SERVICE MANUAL · vss cnvss xin osc2 osc1 p.fail remocon x-ray blue b green g red r blank cvin...

Transcript of SERVICE MANUAL · vss cnvss xin osc2 osc1 p.fail remocon x-ray blue b green g red r blank cvin...

SERVICE MANUAL

COLOR TELEVISION RECEIVER

ORIGINALMFR’S VERSION A

DBTV1901

Design and specifications are subject to change without notice.

SERVICE MANUAL

REVISION 1MFR’S VERSION C

Please file this revision with the original version.

COLOR TELEVISION RECEIVER

DBTV1901

C

A

MFR’S VERSION PCB010 PCB110

TMX494A

TMX494B

TCX352A

TCX352B

Change of PCB

PART NO. DESCRIPTION PART NO. DESCRIPTION

R416 R002T2010J RC 1 OHM 1/2WC422 P613T1154J CMPL 0.15 UF 100V TF

PCB010 A3J907A01AMAIN PCB ASS'Y (VERSION A)TMX494A A3J907A010

MAIN PCB ASS'Y (VERSION C)TMX494B

PCB110 A3J907A11ACRT PCB ASS'Y (VERSION A)TCX352A A3J907A110

CRT PCB ASS'Y (VERSION C)TCX352B

MAIN PCB's and CRT PCB's are not interchangeable.

ADD R416C422

MFR'S VERSION CMFR'S VERSION A

REF. NO.

ELECTRICAL REPLACEMENT PARTS LIST

PRINTED CIRCUIT BOARDS

SOLDER SIDE(VERSION C)

MAIN/CRT (INSERTED PARTS)

IC401

ADD R416C422

DEFLECTION/CRT SCHEMATIC DIAGRAM (MAIN PCB)(VERSION C)

M3J9-07A

W163007

SPEC.NO.

O/R NO.

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

S802Y

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:

C130

0.01 B

C004

0.1

F

C140_1

0.001 Y

C141

0.1 F

C136

0.1 FC139

0.1 F

C121 220P B

C113

12P CHC114

12P CH

C119

0.1

F

C124

0.01 B

C138

560P

W

C120

0.001 CH

C1010.001 CH

C126 0.01 B C127 470P B

C002

470

6.3V

YK

C003

4.750V KA

C115 0.

150

VKA

C122 150V KA

C123 10

25V

KAR607

100

R139 100

R117

15K

R111

22K

R133 1K

R130 1K

R127

2.7K

R126

2.7K

R101

560

R123

4.7KR122

4.7KR121

4.7KR120

4.7K

R124

4.7K

R104

820

R103

820

R102

820

R001

18K 1/2W

R002

18K 1/2W

R112

2.2KR113

2.2K

R141

270

R142

270

R128

560

R115

47K

R132

47K

R129

1M

R134

470

R118

47K

R108

100R107

100

R143

47

R105 4.7K

R106 4.7K

R110 1K 1/4W

R125

47K

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

D607 MTZJ5.6B

D001

MTZ

J30B

D604 MTZJ5.6B

W814

W806

W840

W845

W835

L101

3.3u

H

SW10

1SK

HVBE

D010

CH U

P

SW10

2SK

HVBE

D010

CH D

OWN

SW10

3SK

HVBE

D010

VOL

UP

SW10

4SK

HVBE

D010

VOL

DOW

N

SW10

5SK

HVBE

D010

POW

ER

TU001 ENV56DB6G3

11011

1213

1415

23456789

C118

3306.3V YK

C128

_1

330

6.3V

YK

IC19

9S-

24C0

2BDP

-1A

MEM

ORY

IC

1234

5 6 7 8

GND

B+Vout

OS101PIC-37143SY

1 2 3

IC101 OEC7073AMICON IC

110

1112

1314

1516

1718

192

2021 22

2324

2526

2728

29

3

3031

3233

3435

3637

38394

4041

42

56

78

9

DEFLECTION SIGNAL

B.SIGNALG.SIGNALR.SIGNALTUNER VIDEO SIGNAL

TM101RC-DW010

AGC

GND

IF

TUNER+5V

+B

X-RAY

DEGAUSS

AUDIO_MUTE

H_CTLPROTECT_HI2C_OFF

AFTSYNCHD

VD

OSD_B

OSD_G

OSD_R

OSD_BLK

SDA

SCL

CLOCK_CONT

POWER

FSC

RESET

AT+5V

AT+5VBACKUP

Y_VIDEO

POWER

1

2

43

TO SOUND/AV

TO SOUND/AV

(MAIN PCB)

G-2G-1

FROM/TO CHROMA

FROM POWER

FROM DEFLECTION/CRT

FROM/TO CHROMA

ACCESSORY

TMA525

0.8

5.2

3.2

5.2

5

5.2

4.8

4.8

4.8

5

4.98

4.7

4.7

5.2

2.8

5.2

3.6

0.9

2.26

1.05

5.2

4.98

0

0

0

0

4.98

0

0

0

0

0

4.95

2.27

5

4.99

2.69

0

0

0

5.2

NC

NC

IF BTL

BPL

V.S

SDA

SCL

ADRE

S

AGC

30.0 4.6

6.2

1.3 NCNCNC NCNC0 0 0

4.9

4.8

4.8

MICON/TUNER SCHEMATIC DIAGRAM

0

4.8

4.9

VCC0

Xout

VSS

CNVSS

Xin

OSC2

OSC1

P.FAIL

REMOCON

X-RAY

BLUE B

GREEN G

RED R

BLANK

RESET

CVIN

V.HOLD

HLF

SCL1

SDA1

FSC IN

POWER

CLOCK CONT

V.SYNC

H.SYNC

I2C_OFFSTANDBY_H

SYNC

AV1

AV2

X-RAY_TEST

KEY2

KEY1

AFT

FILT

H_CTL

PROTECT_H

NC

NC

NC

NC

AUDIO MUTE

EXT MUTE

ON TIMER

DEGAUSS

NC

4.8

0 0 00

4.904.8

VSS

E2 E1 E0VC

C

MOD

E

SCL

SDA

PCB010

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

S802X

X602

3.57

9545

MHz

IS NON POLAR ONE.THE ALUMI ELECTROLYTIC CAPACITOR MARKED NPTHE RESISTOR MARKED F IS FUSE RESISTOR.NOTE:

D601

1SS1

33

D605

11E1-EIC

Q609KTC3198

H.CTL

Q603KTC3203_Y

REG

Q605

KTC3203_Y

REG

Q604KTC3203_Y

REG

Q606KTC3203_Y

REG

Q610KTC3198

H.CTL

C627 1

50V

NA

AUDIO SIGNAL

IC601M61250FP

CHROMA IC

1 10 11 12 13 14 15 16

1718

19

2

2021

2223

2425

2627

2829

3

3031

32

33343536373839

4

404142434445464748

49

5

5051

5253

5455

5657

5859

6

6061

6263

64

7 8 9

CF603SFSRA4M50CF00-A0

CF604TPSRA4M50C00-A0

CP60100_8283_0611_00_000

1

2

3

4

5

6

R629 33

3W

GNDOUTOUTIN

CF601_1TSF5229P3

1 2 3 4

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:

C637

0.01

B

C626 0.01 B

C602 0.01 B

C634

100P CH

C607

0.01

B

C616

15P

CH

C623 0.0033 YC655

0.0068 Y

C606

100P

CH

C639

0.01 B

C618

22P

CH

C622

0.02

2B

C621

0.01

B

C640

0.01

B

C614

336.3VKA

C601

100

6.3V

YK

C603 1

50V

KA

C628

0.2250V KA

C613_2

163V MKT

C619

_1

2.2

50V

YK

C625 1

50V

KA

C645

4716

VYK

C635

4716

VYK

C632

0.150V KA

C624 47

16V

YK

C647 1

50V

KA

C638

1050

VKA

C630 47

16V

YK

C612

1000

10V

YK

C629 1

50V

KA

C642

150V KA

C605

0.4750V KA

C604 150V KA

R148

100K

R606

10K

R602 1K

R621

1K

R624

47

R616

10M

R614

2.2K

R619

2.2K

R625

2.2K

R630 100

R627 100

R617 1K

R631 100

R601

2.2K

R635

100

R639

1.5KR6

28

100

R623 120 1/4W

R626

22K

R632

220

R646

47K

R638

22K

R642

1K

R648

1M

R612 1K

R633

8.2K

R615

470

R622 68

R605

4.7K

R641

27K

1/4W

R146

220

R609

220

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

D606

MTZ

J6.8

B

D612

MTZ

J12BD6

10M

TZJ1

2B

D602

MTZ

J8.2

B

D611

MTZ

J12B

W833

W82

3

W818

W82

0

W817

W834

L607

15uH

DEFLECTION SIGNALB.SIGNALG.SIGNALR.SIGNAL

TUNER VIDEO SIGNAL

UNREG+12V

VIDEO_IN

AUDIO_OUT RESET

AUDIO_IN

GND

CLOCK_CONT

RESET

Y_VIDEO

AT+5V VDAT+5VBACKUP H_CTL

TUNER+5V

OSD_

BLK

PROTECT_HAGCSYNC

V_OUT

ABCL

OSD_

G

OSD_

R

OSD_

B

V_FEEDBACK

IF GND

H_OUT

HD

AFT

H_SYNC

B.OUT

G.OUT

R.OUT

CLAMP

GND

HDPOWER

OSD_BOSD_BLK

OSD_GVD

OSD_R

SYNC

I2C_OFF

SDA

SCLFSC

CLOCK_CONT

5

7

10

98

FROM MICON/TUNER

FROM POWER

(MAIN PCB)

