Selective removal of Hg(II) from aqueous solution by functionalized magneticmacromolecular hybrid...

description

Transcript of Selective removal of Hg(II) from aqueous solution by functionalized magneticmacromolecular hybrid...

Accepted Manuscript

Selective removal of Hg(II) from aqueous solution by functionalized magnetic-macromolecular hybrid material

Khalid Z. Elwakeel, Eric Guibal

PII: S1385-8947(15)00798-6DOI: http://dx.doi.org/10.1016/j.cej.2015.05.110Reference: CEJ 13751

To appear in: Chemical Engineering Journal

Received Date: 17 April 2015Revised Date: 28 May 2015Accepted Date: 29 May 2015

Please cite this article as: K.Z. Elwakeel, E. Guibal, Selective removal of Hg(II) from aqueous solution byfunctionalized magnetic-macromolecular hybrid material, Chemical Engineering Journal (2015), doi: http://dx.doi.org/10.1016/j.cej.2015.05.110

This is a PDF file of an unedited manuscript that has been accepted for publication. As a service to our customerswe are providing this early version of the manuscript. The manuscript will undergo copyediting, typesetting, andreview of the resulting proof before it is published in its final form. Please note that during the production processerrors may be discovered which could affect the content, and all legal disclaimers that apply to the journal pertain.

1

Selective removal of Hg(II) from aqueous solution by functionalized

magnetic-macromolecular hybrid material

Khalid Z. Elwakeela, Eric Guibal

b

a Environmental Science Department, Faculty of Science, Port-Said University, Port-Said, Egypt

b Ecole des mines d’Alès, Centre des Matériaux des Mines d’Alès (C2MA), 6, avenue de Clavières,

F-30319 Alès cedex, France

Abstract:

A new hybrid material was prepared using chitosan, glycidyl methacrylate and magnetite

microparticles. The concentration of amine groups on the sorbent was increased by grafting

diethylenetriamine. These materials were tested for the sorption of Hg(II) metal ions. These

materials showed high affinity and selectivity for Hg(II) uptake from aqueous solutions:

maximum sorption capacity reached 2.6 mmol g−1

at pH 4.0. The influence of pH was tested

on the selective separation of Hg(II) from a mixture of Hg(II), Co(II), Cu(II), Fe(II), Ni(II),

Zn(II) and Mg(II). The effect of counter anions was also studied at different pH values.

Sorption may occur on amino groups by chelation of cationic mercury species on amino

groups or by ion exchange of chloroanionic mercury species on protonated amino groups.

Uptake kinetics and sorption isotherms were modeled using the pseudo-second order rate

equation and the Langmuir equation, respectively. The distribution coefficient was obtained at

different temperatures and the thermodynamic parameters have been calculated: the sorption

is endothermic, spontaneous and contributes to increase the entropy of the system. Potassium

iodide was used for Hg(II) desorption from loaded sorbents: desorption yields 99%, and the

sorbent could be efficiently recycled for a minimum of three sorption/desorption cycles.

Keywords: Hg(II) sorption; magnetic hybrid sorbent; diethylenetriamine-grafted chitosan;

uptake kinetics; sorption isotherms; thermodynamics.

1. Introduction

Corresponding author: Fax: +33(0) 466782701 – Phone: +33 (0)466782734

E-mail address: [email protected] (E. Guibal).

2

The regulations at international level are becoming more and more drastic concerning the

discharge of heavy metal ions into the environment. Therefore controls on industrial

wastewater are stressed because of their potential threat on human health and on the

biosphere. In addition, due to the rarefaction of some metal resources (critical, strategic and

precious metals, for example) strongly incentive politics of material reuse and recycling have

been recently elaborated.

The Agency for Toxic Substances and Disease Registry ranked mercury as the third priority

hazardous substance, after arsenic and lead [1]. Water pollution by Hg(II) is thus a serious

environmental issue, though many national or international directives are recommending as

far as possible substituting other metal to mercury or changing the production processes to

avoid using mercury . This metal is non-biodegradable and can threat the ecosystem by being

accumulated in the food chain; the dramatic Minamata intoxication of local population clearly

illustrates this hazardous effect. Hg(II) may be discharged into the environment through

wastewaters issued from different industries such as: electroplating, leather tanning, metal

finishing and petroleum refining.

Hg(II) removal from contaminated water is imperative to make water fit for the human uses

(drinking, agriculture, etc.). The allowed concentrations for discharge into surface water and

for drinking water are 10 µg/L and 1 µg/L, respectively [2]. The aforementioned threats of

mercury require developing treatment processes capable to face, alone or in combination with

other processes, the target levels for discharge into the environment. Generally, metal ions can

be recovered from solutions through conventional processes such as precipitation, solvent

extraction, membrane techniques, ion-exchange and chelating resins. Frequently these

techniques fail to fit with target regulations (technical limitations), or economic constraints

(solvent extraction is not appropriate for dilute effluents; membrane processes may be

expensive for large-scale applications) or produce huge amounts of contaminated sub-

3

products (with potential complementary hazards for the environment, as it may occur with

precipitation processes). Sorption is one of the preferred methods for the removal of metal

ions from the wastewater as it is effective as well as cost-effective [3]. In the field of sorption

processes, several alternative materials have been investigated for the last decades making

profit of materials of biological origin for metal binding: biosorption consists in using

functional groups held on materials of biological origin for metal recovery with mechanisms

similar to those found in ion-exchange and chelating resins. These materials can be issued

from agriculture, fishing or as by-product of other industries : fungal, algal, bacterial biomass,

agriculture or food industry residues, for example. Chitosan ((1,4)-2-amino-2-deoxy-β-D-

glucan) is an emblematic biopolymer that was abundantly studied for metal binding. Being

produced at the commercial scale from the shells of crustacean, it is obtained by alkaline

deacetylation from chitin (the primary resource) and bears many hydroxyl groups (which

bring hydrophilic behavior to the biopolymer, and also possible sites for chemical

modification and grafting) and amino groups. This biopolymer has unique properties among

polysaccharide having cationic behavior in acid solutions. Amino groups are involved in

metal binding through different mechanisms including (a) metal cation chelation in near

neutral solutions (through the free electron doublet of nitrogen), and (b) binding of metal

complex anion by ion-exchange/electrostatic attraction on protonated amino groups (in acidic

solutions). With a pKa that depends on the degree of acetylation (incomplete deacetylation of

chitin) and the degree of neutralization but ranges between 6.3-6.7 for most common

commercial samples [4] the protonation of chitosan leads, in most cases (with the remarkable

exception of sulfuric acid) to the dissolving of chitosan in acid media. This is the base of the

mechanisms used for changing the conditioning of the biopolymer but this is also a serious

drawback for potential applications in the field of metal sorption. A cross-linking treatment or

a chemical modification is thus required for extending the pH field of application (for both

4

sorption and desorption steps). On the other hand, Glycidyl methacrylate (GMA) is an

attractive vinyl monomer because of its low toxicity, lower cost compared with other acrylic

monomers, versatile properties and especially due to the presence of epoxy group in its

molecule [5], which makes it very reactive for chemical modification or for reacting with

other materials. These polymers are potent sorbents for various transition metals [6, 7].

Various studies on metal sorption on chitosan-based materials have pointed out the limitations

in uptake kinetics due to the resistance to intraparticle diffusion (which may be explained by

the residual crystallinity of the biopolymer and by poor porous and surface properties). This

drawback was partially solved changing the conditioning of the biopolymer (manufacturing

gel beads, membranes and so on). Another possibility consists in reducing the size of sorbent

particles but at the expense of serious drawbacks concerning particle recovery at the end of

the process (in batch systems) or head loss (in fixed-bed applications). Recently, a number of

studies have developed an alternative for solving the problem of filtration or recovery of fine

(micro- or nano) particles: the incorporation of a magnetic core (or its in situ production, with

simultaneous coating with biopolymer) in the particle makes easier the handling and recovery

of these fine sorbent particles. These methods are cheap and often highly scalable. Moreover,

these techniques employing external magnetic fields are more amenable to automation [8].

The reactivity of the sorbent can be improved by grafting new functional groups such as

polyamine compounds [9-13]. The objective may consist in increasing the density of sorption

sites, in improving the sorption selectivity, in changing the sorption mechanism (ion-

exchange vs. chelation or the reciprocal), or in extending the field of application (especially

regarding pH range).

