the angle ofhis legs as though he was trying toget comfortable. Let me tell you, this even freaked me out. Is itmemories of Chucky or is it that we just are not used to humanattributes on a mechanical device?

Mind / Iron

by Michael Simpson

Mind/Iron Continued

6 SERVO 01.2007

Mind-FeedJan07.qxd 12/7/2006 2:31 PM Page 6

Dear SERVO:Thank you for running Paul Pawelski's "Beginner's

Robotics on $50 a month." Sure, it's fun to lust after multi-jointed 'bots costing four figures, but robotics doesn't haveto be expensive. This series promises to be an excellent wayfor newcomers to become acquainted with the field orhobby without risking a lot of cash. Paul's article affirms thatSERVO Magazine continues to appeal to a broad range ofages and personal budgets.

K. BowerKamloops BC

It’s probably a little of both.

What is the Robot Fest?

Robot Fest is an annual event held each year inLinthicum, MD at the Historical Electronics Museum. Thenext Fest will be held on April 28, 2007. This is a freeevent that exposes many individuals — children and adults— to varying types of robots. Everything from the largeBattleBots to the smallest walker will be on exhibit. Be sure to check out the Robot Fest website atwww.robotfest.com.

Hope to see you there! SV

Did you know that if you’re a paid subscriberto SERVO Magazine, you can get the online

version for FREE?Go to www.servomagazine.com

SERVO 01.2007 7

Mind-FeedJan07.qxd 12/7/2006 2:31 PM Page 7

8 SERVO 01.2007

Unmanned HelicopterTakes Off

Late last year, Boeing Co.(www.boeing.com) flew what isdubbed the A/MH-6X light-turbine helicopter for the first time. Underdevelopment since 2004, it is actuallya hybrid manned/unmanned aircraftthat combines the abilities of the existing A/MH-6M Mission EnhancedLittle Bird (MELB) with the unmannedaerial vehicle technologies of the Unmanned Little Bird (ULB)Demonstrator shown above. The latter is a modified MD 530F civil helicopter that is readily available from MD Helicopters, Inc. (www.mdhelicopters.com).

So far, the Demonstrator haslogged about 500 flight hours. In thelatest test, the A/MH-6X was flown for14 minutes as a piloted aircraft, butfuture testing will involve bothmanned and unmanned operations.Aircraft performance will be similar to

that of the Demonstrator, but with anadditional 1,000 lbs (increased to3,400+ lbs) of payload that can beused for increased range, endurance,or mission hardware. Interestingly,Boeing says that the unmanned hardware and paraphernalia devel-oped for this program can be adaptedto any helicopter.

Give ‘em the Chair

Like many things we encounterin life, the Robotic Chair, a creationof Cornell’s (www.cornell.edu)Prof. Raffaello D’Andrea and artistMax Dean, admittedly has no utilitar-ian value. And, like many people weencounter in life, its “brain” is locat-ed in its seat. But not everythingneeds to have a mundane purpose,and the chair — designed as art for

art’s sake — has only one function: tofall apart and reassemble itselfautonomously.

The chair’s operation involves 14 motors, two gearboxes, and various other mechanical parts, anda computer uses special algorithmsto tell the chair how to find missingcomponents and rebuild itself.Waxing philosophical, Dean notedthat its operation is “somewhat likewhat we do in our own lives. We fall apart and put ourselves backtogether.”

Maybe it has no utilitarian value,but it could have significant entertainment value if you place acouple of them at the dinner tableand invite the in-laws over. In anyevent, the chair will be exhibited in artshows and museums around theworld and eventually sold to a galleryor collector.

Bot Cleans Up After You

On a much more down-to-earthlevel is the latest creation of Prof.Andrew Ng’s Stanford ArtificialIntelligence Robot (STAIR) project.The dream here is to, within adecade, put a robot in every homeand office to take care of routine

Boeing’s ULB Demonstrator on itsfirst unmanned spin around the block.

Photo courtesy of Boeing.

A plate-grabbing robot, graduatestudents Ashutosh Saxena andMorgan Quigley, and Assistant

Professor Andrew Ng (L to R) — allpart of the STAIR project. Photocourtesy of Stanford University.

The robotic chair in different stagesof collapse and reassembly.

Photos by Raffaello D’Andrea,courtesy of Cornell University.

by Jeff EckertRobytes

Are you an avid Internet surferwho came across something

cool that we all need to see? Areyou on an interesting R&D groupand want to share what you’redeveloping? Then send me anemail! To submit related pressreleases and news items, pleasevisit www.jkeckert.com

— Jeff Eckert

Robytes.qxd 12/7/2006 1:30 PM Page 8

jobs that you don’t really want to do,such as cleaning up after a party, taking out the trash, loading thedishwasher, sobering up Uncle Ralph,and so on. According to Ng, a practical maidbot will need to unite areas of artificial intelligence,including speech processing —navigation, manipulation, planning,reasoning, machine learning, andvision — into one package, whichposes a substantial challenge.

In the present stage of develop-ment, the team designed an algorithm that allowed STAIR to recognize familiar features in variousobjects and select the right grasp topick them up. The robot was trainedin a computer-generated environmentto pick up a cup, a pencil, a brick, abook, and a martini glass. The algorithm locates the best place forthe robot to grasp an object, such asa cup’s handle or a pencil’s midpoint.“The robot takes a few pictures, reasons about the 3-D shape of theobject based upon computing thelocation, and reaches out and graspsthe object,” Ng said.

In tests, the robotic arm pickedup items similar to those for which itwas trained, as well as unfamiliarobjects including keys, screwdrivers,and rolls of duct tape. Which bringsup the question of what STAIR willdo with the duct tape after picking itup. Is a Red Green robot in theworks?

Add YourNomination

Just a reminderthat the fourth annualinduction ceremonyfor the CarnegieMellon Robot Hall ofFame is scheduled forthis summer (date tobe announced) in

Pittsburgh. You are invited to nomi-nate your favorite robot at www.robothallof fame.org/nominate.php. Only one nomination is allowed per computer, and (duh!) previousinductees are not eligible.

One for the GripperIf your bot is having trouble

grasping things using rubber-clad fin-gers or other standard end effectors,maybe you should consider grippersthat are fitted with razor-sharp needles. Assuming you aren’t doing apick-and-place operation on hamsters,the operation could be improved withthe GRN needle grippers from SASAutomation (www.sasgripper.com).

The company recently upgradedthe product to incorporate titaniumneedles rather than the previous steelones, thus offering longer productionlife and lower overall replacementcosts. The needles extend from 3 to 5mm from the gripper body and arepneumatically activated. The grippersare compatible with the entire SAS end-of-arm tooling (EOAT) lineand come in both 14 and 20 mmmounting shaft sizes. Among theusual applications are gripping fabricor mesh, insert molding for floor matsand other automotive materials, and handling of lightweight porousmatting. SV

Robytes

The GRN grippers now feature titanium needles.Photo courtesy of SAS Automation.

SERVO 01.2007 9

AX2550

AX2850

Get the DC Motor Controllersthat are at the heart of many of today’sworld’s most demanding Industrial,Military and Research Robots, and otherinnovative Motion Control applications.

- RS232, RC, or Analog input- Speed or Position Mode- Dual channel output up to 140A- Optical Encoder Inputs- Intelligent Current Limiting- Thermally Protected- Field Upgradable Firmware- Enclosed and Board-Level versions- and many more advanced features ...

