Series Tests of High Gradient Single- cell Superconducting Cavity for the Establishment of KEK...

-

Upload

scott-watts -

Category

Documents

-

view

213 -

download

0

Transcript of Series Tests of High Gradient Single- cell Superconducting Cavity for the Establishment of KEK...

Series Tests of High Gradient Single-cell Superconducting Cavity for the

Establishment of KEK Recipe T. Saeki (1), F. Furuta (1), K. Saito (1), M. Ge (2), Y. Higashi (1), T. Higo (1), S. Kazakov (1), H.

S. Kim (3), H. Matsumoto (1), Y. Morozumi (1), R. S. Orr (4), N. Toge (1), K. Ueno (1), and H. Yamaoka (1)

Affiliation: (1)KEK, (2)IHEP, (3)Kyungpook National Univ., (4)Univ. of Toronto/JSPSEPAC, 26-30 June 2006

(Presentation ID: MOPLS087)

We have performed a series of vertical tests of single cell Niobium superconducting cavities at 2 degrees Kelvin. These tests aimed at establishing the feasibility of reaching an accelerating gradient of 45 MV/m on a routine basis. The cavity profiles were all of the KEK low loss design and were fabricated from deep drawn Niobium half shells using electron beam welding. The cavity surface preparation followed an established KEK procedure of centrifugal barrel polishing, light chemical polishing, high temperature annealing, electro-polishing, and finally a high pressure water rinse. Of the six cavities tested, three exceeded 45 MV/m on the first test. This clearly establishes the feasibility of this gradient. In this paper we describe these tests and our future program for optimizing the surface preparation.

Abstract

1

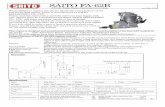

Treatment ProcessRemoval

Thickness

(um)Purpose

Centrifugal Barrel Polishing (CBP)

Mechanical grinding by stones and water 135 – 235

Remove defects of Nb material and smooth EBW seam.

Light Chemical Polishing (CP)

Chemical reaction 10Remove dusts after CBP and

prepare smooth surface before EP

Annealing / degassing

750 OC for 3 hours by furnace -

Release mechanical stress and degass hydrogen

Electro-Polishing (EP)

Chemical + electronic reaction 80 Prepare very smooth surface

High-Pressure Rinsing (HPR)

Rinse with pressured Ultra-Pure Water

(UPW)-

Remove particles and make clean surface

Baking120 OC for 48 hours

with pumping vacuum- Defuse oxidized layer

KEK recipe

Parameters of each process are optimized for good cavity performance with low cost.

2

• Step 0 : Proof of principle for 50 MV/m, done => Poster MOPLS084 by Furuta for details.• Step I : Proof of principle for 45MV/m on the first trial, done• Step II : Yield rate goal = 85% for 45MV/m on the first trial, 50%

• Level III : Why yield rate is 50%? Investigation is ongoing.

• No H Q-disease in series tests.

The establishment of KEK recipe with single-cell cavity

3

Six ICHIRO-shape Single-cell (IS) cavities were fabricated.

Electron Beam Welding (EBW)Both KEK in-house machine and industrial machine were used

Six IS cavities were fabricated(IS#2, #3, #4, #5, #6, #7).Series of tests was done toestablish the KEK recipe.

Deep-drawing Nb cups

4

Centrifugal Barrel Polishing (CBP) / Mechanical grinding

Stones and water

Rough stones Fine stones

KEK recipeRough stones + water : 4 hours x 3 timesRemoval thickness = 25 um x 3 = 75 um

Fine stones + water : 4 hours x 3 timesRemoval thickness = 20 um x 3 = 60 um

Total removal thickness = 135 um.

5

CBP removal thickness depends on surface roughness at EBW seam

Before CBPEquator EBW seam (inner surface)

2nd CBPGood EBW

1st CBP(30um)

Bad EBW

3rd CBP (90um) 12th CBPRemoval thickness> 200 um.

Removal thickness= 60 um.

Bad EBWwith a pit

2nd CBP (60um) 13th CBPRemoval thickness> 200 um.

6

Light Chemical Polishing (CP)and annealing / degassing

Light Chemical Polishing (CP)HF(46%) : HNO3(60%) : H3PO4(85%) = 1 :1 : 1 in volumeCP for 1 minute at 25 OC.Removal thickness = 10 um. Prepare smooth surface before EP.

Annealing/Degassingby furnace750 OC for 3 hoursDegassing of hydrogenis important. Temperature and time is optimized for cavity softness and cost.

7

Cavity

Beam Pipe

Cathode

Cathodebag

AcidLevel

EP acid circulates

Circulating EP acidH2SO4(95%) : HF(46%)

= 10 : 1 in volume

ElectricCurrent

Voltage ~ 20 V, Current ~ 40A

Horizontally Rotated Electro-Polishing (EP)

Back to EP-acidreservoir

tank (100L)

Well established method

8

High Pressure Rinse (HPR)

Ultra Pure Water Specific resistance =18 M Ohm cmTOC = 12 – 22 ppbbacteria = 0 – 3 count / mL

HPR for 1 hour

HPR nozzle

Water pressure= 7 MPa

Flow rate= 10 L/min.