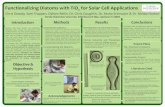

The objective of this work consists in synthesizing a magnetic composite made of glycidyl

methacrylate (GMA) and chitosan (coating the magnetic Fe3O4 core) that is functionalized by

grafting diethylenetriamine (DETA) through GMA (to increase the density of sorption sites

5

(and their potential selectivity). These composite materials are being tested for Hg(II)

recovery through the study of pH effect, the investigation of competition effects (composition

of the matrix: competitor metal ions, counter anions), the determination of sorption isotherms

and thermodynamic characteristics and the identification of controlling steps in uptake

kinetics. Finally the desorption of Hg(II) is studied with the objective of verifying the

possibility to recycle the sorbent.

2. Materials and methods

2.1. Materials

All chemicals used were of analytical grade and demineralized water was used for the

preparation of all aqueous solutions. Glycidyl methacrylate (GMA) was provided by Riedel-

de Haën (Germany), while N,N’ methylenebisacrylamide (MBA) and benzoyl peroxide

(Bz2O2) were supplied by Fluka AG (Switzerland). Chitosan, epichlorohydrin

(chloromethyloxirane) and diethylenetriamine (DETA) were obtained Sigma-Aldrich

(Switzerland) while isopropyl alcohol was provided by Carlo Erba (France). Chitosan was

provided by Aber Technologies (France) ; the deacetylation degree of the biopolymer was 87

ù and the molecular weight (MWn) was 125000 g mol-1

. All other chemicals were Prolabo

products (France) and were used as received. HgCl2 salt was used for the preparation of the

stock solution, except in the case of the study of counter anions (for which the relevant salt of

mercury was used).

Fe3O4 particles were synthesized by co-precipitation of ferric and ferrous salts following a

procedure derived from the so-called Massart method [14]. The amounts of 6.480 g of

FeCl3·6H2O and 3.334 g of FeSO4·7H2O were dissolved into 150 mL of demineralized water.

Then 2 mL of HCl was added under continuous stirring for 30 min, until complete dissolving

6

of precursors salts. The chemical precipitation was achieved at 30 °C under vigorous stirring

by drop wise addition of 10 mL of NaOH solution (50%, v/v). During the reaction process,

pH was maintained around pH 11. The reaction system was maintained under agitation at 30

°C for 15 min. The product was then washed with demineralized water several times and

stored for use.

2.2. Preparation of the magnetic-macromolecular hybrid material

Step 1: Magnetic chitosan particles were prepared by the co-precipitation method, 4 g

chitosan powder was dissolved in a volume of 150 mL of acetic acid solution (10 %, w/v).

The magnetite precursors were mixed with 150 mL of demineralized water (i.e., 6.479 g of

FeCl3·6H2O and 3.334 g of FeSO4·7H2O) using a volume of 2 mL of HCl (concentrated) for

improving salt dissolution under continuous stirring for 30 min. After complete dissolution of

iron salts, the solution was mixed with the chitosan solution. Then the chemical precipitation

of magnetic chitosan material was performed at 30 °C under vigorous stirring by dropwise

addition of 20 mL of NaOH solution (50 %, v/v) for 30 min. The pH was roughly controlled

around pH 11. The solid product that was recovered by centrifugation was freeze-dried using

a freeze-dryer (Bioblock scientific, Christ) at 223 K and 0.01 mbar; this intermediary product

was called MC (magnetic chitosan).

Step 2: The magnetic-chitosan-glycidyl-methacrylate macromolecular hybrid material was

prepared through the polymerization of GMA in the presence of MC particles (Step 1). GMA

(5.0 g) corresponding to a mass ratio of 50 % (w/w, referred to MC amount) was used for

GMA grafting; 0.2 g of MBA was used as the cross-linking agent and 0.1 g of Bz2O (acting as

the initiator of the polymerization reaction) was added under agitation before adding 1.0 g of

magnetite. Three mL of isopropyl alcohol and 25 mL of cyclohexane were mixed and added

to the former solution. The solution was then poured into a flask containing 100 mL (1 %)

7

polyvinyl alcohol and heated on a water bath at 75–80 C under continuous stirring for 3 h.

The product was filtered off and washed repeatedly with demineralized water and acetone

before being air-dried. The product was called MCGMA. The preparation and modification of

magnetic-macromolecular hybrid material is described in Scheme 1, and the suggested

chemical structure of MCGMA is shown in Scheme 2.

2.3. Chemical modification of MCGMA

2.3.1 Diethylenetriamine grafting – First method

MCGMA was suspended in dioxane (100 mL) and then treated with 5 mL of

diethylenetriamine (DETA). The suspension was stirred at 70 °C for 12 h. The product was

successively washed with water and acetone. The product was then air-dried and called

MCGMA-I.

2.3.2 Diethylenetriamine grafting – Second method (via epichlorhydrin)

MCGMA was suspended in 70 mL of isopropyl alcohol. Then 7 mL of epichlorohydrin (62.5

mmol) dissolved in 100 mL acetone/water mixture (1:1 v/v) was added to the suspension. The

reaction was performed under continuous stirring for 24 h at 60 °C. The solid product was

filtered off and washed several times with water. The obtained product was treated with

DETA according to the method reported in section 2.3.1. The product was finally air-dried; it

was sieved and the fraction below 1 mm was retained for experiments. This sorbent was

called MCGMA-II.

2.3.3. Estimation of the amine content

The amine content in the obtained resin was estimated using a volumetric method previously

described by Atia et al. [15]. Fifty mL of HCl (0.05 M) was added to 0.5 g of MCGMA-II or

MCGMA-II and conditioned for 15 h on a shaker at 20 °C. The residual concentration of HCl

8

was measured by the titration against 0.05 M standardized NaOH (using phenolphtalein as the

titration indicator). The number of moles of HCl that reacted with the amino groups was

determined and the concentration of amino group was calculated by the following equation

resin) (mmol/g 50

50212

.

)M(Mgroups)(NHofionConcentrat

(1)

where M1 and M2 are the initial and final concentrations of HCl.

2.3. Analytical methods

Mercury was analyzed using inductively coupled plasma atomic emission spectrometer ICP-

AES (Jobin-Yvon Activa M, Horiba-Jobin Yvon, FRANCE). The morphology and the

elemental distribution of Hg in the magnetic-macromolecular material were analyzed with a

Scanning Electron Microscope coupled with an Energy Dispersive X-ray analysis system

(SEM-EDX; Environmental Scanning Electron Microscope (ESEM) Quanta FEG 200,

equipped with an OXFORD Inca 350 Energy Dis-persive X-ray microanalysis (EDX)

system). The magnetic property of the sorbent was measured on a vibrating-sample

magnetometer (VSM) (Lake Shore 730T, Westerville OH, USA) at room temperature.

2.4. Sorption experiments

Demineralized water was used for the preparation of metal ion solutions. A stock solution (20

mM) of HgCl2 was prepared in demineralized water. The other solutions were obtained by

dilution of the stock solution with demineralized water just prior experiments. HCl (0.5 M)

and NaOH (0.5 M) were used to control the pH of the solutions. 0.1 M of KI was used for

elution of Hg(II) loaded on the sorbent.

Sorption experiments were performed in batch systems using polyethylene flasks and the

temperature was set to 20 ± 1 °C (unless specified). For the study of pH effect 20 mL of 10

9

mM Hg(II) solutions at different pH values (in the range 1-6) were mixed with 50 mg of

sorbent (dried weight) for 5 h, and the stirring speed was maintained at 100 rpm using a

reciprocal agitator Rotabit, J.P. Selecta (Spain). Samples were collected and filtrated through

1.0 µm pore size filtration membrane and/or magnetic separation and the filtrate was analyzed

for residual Hg(II) concentration using ICP-AES. The pH was not controlled during the

sorption but the final pH was systematically recorded.

For sorption isotherms 50 mg of sorbent (m) were mixed with 20 mL (V) of Hg(II) solutions

at different initial concentrations (C0, ranging between 3 and 10 mmol Hg L-1

) for 5 h. The pH

of the solutions was initially set at 4. After solid/liquid separation, the residual concentration

(Ceq, mmol Hg L-1

) was determined by ICP-AES and the sorption capacity (qeq, mmol g−1

)

was determined by the mass balance equation: qeq = (C0-Ceq)V/m.