Model Amps Features PriceAX1500 2x30A B $275AX3500 2x60A O-R-B $395AX2550 2x120A A $495AX2550HE 2x140A A $645AX2850 2x120A O-A $620AX2850HE 2x140A O-A $770A=Aluminum Extrusion, B=Board-Level, O=Optical Encoder In,R= RC outputs. Qty1 price. Contact us for OEM Qty prices

www.roboteq.com

8180 E.Del Plomo Dr. Scottsdale AZ USA 85258

(602) 617-3931 - [email protected]

IndustrialStrength

Motor Controlfor All

AX3500

AX1500

Robytes.qxd 12/7/2006 1:30 PM Page 9

10 SERVO 01.2007

Robots come in all shapes and sizes,and the Bioloid from the Koreancompany Robotis certainly takes

that to heart. When we first receivedthe Bioloid kit, we thought we wouldbe dealing with a robot that looked likethe one in the advertisements and onthe box itself — a bipedal servo walker.We were pleasantly surprised to discov-er that the Bioloid is much more thanjust a humanoid walker; it is quite literally whatever you want it to be.While many bipedal servo walkers usemodular design as a means for the endof achieving an anthropomorphic form,the Bioloid takes full advantage of themodular design and truly invites the tin-kerer to let their imagination run wild.

Gestalt AssaultThe specific kit that we received was

the “comprehensive” Bioloid kit, whichincluded the most structural pieces and18 Dynamixel servo modules. The Bioloidis also available in two other kits: thebeginner and intermediate. We thinkRobotis deserves a standing ovation forthis innovative marketing strategy,because we really feel it provides a viableeducational platform — the Bioloid is,after all, an educational robot kit.Apparently there is also an Expert kit thatincludes a canned curriculum, but wethink the distinctions of the Beginner,Intermediate, and Comprehensive kitscreate an effective naturally progressive

curriculum that will teach any roboticistabout the intricacies of modular robotics.

The Beginner Bioloid kit comes withjust the basics — the CM-5 (the mainbrain for the robot), some structuralbits, four Dynamixel servo modules, andone Dynamixel sensor module. Many ofthe robots detailed in the instructionmanual that can be built with the begin-ner kit are indeed rudimentary, the sim-plest being a “crossing gate” that acti-vates one servo module with the touchof a button. But don’t think that thebeginner kit is by any means boring — itis, in fact, the kit with the greatest variety of robots detailed by step-by-stepinstructions in the manual. Other possible robots include a crocodilemouth and an interactive duck, andevery different design teaches the userabout a new aspect of construction orprogramming, like how to utilize theexpansion PCB and the use of for loops.

The intermediate kit provides somemore complicated designs that use upto eight Dynamixel modules, includinga simple spider and a “battle droid.”The intermediate designs are generallymore interactive, and they usually makeuse of a sensor module that is part ofthe Bioloid kit. We think that the inclusion of a sensor module is a must

THISMONTH:

MightyMorphing

Bioloid

THE BIOLOID KIT. OOOOOOH,THE INSIDE!

TwinTweaks.qxd 12/7/2006 1:32 PM Page 10

for an educational robot, because itallows the Bioloid to achieve true auton-omy and interact with its environment.

The comprehensive kit includesdesigns for four impressive robots withup to 18 joints. The four advanceddesigns are a puppy, a tyrannosaurusrex, the ultra-cool sounding King Spiderand, of course, the iconic humanoid.

Apart from all of the obviously coolstuff in the kit, there are some finaltouches that we really appreciated.Probably the biggest pleasant surprisewas that the Bioloid came with batter-ies included, a phrase practicallyunheard of nowadays. And if that wasn’t cool enough, the batteries arerechargeable, and the kit comes with acharger. We had been working with thekit for a while before we realized thatthe charger was made for AC outlets,but adapters are pretty easy to find.

Commanding theBioloid

The programming environment forthe Bioloid is an interesting beast, and,like the kit itself, comes in multipleforms. The main program editor for theBioloid looks like a Frankensteined version of Easy C and Visual Basic, withliteral blocks of code that encompassfamiliar commands like if, else, and forloops. Sometimes the written commands inside the blocks are accom-panied by curious pictures perhapsmeant to appeal to the more visual programmer, but often times we foundour selves scratching our heads and wish-ing for a Rosetta stone of programming.

The other programming environ-ment is the Motion Editor, somethingakin to what most other servo basedrobots have. Individual servo motorsare assigned valuesto move to certainpositions. The coolthing is that a seriesof commands inthe motion editorcan be saved in a block and implemented in thebehavior controleditor. Synergy is abeautiful thing.

Robots in Disguise ...As Other Robots

We decided that an effective wayto gauge the Bioloid’s effectiveness asan educational tool would be to followthe natural curriculum of the kit. Withthat in mind, we set out to build thesimplest model — a crossing gate. Whilethis might seem like an underwhelmingproject to build first out of such a coolkit, we appreciate the fact that Robotishas provided a simple way for novicetinkerers to get their feet wet. A curso-ry glance at the kit reveals some prettyintimidating stuff — tons of tiny fasten-ers, intricate frame pieces, lots of cablesof various lengths, and a whole mess ofDynamixel servo modules. With such adaunting kit on hand, a painfully simpledesign doesn’t look so painful after all.

The crossing gate did indeed usevery few parts, but it still provided anadequate introduction to the kit and itsunique attributes. One such attribute isa component of the Bioloid’s design,presumably intended to make construc-tion easier: on every servo module andthe CM-5, there are pockets that capturethe nuts. This sounds like a nice way tofree up some hands when building therobot, and it often is. Sometimes,though, we think the Bioloid kit falls vic-tim to a stack up of tolerances. Whenyou’re dealing with mass produced plas-tic parts that are already a tight fit, smallimperfections can stymie even the mosttenacious of efforts. Unfortunately, itseems like to us that this might sometimes be the case with the Bioloid.It could just be us, but it seems like onsome of the modules that we could onlyever get three of the requisite four nutscaptured in the pockets. Even so, thecrossing gate came together without

much difficulty. Most of the beginnerdesigns can be built in a matter of minutes, even for novice roboticists.

Next we tried our hand at an intermediate level robot — the spider. Wefound out that dealing with the pocketsbecomes somewhat easier with practice.A thin screwdriver is a handy way to pro-vide some extra leverage on the nuts, aslong as you’re careful not to screw up thethreads. Intermediate level bots take a bitlonger to build — more like a few hoursinstead of tens of minutes. But once thatspider was finished, it was really excitingto see that a ho-hum crossing gate couldmorph into something so cool.

After graduating from the interme-diate level designs, we felt confidentenough to tackle an advanced design.The puppy seemed like a good choice,because it would be interesting to seehow this modular robot dog comparedto other robots that were designed sole-ly with imitating man’s best friend inmind. The advanced designs take manyhours to complete, so it might be a goodidea for roboticists that cannot devotetheir undivided attention to the Bioloidto find a good stopping point in the mid-dle. Fortunately, that’s pretty easy to dowith the Bioloid puppy — the limbs arebuilt first, and then everything is connected to the body. The synthesis ofthe limbs into a complete bundle ofpuppy joy is by far the most difficult step,but the end result is wonderfully enter-taining. All it takes after construction is aquick download of a sample programfrom the CD, and the puppy is ready tobring smiles to the faces of young andold roboticists alike. The robotic puppycan scamper along at a brisk pace, perhaps not with the agility of other

SERVO 01.2007 11

Mighty Morphing Bioloid

YOU GUESSED IT ... THE CROSSING GATE!

THE BIOLOID SPIDER.

TwinTweaks.qxd 12/7/2006 1:32 PM Page 11

12 SERVO 01.2007

Twin TTweaks ....

robot dogs, but it’s certainly quick andquirky enough to hold its own. The robotpuppy can sit, eat from your hand, andeven do head stands. And as a testa-ment to the Bioloid’s interchangeablenature, a few modifications to the snoutlater we had a passable robot cat, quiteeffective at mimicking the real thing. Allwe had to do was reassign some of thebehaviors in the program to buttons onthe CM-5 (we had removed the sensormodule to achieve a more cat-like face),and the new robot cat was capable ofthe behaviors characteristic of real cats;namely eating and sleeping. When oneof the cat’s ears fell off, we affectionate-ly nicknamed him Vinnie.

