Sequel ‘O’ Stone · Sequel ‘O’ Stone system used a polymer modified dry powder mix to give...

Transcript of Sequel ‘O’ Stone · Sequel ‘O’ Stone system used a polymer modified dry powder mix to give...

Sequel ‘O’ Stone

P E R F E C T I O N Y O U D E S I R E

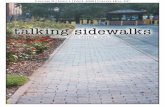

Sequel ‘O’ Stone Sequel ‘O’ Stone system used a polymer modified dry powder mix to

give realistic 3D appearance of natural stone textures on streets,

squares, sidewalks, boulevards, parking, cemeteries, internal yards,

ramps, barns, terrazzo, swimming pools sides, bathrooms, malls and

restructuring of historic centers, either outside or inside. We can

replicate any design, texture and color and create a design to suit your

specific requirements. Our product can complete the desired work in a

fraction of the time than needed for conventional stone applications

and continues to look beautiful after years of exposure to nature's

elements.

Sequel ‘O’ Stone Advantages

Remarkable Realism

Incredible Bonding Ability

Durable, Light Weight

Interior & Exterior

Great Value

Realistic Colors & Designs

High Bonding Strength

Strong & Durable

Water, Fire & Fade Resistant

Less Prep Work

Easy to Clean Surface

Uniform and Intensely Colored Surface

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Sequel ‘O’ Stone

Technical Test Report of Stone Effect

Tests of fresh & solid mortar were performed within the range for the initial

test of a product type according to the requirements of SIST EN 13813:2003

standard. The testing procedures compiled with the standards of the series SIST

EN 1015 & series SIST EN 13892 as well as with SIST EN 1062 – 3 standards, at

factories in- house laboratory testing facilities.

Stone Effect Powder Mix

Measured Property 1 2 Mean Value

Testing Procedure

Consistency – flow table test (mm) 224 221 223 SIST EN 1015-3

Dry bulk density (kg/m3) 1900 1900 1900 SIST EN 1015-6

These tests are carried out by National Test House-Ministry of Consumer Affairs, Govt. of

India as per IS: 1237-1980 specification.

Sequel ‘O’ Stone Water Absorption (In %)

Average water Absorption 2.74

Water Transverse Strength (In N/ mm2)

Average Strength 6.4

Resistance to wear (In mm)

(A) Average wear 3.20

(B) Maximum wear on individual specimen 3.56

Product Stone Effect Powder Mix sample comprised of full tiles and cut piece.

Note: Actual test results achieved as per test conducted at NATIONAL TEST HOUSE

(Ministry Consumer Affairs, Food & Public Distribution Department of

Consumer Affairs, GOVT. of INDIA) V/S Standard Test method & Specification as

per IS: 1237-1980. Tests Result achieved STANDARD

As per IS:1237-1980 1. Dimension (mm)

(a) Length (Avg.) 287 (b) Breadth (Avg.) 287.1 © Thickness (Avg.) 26.42

(a) & (b) Tolerance on length of

breadth shall be 1mm © Tolerance

on thickness shall be ± 5

Sequel ‘O’ Stone

Test Report

2. Water absorption (%)

Average water absorption 2.74 Should not exceed 10%

3. Wet transverse strength N/mm2

Average strength 6. 4 Shall not be less than 3 N/mm2

4. Resistance to wear (mm)

(a) For general purpose tiles (a) Average wear

3.2

(1) Average wear 3.5 mm

(2) Wear in individual specimen is 4mm

(b) For heavy duty floor tiles (b) Maximum wear in

Individual specimens

3.56

(1) Averages wear 2 mm.

(2) Wear in individual specimen is 2.5 mm

Sequel ‘O’ Stone

Contact Us

G1-121-122, Udhyog Vihar,

Bedla Road, Sukher Ind.Area

UDAIPUR – 313001

RAJASTHAN, INDIA

TELEFAX: +91 294 2440829

MOBILE: +91 90012 66999

E-MAIL: [email protected]

WEB: www.ashokamarbles.in

SKYPE: ashoka.marbles