G-4G-3

2.21

5.69

TMA525

60

7.9

6

5

5.63.183.12.51.84.72.808.72.55NC

7.96008.631.70 00

3.6

4.92

3.2

4.8

4.7

0

4.7

4.8

2.4

2.8

2.8

2.8

3.6

4.8

4.8

4.9

3.63.63.60866003.452.74.24.84.82.634.62

1.51

1.51

2.86

2.86

2.27

4.5

2.19

0

0

3.2

3.15

3.08

2.5

2.38

5.65

NC

TEST POINT

FROM SOUND/AV

NC

6

11 12 13

FROM/TO DEFLECTION/CRT

CHROMA SCHEMATIC DIAGRAM

4.9 7.2

5.5

7.2

5.5

8.8

5.54.9

R OU

T

G OU

T

VIF

Vcc

VIF

Vcc

V OU

T

V RA

MP

FEED

BACK

AFC

FILT

ER

DEF

GND

DEF

GND

FBP

IN

H OU

T

STRA

T UP

Vcc

INTELLIGENT MONI

INV FBP OUT

V PULSE OUT

B IN

R IN

G IN

FAST BLK

CLOCK CONT

SDA

SCL

POWER ON CONT

MCU RESET

Y SW OUT

VIDE

O/CH

ROM

A GN

D

VIDE

O/CH

ROM

A GN

D

CHRO

MA

APC

FILT

ER

EXT

C in

VIDE

O CH

ROM

A Vc

c

VIDE

O CH

ROM

A Vc

c

TV/Y

IN

33 ACL/ABCL34 X’TAL

VREG

Vcc

fsc OUT 1

fsc

OUT

2

Hi V

ccNC

32 AT5.7V REG OUT

QIF OUT

AUDIO OUT

AUDIO BYPASS

EXT AUDIO IN

FM DIRECT OUT

VIF VCO F/B

VIF GND

VIF GND

VIF VIDEO OUT

RF AGC OUT

VIF APC FILTER

VIF IN (1)

IF AGC FILTER1

IF AGC FILTER2

64 VIF IN (2)1 V RAMP CAP

2 AFT OUT

47 8.7V REG OUT48 LIMITER IN49 P.Con5.7V REG

16 B OUT17 H VCO F/B

NC

7.9

8.5

11.3

NC

FROM/TO MICON/TUNER

FROM/TO SOUND/AV

PCB010SCL

SDA

IIC_OFF

INT.MONI

VIDEO

GND

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

S801X

CP502A1561WV2-2P

1

2

HS501763WSAA013

R501

3.3 5W

21

L5038R200029

DEGAUSS COIL

FH502EYF-52BC

FH501EYF-52BC

F50151MS040LCC

233004-MB000

Q504LTV-817M-VB

FEED BACK

123

4

B502

W5R

H3.5

X5X1

.0

B501

W5R

H3.5

X5X1

.0

B503

W5R

H3.5

X5X1

.0

L501_11R0A562F20

12

345

TH50

1_2

PTDA

A1BF

3R0Q

100

R518

5.6K

+-1%

R514

0.22 1W

T502 8129092S

10

11

12

13

14

15

16

17

18

2

3

4

5

6

7

8

4A 125V

4A 125V

TYPE 4A 125V (F501).D’INCEIE N’UTILISER QUE DES FUSIBLE DE MEMEPOUR UNE PROTECTION CONTINUE LES RISQUESATTENTION:FUSE.REPLACE ONLY WITH THE SAME TYPE 4A 125V (F501)FOR CONTINUED PROTECTION AGAINST FIRE HAZARD,CAUTION:

S501

AS5

01B

S

DG

Q501STP5NC50FP

FET

BLACK

WHITE

BLAD

EW

IDE

CD501_20R414903

AC120V_60Hz

IS NON POLAR ONE.THE ALUMI ELECTROLYTIC CAPACITOR MARKED NPTHE RESISTOR MARKED F IS FUSE RESISTOR.NOTE:

D510

RU2AM-EIC

D505

SB290S

D501

1N40

05-E

IC

D504

1N40

05-E

IC

D502

1N40

05-E

IC

D503

1N40

05-E

IC

D514

1SS1

33D5

22

1SS1

33

D508

1SS1

33 D512

1SS1

33

D513

SB290S

Q507KTC3198-AT

(Y,GR)

FEED BACKSWITCHING

Q502KTC3198

BUFFER

R517

5.6 2W

R542

0.47

1W

R508

220 1W

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:

C505

0.1

275V

PHE8

40

C517

470P2KV RRC5

14

680P

2KV

RR

C513

_1

0.08

2M

MT

C518

470P500V B

C502

0.001500V B

C503

0.00

150

0VB

C506

0.0047250V KX

C509

0.047 M

C501

0.00

68M

C511

150V KA

C526 33

020

0VUP

R529

47K

R527

12

R520

56K

1/4W

R509

100

1/4W

R511

1.2M 1/4W

R500

3.3M

1/2W

+-10

%

R510

1.2M

1/4W

R519

1.2K

R515

120K

1/2W

R513

2.2K

R512 680

R506

_1

1K1/

4W

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

D506

MTZ

J18B

D509

MTZ

J18B

D528

MTZ

J5.6

B

W828

W844

W829

W824

W821

W83

7

C521 100

160V

MHE

C519 47

016

VYK

C515

1000

16V

YK

DEGAUSS

GND

SOUND+B

SOUND_GND

+B

UNREG+12V

GND

UNREG+12V

TO MICON/TUNER

TO SOUND/AV

POWER SCHEMATIC DIAGRAM

G-6G-5

TMA525

NC

NC

NC

(MAIN PCB)

TO DEFLECTION/CRT

TO CHROMA

9.5

5.56.0

9.50.1

10.511.5

4.8 0.1

0

4.8

144.0

10.0

NC

0

0

1.7

NC 0

132.3

11.3

NC

144.0

10.3

6.6

10.3

PCB010

0.1

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

S801Y

CP401A1561WV2-A5P

1

2

3

4

5

IC401 AN5522V-OUT IC

1 2 3 4 5 6 7

T401ETH09K14BZ

1

2

3 4

6

BGR

1168

109

175

V801A48LGS30X19N45

F

J801ISMS01S

1

345

67

8 9

CD801SM1098-009-1A

Q4012SD2627LS-CBC11

H.OUTPUT

VIDEO

8

E8E25

E12

GND

TERHEAAFC

B+

GND

ABL

GND

COLHV

F

S

FB401 3220052F

1

10

11

2

3

4

5

6

7

8

9

CP802A9253_010_000_000

1

10

2

3

4

5

6

7

8

9

CP802B9253_010_000_000

1

10

2

3

4

5

6

7

8

9

CP801_1A2361WV2-2P

1

2

HS401763WSAA013

HS402763WSAA013

R418_1

27K

R408

10K

+-1%

R409

27K

+-1%

R401

27K +-1%

R429_1

3.9 2W

D407

1SS1

33

D802

1SS1

33

D406_1

1SS133

D403

11E1-EIC

D410

AU02

A-EI

C

D405

AU02

A-EI

C

D408

11E1

-EIC

D411

AU02

A-EI

C

D803

1SS1

33

D801

1SS1

33

Q803_1KTC4217(O,Y)

BLUE OUTQ802_1

KTC4217(O,Y)

GREEN OUTQ801_1

KTC4217(O,Y)

RED OUT

Q4022SC1627_Y

H.DRIVE

R448_1

390 2W

R805

12K

2W

R807

12K

2W

R803

12K

2W

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:

C437

0.39

250V

PMS

C406

39P500V SL

C402

0.012200V PP

C443

_1

0.00

561.

25KV

MPP

C808

470P

B

C809

470P

B

C810

470P

B

C440

0.00

1250

0VB

C819

0.00

12K

VB

C407

56P

CH

C422 0.

1510

0VM

KT

C414 10

035

VYK

C418

470

25V

YK

C448

2220

0V MHE

C403 47

035

VYK

C435

0.1

100V M

HE

C434

2210

0VYK

C446 22

50V

YK

R808

221/

2W

R402

12 1/2W

R420

4.7K

R419 56

0

R815 330

R813 330

R421

100K

1/4W

R445

120K 1/4W

R806

2.7K

1/4W

R410

330

1/2W

R415

1.8K 1/2WR416

11/

2W R816 330

R413

2.2K

1/2W

R403

22K 1/4W

R427

100

1/4W

R422

1.8

1/2W

R417

12K

1/4W

R446

470

1/2W

R423

100 1/4WR424

6.8K

R802

_1

2.7K

1/4W

R804

_1

2.7K

1/4W

R814

4.7K

R811

4.7K

R809

4.7K

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

D404

MTZ

J6.2

B

D619

MTZ

J5.1

B

W84

3

W82

6W

832

W831

W897

W89

6W

809

W812

L402 18uH

C417

1050

VYK

DEFLECTION SIGNALB.SIGNAL

G.SIGNAL

R.SIGNAL

GND GND

CLAMP CLAMP CLAMP

G.OUT G.OUT G.OUT

R.OUT R.OUT R.OUT

B.OUT B.OUT B.OUT

HEATER HEATER

GND GND

180V 180V

X-RAY

+B

GND

V_FEEDBACK

V_OUT

ABCL

H_OUT

H_SYNC

GND

+B

UNREG+12V

CP806SCREEN

17

15

FROM POWER

G-8G-7

FROM CHROMA

FROM/TO CHROMA

UPPUMP

PROTECTIONTHERMAL

AMP

99.66.4

0

0

101.6

96.4

0

0

THE ALUMI ELECTROLYTIC CAPACITOR MARKED NPNOTE:THE RESISTOR MARKED F IS FUSE RESISTOR.