Vinnie’s ear problem actually alertedus to one of the pleasant aspects of theBioloid’s design. Apparently, all the cap-

tured nuts hullabaloo was worth some-thing — when the ear fell off, not a singlepiece was lost. The Bioloid, like manyother robotics kits, is afflicted with therobotic equivalent of the common cold —loose screws. It’s an inevitable maladyunless you use Loctite or Nylocks or someother preventative measure, all of whichare out of the question for modularrobots that are disassembled andreassembled repeatedly. While the folksat Robotis have not implemented a solu-tion for loose screws in the Bioloid, theirsomewhat frustrating design elements oflittle pockets and such will hold onto theloose pieces for dear life, at least cuttingdown on the frustration of trekking outto your local hobby store to find replace-ments for lost mini nuts and screws.

Modular MayhemOnce we were thoroughly

acquainted with the designsincluded in the Bioloid kit, wewere ready to branch out withour own creations. A classicguise taken by modular robots is that of a snake. The highlyarticulated nature of the slithery reptile is hard to replicate with

more traditional robotic designs, so modular robots are the perfect candidatesfor technological mimics. The snake wasliterally quite straightforward to build, butsince there was no example program onthe CD, we had to come up with our own.

An inchworm-like motion was perfectly suited to a synthesis of theBioloid’s motion editor and behaviorprogramming. The motion editor is reminiscent of the classic programmingenvironments for many multiple servobased robots. By hooking the CM-5 intoyour computer, you can dictate the motionof each individual servo, and you evenhave a cool 3D animation for feedback.

Programming a snake motion wasfairly easy — we just had to have our lineof servos give a passable imitation of asine wave. Our single pulse of snakemotion could then be saved and imple-mented in the behavior control program-mer. In many programming environ-ments, a repetitive motion like the onewe wanted for our slithering snake couldbest be achieved by the brute forcemethod of copy and paste. The Bioloid’ssoftware allowed for the much more elegant solution of a for loop or somesimilar command. We think this inclusionof “real” programming in the Bioloid kit isvery important for the Bioloid’s educa-tional goals, because programming in lan-guages like C is much more common thanthe gait tables proffered by most modularkits. Soon, we had a slithering snake thatwas no where near as smooth as the realthing, but it did indeed move.

Another advantage of modulardesign is the prospect of shape shiftingon the fly. Sure, we were able to turn acrossing gate into a spider into a puppyinto a snake, but each time we had to

SEE ANY RESEMBLANCE? THE CM-5. VINNIE!!

THE ALL-TOO-FAMILIAR ROBOT SNAKE.

SLITHERING ALONG ...

TwinTweaks.qxd 12/7/2006 1:33 PM Page 12

completely disassemble and reassemblethe bot. What would truly be amazing isa robot that could take the shape of acrossing gate, spider, puppy, and snakeall without human intervention. That’sright. We’re talking about transformers.

Shape ShiftingSnake Eyes

If cool factor isn’t compellingenough of an argument, there are a multitude of practical reasons that shapeshifting robots are a popular questamong roboticists. Simply put, wheels aregreat for smooth terrain, but when thegoing gets rough, legs are more capable.So why not always use legs? Becausewheels are so much faster on smooth ter-rain. A conundrum — there seems to be atradeoff between speed, simplicity, andthe ability to grapple with uneven terrain.With shape shifting modular robotics,there doesn’t have to be a trade; you canhave it all. There is the possibility of hav-ing a snake to tackle uneven terrain turninto a wheel to race across flat ground.

That’s what we were aiming toachieve with our snake bot — a snakethat could curl up into wheel. It seems abit underwhelming, but it’s harder than itsounds. Real shape shifting modularrobots have ways of reconfiguring on thefly, something that the Bioloid lacks. Realshape shifting robots have ways of recon-necting and disconnecting modules with-out human intervention, either throughautonomous latches or some other fancybit of technology. The only way theBioloid modules are connected arethrough nuts and screws, so there reallywasn’t an easy way to reconfigure on the

fly. The best we could do was to add aclaw to the end of the snake’s tail andhope that would be enough to keep thewheel together. Unfortunately, wealready had a flat tire because we need-ed to include the not so sleek CM-5 in oursnake, and the shaky connection madefor a wheel that any unicyclist wouldavoid. Perhaps the time had come tomove onto something bigger and better.

The Derivative ofOptimus

Advertisements for the Bioloid andthe box of the bot itself are emblazonedwith the iconic form of the humanoidservo walker, so it seems appropriate thatthe humanoid bot is the final, and presumably most difficult, designdetailed in the instruction manual. Thehumanoid design is indeed a challenge,

as it consumes every Dynamixel moduleavailable in the kit. After assemblingbeginner and intermediate designs, constructing the limbs of the humanoidshould be a snap for any roboticist, butattaching everything to the body iswhere the real challenge begins. At timeswe were wishing for more than four collective hands, but eventually we wereable to complete the humanoid Bioloid.

The humanoid Bioloid is filled withpersonality. With the demo program,the Bioloid will fend off obstacles withkarate moves, dance, lay down, and ofcourse walk all over the place. Whileperhaps not as agile as other bipedalservo walkers that we have workedwith, none of those other servo walkerscould brag that they had been a puppymere hours earlier. But is the Bioloid theproverbial jack of all trades, and there-fore master of none? Perhaps the

Mighty Morphing Bioloid

SERVO 01.2007 13

SNAKE WHEEL! DYNAMIXEL SENSOR MODULE. DYNAMIXEL SERVO MODULE.

A PROGRAM!

TwinTweaks.qxd 12/7/2006 1:33 PM Page 13

Bioloid cannot claim utter mastery inany of its more complex forms, but itsversatility is nothing short of impressive.

Never ones to be anthropomorph-centric, we realized that the Bioloidhumanoid might benefit from someshape shifting. Inspired by the roboticheroes on the television shows of ouryouth, we set out to give the Bioloidwheels. Not wheels to replace his feet,of course, but wheels that would allow the Bioloid to transform from ahumanoid into a car. Without the luxuryof reconfiguration on the fly, we had tocome up with a way for the Bioloid tofold up in order to become a car. That’sthe way the Transformers did it too, sowe were confident when we set aboutgiving the Bioloid a new set of arms.

We think that our final trans-

formed product looked kind of like asprint racecar, or if that was perhapstoo flattering maybe an old stylebuggy, the kind that supplanted horsedrawn carriages. Since one of the preprogrammed behaviors of thehumanoid Bioloid was to lay down, allwe had to do was modify that toinclude a very painful looking yogaposition and we had our buggy. Onlythe front two wheels were powered, soour buggy might have benefited from arobotic horse. If we had anotherBioloid kit, we would have made one.

Saving the World,One Robot at a Time

Overall, we are overwhelminglyimpressed with the Bioloid kit. It pro-vides a truly viable educational platformwhile being undeniably entertaining.And even if it can’t live up to the stan-dards of reconfigureability of real worldmodular robots, that is hardly a badthing. The folks at Robotis have createda kit that stimulates the imagination andeducates roboticists of all skill levels.

We really think the offering of theBioloid in three different kits in particu-lar is very conducive to the robot’s stat-ed goal of being educational. As anytype of robot, modular robots like theBioloid can be very intimidating and

confusing for novices. The beginner kitis, however, perfectly suited for begin-ners looking for something “closer toreal” robots (as per the Bioloid’s slogan)than something like LEGO Mindstorms.The Bioloid doesn’t come with an explic-it curriculum, but we really think thatgoing through and building the robotsdetailed in the manual provides a comprehensive walkthrough of the con-struction and programming for the kit.

Also, we think that to be an effectiveeducational tool, the kit has to be widelyaccessible. Any bipedal servo walker canteach a roboticist of any level somethingabout human motion and mechanicallimitations and adaptation, but kitsupwards of one thousand dollars simplyaren’t going to reach that many people.The Bioloid beginner kit will presumablyonly run a couple of hundred dollars,making it far more accessible to roboti-cists, particularly novices looking for a kitwith which to get involved in robotics.