For uptake kinetics 300 mg of sorbent were mixed with 120 mL of Hg(II) solutions (C0: 10

mmol Hg L-1

) at pH 4. Samples (a volume of 4 mL) were collected (the sorbent was

magnetically separated) at fixed times and the residual concentrations were determined by

ICP-AES. The agitation speed was set at 100 rpm while the temperature was maintained at 20

± 1 °C. The sorbed amount of Hg(II) per unit weight of the sorbent at time t (q(t), mmol Hg g-

1), was calculated from the mass balance equation (taking into account the decrement in the

volume of the solution) as:

n

im

itVitCitCtq

1

)1()())()()1()(()( (2)

where C(t)(i) (mmol Hg L-1

) is the Hg(II) concentration of the withdrawn sample number i at

time t and C(t)(0) = C0, V(t)(i) (mL) is the volume of the solution in the flask at sample number

i and time t, and m is the amount of resin added into the flask. Here V(t)(i)-V(t)(i-1) equals 4

mL.

10

Regeneration experiments were performed by contact of 250 mg of the sorbent with 100 mL

of 10 mmol Hg L-1

solution at pH 4 Hg(II) for 5 h. The amount of metal sorbed (and the

sorption capacity) was determined by the mass balance equation. The solution was

magnetically decanted and the sorbent was washed by distilled water. The loaded sorbent was

mixed with 100 mL of 100 mM KI for 50 min. Samples were collected at different time

intervals and the residual concentration of Hg(II) was determined by ICP-AES after

solid/liquid separation. The regenerated sorbent was carefully washed by distilled water for

reuse in the second run. The regeneration efficiency (RE, %) was calculated according to the

following equation:

100 X % RE1)-(nrun at (mmol) Hg(II) desorbed ofAmount

(n)run at (mmol) Hg(II) desorbed ofAmount (3)

3. Results and discussion

3.1. SEM and SEM-EDX analysis

Figure 1 shows the SEM and SEM-EDX analyses of the sorbents MCGMA-I and MCGMA-II

before and after Hg(II) sorption. The surface of MCGMA-I and MCGMA-II is generally

smooth with several small pores inside and interconnected macropores can be identified

within the sorbents (Figure 1-a,b). However, after Hg(II) sorption, differences in the surface

structure of the sorbents clearly appear: agglomerated spherical particles are formed on the

surface and the porous structure disappears (Figure 1-c,d). These conclusions are consistent

with observations made on SEM-EDX analysis (Figure 2): the typical signals of Hg element

are appearing at 1.7, 2.2, 2.6 and 10 keV on both MCGMA-I and MCGMA-II sorbents.

Though a quantitative analysis of the Hg load on the sorbent by SEM-EDX would not be

accurate, the levels of Hg are high enough to demonstrate qualitatively the homogeneous

11

distribution of the metal on the surface of the sorbent. The mass percentages of Hg element

are found close to 27.5 % and 32.9 % for MCGMA-I and MCGMA-II, respectively. This is a

first evidence of the good affinity of the sorbents for mercury. The presence of Cl element is

due to the binding of mercury under the form of chloroanionic species: the sample used for

analysis was collected after metal sorption at pH 3 (controlled with HCl).

Figure AM1 (See Additional Material Section) shows the SEM images of the two sorbents at

different magnitudes. There is a large dispersion in the size of sorbent particles (in the range

10-200 µm) and the particles are characterized as irregularly-shaped flakes.

3.2. Amine content

The amine content in MCGMA, MCGMA-I and MCGMA-II (which was determined by

titration) are 3.12, 5.92 and 6.5 mmol g−1

, respectively. The chitosan used in this study was

characterized by a deacetylation degree of 87 % (this means 6 mmol N g-1

). The magnetite

fraction in the sorbents was characterized by weight loss at 700 °C: the materials contain 36

% and 34 % of magnetite for MCGMA-I and MCGMA-II, respectively. On the basis of

similar magnetite fraction and chitosan (without chemical modification) the theoretical

nitrogen content would be close to 3.9 mmol N g-1

. This confirms the efficient grafting of

additional amino groups on the reference material (MCMA). The semi-quantitative analysis

of nitrogen content obtained by SEM-EDX analysis confirms this trend. Indeed, the nitrogen

mass percentages were close to 8.6 % and 9.1 % for MCGMA-I and MCGMA-II, respectively

(this means 6.15 mmol N g-1

and 6.5 mmol N g-1

, respectively). These observations and

analyses confirm the successful experimental procedure described in Scheme 1 for the

grafting of additional amino group on chitosan backbone.

3.3. Magnetic properties

12

The magnetic properties of the materials were determined using VSM (vibrating sample

magnetometry). Figure 3 shows their typical magnetization loop. There was no remanence

and coercivity, contrary to certain supported-magnetite materials [16]. This means that

MCGMA sorbents are paramagnetic. The saturation magnetization of MCGMA-I and

MCGMA-II were found to be about 19.1 and 17.9 emu g-1

, respectively. These values are

much smaller than the levels reported for bulk phase magnetite (i.e., 92 emu g-1

) and also

smaller than the values obtained for magnetite nanoparticles [17]. The slight decrease in the

magnetization in case of MCGMA-II may be due to the grafting of DETA via epichlorhydrin,

which increase the mass of organic material and decrease the relative percentage of magnetite

in the sorbent. The reported decrease in saturation magnetization can be explained by several

factors including size effect and particle crystallization [17], and obviously by the fact that

only a fraction of the sorbent (about 50 %) is constituted by the magnetic core. Similar

decrease in magnetization was observed for other chitosan-magnetite composites [18].

Therefore, MCGMA sorbents can be readily separated with the help of an external magnetic

field. This may be very helpful for solid/phase separation or for handling the material in

hazardous environment.

3.4. Infra-red spectrometry

FT-IR spectrometry was used to characterize the structure of the sorbents (Figure 4). The two

sorbents have very similar FT-IR profiles: the same bands are appearing on the two spectra,

the only small differences observed are small shifts in some of these bands. The large band

around 3410 cm-1

is generally attributed to the combination of stretching vibrations of OH and

NH2 groups, while a series of –CH vibrations are reported around 2940 cm-1

and 2850-2860

cm-1

. These bands are present in a wide number of compounds and they are bringing poor

information on the specific properties of the sorbents. More interesting and representative are

13

the different bands identified in the range 1800-400 cm-1

. The bands at 1264, 1162 and

986/990 cm-1

are representative of the saccharide ring. The band at 1653-1657 cm-1

is

associated to the CONH2 group [19], while the band at 1561-1573 cm-1

is probably assigned

to the in-plane bending vibration of free amine groups and/or the asymmetric carboxylate

stretching vibration [19, 20]. The grafting of diethylenetriamine, via glycidylmethacrylate,

can be identified by the strong peak observed around 1724 cm-1

(assigned to C=O stretching

vibration) [20, 21]. Additional methylene (-CH2-) groups can probably be associated to the

band observed at 1466-1470 cm-1

[22]. The band at 586-596 cm-1

was attributed to γ-Fe2O3

[23].

3.5. Hg(II) sorption properties

3.5.1. Effect of pH

The pH of the aqueous solution is a key parameter that controls the sorption of the Hg(II).

This effect can be associated to metal speciation, to chemical properties of the polymer

(protonation/deprotonation of amino groups). Figure 5 shows the effect of pH on Hg(II)

sorption (varying the initial pH from 0.9 to 6), and the pH variation observed during sorption

operation. Figure 5a confirms that the pH influences sorption capacity: the sorption increases

with the pH up to pH 4-4.2 before beginning to stable and even reducing when pH exceeds 5.

It is remarkable that the pH variation during metal sorption is not varying significantly

(Figure 5b): at low pH (below pH 4) a slight increase of the equilibrium (below 0.4 pH unit)

is observed, while above pH 4-4.5 the equilibrium pH tended to slightly decrease (variation

being less than 0.5 pH unit). This is remarkably stable compared to other chitosan-based

systems where a kind of “buffering effect” is obtained around 5-6 due to the acid-base

properties of the biopolymer (pKa in the range 6.3-6.7) that binds protons. It is suspected that

14

the grafting of new functional groups (including other amino groups with different acid-base

properties, associated to primary and secondary amino groups) contribute to smooth this pH

variation effect.

