Self-mixing flow sensor using a monolithic VCSEL array with parallel readout

-

Upload

aleksandar-d -

Category

Documents

-

view

213 -

download

1

Transcript of Self-mixing flow sensor using a monolithic VCSEL array with parallel readout

Self-mixing flow sensor using amonolithic VCSEL array with parallel

readout

Yah Leng Lim,1,4 Russell Kliese,1 Karl Bertling,1

Katsuyoshi Tanimizu,2 P. A. Jacobs,2 and Aleksandar D. Rakic1,3

1School of Information Technology and Electrical Engineering, The University of QueenslandBrisbane, QLD 4072, Australia

2School of Mechanical & Mining Engineering, The University of QueenslandBrisbane, QLD 4072, Australia

[email protected] [email protected]

Abstract: The self-mixing sensing technique is a compact, interferometricsensing technique that can be used for measuring fluid flows. In this work,we demonstrate a parallel readout self-mixing flow velocity sensing systembased on a monolithic Vertical-Cavity Surface-Emitting Laser (VCSEL)array. The parallel sensing scheme enables high-resolution full-fieldimaging systems employing electronic scanning with faster acquisitionrates than mechanical scanning systems. The self-mixing signal is acquiredfrom the variation in VCSEL junction voltage, thus markedly reducingthe system complexity. The system was validated by measuring velocitydistribution of fluid in a custom built diverging-converging planar flowchannel. The results obtained agree well with simulation and demonstratethe feasibility of high frame-rate and resolution parallel self-mixing sensors.

© 2010 Optical Society of America

OCIS codes: (280.4788) Optical Sensing & Sensors; (280.3420) Laser Sensors; (250.7260)Vertical cavity surface emitting lasers.

References and links1. R. Lang and K. Kobayashi, “External optical feedback effects on semiconductor injection laser properties,” IEEE

J. Quantum Electron. 16(3), 347–355 (1980).2. Y. Mitsuhashi, J. Shimada, and S. Mitsutsuka, “Voltage change across the self-coupled semiconductor laser,”

IEEE J. Quantum Electron. 17(7), 1216–1225 (1981).3. Y. L. Lim, K. Bertling, P. Rio, J. Tucker, and A. Rakic, “Displacement and distance measurement using the

change in junction voltage across a laser diode due to the self-mixing effect,” vol. 6038, pp. 60381 – (Brisbane,Australia, 2006).

4. F. Gouaux, N. Servagent, and T. Bosch, “Absolute distance measurement with an optical feedback interferome-ter,” Appl. Opt. 37(28), 6684–6689 (1998).

5. S. Donati, M. Norgia, and G. Giuliani, “Self-mixing differential vibrometer based on electronic channel subtrac-tion,” Appl. Opt. 45(28), 7264–7268 (2006).

6. S. Shinohara, A. Mochizuki, H. Yoshida, and M. Sumi, “Laser Doppler velocimeter using the self-mixing effectof a semiconductor laser diode,” Appl. Opt. 25(9), 1417–1419 (1986).

7. F. de Mul, M. Koelink, A. Weijers, J. Greve, J. Aarnoudse, R. Graaff, and A. Dassel, “Self-mixing laser-Dopplervelocimetry of liquid flow and of blood perfusion in tissue,” Appl. Opt. 31(27), 5844–5851 (1992).

8. C. Zakian and M. Dickinson, “Laser Doppler imaging through tissues phantoms by using self-mixing interfer-ometry with a laser diode,” Opt. Lett. 32(19), 2798–2800 (2007).

9. J. R. Tucker, J. L. Baque, Y. L. Lim, A. V. Zvyagin, and A. D. Rakic, “Parallel self-mixing imaging system basedon an array of vertical-cavity surface-emitting lasers,” Appl. Opt. 46(25), 6237–6246 (2007).

10. Y. L. Lim, M. Nikolic, K. Bertling, R. Kliese, and A. D. Rakic, “Self-mixing imaging sensor using a monolithicVCSEL array with parallelreadout,” Opt. Express 17(7), 5517–5525 (2009).

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11720

11. K. Goossen, J. Cunningham, and A. Krishnamoorthy, “1 × 12 VCSEL array with optical monitoring via flip-chipbonding,” IEEE Photon. Technol. Lett. 18(11), 1219–1221 (2006).