Once new roboticists are hooked bythe beginner kit, the Bioloid kit tells youexactly what additional parts you needto be able to build the intermediate andadvanced robots. This step-by-step pro-gression that leads up to a bipedal servowalker is effective for not tossing novicesdown a mercilessly steep learning curveand also for providing motivation to con-tinue working and learning with the kit.

The great motivation that the Bioloidprovides is that the new designs keep getting cooler and cooler. Once a bud-ding roboticist has built the spider, ofcourse they’ll want to build the king spider next. And if just the idea of a coolnew robot isn’t motivation enough, theCD comes with videos demonstrating theabilities of every design detailed in the kit.

The Bioloid is a truly inspirational kit.Even though our first experiences build-ing with it were a bit tedious, we quicklygot past that to realize that the Bioloid isflat out cool. And when there’s an edu-cational robot kit with great potential foreffectiveness that is undeniably cool,everybody wins. And that’s how the realTransformers would have wanted it. SV

Twin TTweaks ....

14 SERVO 01.2007

Recommended WWebsiteFor more information on the

Bioloid, go to www.robotis.com

BIOLOID RACECAR ... ER ... BUGGY!?

HobbyEngineeringHobbyEngineeringHobbyEngineeringHobbyEngineeringThe technology builder's source for kits, components, supplies, tools, books and education.

Robot Kits For All Skill Levels

Motors, Frame Componentsand Scratch Builder Supplies.

ICs, Transistors, Project Kits

BEAM Kits and Components

Books andEducational K

Most orders ship the day received! World-wide shipping. Convenient payment options.

Order by Internet, phone, fax or mail.

www.HobbyEngineering.com

1-866-ROBOT-501-866-762-68501-650-552-9925

1-650-259-9590 (fax)[email protected]

180 El Camino RealMillbrae, CA 94030

Visit our store near SFO!

TwinTweaks.qxd 12/7/2006 1:34 PM Page 14

tSSSS CSSS CC t ™

helping change the face of robotics

Interactive Cybernetics’ REX model uses 46 servos controlled exclusively by Yost Engineering’s ServoCenter 3.1 controller boards.

REX shows a few of its many expressions

“Unlike other servo controllers,the unique features of the YostEngineering ServoCenter 3.1controller allow us to producelifelike facial expressions andrealistic lip sync” says REX EXEXdeveloper Walter Buist.Buist.Buist.

Visit www.icrex.com for REX scheduled

icrex.commmcococrecre

The

servo motors.

The independent control of both servo

position and speed makes the ServoCenter

controllers especially us

applications such as robotics, animatronics,

motion control, automation, retail displays,

and other areas where independent or

www.YostEngineering.com

SERVO 01.2007 15

Full Page.qxd 12/6/2006 10:21 AM Page 15

16 SERVO 01.2007

Q. I have an odd question foryou. I am thinking about buying a mini-lathe, but find it

hard to spend that much money on justone tool. Can you give some reasonswhy a hobbyist would want to buy onefor their own use?

— Troy AlexsonToronto, Canada

A. The first thing that needs to beconsidered is, if it is really need-ed. There are a lot of parts that

can be bought that would meet yourneeds. Sometimes they are not thebest fit, but they can be either modi-fied, or the rest of the project’s designaltered to fit the parts. Even if you havethe tools to make the parts yourself,many hobbyists still look for existingparts to use first before resorting tomaking them themselves. In mostcases, it is less expensive to purchase

parts than to build them yourself.But it is always nice to have your

own tools to make the exact parts thatyou want. Sometimes this is for func-tion, sometimes it is for appearance,and sometimes it is to save money.When people need a special or criticalpart they can’t buy off-the-shelf, theyare left with three choices: abandon theneed for it, have someone make it foryou, or make it yourselves. If you have afriend make the parts for you, you usually end up compensating them fortheir time. If you go to a machine shop,this will cost you more money than hav-ing a friend make it for you. Dependingon what the part is, a machine shopmay be the only practical option.

In my case, I bought a mini-lathe tosave money. Well, I always wanted one,anyway. I had a project where I neededsome special hubs to mount some R/Ctires to an axle and hold a sprocket to

the hub. I made up some drawings andsent them to local machine shops. Thequotes I got were around $600 for theset of hubs. Well, at that time, the mini-lathe I wanted cost a little lessthan $400. So I bought a lathe andabout $100 worth of tools to go withit, and made the hubs myself. In theend, I got the hubs made, saved a$100, and got a lathe for a bunch ofother projects. So buying the lathe canactually save you money.

For most people, making partswith their own hands is what bringsthem joy, and it is the main reason whythey buy the tools for their hobbies. It’sa really addicting passion, making pre-cision parts to make machines work.This is why the whole robotics hobbyexists, making things for yourself.

If you decide to get a lathe, Iwould recommend that you get a bigger lathe than you think you will

need (assuming you can affordit). Eventually, you will want tomake things bigger than thelathe you are currently looking atcan handle. The machines them-selves are usually the cheapestpart of the expense. All of thetooling that you get to use thelathe eventually costs muchmore than the lathe does. And ifyou end up getting a biggerlathe down the road, you mayfind out that all the tooling thatyou currently have no longerworks with the new lathe. So, tosave money in the long run, getthe bigger lathe up front.

Tap into the sum of all human knowledge and get your questions answered here!From software algorithms to material selection, Mr. Roboto strives to meet youwhere you are — and what more would you expect from a complex service droid?

byPete Miles

Our resident expert on all things robotic is merely an Email away.

Figure 1. Lynxmotion Wireless PS2 Controller. Figure 2. Lynxmotion PS2 Adapter Cable.

MrRoboto.qxd 12/7/2006 8:21 AM Page 16

Q. I recently got a wireless PS2controller from eBay toremotely control one of my

robots. The problem I have is that Ican’t get it to work with my BASICStamp. I have tried using the exampleprograms that you showed in the July‘06 issue, but they don’t work. I knowthe controller works fine since it workson my Playstation. Do you have anyidea why your example program workswith a regular PS2 controller, but does-n’t work with a wireless PS2 controller?

— Mark MartinVia Ethernet

A. Thanks for pointing this out.When I wrote that article, Iassumed that a wireless controller

would work the same way as a regularPS2 controller. Since I didn’t have a wireless controller to test at that time, Imade this incorrect assumption. Thecode I presented was based on the codeby Aaron Dahlen on his PS2 controllerarticle controlling a five-axis Lynxmotion(www.lynxmotion.com) arm pub-lished in June ‘03 in Nuts & VoltsMagazine (www.nutsvolts.com), andJon Williams’ PS2 article that was published in September ‘03 in Nuts &Volts. These example programs all workwell with a regular wired PS2 controller.Lynxmotion has quite a few exampleprograms using the PS2 controller with

their robots. Most of the example programs from Lynxmotion use theBasic Atom microcontroller (www.basicmicro.com), which is fast andquite powerful.

In order to try to figure out why awireless controller doesn’t work thesame way as a regular wired PS2 controller, I obtained one of the newwireless controllers that Lynxmotionsells (model number RC-01); see Figure1. At $19.95, it is a pretty good dealfor a wireless controller, cheaper thanthe regular PS2 controller I have. As aside note, I like the feel of Lynxmotion’swireless controller in my hand becauseit is a little larger in size and is easier tohold. Lynxmotion also has a very handyadapter cable for the Playstation compatible controllers (Model NumberPS2C-01) that has the odd shaped con-nector that plugs into the controllerand has a set of regular 0.1 inch spacing connectors that easily interfacewith other electronics; see Figure 2.Their $4.95 price tag make this connec-tor cable a better choice than buyingand hacking the six foot extensioncable I mentioned in my July article.

When I got the controller, I hookedit up to the same test setupshown in my July article, and tomy surprise, it did not work.And just like you mentioned, itworked perfectly when I

plugged it into my Playstation gameconsole. This was very puzzling.