As the pH increases the protonation of amine groups decreases, which, in turn, contributes to

make free the amino groups for interacting with metal cations by chelation. For MCGMA-II

sorbent the sorption capacity increases from pH 1 to pH 4 and then tends to stabilize. At

higher pH (above pH 5) the formation of hydrolyzed species (Hg(OH)+ or soluble Hg(OH)2,

before precipitation) that have less affinity for amino groups, may explain the slight decrease

in sorption capacity (which represents less than 0.2 mmol Hg g-1

). This effect is completed by

the impact of deprotonation of amine groups. On the other hand, at low pH (below 2-3), the

sorption capacity remains quite high (up to 1.5 mmol Hg g-1

), especially compared to the

levels reached with pure chitosan [24]. This can be explained by either (a) differences in the

acid-base properties of amino groups grafted on chitosan (lower pKa compared to chitosan

amino groups), and/or (b) the binding of chloro-anionic mercury species on protonated amino

groups. Indeed, in the presence of HCl, at low pH, metal speciation can be displaced to the

formation of HgCl42-

or HgCl3- species which may be bound to protonated amino groups

through an electrostatic attraction mechanism of an ion-exchange mechanism: chloride ions

bound to protonated amino groups may be exchanged with anionic chloroanions. The sorbent

MCGMA-I has a slightly different behavior: the sorption capacity tends to increase with pH

increasing from 0.9 to 2.5 and progressively decreases when pH increases: the acid-base

properties of the different amino groups present on the sorbent are different to those on the

MCGMA-II sorbent due to differences in their chemical environment. The decrease in amino

group protonation at pH above 2.5 (which contributed to bind anionic mercury chloroanions)

is not compensated by the chelation properties of amino groups and by the speciation of

mercury in solution (metal speciation is shifted from chloroanions to positively charged

15

mercury species with low affinity for protonated amino groups). The two sorbents have

comparable sorption capacities at 2.3: below this value MCGMA-I is more efficient for Hg(II)

binding while above this value the best results were obtained by MCGMA-II sorbent.

Above pH 5 the formation of colloidal mercury species (Hg(OH)2) may occur and their

precipitation may overestimate sorption performance [25]. This phenomenon should be taken

into account. For further experiments the pH was set to 4-4.2.

3.5.2. Kinetics

The uptake kinetics of Hg(II) using MCGMA-I and MCGCMA-II is shown in Figure 6.

Figure 6a shows the relative decay of concentration with time, which allows comparing the

two sorbents both in terms of equilibrium performance and relative decay slopes. Figure 6b

shows the evolution of the concentration of Hg(II) in the sorbent (i.e., q(t) vs. time): the

approach of equilibrium is another method for comparing the kinetic profiles. Experimental

conditions have been selected to be able to illustrate the effect of resistance to diffusion.

Indeed, an excess of sorbent (compared to metal) would lead to fast and complete removal of

the metal bound on the sorption sites at the surface of the sorbent and minimizing the impact

of mass transfer mechanisms. Under these conditions, the solutions is not fully

decontaminated (Figure 6a); this issue (complete metal recovery) is addressed below (see

section 3.5.7)

The kinetic profiles (both in terms of relative concentration decay; i.e., Figure 6a, and metal

concentration in the sorbent; i.e., Figure 6b) are characterized by two main phases in the

uptake: (a) a first initial step that lasts for about 60 min and counts for more than 60 % of total

sorption, (a) a second step that takes about 6 hours and corresponds to a much slower metal

accumulation. The initial section of the curve corresponds to a great availability of reactive

groups (surface coverage is progressively increasing) and a large concentration gradient

16

between the solution and both the surface and the internal sorption sites. These two conditions

may explain the fast initial accumulation of Hg(II). The sorption mainly occurs on the

reactive groups covering the surface of the sorbent. The second step, much slower, is

controlled by the decrease of the concentration gradient and by the resistance to intraparticle

diffusion and requires much longer time for reaching the equilibrium (i.e., about 6 h).

Actually the binding kinetics is controlled by a series of mechanisms including: (a) the bulk

diffusion, (b) the resistance to film diffusion (or external diffusion), (c) the resistance to

intraparticle diffusion, and (d) the proper reaction rate (chemical reaction rate) [26]. Usually a

sufficient agitation allows neglecting the resistance to bulk diffusion and minimizes the

resistance to film diffusion whose contribution in the control of uptake kinetics is mainly

significant within the first minutes of contact. The modeling of such a complex system, which

is beginning even more complex when the sorbent is heterogeneous, when the solution is

subject to changes in the speciation of the metal ions, etc., requires complex numerical tools.

Experimental data have been modeled using simplified conventional equations to fit kinetic

profiles and make possible the comparison of kinetic parameters for the two sorbents. Hence,

the kinetics of Hg(II) sorption on modified MCGMA sorbents were analyzed using the

pseudo-first order rate equation (PFORE) [27], the pseudo-second order rate equation

(PSORE) [28], the simplified resistance to intraparticle diffusion equation [29] and the

Elovich equation [30]. These models and their linear forms are reported in Table 1, where k1

is the pseudo-first order rate constant (min-1

) of sorption and qeq and q(t) (mmol Hg g−1

) are

the amounts of Hg(II) sorbed at equilibrium and time t, respectively, k2 is the pseudo-second

order rate constant (g mmol−1

min−1

), Ki is the intraparticle diffusion rate (mmol g−1

min-0.5

), α

the initial sorption rate (mmol g−1

min−1

) and β the desorption constant (g mmol−1

). The

validity of each model is checked by the correlation coefficient associated to the linear fits.

Table 2 reports the parameters of the different models for both MCGMA-I and MCGMA-II

17

sorbents. Systematically, the best correlation coefficients were found for the PSORE model;

this is confirmed by the plot of experimental data according the linearized forms of these

models: Figure AM2a and Figure AM2b (see Additional Material Section) for PFORE and

PSORE, respectively, show a best fit of kinetic profiles by PSORE. In addition, the

comparison of equilibrium sorption capacities for the calculated values and the experimental

values are only consistent for the PSORE model: the equilibrium sorption capacities are found

close to 1.4 and 2.0 mmol Hg(II) g-1

for MCGMA-I and MCGMA-II, respectively. PSORE

modeling gave values of 1.49 and 2.09 mmol Hg(II) g-1

closer from experimental values than

PFORE (0.91 and 1.27 mmol Hg g-1

, respectively). It was more likely to reflect that the rate-

determining step might be chemical sorption and that the sorption behavior might involve a

chelation mechanism through coordination between Hg(II) ions and the reactive groups of the

sorbents [25]. The Hg(II) ions may form complexes with amino groups of the modified

MCGMA sorbents (with possible contribution of hydroxyl groups in the stabilization of

metal binding) [31].

However, the PSORE describes kinetics data through a global approach, and does not take

into account the contribution of diffusion mechanisms in the control of the kinetics. Under

these conditions, the kinetic parameters should be considered as apparent rate coefficients.

The influence of resistance to intraparticle diffusion has been approached using a simplified

model: the so-called Weber and Morris plot (Table 1). The intraparticle diffusion model

provides a more comprehensive approach for defining of sorption mechanism, and the plot

generally allows identifying different successive steps in the global process [32]. The Weber

and Morris shows multi-linear sections (Figure AM3a, see Additional Material Section), i.e.,

three linear sections (on the plot q(t) vs. t0.5

) with fast kinetics in first step followed by the

gradual attainment of equilibrium for both sorbents, and a pseudo saturation plateau. The

multi-linear plot does not pass through the origin suggesting that the resistance to intraparticle

18

diffusion is not the sole rate-limiting step: other steps, e.g. resistance to film diffusion and/or

reaction rate, are probably involved in the control of uptake kinetics (Table 2, Figure AM3a,

see Additional Material Section). We can assume that the first linear section corresponds to a

regime controlled by the resistance to film diffusion and that the binding is limited in this

stage at the sorption of external sorption sites or on the macropores in the first external layers

of the material. The second section is characterized by a much lower kinetic rate and leads to

a slow approach to equilibrium with the control by the resistance to intraparticle diffusion

(into internal macroporous and mesoporous network). The last step is very slow and

represents only a few percentage of the total sorption: this phase can be associated to the

resistance to diffusion in the microporous network of the sorbent. In addition the progressive

saturation of available and accessible sorption sites influences the local equilibrium on the

surface between surface sorption and desorption. The low values of intraparticle rate constants

(ki) appearing in Table 2 with values available in the literature indicates that the sorbents

(both MCGMA-I and MCGAM-II) are significantly affected by the resistance to intraparticle

diffusion, at least compared to the fast reaction rate of chemical sorption of Hg(II) ions at the

surface of the sorbent [33]. The analysis of the rate constants for the Weber and Morris model

shows that except for the first step, the parameters were systematically higher for MCGMA-II

compared with MCGMA-I. In the initial stage, MCGMA-I seems to be faster in sorption than

MCGMA-II: this first stage corresponds to a kinetic control by external film diffusion and/or

diffusion in the macropores present at the external surface of sorbent particles. While in the

next steps the uptake kinetics is controlled by the diffusion in meso- and micro-pores, which

appears to be a little more accessible for MCGMA-II material.