12. H.-E. Albrecht, M. Borys, N. Damaschke, and C. Tropea, Laser Doppler and Phase Doppler MeasurementTechniques (Springer Verlag, Berlin, 2003).

13. C. Zakian, M. Dickinson, and T. King, “Dynamic light scattering by using self-mixing interferometry with a laserdiode,” Appl. Opt. 45(10), 2240–2245 (2006).

14. Elmo Motion Control, “SimplIQ Digital Servo Drives: Whistle,” (2010), URL http://www.elmomc.com/products/whistle-digital-servo-drive-main.htm.

15. M. Post, R. Richter, R. Keeler, R. Hardesty, T. Lawrence, and F. Hall, “Calibration of Coherent LIDAR Targets,”Appl. Opt. 19(16), 2828–2832 (1980).

16. D. K. Serkland, K. M. Geib, G. M. Peake, R. Lutwak, A. Rashed, M. Varghese, G. Tepolt, and M. Prouty,“VCSELs for atomic sensors,” Proc. SPIE 6484, 648406 (2007).

17. X. Raoul, T. Bosch, G. Plantier, and N. Servagent, “A double-laser diode onboard sensor for velocity measure-ments,” IEEE Trans. Instrum. Meas. 53(1), 95–101 (2004).

18. V. V. Tuchin, Tissue optics : light scattering methods and instruments for medical diagnosis, vol. 2nd ed. (SPIEPress, Bellingham, Washington, 2007).

1. Introduction

The laser self-mixing sensing technique is a simple interferometric sensing technique where aportion of the light emitted from the laser reflects from a target and re-enters the laser cavitywhere it causes measurable changes in emitted power [1] and junction voltage [2]. The resultingoutput power variations are usually monitored by an integrated photodiode within the laserpackage but it is also possible to measure the junction voltage variations which removes theneed for a photodiode [3]. This phenomenon allows the laser itself to function as both thelight source and the detector making possible low-cost and compact sensors. The laser self-mixing sensing technique has been used for a wide variety of measurements including absolutedistance [4], vibrations [5], velocity [6] and fluid flow rate [7].

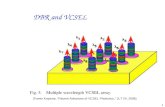

Most self-mixing sensors are single-point systems and acquiring measurements over an areais typically achieved by mechanical scanning [8]. An obvious extension to single-point acqui-sition is to use multiple individual lasers in a single sensor package, however, parallel sensingsystems using individually packaged lasers suffer from misalignment which directly contributesto measurement inaccuracies of flow velocity, as was observed in previous work conducted byTucker et. al [9]. The Vertical -Cavity Vertical-Cavity Surface-Emitting Laser (VCSEL) con-struction offers advantages compared to in-plane lasers because VCSELs emit light normalto the surface of the wafer. VCSELs can therefore be operated without dicing of the substrate,allowing the lasers to maintain their precise lithographic alignment. We have previously demon-strated such an array for velocity measurements [10]. In this work, we present, to the best of theauthors’ knowledge, the first self-mixing flow mapping system utilizing a monolithic VCSELarray with parallel readout.

The multi-channel sensor makes use of a 1×12 VCSEL array for measuring fluid motion todemonstrate the feasibility of a self-mixing array-based flow-imaging system. The self-mixingsignals are obtained directly via feedback-caused variation in the VCSEL junction voltage.This key solution offers significant technological advantage as it avoids optical monitoring oflaser power fluctuations, removing the need for VCSEL-photodiode array hybrid integrationand the complexities associated with this process [11]. Moreover, the feedback occurs in thehigh-finesse laser cavities and is coherent in nature, thus the problem of optical crosstalk isavoided.

The paper is structured to provide the Doppler theory necessary for the flow velocitymeasurements in Sec. 2. A detailed description of the experimental setup is presented in Sec. 3.In Sec. 4 we report on the simulated results for the velocity distribution of fluid within the flow-channel. These simulation results are then compared against the experimental results presentedin Sec. 5. Finally conclusions are drawn in Sec. 6.

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11721

2. Theory

For a moving target with velocity �v, the back scattered light experiences a Doppler frequencyshift fD given by [12]

fD =(�ksc −�kinc) ·�v

2π(1)

where�kinc and�ksc are the wave vectors of the incident and scattered light respectively. In theself-mixing interferometer configuration, the scattered signal is collected by the same lens usedto focus the beam on the target and Eq. (1) becomes

fD =2n k ·�v

λ 0(2)

where k is the unit vector in the direction of the laser emission, λ 0 is wavelength of light invacuum and n corresponds to the refractive index of the medium surrounding the target. Theresult of coherent mixing within the laser cavity between the lasing field and the Doppler-shiftedlight backscattered by a moving target leads to a fluctuation of photon density and consequentlythe output power and junction voltage.