To try to figure out what is goingon, I tapped into the test circuit with myParallax USB Oscilloscope (www.parallax.com part number 28119) to analyzethe signals going between the controllerand the BASIC Stamp. I discovered something very different than what wasexpected (see http://sophiateam.undrgnd.free.fr/psx/index.html). Thespec says the data signal begins whenthe clock signal changes from high tolow (leading edge); see Figure 3. Butwith the wireless controller, the datasignal actually begins before the clocksignal, and changes state when theclock signal changes from low to high(trailing edge); see Figure 4. Figure 5shows a screen capture of the first twobytes of data, device ID $73 analogmode, and ready $5A.

With this bit of knowledge, itbecomes obvious that the previous pro-gram shouldn’t work with a wireless con-troller since the SHIFTIN function’s Modewas configured to use the LSBPOST(read the data Least Significant Bit firstafter sending the clock signal) mode.Since the data bits actually occur before

LSB MSB

CLOCK

DATA

$73 (11001110)

Figure 3. Standard (wired) PS2 Data Signal.

LSB MSB

CLOCK

DATA

$73 (11001110)

Figure 4. Wireless PS2 Data Signal.

Figure 5. Screen capture of the Parallax USB Oscilloscope. Blue line is the clock line, and the red line is the data line.

SERVO 01.2007 17

MrRoboto.qxd 12/7/2006 8:21 AM Page 17

the clock signal, the SHIFTIN’s modeneeds to be changed to LSBPRE (readthe LSB before sending the clock signal).

The program shown in Listing 1includes these changes, and will work

with both wired andwireless controllers.Only one line ofcode needs to bechanged, depend-ing on whether youare using a wired orwireless controller.If you are using a regular wired controller, set theMode to 3, and setthe mode to 1 for awireless controller.Figure 6 shows the electrical wiring

for this circuit.This doesn’t answer the whole

question, however. The wireless con-troller has a much tighter timing require-ment than the regular PS2 controller. If

the Stamp takes toolong to process thedata to and from the controller, thewireless controllerwill time out for amoment and lose itswireless connectionwith the receiver,and only sporadicinformation is trans-mitted. I have triedthree different BASICStamps with this pro-gram. The BS2p24and the BS2px24 arefast enough to keepup with the commu-nications with thewireless controller,but the regular BS2Stamp doesn’t workbecause it is tooslow.

I am not theonly one that hasobserved all this.Read the discussionson the Parallaxforums (http://forums.parallax.com/forums/default.aspx?f=5&p=5&m=138508) aboutwhat other peoplehave learned. Itlooks like the

MadCatz (www.madcatz.com) andthe Lynxmotion controllers requirefaster speeds to keep up with the controllers, whereas the Pelican (www.pelicanper formance.com)and Thrustmaster (www.thrustmaster.com) have been shown towork with regular BS2 Stamps.Logitech (www.logitech.com) has awireless controller, but I haven’t heardof anyone successfully interfacing theircontroller with a microcontroller.

It is interesting how processor speedhas a significant effect on how well youcan interface a wireless controller andnot critical when interfacing with a regular wired PS2 controller. For exam-ple, a Basic Atom microcontroller doesn’tneed to read the data in before the clockpulse (LSBPRE mode), whereas theBASIC Stamp does. In fact, the BasicAtom will not even work if you try toread the data in before the clock pulse.It needs to use the LSBPOST mode in theShiftIn function to properly read in thedata. Measurements on the actual clocksignal from a Playstation console indicatethat its natural clock speed is about 125kHz. Since it is transmitting 21 bytes ofdata, the time required to read in thedata from both controller types is about0.3 ms. A Basic Atom will read in thedata in about 4.5 ms. This speed is prob-ably why the Atom syncs up well withthe controllers. A BS2px24 takes about13.8 ms to read in all the data from thecontroller. Though the Stamp still works,it requires reading in the data in a different format. A regular BS2 Stamp isabout six times slower, and does notsync up with the Lynxmotion wirelesscontroller. This indicates that the com-mon overlap time where both systemswork is not much slower than 14 ms.Figure 6 illustrates this. Slowing the clockspeed increases the common overlaptime, but longer clock times can result inthe wireless controllers timing out.

Interfacing a microcontroller to awireless controller is pretty straight-forward, but it should be done with thefaster microcontrollers such as a BS2px24,Basic Atom, or even the new Propellerchip from Parallax. This is kind-of a longdiscussion about wireless controllers ingeneral, I am hoping that it provides youenough information to get your controllerto work with your robot. SV

LSB MSB

CLOCK

STANDARDPS2 DATA

WIRELESSPS2 DATA

COMMON TIMEOVERLAP

Figure 6. Data signal comparisons between wired andwireless controllers with respect to the same clock signal.

‘{$STAMP BS2px}‘ {$PBASIC 2.5}‘ This demo program has been shown to work with‘ BS2p24 and BSpx24, and does not work with regular‘ BS2 Stamps with the Lynxmotion wireless controller.

clk PIN 7 ‘ Clock Lineatt PIN 6 ‘ Attention Linedat PIN 4 ‘ Data Linecmd PIN 5 ‘ Command Line

Mode CON 3 ‘ 1 = Wireless Controller = LSBPRE‘ 3 = Wired Controller = LSBPOST

Temp VAR Byte(8) ‘ Controller datai VAR Byte ‘ Loop Counter

‘ Main Wireless Controller loop

Main:GOSUB Wireless_PS2GOTO main

Wireless_PS2:‘ Read Controller mode $41=digital, $73=analogLOW attSHIFTOUT cmd, clk, LSBFIRST, [$01]SHIFTIN dat, clk, mode, [temp(1)]HIGH att‘ Read controllerrLOW attSHIFTOUT cmd, clk, LSBFIRST, [$01,$42,$00]FOR i = 2 TO 7

SHIFTIN dat, clk, mode, [temp(i)]NEXTHIGH att‘ Display ResultsDEBUG CRSRXY, 0, 2,”Mode: “,IHEX2 temp(1), “ “, CRDEBUG CRSRXY, 0, 3,BIN8 temp(2), “ “, BIN8 temp(3),

“ “, DEC3 temp(4), “ “, DEC3 temp(5), “ “,DEC3 temp(6), “ “, DEC3 temp(7), CR

RETURN

Listing 1

18 SERVO 01.2007

MrRoboto.qxd 12/7/2006 8:21 AM Page 18

Full Page.qxd 12/6/2006 10:13 AM Page 19

20 SERVO 01.2007

The “mobile or static, High OctaneRobotic Combat System” brings the

arena and ready-made battle botswherever an event or gathering hiresthe system and its operators/makers to come. Highly successful since 2004 when RoboGeddon debuted atLEGOLAND of Windsor (UK), the gamehas gone on to be a highly soughtattraction by amusement vendors andconsumers.

Part-speakRoboGeddon’s parts include the

Arena (either portable or “static” as

the creators like to say, meaning setpermanently in one place) and four 80kg robots. The robots can flip eachother over and get themselves uprightwhen fallen in battle (with player assistance by remote) by use of thesame, single flipper.

There is also a computerized gamecontrol system with music, a publicaddress system, and sound effects thatinteract with game play. Robots arecontrolled by radio transmissions.

RoboGeddon can be coin-operatedin “stand alone” mode (controlled bythe master computer control system),as in a large arcade attraction or be

operated by a live operator.During game play, you try to score

points by ramming your bot into theother player’s “bump goals,” behindwhich the respective players also control their robots. “The early prototype bumpers on the bots,” saysRoboGeddon representative AndrewCotterell, “were made of steel but wediscovered that a 80 kg robot travelingat 6 mph into another traveling at thesame speed tended to bend thebumpers — we now use plasticbumpers with shock mounts.”

A winner is decided by highestscore after a round of two minutes.