IS NON POLAR ONE.

TO DY

TMA525

2.73.2 3.23.2

NC

NC

NC

2.7

120.5

2.7

126.0128.0

FOCUS

NC

FOCUS

PCB110

2

1

130.0

00

0

27.0

0.3

3.5 2.0 12.0 25.0 3.5

18

19

20 21 22

0

0

0

025.0

132.5

48.0

7.04.3

25.0

132.5

NC

(MAIN PCB)DEFLECTION/CRT SCHEMATIC DIAGRAM

NC

NC

GND GND

CLAMP CLAMP

G.OUT G.OUT

R.OUT R.OUT

B.OUT B.OUT

HEATER HEATER

GND GND

180V 180V

14

PCB010

130.0

16

NC

TCA384A

TO MICON/TUNER

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

SPEAKER

SP1001S08F218 OHM

CD101ACH012002

1

CD101BCH012003

1

H E

J703AV1-09D-4

12H E

J702AV1-09D-3

12

AUDIO SIGNAL

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:C1

004_

1

0.00

15CH

C1001

0.150V KA

C100

5

1025

VKA

R701

681/

4W

R702

47K

R703

820

R704

10

R1003

68K

R1001

47K

R100

5

270K

R100

4

100K

R100

8

68K

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

W807

W80

3

W805

C1002_1

47010V YK

C100

3

150

VKA

IC10

01AN

7511

SOUN

D AM

P IC

1234

5 6 7 8

TUNER VIDEO SIGNAL

AUDIO_IN

VIDEO_IN

GND

SOUND_GND

SOUND+B

GND

AUDIO_MUTE

POWER

AUDIO_OUT

G-10G-9

TO CHROMA

VIDEO 2

AUDIO 2

26

25

(FRONT)

V_IN

A_IN

FROM MICON/TUNER

FROM TV POWER

1

2

-+

0

08.2 3.5 3.4

3.95.1 0.3

24

FROM CHROMA

23

TMA525PCB010

SOUND/AV SCHEMATIC DIAGRAM(MAIN PCB)

MICON/TUNER

61 0.5V 20µs/div

2

5

WAVEFORMS

0.5V 20µs/div

200mV 5ms/div

200mV 5ms/div4

0.5V 2ms/div

200mV 20µs/div7

9 200mV 20µs/div

CHROMA

0.5V 5ms/div10

11 1V 20µs/div

12 1V 20µs/div

1V 20µs/div138 20V 20µs/div3 200mV 20µs/div

DEFLECTION/CRT

14 0.5V 5ms/div

15 20V 20µs/div

H-1

NOTE: The following waveforms were measured at the point of the correspondingballoon number in the schematic diagram.

16 2V 20µs/div 21 50V 20µs/div

200V 20µs/div17 22 50V 20µs/div

SOUND/AV

0.5V 1ms/div2310V 5ms/div18

10V 5ms/div19 1V 1ms/div24

50V 20µs/div20

NOTE: The following waveforms were measured at the point of the correspondingballoon number in the schematic diagram.

H-2

25 500mV 1ms/div

WAVEFORMS

26 500mV 20us/div

MECHANICAL EXPLODED VIEW

I-1

107

108202

202

202

202

202

103

SP1001

105

104

203

110

111

101

201

201

201

201

L503

106

J801

PCB110(CRT PCB)

V801

102

109

FB401

204

PCB010(MAIN PCB)

205

204

TU001

MECHANICAL REPLACEMENT PARTS LIST

REF. NO. PART NO. DESCRIPTION101 A3L211C720 CABINET,FRONT ASSY

102 723000B325 FILM,DECORATION

103 701WPJB715 CABINET,FRONT

104 713WPAA047 GUIDE ,REMOCON

105 735WPAA417 BUTTON,FRAME

106 741WUA0019 SPRING,EARTH

107 702WPAA183 CABINET,BACK

108 722552A019 SHEET,RATING

109 7220001119 SHEET,CSA WARNING

110 7220001107 SHEET,HWC

111 7230006818 SHEET,CAUTION

201 8121F50B84 SCREW,TAPPING(BO) FAI20 FLAT 5x28

202 8117540A64 SCREW,TAPPING(B0) TRUSS 4x16

203 8110630A04 SCREW,TAP TITE(P) BRAZIER 3x10

204 8109I30A04 SCREW,TAP TITE(B) WH7 3x10

205 8109630802 SCREW,TAP TITE(B) BRAZIER 3x8

--- 791WHAA017 LAMIFILM BAG

--- 792WHAA040 PACKAGE,TOP

--- 792WHAA041 PACKAGE,BOTTOM

--- 793WCDB237 GIFT BOX

--- JB5K0200 POLYBAG,INSTRUCTION

--- J3L10502 WARRANTY SHEET

--- J3L21101 INSTRUCTION BOOK

--- A3L211C975 INSTRUCTION BOOK KIT

J1-1

ELECTRICAL REPLACEMENT PARTS LIST

REF. NO. PART NO. DESCRIPTION REF. NO. PART NO. DESCRIPTIONRESISTORS DIODES

R148 R00106104J RC 100K OHM 1/6W or D28T11E2N2 DIODE SILICON 11E2N-TA1B2R001T6104J RC 100K OHM 1/6W D606 D97U06R81B DIODE,ZENER MTZJ6.8B T-77

! R401 R4X5T6273F R,METAL 27K OHM 1/6W D607 D97U05R61B DIODE,ZENER MTZJ5.6B T-77! R409 R4X5T6273F R,METAL 27K OHM 1/6W D610 D97U01201B DIODE,ZENER MTZJ12B T-77! R429 R6558A3R9J R,FUSE 3.9 OHM 2W D611 D97U01201B DIODE,ZENER MTZJ12B T-77

R448 R3X18A391J R,METAL OXIDE 390 OHM 2W D612 D97U01201B DIODE,ZENER MTZJ12B T-77! R500 R0G3K2335K RC 3.3M OHM 1/2W D619 D97U05R11B DIODE,ZENER MTZJ5.1B T-77! R501 R5Y2CD3R3J R,CEMENT 3.3 OHM 5W D801 D1VT001330 DIODE,SILICON 1SS133T-77

R508 R3X181221J R,METAL OXIDE 220 OHM 1W D802 D1VT001330 DIODE,SILICON 1SS133T-77R514 R63581R22J R,FUSE 0.22 OHM 1W D803 D1VT001330 DIODE,SILICON 1SS133T-77

! R515 R002T2124J RC 120K OHM 1/2W ICS! R517 R3X28A5R6J R,METAL OXIDE 5.6 OHM 2W IC101 I56F07073A IC OEC7073A! R518 R4X5T6562F R,METAL 5.6K OHM 1/6W IC199 A3L211C015 IC S-24C02BDP-1A! R519 R001T6122J RC 1.2K OHM 1/6W ! IC401 I01TD55220 IC AN5522! R542 R3X181R47J R,METAL OXIDE 0.47 OHM 1W IC601 I06FC61250 IC M61250FP! R629 R3X28B330J R,METAL OXIDE 33 OHM 3W IC1001 I01DP75110 IC AN7511! R641 R002T4273J RC 27K OHM 1/4W TRANSISTORS! R803 R3X18A123J R,METAL OXIDE 12K OHM 2W ! Q401 TD30026270 TRANSISTOR SILICON 2SD2627LS-CBC11! R805 R3X18A123J R,METAL OXIDE 12K OHM 2W ! Q402 TC5T01627Y TRANSISTOR SILICON 2SC1627_Y(TPE2)! R807 R3X18A123J R,METAL OXIDE 12K OHM 2W Q501 TJXG5NC500 FET STP5NC50FP

CAPACITORS ! Q502 TCATC31980 TRANSISTOR,SILICON KTC3198-AT(Y,GR)C402 P3N1F2123J CPP 0.012 UF 200V ! Q504 0002E00610 PHOTO COUPLER LTV-817M-VB

! C403 E02LT4471M CE 470 UF 35V Q507 TCATC31980 TRANSISTOR,SILICON KTC3198-AT(Y,GR)! C414 E02LT4101M CE 100 UF 35V Q603 TCAT032034 TRANSISTOR, SILICON KTC3203_Y-AT! C418 E02LT3471M CE 470 UF 25V Q604 TCAT032034 TRANSISTOR, SILICON KTC3203_Y-AT

C437 P4J7F3394J CMPP 0.39 UF 250V PMS Q605 TCAT032034 TRANSISTOR, SILICON KTC3203_Y-AT! C443 P4N8FJ562H CMPP 0.0056UF 1.25KV Q606 TCAT032034 TRANSISTOR, SILICON KTC3203_Y-AT! C446 E02LT5220M CE 22 UF 50V Q609 TCATC31980 TRANSISTOR,SILICON KTC3198-AT(Y,GR)! C448 E5EZ0C220M CE 22 UF 200V Q610 TCATC31980 TRANSISTOR,SILICON KTC3198-AT(Y,GR)! C502 C0JTB0513K CC 0.001 UF 500V B Q801 TCA0042170 TRANSISTOR SILICON KTC4217(O,Y)! C503 C0JTB0513K CC 0.001 UF 500V B Q802 TCA0042170 TRANSISTOR SILICON KTC4217(O,Y)! C505 P2472B104M CMP 0.1 UF 275V PHE840 Q803 TCA0042170 TRANSISTOR SILICON KTC4217(O,Y)! C506 CD39E0MQ3M CC 0.0047UF 250V COILS &TRANSFORMERS! C511 E50HU5010M CE 1 UF 50V L101 021LA63R3K COIL 3.3 UH