The Elovich equation was developed for modeling chemisorption processes [30]. Table 1

displays the model equation and its linearization as well the plots to be used for determining

the parameters (which are reported in Table 2). The values of α and β were determined from

19

the intercept and slope, respectively, of the linear plot of qt vs ln t (Figure AM3b, see

Additional Material Section). The values of α for the sorption of Hg(II) ions on the modified

sorbents are 0.46 and 0.73 (mmol g−1

min−1

) for MCGMA-I and MCGMA-II, respectively.

These values are higher than the values cited in literature [34, 35], which may be attributed to

the high concentration of active sites on the sorbent surface allowed for reacting with Hg(II)

ions. The values of β (desorption constant) are found to be 4.54 and 3.54 g mmol−1

for

MCGMA-I and MCGMA-II, respectively. These values are smaller compared with the levels

cited in the literature [34, 35]. This is another confirmation of the high affinity of the sorbents

for Hg(II) ions.

3.5.3. Equilibrium sorption isotherm

The sorption isotherms represent the distribution of the sorbate between the solid (sorption

capacity or sorbate concentration in the solid) and liquid phase (residual concentration of the

sorbate in the solution), at equilibrium. This distribution is only controlled by the temperature

and is independent on the size of sorbent particles, on the experimental procedure (batch,

fixed-bed column) providing a sufficient time has been given to the process of reaching

equilibrium. The distribution of the sorbate between the two phases can be modeled using

different equations; however, the most frequents models used for describing solid/liquid

equilibrium systems have been established by Langmuir [36], Freundlich [37], and Dubinin-

Radushkevich [38]. These models and their linear forms are reported in Table 3, where qeq the

sorbed value of Hg(II) at equilibrium concentration (mmol Hg g−1

), qm,L is the maximum

sorption capacity (corresponding to the saturation of the monolayer, mmol Hg g−1

) and KL is

the Langmuir binding constant which is related to the energy of sorption (L mmol−1

), Ceq is

the equilibrium concentration of Hg(II) in solution (mmol Hg L−1

). KF (mmol g−1

) (L

mmol−1

)1/n

and n are the Freundlich constants related to the sorption capacity and intensity,

20

respectively. KDR (J2 mol

−2) is a constant related to the sorption energy, qDR (mmol g

−1) is the

theoretical saturation capacity, ε (J2 mol

−2) is the Polanyi potential.

At low initial concentrations (1.0–3.0 mM) the sorption of Hg(II) was almost quantitative.

Brunauer et al. [39] divided the sorption isotherms into five types. Type I isotherm represents

unimolecular sorption and applies to non-porous, microporous and sorbents with small pore

sizes (not significantly greater than the molecular diameter of the sorbate). The isotherm

curves (Figure 7) are following the typical shape of I-type systems, according to the BET

classification [39]: they are characterized by a high degree of sorption at low concentrations.

At higher concentrations, the sorption sites becoming progressively occupied the sorption

tends to stabilize and forms the saturation plateau.

The Langmuir model is the simplest theoretical model that is used for describing monolayer

sorption onto a surface with a finite number of identical sites. It was originally developed to

represent gaz/solid sorption before being extrapolated to liquid/solid sorption. The values of

qm,L and KL were determined from the slope and intercept, respectively, of the linear plot of

Ceq/qeq vs. Ceq (Figure AM4a, see Additional Material Section); parameters of the Langmuir

equation are reported in Table 3. The maximum sorption capacities (qm,L) are in good

agreement with the experimental values. The correlation coefficients reported in Table 4

confirm the better fit of experimental data by the Langmuir model compared with the other

two models. Though the fact that the mathematical fit of the sorption equation fits well

experimental data does not necessarily mean that the hypotheses associated to the model are

verified this is indicative of the relative homogeneity of the surface; or at least that the active

sites are energetically equivalent. Furthermore, the Langmuir parameters can be used to

predict the affinity between the sorbate and sorbent using the dimensionless separation factor

RL

o

LC1

1R

LK (4)

21

where KL is the Langmuir equilibrium constant and Co is the initial concentration of Hg(II)

ions. Values of 0 < RL < 1 indicates the “suitability” of the process. In this study, the values of

RL for the resin for the sorption of Hg(II) ions lie between 0.002 and 0.088 for each sorbents

and all concentrations at 20 oC. These values confirmed the affinity of modified MCGMA

sorbents for Hg(II) ions.

The Freundlich isotherm model is applicable to highly heterogeneous surfaces, and a sorption

isotherm lacking to form a saturation plateau indicates a multi-layer sorption. The values of n

and KF were determined from the slope and intercept, respectively, of the linear plot of ln qeq

vs. ln Ce (Figure AM4b, see Additional Material Section) and the calculated parameters of the

Freundlich equation are summarized in Table 4. Both the saturation plateau formed on Figure

7 at high residual mercury concentration and the relatively low correlation coefficients

confirm that the Freundlich poorly fit experimental data.

Another popular equation for the analysis of isotherm was proposed by Dubinin and

Radushkevich (Table 3). This isotherm was developed taking into account the effect of the

porous structure of the sorbent, and the energy involved in the sorption process. The Polanyi

potential ( ) given as Eq. (5) [38]:

) C

1 (1ln RT

eq

(5)

R is the universal gas constant (8.314 J mol−1

K−1

) and T is the absolute temperature (K). The

slope of the plot of ln qeq vs. 2 (Figure AM4c, see Additional Material Section) gives KDR

and the intercept yields QDR (Table 4). The D–R constant (KDR) can give valuable information

regarding the mean energy of sorption (Ea, J mol-1

) by Eq. (6):

5.0)2(

1

aE

DRK (6)

The results of D–R isotherm are reported in Table 4. Figure AM4c (See Additional Material

Section) shows that the experimental data are poorly fitted to the model (consistently with the

22

low value of correlation coefficients): the values of the parameters of the model should be

taken as indicative values (order of magnitude). The values of the mean energy of sorption

range between 8.7 and 10.3 kJ mol-1

: this is consistent with the proposed mechanism of

chemisorption. Indeed, it is generally admitted that 8 kJ mol-1

is the limit energy for

distinguishing physical (below 8 kJ mol-1

) and chemical sorption. A comparison of the

correlation coefficient values obtained from the Langmuir, Freundlich and D–R isotherm

models in Table 4 reveals that the correlation coefficients for the Langmuir isotherm are

somewhat higher than those for the Freundlich and D–R isotherm. This result suggests that

the binding of Hg(II) may occur as a monolayer on the surface of the sorbent and that the

uptake occurs on a homogenous surface by monolayer sorption. This should be confirmed by

experimental observation for confirmation (as reported above the mathematical fit of isotherm

curve by a given model equation does not mean that the relevant hypotheses of the model are

verified). The uptake can be described in terms of chemisorption as the formation of ionic or

covalent bonds between the sorbent (free mercury species or chloroanionic species, depending

on the pH and the sorption mechanism) and the sorbate (free amine groups or protonated

amino groups depending on the pH).

The coexistence of different metal species that could be sorbed in function of the pH as well

as the different mechanisms, and the simultaneous presence of different types of amino

groups are not comforting the hypothesis of homogeneous surface (or homogeneous energies

of sorption).

3.5.4 Influence of temperature

The sorption performance may be controlled by the temperature both in terms of kinetics

(depending on the activation energy) and equilibrium: the thermodynamics of the process

influences the instantaneous kinetics of sorption and desorption, and consequently the

23

equilibrium. The sorption capacities were compared at different stabilized temperatures

(under identical experimental conditions) for both MCGMA-I and MCGMA-II (Table 5): the

sorption capacity increases with temperature and the sorption is an endothermic process. The

sorption equilibrium constant, Kc was determined (Eq. 7) and used with the van’t Hoff

equation (Eq. 8) and conventional thermodynamic equation (Eq. 9) for evaluating the

thermodynamic constants of the sorbents (i.e., the standard enthalpy change, ∆Ho, the

standard free Gibbs energy, ∆Go, and the standard entropy change, ∆S

o).

eqC

eqqcK (7)

where qeq and Ceq are equilibrium concentrations of Hg(II) on the sorbent and in the solution,

respectively.