In fluid flow, the moving target consist of moving particles suspended in the fluid. The lightscattered from a moving particle is frequency shifted by an amount determined by the Dopplereffect as indicated by Eq. (2). The optical system collects light scattered from a number ofdifferent particles with different velocities, which leads to a distribution of Doppler shifts in theoutput power spectrum and its shape is dependent on the level of particle concentration in thesolution [13]. For a solution where particle concentration is low enough that multiple scatteringcan be ignored, a well defined peak appears in the frequency spectrum corresponding to theDoppler frequency of the moving particle [7]. This information can then be used to determinethe flow rate of the liquid.

3. Experimental setup

Figure 1 shows the schematic diagram of the experimental setup used to measure the fluid flowprofile in a custom made flow channel. The source used was a commercial 1×12 monolithicVCSEL array (EMCORE Corporation, Gigalase 8185-1100) which are AlGaAs planar, top sur-face emitting devices with 15 µm apertures in the top mirror contact and laser pitch of 250 µm.The average threshold current of the VCSELs is about 6 mA and each laser has a peak wave-length at around 850 nm. C-mount camera objective lenses were selected to image the laserbeams on the flow channel to minimize field distortion. The imaging system was designed toprovide a non-inverted image with 2× magnification and made use of a 25 mm focal lengthlens (lens 1) and a 50 mm focal length lens (lens 2). The pitch between the spots on the flowchannel is 500 µm.

Figure 2(a) shows the dimensions of the custom made diverging-converging planar flow-channel. It is 3 mm deep and a microscope cover slip of 160 µm thickness is employed asthe top window sealing cover allowing the VCSEL beams to illuminate different points in thechannel. The channel was mounted onto a translation stage that has 50 mm travel in the scanningdirection and the stage movement was driven by a DC servo motor that was controlled by anElmo Whistle [14] motor controller. The scanning was carried out with a step size of 1 mm inall experiments.

A custom built 12-channel laser driver was used to individually bias each laser just aboveits threshold in order to obtain maximum sensitivity to the self-mixing effect. The self-mixingsignals were obtained through terminal voltage variations across individual VCSELs. Terminal

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11722

PCData Acquistion

card

12-ChannelLD Driver

X100

12

5Mux Address

1x12monolithic

VCSEL array

Lens 1

Flow Channel

Lens 2

Flow Direction

z x

y

12-ChannelPre-amp

Analog Mux

θ

Fig. 1. Schematic diagram of the flow measurement system based on a monolithic VCSELarray. The fluid is fed into the flow-channel using gravitational feed to ensure smooth flow.The angle between the flow channel and the laser axis is set to 10° to provide a smallvelocity component in the direction of the laser beam (θ = 80◦).

voltage fluctuations were first amplified individually using an ac-coupled, low noise preampli-fier with a voltage gain of 100. The pre-amplified voltage signals were then fed to a computercontrolled analog multiplexing module for addressing and switching of the laser signals. Ad-ditional amplification (G = 100) was subsequently applied to the multiplexed voltage signal,bringing it to a level suitable for processing by a 16-bit data acquisition card. The total band-width of this multi-stage amplification system is 600 kHz. A sampling rate of 800k samplesper second was used to acquire the self-mixing signals which gives a effective measuring band-width of 400 kHz. Fast-Fourier Transform (FFT) was applied to the time-domain signals toobtain frequency spectra consisting of 32k points. The frequency spectrum for each channelswas subsequently averaged 32 times and saved. A customized LabVIEW application was devel-oped to carry out the signal acquisition, in conjunction with automating the channel scanning.

4. Flow-channel simulations

The fluid flow distributions in the flow channel depicted in Fig. 2(a) were simulated in orderto provide a comparison to the experimental results obtained with the experimental resultsfrom the self-mixing sensor. The fluid parameters used for the simulations were those of waterat room temperature. The simulations were performed using the commercial computationalfluid dynamics package, CFD-ACE+ from ESI-Group. The results provide 3-D distribution ofthe velocity vectors for points within the flow channel on a fine hexahedron structured gridcontaining 30, 292 and 31 points in the x, y and z directions respectively [see Fig. 2(a)].