C513 P23200823J CMPL 0.082 UF 50V MMT or L402 02186G180M COIL 18 UHP232W0823J CMPL 0.082 UF 50V MMTS ! L501 029T000104 COIL,LINE FILTER 1R0A562F20

C514 C0PLRR7U2K CC 680 PF 2KV RR ! L503 028R200029 COIL,DEGAUSS 8R200029! C515 E02LT2102M CE 1000 UF 16V L607 021LA6150K COIL 15 UH

C517 C0PLRR7Q2K CC 470 PF 2KV RR or T401 045009003J TRANS,HORIZONTAL DRIVE ETH09K14BZC01BBP7Q2K CC 470 PF 2KV BP or ! T502 048129092S TRANSFORMER,SWITCHING 8129092SC01TBP7Q2K CC 470 PF 2KV BP JACKS

! C519 E02LT2471M CE 470 UF 16V J702 060Q401077 RCA JACK AV1-09D-3! C521 E5EZFB101M CE 100 UF 160V J703 060Q401076 RCA JACK AV1-09D-4! C526 E51CGC331M CE 330 UF 200V ! J801 066F120018 SOCKET,CATHODE RAY TUBE ISMS01S

C634 CQG0CH412J CC 100 PF 50V CH or SWITCHESCQGTCH412J CC 100 PF 50V CH SW101 0504201T31 SWITCH,TACT SKHVBED010

C819 C0JBB0713K CC 0.001 UF 2KV B SW102 0504201T31 SWITCH,TACT SKHVBED010DIODES SW103 0504201T31 SWITCH,TACT SKHVBED010

D001 D97U03001B DIODE,ZENER MTZJ30B T-77 SW104 0504201T31 SWITCH,TACT SKHVBED010D403 D2WT011E10 DIODE SILICON 11E1-EIC or SW105 0504201T31 SWITCH,TACT SKHVBED010

D28T11E2N2 DIODE SILICON 11E2N-TA1B2 P.C.BOARD ASSEMBLIESD404 D97U06R21B DIODE,ZENER MTZJ6.2B T-77 PCB010 A3L211C010 PCB ASS'Y TMA525A

! D405 D2WTAU02A0 DIODE SILICON AU02A-EIC PCB110 A3L208C110 PCB ASS'Y TCA384AD406 D1VT001330 DIODE,SILICON 1SS133T-77 MISCELLANEOUSD407 D1VT001330 DIODE,SILICON 1SS133T-77 B501 024HT03553 CORE,BEADS W5RH3.5X5X1.0D408 D2WT011E10 DIODE SILICON 11E1-EIC or B502 024HT03553 CORE,BEADS W5RH3.5X5X1.0

D28T11E2N2 DIODE SILICON 11E2N-TA1B2 B503 024HT03553 CORE,BEADS W5RH3.5X5X1.0! D410 D2WTAU02A0 DIODE SILICON AU02A-EIC ! CD501 120R414903 CORD AC BUSH 0R414903! D411 D2WTAU02A0 DIODE SILICON AU02A-EIC CD801 06CU82039A CORD CONNECTOR SM1098-009-1A! D501 D2WXN40050 DIODE SILICON 1N4005-EIC CF601 1029045R7G FILTER,SAW TSF5229P3! D502 D2WXN40050 DIODE SILICON 1N4005-EIC CF603 1012T4R520 FILTER,CERAMIC SFSRA4M50CF00-A0! D503 D2WXN40050 DIODE SILICON 1N4005-EIC CF604 1012T4R519 FILTER,CERAMIC TRAP TPSRA4M50C00-A0! D504 D2WXN40050 DIODE SILICON 1N4005-EIC CP401 069S450089 CONNECTOR PCB SIDE A1561WV2-A5P! D505 D2WXB290S0 DIODE SILICON SB290S CP502 069S420110 CONNECTOR PCB SIDE A1561WV2-2P

D506 D97U01801B DIODE,ZENER MTZJ18B T-77 CP601 069E260659 CONNECTOR PCB SIDE 00_8283_0611_00_000 orD508 D1VT001330 DIODE,SILICON 1SS133T-77 0694260139 CONNECTOR PCB SIDE 173979-6 or

! D509 D97U01801B DIODE,ZENER MTZJ18B T-77 0694260669 CONNECTOR PCB SIDE 175489-6! D510 D2WXRU2AM0 DIODE SILICON RU2AM-EIC CP801 069S320010 CONNECTOR PCB SIDE A2361WV2-2P

D512 D1VT001330 DIODE,SILICON 1SS133T-77 CD101A 06CH012002 CORD CONNECTOR CH012002! D513 D2WXB290S0 DIODE SILICON SB290S CD101B 06CH012003 CORD CONNECTOR CH012003

D514 D1VT001330 DIODE,SILICON 1SS133T-77 CP802A 067N010039 WIRE HOLDER 9253_010_000_000 or! D522 D1VT001330 DIODE,SILICON 1SS133T-77 067U010049 WIRE HOLDER B2013H02-10P

D528 D97U05R61B DIODE,ZENER MTZJ5.6B T-77 CP802B 067N010039 WIRE HOLDER 9253_010_000_000 orD601 D1VT001330 DIODE,SILICON 1SS133T-77 067U010049 WIRE HOLDER B2013H02-10PD602 D97U08R21B DIODE,ZENER MTZJ8.2B T-77 EL002 124120301A EYE LET XRY20X30BDD604 D97U05R61B DIODE,ZENER MTZJ5.6B T-77 ! F501 081PC04004 FUSE 51MS040LCCD605 D2WT011E10 DIODE SILICON 11E1-EIC or ! FB401 043220052F TRANSFORMER,FLYBACK 3220052F

J2-1

ELECTRICAL REPLACEMENT PARTS LIST

REF. NO. PART NO. DESCRIPTIONMISCELLANEOUS

FH501 06710T0006 HOLDER,FUSE EYF-52BCFH502 06710T0006 HOLDER,FUSE EYF-52BCOS101 077Q037003 REMOTE RECEIVER PIC-37143SYS101 WHL6032038 FLAT CABLE AWG26 10C BLACK 320MM

! SP1001 070Y132018 SPEAKER S08F21TH501 DF20A3R0Q0 DEGAUSS ELEMENT PTDAA1BF3R0Q100TM101 076N0DW010 TRANSMITTER RC-DW010

! TU001 0145100059 TUNER,VHF-UHF ENV56DB6G3! V801 098Y200480 COLOR PICTURE TUBE W/DY A48LGS30X19N45

X602 100CT3R505 CRYSTAL HC-49/C

RESISTORRC...............…..CARBON RESISTOR

CAPACITORSCC................… CERAMIC CAPACITORCE................……ALUMI ELECTROLYTIC CAPACITORCP................……POLYESTER CAPACITORCPP...............…POLYPROPYLENE CAPACITORCPL...............…PLASTIC CAPACITORCMP................. METAL POLYESTER CAPACITORCMPL............…METAL PLASTIC CAPACITORCMPP..........…. METAL POLYPROPYLENE CAPACITOR

J2-2

M3L2-11C

O/R NO.

SPEC.NO.

W223003

SERVICE MANUAL

DBTV1901 Series B

Design and specifications are subject to change without notice.

COLOR TELEVISION RECEIVER

ORIGINALMFR'S VERSION B

The parts in this equipment have the specificcharacters of incombustibility and withstandvoltage for safety. Therefore, the part which isreplaced should be used the part which hasthe same character.Especially as to the important parts for safetywhich is indicated in the circuit diagram or thetable of parts as a mark, the designatedparts must be used.

SERVICING NOTICES ON CHECKING

6. AVOID AN X-RAY1. KEEP THE NOTICES

As for the places which need special attentions,they are indicated with the labels or seals on thecabinet, chassis and parts. Make sure to keep theindications and notices in the operation manual.

3. USE THE DESIGNATED PARTS

5. TAKE CARE TO DEAL WITH THECATHODE-RAY TUBE

In the condition that an explosion-proof cathode-ray tube is set in this equipment, safety issecured against implosion. However, whenremoving it or serving from backward, it isdangerous to give a shock. Take enough care todeal with it.

Safety is secured against an X-ray by consider-ing about the cathode-ray tube and the highvoltage peripheral circuit, etc.Therefore, when repairing the high voltage pe-ripheral circuit, use the designated parts andmake sure not modify the circuit.Repairing except indicates causes rising of highvoltage, and it emits an X-ray from the cathode-ray tube.

Please include the following informations when you order parts. (Particularly the VERSION LETTER.)1. MODEL NUMBER and VERSION LETTER

The MODEL NUMBER can be found on the back of each product and the VERSION LETTER can befound at the end of the SERIAL NUMBER.

2. PART NO. and DESCRIPTIONYou can find it in your SERVICE MANUAL.

HOW TO ORDER PARTS

PERFORM A SAFETY CHECK AFTERSERVICING

7.

Confirm that the screws, parts and wiring whichwere removed in order to service are put in theoriginal positions, or whether there are theportions which are deteriorated around theserviced places serviced or not. Check theinsulation between the antenna terminal orexternal metal and the AC cord plug blades.And be sure the safety of that.

(INSULATION CHECK PROCEDURE)

1.2.

3.

4.

Unplug the plug from the AC outlet.Remove the antenna terminal on TV and turnon the TV.Insulation resistance between the cord plugterminals and the eternal exposure metal[Note 2] should be more than 1M ohm byusing the 500V insulation resistance meter[Note 1] .If the insulation resistance is less than 1Mohm, the inspection repair should berequired.

[Note 1]

If you have not the 500V insulationresistance meter, use a Tester.