∆Go = -RT lnKc (8)

∆Go = ∆H

o − T∆S

o (9)

Therefore the van’t Hoff equation becomes:

R

S

RT

H- ln C

K (10)

The values of standard enthalpy change (∆Ho) and standard entropy change (∆S

o) for the

sorption process are thus determined from the slope and intercept of the plot of ln Kc versus

1/T: the values of thermodynamic parameters are reported in Table 6. The positive values of

∆Ho confirm the endothermic nature of sorption process. The negative values of ∆G

o indicate

that the sorption reaction is spontaneous. The increase in the negativity of ∆Go with

increasing temperature confirms that the “favorability” increases with temperature. In

addition, the values of standard free energy change for MCGMA-II are more negative than

these of MCGMA-I: Hg(II) sorption is more favorable on MCGMA-II than on MCGMA-I,

especially at low temperature. The density of sorption sites and the spatial arrangement of

24

functional groups are more favorable for Hg(II) binding on MCGMA-II sorbent. It is

noteworthy that in the case of MCGMA-I, the standard free Gibbs energy becomes positive

only at higher temperature (i.e., above 40 °C): the spontaneous nature of sorption process is

only possible when the system is “activated” by temperature. With MCGMA-II more amine

groups are available; in addition their distribution along a free long chain makes them more

accessible. This could explain the better “spontaneity” of sorption process for MCGMA-II

compared to MCGMA-I (which possibly requires an increase in temperature for the

enhancement of metal ion or polymer chains “mobility” that, in turn, improves sorption

performance).

In industry and water purification plants the optimum temperature at which the sorption is

highly feasible and spontaneous is essential. The sorption of metals onto sorbent surfaces may

be either spontaneous or non-spontaneous in function of temperature. The limit temperature

value corresponding to a null value of standard free energy can thus be deduced from Eq. 11.

The range of temperature can be predicted from the value of temperature at which the

standard free energy is zero (T0), and then the minimal temperature for the process to being

spontaneous.

S

HT0

(11)

Here, the calculated values of zero standard free energy temperature (T0) are 312.8 and 283.8

for MCGMA-I and MCGMA-II, respectively. The low T0 for MCGMA-II indicates the

feasibility of Hg(II) removal at ambient temperature, while MCGMA-I sorbent requires a

thermal activation: the spontaneous reaction occurs at around 40 °C.

3.5.5. Effect of counter anions and metal speciation

The effect of the counter anion on the uptake of Hg(II) by modified MCGMA sorbents was

investigated at different pH values using different mercury salts. The pH of the solution was

25

adjusted using HCl for HgCl2 solution, HNO3 for Hg(NO3)2 solution and H2SO4 for HgSO4

solution. Table 7 shows that at low pH (i.e., 0.95) an appreciable sorption was obtained in the

case of HgCl2 for both sorbents, while with Hg(NO3)2 and HgSO4 salts the sorption was

negligible. This result can be explained by the possibility for the sorbents to bind mercury by

an ion-exchange between the counter anions (chloride) bound to amino groups and the Hg(II)

chloroanions (HgCl3- or HgCl4

2-) [25]. In the case of other counter-anions, mercury does not

form stable anionic complexes that could be bound to protonated amine groups by ion-

exchange and the sorption strongly decreases. The limited uptake in the case of Hg(NO3)2 or

HgSO4 salts may be also attributed to the higher stability of (MCGMA-NH+)NO3

− or the

(MCGMA-NH+)2SO4

2− that retards the ion exchange mechanism. At pH 2.12 for both

MCGMA-I and MCGMA-II Hg(II) was significantly sorbed when using HgCl2 or Hg(NO3)2

salts, while the sorption was negligible with HgSO4 salt. Sulfate salts have more affinity for

protonated amine groups than other mono-anions making more difficult metal anion

exchange. The composition of the solution may thus have a significant impact on the sorption

performance, especially at pH where the ion-exchange is the predominant sorption

mechanism.

3.5.6. Selectivity of modified MCGMA for Hg(II) sorption

In order to evaluate the possible selectivity of the sorbents Hg(II) sorption was carried out in

multicomponent solutions (containing Hg(II), Co(II), Cu(II), Fe(II), Ni(II), Zn(II) and Mg(II))

at different pH values (0.4 -1.6). Table 8 shows that the recovery of Hg(II) is almost

quantitative in the presence of equimolar concentrations of other base metal cations,

regardless of the pH (at least in the selected pH range). Whatever the pH, the maximum

sorption capacities of competitor metal ions by the modified MCGMA sorbents is less than

5.0 % of sorbed amounts of Hg(II) ions. The sorbents appears to have a selective recognition

26

pattern for Hg(II) ions against other selected heavy metal ions. The reported negative values

for the uptake of Fe(II) can be attributed to the release of iron from magnetite at low pH:

when the pH increases this release decreases. The stability of the composite material is an

important issue to take into account and it sounds preferable managing the hybrid material in

solution whose pH is higher than pH 1.5-2. The selectivity of the sorbents for Hg(II) against

other base metals may be explained by the sorption mechanism which is attributed to ion-

exchange of Hg(II) chloro-anions on protonated amine groups in acid conditions: the other

selected metal ions are not supposed to form stable chloro-anions under selected experimental

conditions.

3.5.7. Effect of sorbent dose

The sorption of Hg(II) on modified MCGMA sorbents was studied by changing the sorbent

dosage (in the range 1.5-10 g L-1

), metal concentration being fixed to 9.8 mM (pH 4 and T: 20

°C). Figure AM5a (See Additional Material Section) shows the variation in sorption capacity

with sorbent dosage: the sorption capacity decreases from 1.52 to 0.97 mmol Hg g-1

and from

2.07 to 0.97 mmol Hg g-1

for MCGMA-I and MCGMA-II, respectively when the SD

increases from 1.5 to 10 g L-1

. Figure AM5b (See Additional Material Section) shows the

effect of sorbent dosage on the relative equilibrium concentration (C/C0). As expected when

the sorbent dosage increases, the equilibrium concentration of Hg(II) decreased. The results

shown indicate that the residual concentration C/C0 may decrease up to 0.0014 for SD = 10 g

L-1

. At low sorbent dosage, all sorption sites are exposed and the can be easily saturated. With

an increase of sorbent dosage the amount of sorption sites becomes in excess compared to

present metal ions and the saturation of the sorption sites is not achieved. According to these

results, the sorbent dosage of 1.5 g L-1

allows achieving the saturation of the sorbent and

makes possible the concentration effect and the enrichment of mercury after desorption step.

27

On the opposite hand with a sorbent dosage of 10 g L-1

it is possible removing about 99.6 %

of mercury from the solution (achieving environmental target). The sorbent dosage to be used

depends on the target of the sorption process: concentration effect or maximum

decontamination.

3.5.8. Comparison of sorption capacity for Hg(II) ions with various sorbents

Table 9 shows the comparison of maximum sorption capacities of MCGMA-I and MCGMA-

II with a series of values found in the literature (together with the best operating conditions

reported by respective authors). A direct comparison of sorption performance is difficult due

to different experimental conditions; however, this is a useful criterion for roughly evaluating

the potential of these materials. The modified MCGMA sorbents have a sorption capacity of

the same order of magnitude as other sorbents; although chitosan foam [40] and thiol-

modified activated coke [41] showed better sorption capacity. It is noteworthy that the

modified MCGMA sorbents have an important advantage related to their fast kinetics. The

high sorption capacity of the modified MCGMA sorbents towards Hg(II) ions reveals that

sorbents could be promising for practical application in Hg(II) ions removal from

wastewater.

3.5.9. Regeneration

Three successive sorption/desorption cycle runs were performed using 100 mL of 0.1 M KI

solutions for 50 min. Samples were collected at different time intervals and the residual

concentration of Hg(II) was determined. Figure 8 shows the time course of released Hg(II)

ions. About 97% of the sorbed Hg(II) ions is released within 15 min. The desorption is even

faster than the sorption. Though a slight and progressive decrease in the amount of desorbed

Hg(II) ions is observed along the successive cycles the desorption efficiencies remained

28

higher than 90 % after three sorption/desorption cycles. The sorbent MCGMA-I seems to be

slightly more efficient than MCGMA-II sorbent in terms of desorption with desorption yield

of 97.2, 98.2 for MCGMA-I and 99.6%, 89.0% for MCGMA-II for the first three

sorption/desorption cycles, respectively.