5. Measurement results

The experiment was carried out with the angle, θ , between the flow channel and the laser axisset to 80◦. The fluid used was a dilute solution of one part homogenised full cream milk to 50parts water to obtain a single scattering regime. The total image height of the 12-channel arrayprojected onto the flow channel is 5.5 mm. Laser LD6 of the VCSEL array was set along thecenter-line of the channel while the last channel (LD12) was omitted in experiments to achievegeometrical symmetry as shown in Fig. 2(a). The entire channel was scanned by performing

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11723

(a)

16

Scan Area56

Source Sink

Flow Direction

0 30

LD1

LD11

x

y

z

0 5 10 15 20 25 30 35 400

0.005

0.01

0.015

0.02

0.025

Frequency (kHz)

Pow

er (A

.U.)

(c)(b)

Fig. 2. (a) Mechanical layout of the flow-channel. The channel is 56 mm in length by19.75 mm (at its widest point) and has a depth of 3 mm. The shaded area indicates the ef-fective area scanned with three consecutive broom sweep using an array of 11 laser beams.(b) Video recording showing the array of laser beams scanning along the central regionof the flow channel (Media 1). (c) Doppler frequency spectra of slow (blue-line) and fast(red-line) points in the flow channel obtained from laser LD8 with an inlet flow rate of15mL/min. The positions corresponding to the measured spectra is represented in (a) usingmatching colors.

three horizontal broom sweeps starting from the top portion of the channel, resulting in a totalof 33 vertical points that are swept across the channel. The area of the channel that was scannedis shaded in Fig. 2(a).

The frequency spectra of self-mixing signals acquired at two points in the channel for a15 mL/min inlet flow rate are plotted in Fig. 2(c) where the color of the spectra corresponds tothe same colored dots as indicated in Fig. 2(a). It was observed that the width of the Dopplerfrequency peak increases with increasing velocity, and it’s amplitude decreases. These spec-tral trends were consistent to the work by Post et. al [15]. The spectral width of the Dopplerfrequency should be proportional to the velocity and the spot size of the laser beam. Since thespot-size remains constant throughout the experiments, the broadening of the spectral widthwill depend solely on the velocity. This observation was used in formulating the following be-havioral function which was fitted to the measured spectra in order to extract the frequencypeak corresponding to fD:

PSD( f ) =af b + c+

d(1+( f− fD

f/n )2) (3)

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11724

where a and b in the first term are parameters used for fitting the 1/ f -noise as suggested bySerkland et. al. [16]. The second term, c, is used for fitting the spontaneous emission of thelaser. The last term is a Lorentzian function where d corresponds to the strength of the Dopplerpeak. The half-width at half-maximum of the Doppler spectra is represented by the denominatorterm, f/n, which is scaled by factor n and is directly proportional to frequency. The inclusion ofnoise in our fitting routine is required to ensure an accurate value of fD is extracted as the noisehas a significant influence on the acquired spectra, particularly at low frequencies as can be seenin Fig. 2(c). Subsequently, the component of velocity in the direction of the laser beams can beinferred from fD at each spatial position on the flow channel Eq. (2), taking into considerationthe refractive-index of the fluid (n ≈ 1.333) that will refract the laser emission.

Simulation showed that there is a small component of velocity in the z-axis which will havethe effect of introducing errors in the inferred x-axis flow velocities. However, these velocitycomponents were only significant around the inlet and outlet regions of the channel. As a result,flow distributions were measured in the center region of the channel approximately 10 mmfrom the left and right edges of the flow channel where there is no significant flow in the z-axisdirection. It would be possible to add additional lasers with different emission angles in order to

0 5 10 15 20 25 30 35 40 450

1

2

3

4

5

6

7

8

9

10

H−position (mm)

velo

city

(mm

/s)

0 5 10 15 20 25 30 35 40 450

1

2

3

4

5

6

H−position (mm)

Vel

ocity

(mm

/s)

0 5 10 15 20 25 30 35 40 450

2

4

6

8

10

H−position (mm)

Vel

ocity

(mm

/s)

(a)

(d)

(b)

(c)

Fig. 3. Velocity profile along the center-line of the channel at (a) 10 mL/min,(b) 15 mL/min, and (c) 20 mL/min. The blue dots represent the measured data. The red linesshow the upper and lower range of depth used to calculate the average curve (green lines)for fitting the measured values. The calculated sensing depth is approximately 278 µm. Weuse 300 µm for fitting the measured values. (d) Video recording showing a trapped bub-ble on the back surface of the glass window and the effect that a bubble has on the laserbeam. This causes errors in the acquired Doppler frequency fD resulting in outliers alongthe curves.(Media 2)

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11725

extract the individual flow velocity components [17]. In many applications this is not necessaryas the fluid flow direction is well known. For example, flow direction in peripheral tissues iswell guided by the blood vessels [18].