[Note 2]External exposure metal: Antenna terminal

2. AVOID AN ELECTRIC SHOCKThere is a high voltage part inside. Avoid anelectric shock while the electric current isflowing.

4. PUT PARTS AND WIRES IN THEORIGINAL POSITION AFTERASSEMBLING OR WIRINGThere are parts which use the insulationmaterial such as a tube or tape for safety, orwhich are assembled in the condition thatthese do not contact with the printed board.The inside wiring is designed not to get closerto the pyrogenic parts and high voltage parts.Therefore, put these parts in the originalpositions.

A1-1

!

Inferior silicon grease can damage IC's and transistors.When replacing an IC's or transistors, use only specified silicon grease (YG6260M).Remove all old silicon before applying new silicon.

IMPORTANT

CONTENTS

SERVICING NOTICES ON CHECKING .........................................................................................................HOW TO ORDER PARTS ...............................................................................................................................IMPORTANT ....................................................................................................................................................CONTENTS ......................................................................................................................................................GENERAL SPECIFICATIONS ........................................................................................................................DISASSEMBLY INSTRUCTIONS

1. REMOVAL OF ANODE CAP ..............................................................................................................2. REMOVAL AND INSTALLATION OF FLAT PACKAGE IC ...............................................................

SERVICE MODE LIST ....................................................................................................................................CONFIRMATION OF HOURS USED .............................................................................................................WHEN REPLACING EEPROM (MEMORY) IC .............................................................................................ELECTRICAL ADJUSTMENTS ......................................................................................................................BLOCK DIAGRAM ..........................................................................................................................................PRINTED CIRCUIT BOARDS

MAIN/CRT ..............................................................................................................................................SCHEMATIC DIAGRAMS

MICON/TUNER ..................................................................................................................................... CHROMA ............................................................................................................................................... POWER ..................................................................................................................................................

DEFLECTION/CRT ................................................................................................................................ SOUND/AV ............................................................................................................................................WAVEFORMS .................................................................................................................................................MECHANICAL EXPLODED VIEW .................................................................................................................MECHANICAL REPLACEMENT PARTS LIST .............................................................................................ELECTRICAL REPLACEMENT PARTS LIST ...............................................................................................

A2-1

A1-1A1-1A1-1A2-1A3-1~A3-4

B1-1B2-1, B2-2C-1C-1C-1D-1~D-5E-1, E-2

F-1~F-4

G-1, G-2G-3, G-4G-5, G-6G-7, G-8G-9, G-10H-1, H-2I-1J1-1J2-1, J2-2

GENERAL SPECIFICATIONS

G-1 TV CRT CRT Size / Visual Size 19 inch / 480.0mmV

System CRT Type Normal

Deflection 90 degree

Magnetic Field BV/BH +0.45G/0.18G

Color System NTSC

Speaker 1Speaker

Position Bottom

Size 3 Inch

Impedance 8 ohm

Sound Output MAX 1.5 W

10%(Typical) 1.0 W

NTSC3.58+4.43 /PAL60Hz No

G-2 Tuning Broadcasting System US System M

System Tuner and System 1Tuner

Receive CH Destination Ohers

Tuning System F-Synth

Input Impedance VHF/UHF 75 ohm

2 - 69, 4A, A-5 - A-1,

CH Coverage A - I, J - W, W+1 - W+84

Intermediate Picture(FP) 45.75MHz

Frequency Sound(FS) 41.25MHz

FP-FS 4.50MHz

Preset CH No

Stereo/Dual TV Sound No

Tuner Sound Muting Yes

G-3 Power Power Source AC 120V AC 60Hz

DC

Power Consumption at AC

73 W at AC 120 V 60 Hz

Stand by (at AC) 5 W at AC 120 V 60 Hz

Per Year -- kWh/Year

Protector Power Fuse Yes

G-4 Regulation Safety UL / CSA

Radiation FCC / IC

X-Radiation DHHS / HWC

G-5 Temperature Operation +5oC ~ +40oC

Storage -20oC ~ +60oC

G-6 Operating Humidity Less then 80% RH

G-7 On Screen Menu Yes

Display Menu Type Character

Picture Yes

Contrast Yes

Brightness Yes

Color Yes

Tint Yes

Sharpness Yes

Audio No

Bass No

Treble No

Balance No

BBE On/Off No

Stable Sound On/Off No

CH Set Up Yes

TV/CATV Yes

Auto CH Memory Yes

Add/ Delete Yes

Language Yes

V-chip Yes

CH Label No

Favorite CH No

Color Stream DVD/DTV No

Control Level Yes

Volume Yes

Brightness Yes

A3-1

GENERAL SPECIFICATIONS

Contrast Yes

Color Yes

Tint (NTSC Only) Yes

Sharpness Yes

Tuning No

Bass No

Treble No

Balance No

Back Light No

Stereo,Audio Output,SAP No

Video Yes

Color Stream No

Channel(TV/Cable) Yes

CH Label No

Sleep Timer Yes

Sound Mute Yes

V-chip Rating Yes

G-8 OSD Language English French Spanish

OSD Language Setting English

G-9 Clock and Sleep Timer Max Time 120 Min

Timer Step 10 Min

On/Off Timer Program(On Tim / Off Tim) No

Wake Up Timer No

Timer Back-up (at Power Off Mode) more than -- Min Sec

G-10 Remote Unit RC-DW

Control Glow in Dark Remocon No

Format NEC

Custom Code 86-05 h

Power Source Voltage(D.C) 3V

UM size x pcs UM-4 x 2 pcs

Total Keys 27 Keys

Keys Power Yes

1 Yes

2 Yes

3 Yes

4 Yes

5 Yes

6 Yes

7 Yes

8 Yes

9 Yes

0 Yes

100 No

CH Up Yes

CH Down Yes

Volume Up Yes

Volume Down Yes

TV/Caption/Text Yes

CH1/CH2 Yes

TV/Video(TV/AV) Yes

CH RTN/CH ENT(Quick View) Yes

Sleep Yes

RE Call(Call) Yes

Reset Yes

Menu Yes

Enter Yes

Mute Yes

Exit No

MTS(Audio Select) No

Set + Yes

Set - Yes

Multi Brand Keys CH Up(VCR) No

CH Down(VCR) No

Pause/Still No

A3-2

GENERAL SPECIFICATIONS

TV/VCR(VCR) No

Code No

FF No

Rew No

Rec No

Play No

Stop No

TV No

VCR No

Cable No

G-11 Features Auto Degauss Yes

Auto Shut Off Yes

Canal+ No

CATV Yes

Anti-theft No

Rental No

Memory(Last CH) Yes

Memory(Last Volume) Yes

V-Chip Yes

Type USA,ORION Type

BBE No

Auto Search No

CH Allocation No

SAP No

Channel Lock No

Just Clock Function No

Game Position No

CH Label No

VM Circuit No

Full OSD No

Premiere No

Comb Filter No

Lines

Auto CH Memory Yes

Hotel Lock No

Closed Caption Yes

Stable Sound No

Energy Star No

Favorite CH No

G-12 Accessories Owner's Manual Language English /French

w/Guarantee Card No

Remote Control Unit Yes

Rod Antenna No

Poles

Terminal

Loop Antenna No

Terminal

U/V Mixer No

DC Car Cord (Center+) No

Guarantee Card Yes

Warning Sheet No

Circuit Diagram No

Antenna Change Plug No

Service Facility List No

Important Safeguard No

Dew/AHC Caution Sheet No

AC Plug Adapter No

Quick Set-up Sheet No

Battery No

UM size x pcs

OEM Brand No

AC Cord No

AV Cord (2Pin-1Pin) No

Registration Card No

A3-3

GENERAL SPECIFICATIONS

PTB Sheet No

300 ohm to 75 ohm Antenna Adapter No

G-13 Interface Switch Front Power Yes

System Select No

Main Power SW No

Sub Power No

Channel Up/Reset Yes

Channel Down/Enter Yes

Volume Up/Set Up Yes

Volume Down/Set Down Yes

MENU=Volume Up+Volume Down Yes

Rear AC/DC No

TV/CATV Selector No

Degauss No

Main Power SW No

Indicator Power No

Stand-by No

On Timer No

Terminals Front Video Input RCA Audio Input RCA x 1 Other Terminal No

Rear Video Input(Rear1) No

Video Input(Rear2) No

Audio Input(Rear1) No

Audio Input(Rear2) No

Video Output No

Audio Output No

Euro Scart No

Color Stream No

Diversity No

Ext Speaker No

DC Jack 12V(Center +) No

VHF/UHF Antenna Input F TypeAC Outlet No

G-14 Set Size Approx. W x D x H (mm) 488 x 465 x 416

G-15 Weight Net (Approx.) 17.5kg ( 38.6 lbs)

Gross (Approx.) 20.0kg ( 44.1lbs)

G-16 Carton Master Carton No

Content ---- Sets

Material -- /--

Dimensions W x D x H(mm) -- x -- x --

Description of Origin No

Gift Box Yes

Material Double Full Color Carton W/Photo

Dimensions W x D x H(mm) 546 x 526 x 472

Design As per Buyer's

Description of Origin Yes

Drop TestNatural Dropping At 1 Corner / 3 Edges / 6

SurfacesHeight (cm) 46

Container Stuffing 436 Sets/40' container

G-17 Cabinet Material Cabinet Front PS 94V0 DECABROM

Cabinet Rear PS 94V0 DECABROM

A3-4

1. REMOVAL OF ANODE CAPRead the following NOTED items before starting work.

After turning the power off there might still be a potentialvoltage that is very dangerous. When removing theAnode Cap, make sure to discharge the Anode Cap'spotential voltage.Do not use pliers to loosen or tighten the Anode Capterminal, this may cause the spring to be damaged.