Contact the author at [email protected] David Geer

RoboGeddon It!Are You Getting It?

You could be getting into RoboGeddon — a good-sized scale versionof events like BattleBots or Robot Wars — without traveling very far.

The portable robot battle game comes to you via trailer at your local amusement park or event, as well as being available as a

permanent install at some attractions (mostly in the UK for now).

A RoboGeddon battle in progress, flippers a-flying! Fully inflated RoboDome surrounds RoboGeddonwhile crowds watch.

Geerhead.qxd 12/6/2006 11:48 AM Page 20

GEERHEAD

People WatchingAssessmentsSurroundingRoboGeddon

In actual play, younger children generally defeat olderkids because they have a muchgreater mastery of the joystickcontrol and a familiarity with it,according to the RoboGeddonmaker (RobotsRUs) companyrepresentative Andrew Cotterell.

Likewise, girls generally beat theboys as they concentrate more on howto score points and figure that part outmore quickly. “All the boys want to dois flip and bash other bots,” saysCotterell (not surprising). Sometimes,players will find out they have beenwatching the wrong robot and wonderwhy it isn’t responding to the actionsthey take with the controls.

Back to the TangiblesThe mobile version of RoboGeddon

comes with a trailer system withhydraulically-operated sides that dropdown to form the actual gaming plat-form. The platform installs in about anhour and is quite sturdy and permanentlooking. This is an “all-weather” gamingsystem with a site space requirement of11 meters square.

The RoboGeddon makers hadthought that it would take longer toput up the mobile system in badweather, but it actually takes less timeas the crew works harder to get it upand get out of the rain.

The trailer system is complete untoitself with a foldout “crowd barrier system.” Ask the company about additional add-on features. In additionto coin-operated and human-operatedgame play, RoboGeddon can be set upfor free play if you are providing itgratis for your family or guests. Gameplay is computer assisted.

The system is appropriate for indoorand outdoor attractions and anywhereguests or customers may congregateincluding theme parks, family entertain-ment centers, hotels, resorts, confer-

ence centers, fair grounds, trade shows,malls, museums, and go-kart tracks.

RoboGeddon’s gaming arena is 36square meters, topped by an inflatableRoboDome. Four Cyber Raptor robotscome with each setup and can bemanipulated to flip other robots over orout of the way or to put themselvesupright again once they have beenflipped. The flipping and repositioninghelps your robot to successfully get toan opposing robot’s corner to score.

Each robot is powered by a rapidrecharge cell that can be recharged inthe charge control system in about 45minutes. There are four spare cells sothat the robots don’t ever have to bewithout power.

The system also comes with instal-lation and maintenance manuals, aswell as training manuals for operation.Outside maintenance contracts areavailable from the company, as well as aphone number for expert consultation.

Static Install StatisticsA permanently installed

RoboGeddon can be had cheaperbecause the cost of the trailer system —which is not required — is subtractedfrom the total cost. Installs of the static system are highly customizable —including the size of the arena itself —to suit your permanent location.

This system is suitable for venuessimilar to those for the mobile systemand includes piers, zoos, campgrounds,and other locations. Multiple game formats are available for “programmedcomputer-assisted” play.

Systems also come with four player controls/consoles with coinoperation mechanisms, score panels,and bump goals. Remote score panelsare also available.

RoboGeddon cost around 900,000GBPs (about US $1.7 million) to buildfrom initial research to today’s product

RoboGeddon Raptor robot close-up.Player console close-up with lots

of colors and buttons.

SERVO 01.2007 21

RoboSoccer involves four playersand four robots in soccer play in aspace of about 7.5 by 5 meters.

This rugged system is designed tobe used constantly, so it is protected byimpact-resistant barriers and surround-ed by a crowd-retaining barrier.

Its integrated goal system and play-er control system are each fitted at bothends of the playing field, where playersstand and manipulate the controls for agame of soccer that can last up to fourminutes. The game system and equip-ment can be set up in three hours.

The system comes with four robotcombat vehicles for soccer play that can

maneuver the soccer ball and otherplayers around the playing field. Theactual area that is available for play is 24feet by 16 feet. There are two goal stations, two player stations, and eachstation controls two robots. The game isoperated by a computer system that isprogrammed to control cash paymentsto play or free play, as well as the soundsystem for effects and background musicand the robots. The robots operate onfour batteries/power cells — one each —and there are four spare cells, as well.

You can see RoboSoccer in the UKand via video clip (provided in theResources).

ROBOSOCCER — UNDER THE MICROSCOPE

Geerhead.qxd 12/6/2006 11:48 AM Page 21

22 SERVO 01.2007

over a three-year span.

UpgradesInitially, the game format was

extremely complex, too much so forthe general public to easily use andappreciate. Much of the engineeringand upgrades went into resolving thisproblem. The initial system was onlystatic, for example, which was tooexpensive a system to succeed com-mercially. This led to the mobile system.

The mobile system worked well forevents but theme parks and ongoingvenues required the static systems.

The robots themselves have beenimproved upon many times for reliability.Improvements to the four robots haveincluded improved drive belts, motorcontrol, lifter mechanisms, bumper sys-tems, crash absorption devices, powerhandling, heat control, sound use, playa-bility, and the ability to use add-ons.

Further planned upgrades includerobot feedback to the control systemso it knows how much power therobots have left. The system will soonbe able to tell for certain which robotsdo the actual flipping over. Right now,it only knows when points have beenscored. The game currently factorswho has won by the number of pointsgiven up by other opponents.

Rock ‘em, Sock ‘em,RoboSoccer andRoboDerby

RoboSoccer has just beenlaunched. This robot game uses the

same basic robot builds but no flippers.The game is played on a soccer fieldinside the game arena by two blue andtwo red robots. Players win by usingthe robots to score soccer goals.

The included soccer ball is 14 lbs.This is a coin-operated game for themeparks and similar venues. The robotsrun all day with no recharge.

RoboDerby is a soon-to-be-releasedrobotic horse that can carry an adult.RobotsRUs — the company behindRoboGeddon, RoboSoccer, andRoboDerby — plans to sell sets of fourrobot horses so the new owners cantransport them by trailer to events andrun the horses as robot race horses. By pulling the tail of the horse in frontof you, you can slow it down by 25 percent and gain the lead on it.

US AvailabilityRobotsRUs is in talks with many

domestic event promoters who haveexpressed an interest in involving themselves in bringing theRoboGeddon system to the UnitedStates. Stay tuned! SV

GEERHEAD

Trailer arena close-up with robots. Circuitry.RoboGeddon trailer, arena open

with dome, close-up.

www.robogeddon.com/index.aspRoboGeddon site

www.Robosoccer.co.ukRoboSoccer site

www.robogeddon.com/movies/Robosoccer_streamer.rm

RoboSoccer Streaming Video

www.robogeddon.com/links.aspRoboGeddon permanent install

locations and entertainment providers

RESOURCES

RoboGeddon is the first commer-cially sold, mobile robot combat system for game play, available in theUK for almost three years now.

The most unique design problemwas giving the robots the ability toreposition themselves upright fromwhatever laying position they hadbeen flipped in. Other challengesincluded keeping the system fun whilealso affordable.

The actual robots, according toRobotsRUs representative AndrewCotterell, are a cross between a BatMobile and a Humvee. They’re fast yet maneuverable, since they weredesigned by world champion robotbattlers and engineers, Team Razer.Those who have followed Robot Warsand BattleBots may know of TeamRazer, the Razer fighting robot, and IanLewis, designer and owner of Razer.

ROBOGEDDON FUN FACTSTeam Razer robot.

Geerhead.qxd 12/6/2006 11:49 AM Page 22

Electronic Parts & Supplies Since 1967

For the finest in robots, parts, and services, go to www.servomagazine.com and click on Robo-Links.