4. Conclusion

Novel magnetic macromolecular hybrid materials were prepared by grafting glycidyl

methacrylate (synthetic polymer) to chitosan (biopolymer) and functionalizing the

intermediary compound with diethylenetriamine (directly, or via epichlorhydrin spacer,

MCGMA-I and MCGMA-II, respectively). The two sorbents are characterized by efficient

and selective sorption towards Hg(II) ions from aqueous medium at approximately pH 4. The

uptake kinetics are well fitted by the PSORE, while the distribution of the metal at

equilibrium between the solid and the liquid is modeled by the Langmuir equation. The

maximum capacity reached 1.43 mmol g−1

for MCGMA-I and 2.01 mmol g−1

for MCGMA-

II at 20 oC. The tests performed in the presence of other heavy metals (multicomponent

solutions) demonstrated the selectivity of the sorbents for Hg(II). Depending on the pH two

sorption mechanisms can be involved: ion-exchange on protonated amine groups in acidic

solutions, or chelation on amine groups at mild acidic pH. However, this interpretation of

sorption mechanisms is affected by the composition of the solution and more specifically the

nature of counter-anions present in the solution. The presence of counter anions that form

anionic complexes in acidic solutions makes possible Hg(II) sorption while those counter

anions that do not form stable complexes with mercury reduce the affinity of the sorbent for

metal ions. The investigation of temperature effect on Hg(II) sorption isotherm confirms that

the sorption mechanism is endothermic. Mercury ions bound to the sorbents can be

29

successfully desorbed using 0.1 M potassium iodide solutions and the sorbent can be

effectively re-used.

Acknowledgements

This study was supported by the French Government through a fellowship granted from the

French Embassy in Egypt (Institut Français d'Égypte). The authors would like to thank

Thierry Vincent, André Brun and Jean-Marie Taulemesse for their technical and scientific

contributions to this work.

References

[1] ATSDR, Prioritary List of Hazardous Substances,

http://www.atsdr.cdc.gov/SPL/index.html, Accessed: 4/16/2015.

[2] C. Namasivayam, K. Periasamy, Bicarbonate-treated peanut hull carbon for mercury (II)

removal from aqueous solution, Water Res., 27 (1993) 1663-1668.

[3] H. Demey, T. Vincent, M. Ruiz, A.M. Sastre, E. Guibal, Development of a new

chitosan/Ni(OH)2-based sorbent for boron removal, Chem. Eng. J., 244 (2014) 576-586.

[4] P. Sorlier, A. Denuzière, C. Viton, A. Domard, Relation between the degree of acetylation

and the electrostatic properties of chitin and chitosan, Biomacromolecules, 2 (2001) 765-772.

[5] T.S. Anirudhan, L. Divya, J. Parvathy, Arsenic adsorption from contaminated water on

Fe(III)-coordinated amino-functionalized poly(glycidylmethacrylate)-grafted TiO2-densified

cellulose, J. Chem. Technol. Biotechnol., 88 (2013) 878-886.

[6] A.S.K. Kumar, M. Barathi, S. Puvvada, N. Rajesh, Microwave assisted preparation of

glycidyl methacrylate grafted cellulose adsorbent for the effective adsorption of mercury from

a coal fly ash sample, J. Environ. Chem. Eng., 1 (2013) 1359-1367.

30

[7] G.Z. Kyzas, N.A. Travlou, E.A. Deliyanni, The role of chitosan as nanofiller of graphite

oxide for the removal of toxic mercury ions, Colloids Surf., B, 113 (2014) 467-476.

[8] K.Z. Elwakeel, A.A. Atia, E. Guibal, Fast removal of uranium from aqueous solutions

using tetraethylenepentamine modified magnetic chitosan resin, Bioresour. Technol., 160

(2014) 107-114.

[9] X.-Y. Huang, X.-Y. Mao, H.-T. Bu, X.-Y. Yu, G.-B. Jiang, M.-H. Zeng, Chemical

modification of chitosan by tetraethylenepentamine and adsorption study for anionic dye

removal, Carbohydr. Res., 346 (2011) 1232-1240.

[10] P.D. Chethan, B. Vishalakshi, Synthesis of ethylenediamine modified chitosan and

evaluation for removal of divalent metal ions, Carbohydr. Polym., 97 (2013) 530-536.

[11] G. Dodi, D. Hritcu, G. Lisa, M.I. Popa, Core–shell magnetic chitosan particles

functionalized by grafting: Synthesis and characterization, Chem. Eng. J., 203 (2012) 130-

141.

[12] J.-S. Wang, R.-T. Peng, J.-H. Yang, Y.-C. Liu, X.-J. Hu, Preparation of ethylenediamine-

modified magnetic chitosan complex for adsorption of uranyl ions, Carbohydr. Polym., 84

(2011) 1169-1175.

[13] L. Zhou, J. Xu, X. Liang, Z. Liu, Adsorption of platinum(IV) and palladium(II) from

aqueous solution by magnetic cross-linking chitosan nanoparticles modified with

ethylenediamine, J. Hazard. Mater., 182 (2010) 518-524.

[14] R. Massart, Preparation of aqueous magnetic liquids in alkaline and acidic media, IEEE

transactions on magnetics, 17, 2, 1981. 1247–1248). IEEE Trans. Magn., 17 (1981) 1247-

1249.

[15] A.A. Atia, A.M. Donia, K.Z. Elwakeel, Adsorption behaviour of non-transition metal

ions on a synthetic chelating resin bearing iminoacetate functions, Sep. Purif. Technol., 43

(2005) 43-48.

31

[16] X. Wang, Z. Zhao, J. Qu, Z. Wang, J. Qiu, Fabrication and characterization of magnetic

Fe3O4-CNT composites., J. Phys. Chem. Solids, 71 (2010) 673-676.

[17] B. Wang, Q. Wei, S. Qu, Synthesis and characterization of uniform and crystalline

magnetite nanoparticles via oxidation-precipitation and modified co-precipitation methods.,

Int. J. Electrochem. Sci., 8 (2013) 3786-3793.

[18] D.H.K. Reddy, S.-M. Lee, Application of magnetic chitosan composites for the removal

of toxic metal and dyes from aqueous solutions, Adv. Colloid Interface Sci., 201–202 (2013)

68-93.

[19] L.F. Qi, Z.R. Xu, X. Jiang, C.H. Hu, X.F. Zou, Preparation and antibacterial activity of

chitosan nanoparticles, Carbohydr. Res., 339 (2004) 2693-2700.

[20] A.T. Paulino, A.G.B. Pereira, A.R. Fajardo, K. Erickson, M.J. Kipper, E.C. Muniz, L.A.

Belfiore, E.B. Tambourgi, Natural polymer-based magnetic hydrogels: Potential vectors for

remote-controlled drug release, Carbohydr. Polym., 90 (2012) 1216-1225.

[21] S.H. Huang, D.H. Chen, Rapid removal of heavy metal cations and anions from aqueous

solutions by an amino-functionalized magnetic nano-adsorbent, J. Hazard. Mater., 163 (2009)

174-179.

[22] J. Coates, Interpretation of Infrared Spectra, A Practical Approach, in: R.A. Meyers (Ed.)

Encyclopedia of Analytical Chemistry, John Wiley & Sons Ltd, Chichester, U.K., 2000, pp.

10815-10837.

[23] Y.-T. Zhou, H.-L. Nie, C. Branford-White, Z.-Y. He, L.-M. Zhu, Removal of Cu2+

from

aqueous solution by chitosan-coated magnetic nanoparticles modified with alpha-ketoglutaric

acid, J. Colloid Interface Sci., 330 (2009) 29-37.

[24] P. Miretzky, A.F. Cirelli, Hg(II) removal from water by chitosan and chitosan

derivatives: A review, J. Hazard. Mater., 167 (2009) 10-23.

32

[25] A.A. Atia, A.M. Donia, K.Z. Elwakeel, Selective separation of mercury (II) using a

synthetic resin containing amine and mercaptan as chelating groups, React. Funct. Polym., 65

(2005) 267-275.

[26] X. Li, Z. Liu, J.-Y. Lee, Adsorption kinetic and equilibrium study for removal of

mercuric chloride by CuCl2-impregnated activated carbon sorbent, J. Hazard. Mater., 252–

253 (2013) 419-427.

[27] S. Lagergren, About the theory of so-called adsorption of soluble substances., Kungliga

Swenska Vet., 24 (1898) 1-39.

[28] Y.S. Ho, G. McKay, Pseudo-second order model for sorption processes, Process

Biochem., 34 (1999) 451-465.

[29] W.J. Weber, J.C. Morris, Kinetics of adsorption on carbon from solutions., J. Sanitary

Eng. Div., ASCE, 89 (1963) 31-60.