HPR is a very powerful tool to remove particle contaminationon the inner surface of Nb cavity.

9

10

20

30

40

50

60

70

Eac

c,m

ax [

MV

/m]

Date (Year)'91 '00'95 '05'93 '97 '03

High pressuer water rinsing

(HPR)

Electropolshing(EP)

+ HPR + 120 OC Bake

New Shape

Chemical Polishing

Proof of principle for 50 MV/m with ICHIRO single-cell cavity

Press release’05 28th Sept. NHK news, “Good morning Japan”’05 12th Oct. Nikkan Kogyo News’05 21st Oct. Energy News Weekly’05 1st Nov. Daily Yomiuri’06 24th Jan. Nihon Keizai News

Eacc = 53.5 MV/m was achieved.This is the world record.

10

~45MV/m achievement with six single-cell cavities on the first trial (Goal is 85%)

yield rate for ~45 MV/m= 50% on the first trial

108

109

1010

1011

0 10 20 30 40 50

ICHIRO Single cell 1st round

IS#2-2nd

IS#3-1st

IS#4-1st

IS#5-1st

IS#6-1st

IS#7-1st

Qo

Eacc[MV/m]Statistics

Accidental16.7%

FE initiated by MP16.7%

Quench16.7%

No problem50%

Oxidation, EBW,field enhancement ?

EP acid contamination ?

Assembly or HPR problem

Quench

FE

Accidental

3 cavities in 6 achieved the gradient > 44 MV/m.3 cavities failed.

11

Why three cavities (50 %) failed

What 50% failed

Easy mistakein HPR or

careless assembly in clean room

Sulfur or oxidizationContaminationin EP process

Defect of materialor roughnessat EBW seam

Particle on the surface should

be removed

Particle on the surface should

be removed

Much thicker removal

Re-HPR andcareful assembly

Light EP with fresh EP acid

or light CP

EP with thick removal

or CBP

How toimprove?

Additionaltreatments

Possiblesources offailure

No removal Light removal Heavy removal

12

108

109

1010

1011

0 10 20 30 40 50

IS#2-3rd

IS#3-3rd

IS#4-1st

IS#5-1st

IS#6-1st

IS#7-2nd

Qo

Eacc[MV/m]

After HP-rins (20min) for IS#2 and 3

50 % failure from very thin surface?

Pilot study for new recipeHF rinse (0.2 um) + HPR(UPW)

Field emission disappeared after re-HPR.

But no significant improvement in the gradient…..

13

Failed 50% were recovered by light removal

IS#7

IS#3 IS#2 IS#2, EP(20 um) + EP(fresh acid, 3um) Eacc, Q0 = 47.1 MV/m, 1.06e10

IS#3, EP(20-30 um) + EP(fresh acid, 3 um) + HF rinse Eacc, Q0 = 44.7 MV/m, 0.98e10

IS#7, EP(20-30 um) + EP(fresh acid, 3 um) + HF rinse Eacc, Q0 = 43.9 MV/m, 1.17e10

Conclusion:No problem in the material quality, deep-drawing,CBP (mechanical grinding), EBW and all mechanical issues. The source of failure (50%) iscoming from thin surface < ~20 um. Oxidation layer is most suspicious?The KEK recipe needs some modifications for higher yield rate > 85%. But change might be minor.

~20 um removal

All 6 cavitiesEacc > ~44 MV/m

IS#6IS#4

IS#5

Fresh EP acid was used forlast 3 um to avoid contamination.

14

IS#2 IS#3 IS#4 IS#5 IS#6 IS#7

KEK RecipeEacc 36.9 31.4 45.1 44.2 48.8 28.3

Qo 1.53e10 8.66e9 9.07e9 5.38e9 9.56e9 1.94e9

+re-HPR37.6 32.7 42.7 51.4 29.9

1.42e10 7.27e9 5.66e9 7.78e9 1.1e10

+HF rinse

+HPR

37.1 36.7 50.4 50.2 30.0

1.64e10 1.43e10 9.97e9 3.9e9 3.33e9

+CP(10um)

+HPR+Baking

41.0 40.5

6.65e9 5.57e9

+EP (fresh acid, 3 um)

+HPR+Baking

41.6 40.3 41.1

1.00e10 1.28e10 1.17e10

+EP(20-30um)+EP(3um)

+HPR+Baking

47.1 47.8

1.06e10 7.81e9

+EP(20-30um)+EP(3um)

+HF rinse+HPR+Baking

44.7 53.5 43.9

0.98e10 7.83e9 1.17e10

Results of series tests for six ICHIRO Single-cell (IS) cavities

15

IS#2 IS#3 IS#4 IS#7KEK recipe (EP 80um)

+HF rinse +HPRKeep 100K

for 12hKeep 100K

for 21hKeep 100K

for 12h

+EP (fresh acid, 3 um)

+HPR+BakingKeep 100K

for 12hKeep 100K

for 38hKeep 100K

for 40h

+EP(20-30um)+EP(3um)+ HF rinse

+HPR+BakingKeep 100K

for 24h

CP(10um)+EP(20-30um)+EP(3um)

+ HF rinse +HPR+BakingKeep 100K

for 24h

No H Q-disease

H Q-disease was checked by keeping cavities at 100K for >12 hoursin 8 tests with 4 cavities.