Figure 3 shows the laminar flow profile along the center-line of the flow channel at 3 differentinlet flow-speeds of 10, 15 and 20 mL/min respectively. The red-lines in Fig. 3(a), 3(b) and 3(c)represent the fluid velocity in the direction of the laser beam at different channel depths, ob-tained from simulations. The depth spacing between adjacent red lines is 100 µm. The opticalarrangement employed in this system ensures a shallow depth-of-focus when compared to sin-gle lens systems employing a collimated beam. Using the Gaussian beam approximation, wecalculated the depth-of-focus of the laser beams to be 254 µm. This suggests that the measuredresults correspond only to a limited section of the entire channel. The green-line in each graphrepresents the average fluid velocity calculated across a selected section 300 µm deep (withinthe range of red-lines) that best fits the measurement results. The results show close correlationwith similar trend between simulated and measured results. However, there are minor discrep-ancies in the measurements which are likely caused by micro bubbles present in the channelwhile laser scanning was performed. Figure 3(d) illustrates the effect of a tiny trapped air bub-ble on the back face of the glass window, which was encountered while laser scanning wasperformed. These air bubbles alter beam parameters such as depth-of-focus and spot-size, andcan significantly alter the beam angle which leads to erroneous reading of fD.

All the measured data were subsequently combined to form a two-dimensional map of thefluid flow distribution as depicted in Fig. 4. A good agreement can be seen between the simu-

V−

Pos

ition

(m

m)

Simulated

0 5 10 15 20 25 30−8

−4

0

4

8

H−position (mm)

V−

Pos

ition

(m

m)

Measured

Flow speed (mm/s)

0 5 10 15 20 25 30−8

−4

0

4

8

0 1 2 3 4

Fig. 4. A comparison between the simulated and measured velocity distributions within theflow channel with an inlet flow rate of 15 mL/min. The flow speeds are in the direction ofthe laser beams.

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11726

lated and measured results confirming the ability of the system to accurately create a 2-D flowmap. A minor difference between the measured and simulated results is the stronger central jetin the measured results. This may be due to the high sensitivity of the flow profile on the inletgeometry and surface properties that are difficult to reproduce accurately in the simulation.

6. Conclusion

In this paper, we demonstrated a full-field self-mixing sensor system with simultaneous read-out from an array of VCSELs for measuring fluid-flow velocities. A small scale prototype ofthe system, based on the 1×12 VCSEL array has been implemented. The performance of thesystem has been validated by imaging the distribution of fluid flow velocity in a custom madechannel. The results obtained match closely the simulated velocity distributions of the channeland suggest that the image quality improvement due to lithographic alignment of lasers consti-tuting the monolithic array is essential for expanding this concept in the creation of a massivelyparallel Doppler imaging systems based on two-dimensional VCSEL arrays. The VCSELs inthis system are used as both the light source array and the sensor array by sensing the change injunction voltage across each VCSEL. This sensing technique removes the need for the hybridintegrated photodetector array with the VCSEL array, which significantly reduces the complex-ity the proposed system. Furthermore, this coherent detection scheme efficiently suppresses theoptical crosstalk from the neighboring lasers. In comparison with a single spot-raster scan sys-tem, the acquisition time is significantly shortened as the mechanical scanning process in oneaxis is replaced by concurrent acquisition at all channels/pixels. Further to this, the use of a2-D VCSEL array will remove the need for mechanical scanning completely, thus improvingacquisition time, temporal resolution and reducing mechanical complexity.

Acknowledgements

This research was supported under Australian Research Council’s Discovery Projects fundingscheme (DP0988072).

#126779 - $15.00 USD Received 9 Apr 2010; revised 30 Apr 2010; accepted 13 May 2010; published 18 May 2010(C) 2010 OSA 24 May 2010 / Vol. 18, No. 11 / OPTICS EXPRESS 11727