REMOVAL

1. Follow the steps as follows to discharge the Anode Cap.(Refer to Fig. 1-1.)Connect one end of an Alligator Clip to the metal part ofa flat-blade screwdriver and the other end to ground.While holding the plastic part of the insulated screwdriver,touch the support of the Anode with the tip of thescrewdriver.A cracking noise will be heard as the voltage is discharged.

Flip up the sides of the Rubber Cap in the direction of thearrow and remove one side of the support.(Refer to Fig. 1-2.)

2.

GND on the CRT

Screwdriver

Alligator Clip

SupportCRT

GND on the CRT

Rubber Cap

CRTSupport

Fig. 1-2

3. After one side is removed, pull in the opposite direction toremove the other.

NOTE

Take care not to damage the Rubber Cap.

INSTALLATION

1. Clean the spot where the cap was located with a smallamount of alcohol. (Refer to Fig. 1-3.)

Location of Anode Cap

NOTE

Confirm that there is no dirt, dust, etc. at the spot wherethe cap was located.

2.

3.

Arrange the wire of the Anode Cap and make sure thewire is not twisted.Turn over the Rubber Cap. (Refer to Fig. 1-4.)

4. Insert one end of the Anode Support into the anode button,then the other as shown in Fig. 1-5.

5.6.

Confirm that the Support is securely connected.Put on the Rubber Cap without moving any parts.

CRTSupport

DISASSEMBLY INSTRUCTIONS

Fig. 1-3

Fig. 1-4

Fig. 1-5

*

*

Fig. 1-1

B1-1

B2-1

Masking Tape(Cotton Tape)

DISASSEMBLY INSTRUCTIONS

2.

REMOVAL

IC

Put the Masking Tape (cotton tape) around the FlatPackage IC to protect other parts from any damage.(Refer to Fig. 2-1.)

1.

Fig. 2-1

NOTE

REMOVAL AND INSTALLATION OFFLAT PACKAGE IC

Some ICs on the PCB are affixed with glue, so becareful not to break or damage the foil of each ICleads or solder lands under the IC when removing it.

NOTE

Masking is carried out on all the parts located within10 mm distance from IC leads.

Blower type ICdesoldering machine

IC

Heat the IC leads using a blower type IC desolderingmachine. (Refer to Fig. 2-2.)

2.

Fig. 2-2

NOTE

Do not add the rotating and the back and forthdirections force on the IC, until IC can move back andforth easily after desoldering the IC leads completely.

When IC starts moving back and forth easily afterdesoldering completely, pickup the corner of the IC usinga tweezers and remove the IC by moving with the ICdesoldering machine. (Refer to Fig. 2-3.)

3.

Blower type ICdesolderingmachine

IC

Fig. 2-3

Tweezers

Peel off the Masking Tape.4.

Absorb the solder left on the pattern using the BraidedShield Wire. (Refer to Fig. 2-4.)

5.

NOTE

Do not move the Braided Shield Wire in the verticaldirection towards the IC pattern.

Braided Shield Wire

Soldering Iron

Fig. 2-4IC pattern

B2-2

DISASSEMBLY INSTRUCTIONS

Supply solderingfrom upper positionto lower position

IC

Supply the solder from the upper position of IC leadssliding to the lower position of the IC leads. (Refer to Fig. 2-6.)

2.

Fig. 2-6

Soldering IronSolder

IC

Absorb the solder left on the lead using the BraidedShield Wire. (Refer to Fig. 2-7.)

3.

Fig. 2-7

Soldering Iron

Braided Shield Wire

NOTE

Do not absorb the solder to excess.

IC

When bridge-soldering between terminals and/or thesoldering amount are not enough, resolder using a Thin-tip Soldering Iron. (Refer to Fig. 2-8.)

4.

Fig. 2-8

Thin-tip Soldering Iron

NOTE

When the IC leads are bent during soldering and/orrepairing, do not repair the bending of leads. If thebending of leads are repaired, the pattern may bedamaged. So, be always sure to replace the IC in thiscase.

Finally, confirm the soldering status on four sides of theIC using a magnifying glass.Confirm that no abnormality is found on the solderingposition and installation position of the parts around theIC. If some abnormality is found, correct by resoldering.

5.Solder temporarily

Soldering Iron

INSTALLATION

Take care of the polarity of new IC and then install thenew IC fitting on the printed circuit pattern. Then soldereach lead on the diagonal positions of IC temporarily.(Refer to Fig. 2-5.)

1.

Fig. 2-5

Solder temporarily

SERVICE MODE LIST

This unit provided with the following SERVICE MODES so you can repair, examine and adjust easily.To enter the Service Mode, press both set key and remote control key for more than 1 second.

Set Key Remocon Key Operations

VOL. (-) MIN 0 Releasing of V-CHIP PASSWORD.

VOL. (-) MIN 1 Initialization of the factory.NOTE: Do not use this for the normal servicing.

If you set a factory initialization, the memories are reset such as the clock setting, the channel setting, the POWER ON total hours, and PLAY/REC total hours.

C-1

VOL. (-) MIN 6

POWER ON total hours is displayed on the screen.Refer to the "CONFIRMATION OF HOURS USED".

Can be checked of the INITIAL DATA of MEMORY IC.Refer to the "WHEN REPLACING EEPROM (MEMORY) IC".

VOL. (-) MIN 8 Writing of EEPROM initial data.NOTE: Do not use this for the normal servicing.

VOL. (-) MIN Display of the Adjustment MENU on the screen.Refer to the "ELECTRICAL ADJUSTMENT" (On-Screen Display Adjustment).

9

CONFIRMATION OF HOURS USED

POWER ON total hours can be checked on the screen. Total hours are displayed in 16 system of notation.

1.2.

3.

Set the VOLUME to minimum.Press both VOL. DOWN button on the set and Channelbutton (6) on the remote control for more than 1 second.After the confirmation of using hours, turn off the power.

INIT 00 83

0010CRT ON

ADDRESS DATA

FIG. 1

Initial setting content of MEMORY IC.

POWER ON total hours. = (16 x 16 x 16 x thousands digit value) + (16 x 16 x hundreds digit value) + (16 x tens digit value) + (ones digit value)

WHEN REPLACING EEPROM (MEMORY) IC

If a service repair is undertaken where it has been required to change the MEMORY IC, the following steps should be taken toensure correct data settings while making reference to TABLE 1.

Table 1

1.2.

3.

4.5.6.7.8.The unit will now have the correct DATA for the new MEMORY IC.

Enter DATA SET mode by setting VOLUME to minimum.Press both VOL. DOWN button on the set and Channel button (6) on the remote control for more than 1 second.ADDRESS and DATA should appear as FIG 1.ADDRESS is now selected and should "blink". Using the SET + or - keys on the remote, step through the ADDRESS untilrequired ADDRESS to be changed is reached.Press ENTER to select DATA. When DATA is selected, it will "blink".Again, step through the DATA using SET + or - until required DATA value has been selected.Pressing ENTER will take you back to ADDRESS for further selection if necessary.Repeat steps 3 to 6 until all data has been checked.When satisfied correct DATA has been entered, turn POWER off (return to STANDBY MODE) to finish DATA input.

+2INI +0 +1 +3 +4

00

+A

09 4408 20 99 02

+9+5 +6 +7 +8

B3 24 19 01 00

+F+B +C +D +E

05 00 D5 FF A5

ELECTRICAL ADJUSTMENTS

1.

Read and perform these adjustments when repairing thecircuits or replacing electrical parts or PCB assemblies.

CAUTION

•

•

•

•

Use an isolation transformer when performing any service onthis chassis.Before removing the anode cap, discharge electricity becauseit contains high voltage.When removing a PCB or related component, afterunfastening or changing a wire, be sure to put the wire backin its original position.Inferior silicon grease can damage IC's and transistors. WhenWhen you exchange IC and Transistor for a heat sink,apply the silicon grease (YG6260M) on the contractsection of the heat sink, Before applying new silicongrease, remove all the old silicon grease. (Old greasemay cause damages to the IC and Transistor.)

2. BASIC ADJUSTMENTS2-1: RF AGC DELAY

D-1

Place the set with Aging Test for more than 15 minutes.Receive an 63dB monoscope pattern.Connect the digital voltmeter to W043.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (02) on the remote control toselect "RF.AGC".Press the VOL. UP/DOWN button on the remote controluntil the digital voltmeter is 2.50 ± 0.05V.

1.2.3.4.

5.

BEFORE MAKING ELECTRICALADJUSTMENTS

2-2: CUT OFF

1.

2.3.

4.

Adjust the unit to the following settings.R.DRIVE=10, B.DRIVE=10, R.BIAS=64, G.BIAS=64,B.BIAS=64, BRIGHTNESS=125, CONTRAST=60.Place the set with Aging Test for more than 15 minutes.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (01) on the remote control toselect "CUT OFF".Adjust the Screen Volume until a dim raster is obtained.

1. Synchro Scope2. Digital Voltmeter

On-Screen Display Adjustment

In the condition of NO indication on the screen.Press the VOL. DOWN button on the set and theChannel button (9) on the remote control for more than1 second to appear the adjustment mode on thescreen as shown in Fig. 1-1.

1.

Fig. 1-1

Use the Channel UP/DOWN button or Channel button(0-9) on the remote control to select the options shownin Fig. 1-2.Press the MENU button on the remote control to endthe adjustments.

2.

3.

Prepare the following measurement tools for electricaladjustments.