SERVO 01.2007 23

RobolinksJan07.qxd 12/7/2006 9:17 PM Page 23

Brushless Motor RPM Sensor

Eagle Tree Systems announces their innovative newBrushless Electric Motor RPM Sensor/Tachometer. The

brushless RPM sensor makes it easy to measure RPM.To measure RPM on a brushless electric plane, heli,

car, or boat, just tap one wire from the tiny new sensorinto one motor lead, enter motor parameters to the soft-ware, and you are ready to go. The brushless RPM sensoris compatible with Eagle Tree’s MicroPower, PowerPanel,Seagull, and Data Recorder products. Using the BrushlessRPM Sensor with Eagle Tree’s Seagull and Data Recorderproducts requires firmware level 4.XX or higher, which hasbeen shipping since approximately August 2005.

For further information, please contact:

All New SoundPlexer8000

The SoundPlexer8000 unit from GBInnovations will allow you to

record/playback sounds and routethem to any of the eight speaker out-puts, in any combination (for example,sound track 1 can be heard out ofspeakers 2, 5, and 7 or sound track 7can be routed to all eight speakerssimultaneously). The SoundPlexer8000 can also be config-ured to trigger these sounds via simple switches or PIRsensors (for example, sound track 2 can be sent to speak-ers 2, 6, and 8 when input 2 is triggered). Any combina-tion of speakers/inputs/outputs can be programmedthrough the intuitive menu system via the built-in LCD dis-play. The SoundPlexer8000 makes adding sound to anyenvironment/project easy.

What Can the SoundPlexer8000 Do?

Imagine the sound of a ghost following someonedown a hallway, or a haunted room with different soundscoming from different objects around the room. Or, howabout a model train layout with different sound effects

throughout the entire landscape, yet specific sounds atspecific locations when the train arrives or passes by.Perhaps you want to add different sounds to every roomof a dollhouse. Or, add sounds to your robot or animatron-ics character. All this is possible with the SoundPlexer8000.

SoundPlexer8000 features include:

• Records up to eight one-minute tracks.

• Built-in LCD display screen with an intuitive menu systemfor quick and simple programming, recording, and play-back. No computer or host system needed.

• Record from either the built-in microphone or line infrom any sound source line out.

• Playback any track through one or all eight speakerssimultaneously.

• Each output is capable of driving an eight-ohm speakerwith one watt of continuous and up to two watts of peakpower.

• Master volume control.

• Eight selectable inputs which are edge triggered. Eitherlow or high going sensor pulses will trigger the input.

• Programmable delays which will delay the track fromplaying after an input has been triggered.

• Program any switch input to trigger any track (sound)out of any of the eight speakers via the user programma-ble “Play list.” Play lists are stored in EEPROM for dataretention.

• Built-in +-5V supply, via phoenix-style connectors for allsensors/switches.

• PIR sensor compatibility.

SoundPlexer8000s are being distributed through BluePoint Engineering and can be ordered directly from BluePoint Engineering’s website.

For further information, please contact:

New Products

SENSORS

SOUND PROCESSING

Tel: 631•891•8034Email: [email protected]

Website: www.bpesolutions.com/asoundeuipspecial.html

GB Innovations

24 SERVO 01.2007

NNEEWW PPRROODDUUCCTTSS

4957 Lakemont Blvd. SE, Ste. C-4, PMB 235Bellevue, WA 98006

Email: [email protected]: www.eagletreesystems.com

Eagle TreeSystems

Jan07NewProd.qxd 12/7/2006 7:55 PM Page 24

SERVO 01.2007 25MaximumRobotics.com

1-800-979-9130

Wiring Robot Controller· 43 Digital I/O Pins· 8 Analog Inputs· 8 External Interupts· 6 PWM Channels· 2 Serial Ports includingBi-Directional USB

· 128k Memory· The Wiring Programming Language

The Wiring language provides a simplifiedsubset of C or C++ that hides more advancedconcepts like classes, objects, pointers (while stillmaking them accessible for advanced users). You getthe power of C or C++ with the ease of a language likeBasic. Programs written in Wiring are translated andthen run as C++ programs on the Wiring I/O board.

*Use code servo0107. Offer expires 2/28/2007

GrandOpening Sale!15% off yourfirst order!*

$69.95 Only $59.46 after discount!

Page 25.qxd 12/7/2006 7:49 PM Page 25

Featured This MonthParticipation26 First Aid for Bot Builders

by Kevin Berry

27 Entering Combat Robotics ata Young Age by Aaron Taggart

Feature28 Gone Postal: The Building of

a 12 lb Robot by Brian Benson

Events29 Results — Oct. 14 - Nov. 1332 Upcoming — Jan. and Feb.

Technical Knowledge30 Four Bar Lifters in Combat

Robotics by Adam Wrigley

Product Review32 Astroflight 109 Charger

by Bradley Hanstad

Bot builders are famous for getting minor “dings” when

building bots, both at home andin the pits. Every builder shouldhave a minimal first aid kit around,with bandages, peroxide, antibiot-ic ointment, and aloe vera (forminor burns). The other thingbuilders should have in their kits isa sense of their own vulnerability.Some injuries can be safely treatedat home, some require medicalassistance. A few need immediate9-1-1 calls!

I’ve seen a builder, in theabsence of proper supplies, pokehimself in the knuckle with apower drill, staunch the bleed-ing with a dirty paper towel,and slap a strip of duct tapeover the whole enchilada.Two days later, after finish-ing the bot and competingin the event (I won, by theway), this mystery manfinally treated the woundwith proper supplies, and

amazingly didn’t get bloodpoisoning. I, er I mean, he,

seemed to think germs had the same priorities he did — that is,finishing the bot counted morethan treating wounds.

Some things, such as bleedingpuncture wounds, chest pains, dizzi-ness, and double vision, need imme-diate medical attention. A dead botbuilder is good to no one, and bythe way, can’t compete in events (atleast in most of them, anyway.) Sobuild safe, and judge well when itcomes to injuries and illnesses. Tomangle an expression, “the builderwho has himself for a doctor has anidiot for a patient.” SV

26 SERVO 01.2007

PARTICIPATI NFirst Aid for Bot Builders

● by Kevin Berry

CombatZone.qxd 12/6/2006 11:39 AM Page 26

SERVO 01.2007 27

So, you may have seen the showBattlebots on TV, or heard about

the Robot Fighting League (RFL) orthe North East Robotics Club (NERC)in the local news or on the Internetand liked what you saw. If you werelike me, you probably thought toyourself “Hey, that looks like fun, Icould do that!”

The first time I saw Battlebots onTV I was 11 years old and flippingthrough the channels one day when Iwas bored. I became hooked on theshow, and followed it from then onuntil its final season on Comedy Centralin 2002. Around 2000-2001, I startedto get more interested, looked aroundonline for more information, and foundthe Battlebots Forum on Delphi. Ilurked around for a while beforebecoming a member in late 2001. Icasually chatted with other builders inthe chat room, who were very helpful.

Around 2002 I discovered theNorth East Robotics Club, which wascomposed of smaller events primarilybased around the Pennsylvania–NewJersey area with weight classes ranging from 1 lb to 30 lbs. In June of2003 when I was 13, I went to my firstevent, 12 lbs of Pain, hosted by Poundof Pain and the NERC in Concord, NH.I went to watch, and to see whatgoing to an event in person was like,since I had only seen videos onlineand Battlebots on TV. The fights weregreat and the builders — some ofwhich I had talked to previously online— were friendly. I then competed atmy first event in August of the sameyear, in Syracuse, NY that was hosted

by Team Infinity, the builders of theSuper Heavy Weight robot “FinalDestiny,” who had appeared on TVon Battlebots. I did pretty well for myfirst time, placing 3rd with three winsand two losses, losing to the 1st and2nd place robots.

Since then, I have competed at20 events and attended 23. Therehave been times when I was frustratedenough to think about taking a breakfor a while after doing poorly at anevent, but then I bounced back anddid well for the next few. As of thiswriting, I have the #1 ranked active 12-lber, according to Botrank (anonline robot ranking service), and the3rd ranked 12-lber historically. There isno limit to what you can do if youapply yourself and are willing to learn.

