Semi-Submersible Drilling Rig - Rigmar Services Ltd Study QuikDeck Full Underdeck for Steel Repairs...

Transcript of Semi-Submersible Drilling Rig - Rigmar Services Ltd Study QuikDeck Full Underdeck for Steel Repairs...

Case Study QuikDeck Full Underdeck for Steel Repairs and Fabric Maintenance

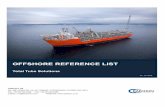

Semi-Submersible Drilling Rig

Drilling Contractor2013Hartlepool

End-Client:Date:Location:

Scope of Work:

• Detailed rigging survey• Detailed QuikDeck® platform design and load calculations• Full encapsulation and subsequent calculation package under wind load• Design, planning and deployment of ‘end-to-end’ system from container unloading to installation: ‘Lean Thinking’• Installation of 3500M² of QuikDeck®• Integrated rubble chutes, direct to quayside skips from 35 metres• Full perimeter cantilever for system scaffold access to elevation faces• Multi-height trenches to access underside of main girders • Mobilisation of 16 containers and 21 rope access riggers• Site management of all interfaces during installation and deconstruct• Daily reporting of progress to plan using visual aids and % completion• Training of all personnel requiring access to the deck• Daily Inspection of the platform and monitoring of client conformity to loading etc.

CS-025

Rigmar operate internationally from offices in the UK, Canada, UAE, Ghana, Singapore and Angola

For more information, contact Rigmar Services Ltd on:

+44 (0)1224 243000 [email protected] www.rigmar.co.uk

Hareness CircleAltens Industrial Estate

AberdeenAB12 3LY

Key Benefits:

• 3500M² installed in 18 days with 18 dedicated technicians• 50% faster installation time than scaffold• 75% less contact points than scaffold, reducing the volume of ‘snagging’ work by 75%• 244KG/M² live load capability • 100% DROPS free• Rapid equipment supply by integrating with spaceframe• Improved quality of access over any other system

The solution provided by Rigmar, combined both their QuikDeck® and Spaceframe systems, with the Spaceframe platform acting as a material supply line from the quayside to the under deck construction scope. The entire process from the container orientation on the quayside, to the leading edge build team was carefully developed to the last detail using ‘lean thinking’ principles adopted from the manufacturing sector, ensuring balanced flow, 100% productivity and zero downtime.

The end client selected Rigmar as a ‘nominated sub-contractor’ to support the principle contractor in ensuring the under deck access of the project became low risk in terms of the critical path. Rigmar succeeded in delivering the under deck ahead of schedule, with zero accident or incidents in over 10,000 man hours on site.

Rigmar Services were contracted to design and install a 3500M² QuikDeck® platform to allow client access at 35 metres above sea level, to conduct steel deck replacement and fabric maintenance.

AberdeenHareness CircleAltens Industrial EstateAberdeenAB12 3LYTel: +44 (0)1224 243000Email: [email protected]

InvergordonUnit 8/9, Supply BaseShore RoadInvergordon, Ross-shireIV18 0EXTel: +44 (0)1349 856300Email: [email protected]

Sheffield7th Floor, The Balance,2 Pinfold StreetSheffieldS1 2GUTel: +44 (0)1142 094049Email: [email protected]

Contact us

www.rigmar.co.uk

Abu DhabiPO Box 31455Abu DhabiUAETel: +971 (0)2447 7741Email: [email protected]

AngolaRua Banto Banha CardosoNo. 20/22Bairro MaculussoLuandaTel: +244 943 026 139Email: [email protected]

GhanaNo. 2 Parkview PlazaCommunity 1TemaTel: +233 (0)303 209863Email: [email protected]

Canada1247A Kenmount RoadParadiseNewfoundlandA1L 0V8Tel: +1 709 743 4904Email: [email protected]

Singapore74 Tras Street#02/01Singapore079013Tel: +65 6224 8851Email: [email protected]