No H Q-disease was found after treatments and warming-up to 100K in the above table.

16

Histograms for series tests

ICHIRO shape + KEK recipeFE and Q-slope removed Mean = 44 MV/m.Sigma = 6 MV/m.

Eacc [MV/m]

Repeated tests removedMean = 44 MV/m.Sigma = 7 MV/m.

All testsMean = 38 MV/m.Sigma = 9 MV/m.

Eacc [MV/m]

Eacc [MV/m]

17

Summary• Six ICHIRO-shape single-cell cavities were fabricated for series tests t

o establish the KEK recipe. • The KEK recipe : CBP (mechanical grinding), light CP (10um), annealing / degassing (750 OC for 3 hours), EP (80 um), HPR (Ultra-Pure Water) for 1 hour, Baking (120 OC for 48 hours)• Proof of principle for Eacc=50 MV/m was done. Eacc = 53 MV/m (the world record).• Yield rate of the KEK recipe for Eacc>44 MV/m = 50% (3 in 6) on the first trial.• Pilot study of new recipe. HF rinsing + HPR, EP(3 um) + HPR, EP(20+3 um) + HPR etc..• 3 failed cavities were recovered by additional treatments: EP (20-30 um +3 um) + HPR, EP(20-30 um +3 um) + HF rinse + HPR => All 6 cavities reached Eacc > 44 MV/m => The source of failure exists within the depth of <~30 um.• No H Q-disease was found in 8 tests with 4 cavities.• Eacc histograms were made for the series tests. Mean(Eacc) = 44 MV/m and Sigma(Eacc) = 6 MV/m, if removing FE and Q-slope.• KEK recipe needs some modifications for higher yield rate (>85%) but modification might be minor.

18

OPTIONAL POSTERS

TESLA design cavitiesOperation at 31.5 MV/m

Four 9-cell ICHIRO LL cavities

Already fabricated.

STF Phase 1

Operation at 36 MV/m

STF @ KEK

OP1

ICHIRO 9-cell cavities

MP barrier was severe.(1)Contamination in EP acid?(2)Ununiform gas-absorption during cooling-down cavity?

Feed-back the results from single-cell cavities to the 9-cell cavities.

Even if Eacc<45MV/m, we will install the four 9-cell cavities into STF.

8th Vertical Test (V.T.)

ICHIRO 9-cell#0 Cavity

Eacc = 15.9 MV/mQ0 = 3.4e9

MPEacc = 29.3 MV/mQ0 = 1.02e10

HOM study

Tuner study

MP at HOM coupler?

1st V.T.

#1

#2

#3

#0

OP2

9-cell ICHIRO high-gradient Low-Loss (LL) cavity

Our goal is 51 MV/m !(36 MV/m in operation)

Record breaker, 262 hits in single season in 2004.

Most famous Japanese baseball-player.

Hp/Eacc = 36 Oe/(MV/m)(Designed at KEK in collaboration with DESY.)

OP3

Snowmass ILC 2nd Workshop( 20th Aug. 2005)

• Cavity shape Baseline Configuration (BC): TESLA shape Alternative Configuration (AC): Re-entrant (RE) / Low-Loss (LL) shapes• Cavity gradient (acceptance by pulsed-power sampling test) BC: 35MV/m (TESLA shape) AC: 41MV/m (RE/LL shapes)• Operation gradient (in the cryostat of main linac) BC: 31.5MV/m (TESLA shape) with RF distribution for 35MV/m AC: 36MV/m (RE/LL shapes) Our target at the beginning of 2005 was “to include the possibility of the

operation gradient of 40 MV/m in the appendix of CDR”.

The result was “the operation gradient of 36 MV/m (LL/RE) was adopted as AC”.

OP4

Water quality control R&D

UPW@Nomura

PW (old)@KEK

TOC (ppb)

Bacteria(count / mL)

HPR with Updated Pure Water (PW) at KEK is OK up to the cavity performance of ~46 MV/m.

10 - 20 50 - 150

PW (new)@KEK

50 - 150

0 - 5 10 - 200

PW (old) @KEK is OK up to 36 MV/m

5 - 15

PW (new) @ KEK is OKup to 46 MV/m

KEK PW facilityupdated

Correlation between HPR water-quality and cavity performance was checked.

OP5