The best advice I can give toyoung people is to look around. Lookat people’s websites, read buildreports, and watch fight videos. Thiswill help you get an idea of what isgoing on, and also give you someideas of your own. Be prepared tolearn a lot. There are a lot of tricksyou can pick up by watching whatothers do. There are no real “tricks towinning,” but there are plenty ofways not to lose. If you find an eventgoing on near you, go check it out.You will have a good time, you willget to see the robots in person, andyou will meet the builders. Do yourbest to make some friends in thecommunity, which will help youimmensely in the future; a goodfriend goes a long way. I would notbe nearly as successful now if it

weren’t for the advice given to me byfriends Jr. of Team Mad Cow, Jon ofTeam Anarchy, and James Arluck.

With their advice, tricks, andgeneral knowledge I was able tolearn a lot of things I would neverhave thought of on my own. Thebest part of going to an event is thatyou can see first hand what worksand what doesn’t. There isn’t reallyanything to be taught in a classroomabout this, as it is more of anacquired skill/understanding. Youwill pick up many skills that can beuseful later in life if you decide to pursue a career in engineering, man-ufacturing, or machine work, and italso looks good for college applica-tions as an extra-curricular activity.

One important thing to remem-ber is if you come off as a jerk, people will generally react in anaccording manner. (Don’t be the per-son who gets ribbed on all the time,you want to be with the in-crowdwho does the ribbing.) The easiestway to get on the nerves of buildersis by asking questions that haveanswers that are easy to find. Whenonline, poor spelling turns off a lot ofpeople — so use some kind of a spellchecker. When you go to your firstevent as a competitor, remember to

Entering Combat Robotics at a Young Age● by Aaron Taggart

Author at House of NERC 2006 working onRants Pants. Photo taken by Jon Durand.

From left to right: Brad Handstad, Chad New,Darci Trousdale, Aaron Taggart, Jon Durand.

Photo is from 2005 RFL Nationals in San Francisco, CA.

Author and Vadim Chernyak setting upthe arena at the House of Slackers event.

Photo taken by Ray Barsa.

ResourcesRFL — www.botleague.net

NERC — www.nerc.us

Botrank — www.botrank.com

BuildersDB — www.buildersdb.com

CombatZone.qxd 12/6/2006 11:39 AM Page 27

28 SERVO 01.2007

bring all of your parts and tools youwill need. It is always important tohave spares, as well as tools andother necessities such as a power-strip so that you don’t constantly

have to go hunting for tools fromothers. However, do note that manybuilders will be more than willing tolend you a tool or plug into theirpower strip, but remember to bring

back what you borrow. There is avast amount of information availableon the Internet, and the best way toget ahead and off on the right foot isto use it to your advantage. SV

There are many different tech-niques and approaches to building

12 pound combat robots. They rangefrom the extreme of designing theentire robot on the computer, to thegathering of a pile of parts and put-ting it together whatever way looksbest. For builders that are just begin-ning, the second method is a greatway to get a robot built, have somefun, and gain some experience. I hadonly two weeks to build Gone Postal,so this technique worked out well.

I decided I was going to build a12 lb robot because many of theparts I had would fit easily into arobot that size, and I could cost-effectively use cordless drill motorsand batteries. My first step was deter-mining what type of weapon therobot would have. After consideringa variety of designs, I concluded thata hammer robot would be the bestchoice. It would allow for the driveand weapon motors to be the same,it would be easy to build, and notmany hammer robots were around soit would be a little different.

Components

My first choice before buildingthe robot was picking the mechanical

components and the materials tobuild the frame out of. For themechanical and electrical compo-nents, I choose: two IFI Victor 833speed controllers because I alreadyhad them on hand; three 12 voltHarbor Freight cordless drill motors;batteries from the drill for power; aTeam Delta Bigger Dual Ended Switch(Part #RCE225) to control the hammermotor; a PCM receiver; and 4” Colsonwheels. For building materials, I want-ed something durable, lightweight,and easy to work with. I chose 1/2inch thick UHMW (ultra high molecu-lar weight polyethylene) for the sides,1/8-inch thick 6061 aluminum for thebase plate, and .09-inch thick surpluscarbon fiber sheet for the top plate.With my pile of parts gathered, I couldbegin on the robot!

Organized Pile of Parts

I began by assembling the batter-ies; building two 12 volt packs usingthe cells that had come with the drills.Now that I had the basic compo-nents, I played with different layoutsuntil I found one that I was happywith based on how well it would driveand perform and how compactly it fittogether. I then weighed everything

in order to get a basic idea of howwell I would meet the 12 lb maximumrequirement, shown in Figure 1.

The Frame

With the components chosen, Iwas able to determine the basic framesize and begin. I cut the 1/2” UHMWouter frame with a wood saw and thealuminum base plate using a plasmacutter, although a jigsaw would havealso been a fine substitute for theplasma cutter for those without one.Figure 2 shows the frame membersand base plate laid out.

Drive Train

Now that I had a frame, I neededto start on the drive train. I used off-the-shelf wheel hubs made specificallyfor attaching Colsons to drill motors. Imodified the drills to lock the clutchand used more of the 1/2” UHMW forthe motor mounts. I cut out the cen-ter holes with a hole saw on the drillpress and a scroll saw for the secondsquare shaped hole. Figure 3 shows

FIGURE 1. Weighing the components. FIGURE 2. Test-fitting the frame pieces.

FIGURE 3. Motor mounts cut out and ready to go.

GONE P STALTHE BUILDING OF A 12 POUND ROBOT

● by Brian Benson

CombatZone.qxd 12/6/2006 11:40 AM Page 28

SERVO 01.2007 29

the finished mounts ready for use.

Finishing Touches

With the motor mounts com-plete and sides cut out, all I had leftto do on the base plate was to cutout the holes for the wheels, which Idid using a plasma cutter. With eachsubcomponent complete, it was timeto combine them. I decided to use10-24 size screws to fasten it togeth-er. The motors were mounted, thesides were attached to the baseplate, and the electronics shockmounted. Shock mounting is alwayscritical for electrical components. Asyou can see in Figure 6, the speedcontrollers and relay board wereshock mounted to an 1/8” sheet ofpolycarbonate, which was then shockmounted to the frame. The batteriesmust always be easily accessible; tomeet this requirement, I chose to useVelcro straps to secure them.

At this point, as you can see inFigure 4 the robot was missing thefront half. For this, I chose a wedgeto allow me to gain control of otherrobots to help me use my hammer toits full effect. After choosing anangle, I made the wedge andattached it using the same methodsas the rest of the frame. Figure 5

shows the robot nearly done!Everything was complete except

for the top armor, the hammer, and thewiring. I made the top armor out of .09inch carbon fiber sheet for its strengthand minimal weight. For this, I used adiamond wet saw, the key word beingwet. Carbon fiber dust can be extreme-ly harmful and should not be breathedin under any circumstances.

Through a combination of hav-ing water constantly pumping ontothe cutting edge to eliminate dustand a respirator, I was able to easilyand safely cut the top plate. The ham-mer was more fun, for this I found apiece of 1/8” steel and used the plasma cutter to create the hammershape I was looking for. To attach thehammer to the drill, I took advantageof the threaded shaft, clamping thehammer arm between the shoulderof the shaft and a tightened nut. Thenut and threaded shaft then had an1/8” hole that a pin went into tokeep the nut from backing off. Witheverything mounted and ready to go,I wired the robot up using primarily14 gauge wire. Figure 6 shows GonePostal at the event ready for battle.

Conclusion

Overall, Gone Postal has under-

gone four iterations since it was firstbuilt, gaining spring steel armor overthe side UHMW and a titaniumwedge and hammer arm. In eachiteration, it has become a little smaller and a little tougher, but thesame core building techniques havebeen used each time.