FUNCTIONOSD HCUT OFFRF DELAYVIF VCOH.VCOH.PHASEV.SIZEV.SHIFTR.DRIVEB.DRIVER.BIASG.BIASB.BIASBRIGHT CENTBRIGHT MEXBRIGHT MIN

NO.00010203040506070809101112131415

Fig. 1-2

FUNCTIONCONTRAST CENTCONTRAST MAXCONTRAST MINCOLOR CENTCOLOR MAXCOLOR MINTINTSHARPNESSFM LEVELLEVELSEPARATION 1SEPARATION 2TEST MONOTEST STEREOX-RAY TEST

NO.161718192021222324252627282930

TV

00 OSD 15

2-3: WHITE BALANCE

NOTE: Adjust after performing CUT OFF adjustment.

Place the set with Aging Test for more than 10 minutes.Receive the white 100% signal from the PatternGenerator.Using the adjustment control, set the brightness andcontrast to normal position.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (10) on the remote control toselect "R.BIAS".Using the VOL. UP/DOWN button on the remote control,adjust the R.BIAS.Press the CH. UP/DOWN button on the remote control toselect the "R.DRIVE", "B.DRIVE", "G.BIAS" or "B.BIAS".Using the VOL. UP/DOWN button on the remote control,adjust the R.DRIVE, B.DRIVE, G.BIAS or B.BIAS.Perform the above adjustments 6 and 7 until the whitecolor is looked like a white.

2-4: SUB TINT/SUB COLOR

1.2.3.

4.

5.6.

7.

8.9.

Receive the color bar pattern.Connect the oscilloscope to TP023.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (22) on the remote control toselect "TINT".Press the VOL. UP/DOWN button on the remote controluntil the section "A" becomes as straight line(Refer to Fig. 2-1)Connect the oscilloscope to TP022.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (19) on the remote control toselect "COL.CENT".Press the VOL. UP/DOWN button on the remote controluntil the red color level is adjusted to 120% of the whitelevel. (Refer to Fig. 2-2)Receive the color bar pattern. (Audio Video Input)Press the TV/AV button on the remote to set to theAV mode. Then perform the above adjustment 2~7.

1.2.

3.

4.

5.

6.

7.

8.

D-2

ELECTRICAL ADJUSTMENTS

Fig. 2-1

Fig. 2-2

2-8: OSD HORIZONTAL

1.2.

Activate the adjustment mode display of Fig. 1-1.Press the VOL. UP/DOWN button on the remotecontrol until the difference of A and B becomesminimum. (Refer to Fig. 2-3)

BA

TV

00 OSD 15

Fig. 2-3

2-9: VIF VCO

1.2.3.

4.

5.

Place the set with Aging Test for more than 10 minutes.Receive an 80dB monoscope pattern.Connect the digital voltmeter between the pin 5 ofCP601 and the GND.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (03) on the remote control toselect "V.VCO".Press the VOL. UP/DOWN button on the remote controluntil the digital voltmeter is 2.5V.

2-5: HORIZONTAL PHASE

1.

2.

3.

Receive the center cross signal from the PatternGenerator.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (05) on the remote control toselect "H.PHAS".Press the VOL. UP/DOWN button on the remotecontrol until the SHIFT quantity of the OVER SCAN onright and left becomes minimum.

2-6: VERTICAL SIZE

Receive an 70dB the color bar pattern.Activate the adjustment mode display of Fig. 1-1press the channel button (17) on the remote controlto select "CONT.MAX".Press the VOL. UP/DOWN button on the remote controluntil the contrast step No. becomes "66".Press the TV/AV button on the remote to set to theAV mode. Then perform the above adjustment 2, 3.

1.2.

3.

4.

2-11: SUB CONTRAST MANUAL

Receive an 70dB monoscope pattern.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (13) on the remote control toselect "BRI.CENT".Press the VOL. UP/DOWN button on the remote controluntil the screen begin to shine.Press the TV/AV button on the remote to set to theAV mode. Then perform the above adjustment 2, 3.

1.2.

3.

4.

2-10: SUB BRIGHTNESS

1.

2.

3.

4.

Receive the crosshatch signal from the PatternGenerator.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (06) on the remote control toselect "V.SIZE".Press the VOL. UP/DOWN button on the remote controluntil the SHIFT quantity of the OVER SCAN on upsideand downside becomes 10 ± 2%.Receive a broadcast and check if the picture is normal.

2-7: VERTICAL SHIFT

1.

2.

3.

Receive the crosshatch signal from the PatternGenerator.Activate the adjustment mode display of Fig. 1-1 andpress the channel button (07) on the remote control toselect "V.SFT".Press the VOL. UP/DOWN button on the remotecontrol until the horizontal line becomes fit to the notchof the shadow mask.

2-12: FOCUS

1.2.3.

Receive the monoscope pattern.Turn the Focus Volume fully counterclockwise once.Adjust the Focus Volume until picture is distinct.

"A"

120%

0%

100%

D-3

2-13: Confirmation of Fixed Value (step No.)

Please check if the fixed values of the each adjustmentitems are set correctly referring below.

NO.0414151618202123242526272829

FUNCTIONH VCOBRIGHT MAXBRIGHT MINCONT CENTCONT MINCOLOR MAXCOLOR MINSHARPNESSFM LEVELLEVELSEPARATION 1SEPARATION 2TEST MONOTEST STERO

RF04183603012700140000000000000

AV04183603012700140000000000000

ELECTRICAL ADJUSTMENTS

ELECTRICAL ADJUSTMENTS

3.

1.

2.

3.

1.

2.

3.

4.

5.

6.

7.

8.

3-2: PURITY

NOTE

Adjust after performing adjustments in section 3-1.

1.

2.

3.

4.5.

Receive the green raster pattern from color bargenerator.Adjust the pair of purity magnets to center thecolor on the screen.Adjust the pair of purity magnets so the color at theends are equally wide.Move the deflection yoke backward (to neck side)slowly, and stop it at the position when the wholescreen is green.Confirm red and blue colors.Adjust the slant of the deflection yoke while watching thescreen, then tighten the fixing screw.

DEFLECTION YOKEDEFLECTION YOKE SCREWMAGNET SCREW

PURITY MAGNETS6 POLE MAGNETS4 POLE MAGNETS

Fig. 3-1

PURITY AND CONVERGENCEADJUSTMENTS

NOTE

3-1: STATIC CONVERGENCE (ROUGH ADJUSTMENT)

Tighten the screw for the magnet. Refer to the adjustedCRT for the position. (Refer to Fig. 3-1)If the deflection yoke and magnet are in one body,untighten the screw for the body.Receive the green raster pattern from the color bargenerator.Slide the deflection yoke until it touches the funnelside of the CRT.Adjust center of screen to green, with red and blue on thesides, using the pair of purity magnets.Switch the color bar generator from the green rasterpattern to the crosshatch pattern.Combine red and blue of the 3 color crosshatch patternon the center of the screen by adjusting the pair of4 pole magnets.Combine red/blue (magenta) and green by adjusting thepair of 6 pole magnets.Adjust the crosshatch pattern to change to whiteby repeating steps 6 and 7.

Turn the unit on and let it warm up for at least 30minutes before performing the following adjustments.Place the CRT surface facing east or west to reduce theterrestrial magnetism.Turn ON the unit and demagnetize with a Degauss Coil.

3-3: STATIC CONVERGENCE

D-4

1.

2.

3.

3-4: DYNAMIC CONVERGENCE

Adjust after performing adjustments in section 3-3.

1.

2.

Adjust the differences around the screen by movingthe deflection yoke upward/downward and right/left.(Refer to Fig. 3-2-a)Insert three wedges between the deflection yokeandCRT funnel to fix the deflection yoke.(Refer to Fig. 3-2-b)

R G B

RGB

Fig. 3-2-a

WEDGE WEDGE

WEDGE

WEDGE POSITION

Fig. 3-2-b

R G B

RGB

Receive the crosshatch pattern from the color bargenerator.Combine red and blue of the 3 color crosshatch patternon the center of the screen by adjusting the pair of4 pole magnets.Combine red/blue (magenta) and green by adjusting thepair of 6 pole magnets.

UPWARD/DOWNWARD SLANT RIGHT/LEFT SLANT

Adjust after performing adjustments in section 3-2.

NOTE

NOTE

ELECTRICAL ADJUSTMENTS

4. ELECTRICAL ADJUSTMENT PARTS LOCATION GUIDE (WIRING CONNECTION)

TU001

FB401

S501B

S501A

AC IN

CP601

CP502

T502

CD101B

CD101A

W043

CR

T

CP401

SPEAKER

TP023TP022

R80

7

R80

3

J801

CP806_1

CP801_

1

CP802B

CP

802A

CD801

CRT

L503

CRT

D-5

MAIN PCB

CRT PCB

BLOCK DIAGRAM

20

15

14

16

59

64

63

47

51

CF601

SAW FILTER

30

AG

C

IF

TU001

11 1

CHROMA ICIC601 M61250FP

IC1001 AN7511

SP1001

Q801

RED OUT

Q802

GREEN OUT

Q803

BLUE OUT

CRT

3 9 7

RGB

Heater

F 8

37V. SYNC

MICON ICIC101 OEC7073A

9

HV

F

S

FB401

10

1

AUDIO MUTE1

28

4

34

X6023.579545MHz

Q606

REG.

2 6

E-1 E-2

SOUND AMPIC

2

POWER

VOL. UP

KEY16

CH. UP

VOL. DOWN

CH. DOWN

REMOCON9

4

SD

A

5

SC

L

4

30SCL1

31SDA1

65 MEMORY ICIC199 S-24C02BDP-1A

27

26

8

UNREG + 12V

11

3

AUDIO OUT

8.7V REG OUT

R OUT

G OUT

B OUT

POWER ON CONT

H OUT

X' TAL

RF AGC OUT

VIF IN (1)

VIF IN (2)

V PULSE OUT

SCL

SDA

MCU RESET

KEY27

SDA SCL

19 INV FBP OUT38H. SYNC

2433BLANK FAST BLK

21 B IN36BLUE B

2235GREEN G G IN

23 R IN34RED R

26CVIN 31 Y SW OUT

32AT5.7V REG OUT

42VREG VCC

10FBP IN

Q603

REG.

DY

49P.CON 5.7V REG

Q604, Q605

REG.

D501~D504

RECTIFIER

25

13L501

AC IN

F501R. SIGNAL

B. SIGNAL

DEFLECTION SIGNAL

G. SIGNAL

AUDIO SIGNAL

TUNER VIDEO SIGNAL

Q507Q504

FEED BACK

T502

4

8

13

FEED BACKSW

Q502

BUFFER

Q501

SWITCHING

6

41TV/Y IN

58VIF VIDEO OUT

LUMINANCE SIGNAL

27RESET

Q610

H-CTL

DEGAUSS COILL503

5 V OUT

38 EXT Cin

53 EXT AUDIO IN

OS101

1

J702

2

J703

2

42H-CTL

29POWER

7 365

V-OUT ICIC401 AN5522

PUMP UP

AMP+

-

Q402

H. DRIVE

Q401

H. OUTPUT

AG

C

*

*

*

**

**

* *

*

RISK OF FIRE - REPLACE AS MARKED.

C12

3

IC199

X602

SW101

SW102

SW104

SW105

FH501FH502 F501

CP502R500

R445

R002

C00

4

C00

3

R41

0

R40

3

C43

7

D41

0

R423

C41

7

C41

8

C41

4

D40

4

R42

1

C446C44

0 Q402

T401

R446

R429_1

IC1001

R415 R413

R416

CP802A

OS101

W001

W002

TU001

W003

W004

W005

W006

C526

D50

1

D503

D502

C502

C503

Q50

4

D509

R508

R51

0

R51

1

C50

9

Q502

D508

C501

D50

6

C514

C518

C51

5

D52

8

SW103

CP601

AFC

GND

ABL

8V 12V

25V

B+

COL

T502

R417

D00

1

C44

8

C407

C40

6

D505 C517

D51

3

IC401

CP

401

Q507

FB401

D510

W826

W007

R527

Q501

R422

C506

D504

R42

7

R51

7

C00

2

J703

J702

W008

R51

5

S501B

S501A

W009

R424

W010

C443_1

C43

5

W011

W80

3

C521

R001

C40

3

C511

HS

501

HS402

HS401

Q401

W82

4

C50

5

W012

R701

W807

C10

05

C10

03

C1004_1

C10

01

L10

1

W83

5

C128_1

C10

1

C122

C120

C11

5

C14

1

C61

3_2

C62

1

C60

1

C62

8

C60

5

CF604

L607C

632

C606

C64

2C

604

CF603

C63

0

Q605

Q604

Q606

C61

9_1

C62

4 D60

1

D60

2

W017

C625

Q603C638W818

W01

8

W01

9

C63

5R635

C61

2

D610

D61

1D

612

W02

2

R61

4C

603

Q610

Q609

R62

7

R63

1

R63

0

R629

W023W024

W025

R606

W026

D605

W027

C51

9

W03

0

W031

CP802B

CP801_1

Q803_1

Q801_1Q802_1

R80

6

R80

3

J801

R80

7

R80

5

C118W034

R40

1R

408

D61

9

W03

6

D406_1

W03

7

R514

C40

2

R40

2

W040

W041

CF601_1

W04

2

W043

W044

C64

7

W821

C64

5

W83

1

W89

7

W83

2

W896

R804_1

R802_1

R51

2

W047

R64

1

R519R518

D514

R51

3

R110

W04

9

CD101B

CD101A

W05

0

D403

D40

5

D411W809

W05

1

C11

9

W812

D522

W05

6

W057

R108

R10

7

R448_1

R542

W01

5

W01

6

R1003

W058

R117

R64

8

C616

R52

0

R509

R14

6

D512

R623

D803

D80

1 D80

2

W059

C62

7C

629

W805

C12

7

C12

6

R50

6_1

W83

7

D60

4

D60

7

C130

C13

9

C13

6

L501_1

D40

8

R50

1

TH501_2

C422

C10

02_1

W03

2

C62

6C

602 C60

7

W052

C63

7

C639

C12

4C62

2

B503

C640

C43

4

R409

TP402

R70

4

L402

W817

W840

R624

W834

W82

0

W82

3

W829

W843

W806

W84

5

R418_1

W06

0

CD501

R61

6

C819

C634

R139

W84

4

W833

W03

5

W82

8

W81

4

D60

6

S802X

S802Y

S801Y

S801X

B50

1

B502

C51

3_1

D407

R808

C614

R14

8

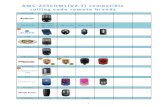

PRINTED CIRCUIT BOARDSMAIN/CRT (INSERTED PARTS)

SOLDER SIDE

F-1 F-2

CP806_1

TP023

TP022

*

*

17

33

49

1

C62

0

IC101

IC60

1

R12

8

R10

1

R12

6

R41

9

R420

R11

2

R70

3R

702

R14

3

R11

3

R10

05

R1004

R12

7 C113C114

R132

R11

5

R12

4

R104

R12

2R

102

R12

3

R10

3R

121

R12

0

R10

6

R10

5

R13

0

C12

1C

138

R134

R601

R60

2

R60

9

R62

2R

615

C65

5

R628

R63

9

R63

2

R633

R64

6 R64

2

C14

0_1

R61

9R

605

R617

R14

1

R14

2

R81

1

R80

9

R814

R81

5

R81

3

R81

6

R129

R63

8

R62

6

R1001

R133

R612

R11

1

C81

0

C80

8C80

9

R118

R1008 R12

5

C61

8

R62

5

C62

3

R621

R529

R60

7

PRINTED CIRCUIT BOARDSMAIN/CRT (CHIP MOUNTED PARTS)

SOLDER SIDE

F-3 F-4

A B C D E F G H

A B C D E F G H

2

1

3

4

5

6

7

8

2

1

3

4

5

6

7

8

THE DC VOLTAGE AT EACH PART WAS MEASURED WITH THE DIGITAL TESTER WHEN THE COLOR BROADCAST

WAS RECEIVED IN GOOD CONDITION AND PICTURE IS NORMAL.

NOTE:

C134

_1

0.1

M

C124

0.1 F

C120

0.001 Y

C121

200P CH

C130

0.01 Y

C113

12P CH

C114

12P CH

C004

0.02

2F

C117

220P B

C116

220P B

C138

560P

W

C135

_1

0.01

F

C119

_1

0.1

F

C125

0.150V KA

C137

0.150V KA

C002 470

6.3V

YK

C003

4.750V KA

C115 0.

150

VKA

C122

150V KA

C129

0.150V KA

R112 2.2K

R113 2.2K

R131

100

R117

47K

R115

47K

R123

4.7KR122

4.7KR121

4.7KR120

4.7KR1

29

1M

R116

47K

R114

10K

R119

1K

R107

10K

R102

680

R103

680

R104

680

R124

4.7K

R127

2.7K

R110

1K1/

4W

R106

4.7K

R007

270

R006

270

R105

4.7K

R001

18K 1/2W

R002

18K 1/2W

R134

470

R111

10K

R130

1K

R128

560R126

2.7K

R101

560

OF PRINTING AND SUBJECT TO CHANGE WITHOUT NOTICENOTE:THIS SCHEMATIC DIAGRAM IS THE LATEST AT THE TIME

DANS LA NOMENCLATURE DES PIECESN’UTILISER QUE CELLS DECRITESDANGEREUSES AN POINT DE VUE SECURITE

ETANTLES PIECES REPAREES PAR UNATTENTION:

DESCRIBED IN PARTS LIST ONLYCRITICAL FOR SAFETY,USE ONES

ARESINCE THESE PARTS MARKED BYCAUTION:

D001

MTZ

J30B

W819

W820

W837

W813

W815

W809

W822

L101

3.3u

H

SW10

1SK

HVBE

D010

CH U

P

SW10

2SK

HVBE

D010

CH D

OWN

SW10

3SK

HVBE

D010

VOL

UP

SW10

4SK

HVBE

D010

VOL

DOW

N

SW10

5SK

HVBE

D010

POW

ER

TU001 ENV56D66G3

11011

1213

1415

23456789

C118

4706.3V YK

IC19

9S-

24C0

2BDP

-1A

MEM

ORY

IC

1234

5 6 7 8

GND

B+Vout

OS101PIC-28143SY-2

1 2 3

IC101 OEC7045BMICON IC

110

1112

1314

1516

1718

192

2021 22

2324

2526

2728

29

3

3031

3233

3435

3637

38394

4041

42

56

78

9

X101_1EFOEC8004T4 1

2

3

DEFLECTION SIGNALB.SIGNALG.SIGNALR.SIGNAL

TUNER VIDEO SIGNAL

TM101RC-DW010

AGC

GND

TUNER+5V

IF

I2C_OFF

VD

HD

OSD_R

OSD_G

OSD_B

OSD_BLK

AUDIO_MUTE

POWER

+B

X-RAY

POWER

SCL

SDA

AFT

RESET

AT+5V

Y_VIDEO

SYNC

TO SOUND/AV

FROM DEFLECTION/CRT

NC

0

NC

0

NC

0