[30] J. Zeldowitsch, The catalytic oxidation of carbon monoxide on manganese dioxide., Acta

Physicochim URSS, 1 (1934) 364-449.

[31] A.M. Donia, A.A. Atia, K.Z. Elwakeel, Selective separation of mercury(II) using

magnetic chitosan resin modified with Schiff's base derived from thiourea and glutaraldehyde,

J. Hazard. Mater., 151 (2008) 372-379.

[32] J.S. Markovski, V. Đokić, M. Milosavljević, M. Mitrić, A.A. Perić-Grujić, A.E. Onjia,

A.D. Marinković, Ultrasonic assisted arsenate adsorption on solvothermally synthesized

calcite modified by goethite, α-MnO2 and goethite/α-MnO2, Ultrason. Sonochem., 21 (2014)

790-801.

[33] P.R. Grossl, M. Eick, D.L. Sparks, S. Goldberg, C.C. Ainsworth, Arsenate and chromate

retention mechanisms on goethite. 2. Kinetic evaluation using a pressure-jump relaxation

technique, Environ. Sci. Technol., 31 (1997) 321-326.

33

[34] B. Dou, V. Dupont, W. Pan, B. Chen, Removal of aqueous toxic Hg(II) by synthesized

TiO2 nanoparticles and TiO2/montmorillonite, Chem. Eng. J., 166 (2011) 631-638.

[35] F. Raji, M. Pakizeh, Kinetic and thermodynamic studies of Hg(II) adsorption onto

MCM-41 modified by ZnCl2, Appl. Surf. Sci., 301 (2014) 568-575.

[36] I. Langmuir, The adsorption of gases on plane surfaces of glass, mica and platinum, J.

Amer. Chem. Soc., 40 (1918) 1361-1402.

[37] H.M.F. Freundlich, Uber die adsorption in lasungen, Z. Phys. Chem., 57 (1906) 385-470.

[38] M.M. Dubinin, E.D. Zaverina, L.V. Radushkevich, Sorption and structure of active

carbons. I. Adsorption of organic vapors, Zh. Fiz. Khim., 21 (1947) 1351-1362.

[39] S. Brunauer, P.H. Emmett, E. Teller, Adsorption of gases in multimolecular layers, J.

Am. Chem. Soc., 60 (1938) 309-319.

[40] F.-N. Allouche, E. Guibal, N. Mameri, Preparation of a new chitosan-based material and

its application for mercury sorption, Colloids Surf., A, 446 (2014) 224-232.

[41] Z. Li, L. Wu, H. Liu, H. Lan, J. Qu, Improvement of aqueous mercury adsorption on

activated coke by thiol-functionalization, Chem. Eng. J., 228 (2013) 925-934.

[42] M. Monier, I.M. Kenawy, M.A. Hashem, Synthesis and characterization of selective

thiourea modified Hg(II) ion-imprinted cellulosic cotton fibers, Carbohydr. Polym., 106

(2014) 49-59.

[43] S. Thakur, S. Kumari, P. Dogra, G.S. Chauhan, A new guar gum-based adsorbent for the

removal of Hg(II) from its aqueous solutions, Carbohydr. Polym., 106 (2014) 276-282.

[44] N. Rahman, N. Sato, M. Sugiyama, Y. Hidaka, H. Okabe, K. Hara, Selective Hg(II)

adsorption from aqueous solutions of Hg(II) and Pb(II) by hydrolyzed acrylamide-grafted

PET films, J. Environ. Sci. Health., Part A, 49 (2014) 798-806.

[45] F. Raji, M. Pakizeh, Study of Hg(II) species removal from aqueous solution using hybrid

ZnCl2-MCM-41 adsorbent, Appl. Surf. Sci., 282 (2013) 415-424.

34

[46] A. Dawlet, D. Talip, H.Y. Mi, MaLiKeZhaTi, Removal of mercury from aqueous

solution using sheep bone charcoal, Procedia Environ. Sci., 18 (2013) 800-808.

35

List of Tables

Table 1: Kinetics models and their linear forms

Table 2: Kinetic parameters for Hg(II) sorption

Table 3: Sorption isotherms and their linear forms

Table 4: Parameters of the models for sorption isotherms

Table 5: Effect of temperature on Hg(II) sorption capacity

Table 6: Standard enthalpy, entropy and free energy changes for Hg(II) sorption

Table 7: Effect of counter ion on Hg(II) sorption

Table 8: Multicomponent sorption – Effect of pH on the sorption capacity for Hg(II) Co(II),

Cu(II), Fe(II), Ni(II), Zn(II) and Mg(II) (initial concentration of 1.0 mmol metal L-1

for each

metal ion).

Table 9: Comparison of sorption capacity for Hg(II) ions with various sorbents

36

Table 1: Kinetics models and their linear forms

Kinetic model Non-Linear form Linear form Plot References

Pseudo-First

order ]1[ 1 tk

eqq et

t)

2.303

k(q log )q(q log 1

ete log (qe- qt) vs. t [27]

Pseudo-Second

order tqk

tkq

e

t

2

2

1 t)

q

1(

qk

1

q

t

e2

e2t

(t/qt) vs. t [28]

Intraparticle

diffusion

- qt = Kit

0.5 + X qt vs. t

0.5 [29]

Elovich

equation q

edt

dqt

lnt

1ln

1

tq

qt vs. lnt [30]

37

Table 2: Kinetic parameters for Hg(II) sorption

PFORE PSORE Weber & Morris model Elovich equation

Sorbent qe,exp k1 qe, calc R2 k2 qe, calc R

2 Ki X R

2 α β R

2

MCGMA-I 1.43 0.0130 0.91 0.942 0.035 1.49 0.9976

Ki1 0.124 0.247 0.953

0.470 4.55 0.993 Ki2 0.042 0.751 0.942

Ki3 0.013 1.178 0.889

MCGMA-II 2.01 0.0095 1.27 0.979 0.017 2.10 0.9899

Ki1 0.091 0.664 0.991

0.736 3.54 0.951 Ki2 0.079 0.689 0.989

Ki3 0.035 1.342 0.996

Units: qe, exp/calc: mmol g-1

., k1: min-1

), k2: g mmol-1

min-1

; Ki: mmol g-1

min0.5

; α: mmol g-1

min-1

; β: g mmol-1

.

38

Table 3: Sorption isotherms: equation in their linear and non-linear forms

Isotherm Non-Linear form Linear form Plot References

Langmuir eqL

eqLLmeq

CK

CKqq

1

,

Lm,Lm,

eq

eq

eq

q

1

q

C

q

C

LK

eqqeqC

vs. eqC [36]

Freundlich n

eqFeq CKq /1 eqCln

n

1Kln q ln feq ln qeq vs. ln Ceq

[37]

Dubinin–Radushkevich 2

expDR

DR

KQ

eqq

2

e lnqln DRDR KQ ln qeq vs. 2 [38]

39

Table 4: Parameters of the sorption isotherm models

Langmuir model Freundlich model Dubinin-Radushkevich (D-R) model

Sorbent qmax,exp

(mmol g−1

)

qm,L

(mmol g−1

)

KL

(L mmol−1

)

R2

n KF (mmol g

−1)

(L mmol−1

)1/n

R2 QDR

(mmol g−1

)

KDR

(J2 mol

−2)

Ea

(kJ mol−1

)

R2

MCGMA-I 1.43 1.55 27.78 0.999 12.87 1.37 0.965 1.50 4.72 × 10-9

10.3 0.892

MCGMA-II 2.02 2.28 16.48 0.999 7.98 1.89 0.945 2.16 6.48 × 10-9

8.78 0.894

40

Table 5: Effect of temperature on Hg(II) sorption capacity

Temperature oC

Sorption capacity (mmol Hg g-1

)

MCGMA-I MCGMA-II

20 1.48 2.12

30 1.74 2.40

40 1.91 2.58

50 2.21 2.65

Table 6: Standard enthalpy, entropy and free energy changes for Hg(II) sorption

Adsorbent

∆Ho

(kJ mol−1

)

∆So

(J mol−1

K−1

)

T0

(K)

∆Go (kJ mol

−1)

293 K 303 K 313 K 323 K

MCGMA-I 19.2 61.4 312.8 1.22 0.60 -0.01 -0.62

MCGMA-

II 15.3 54.0 283.8 -0.50 -1.04 -1.58 -2.12

41

Table 7: Effect of counter ion on Hg(II) sorption

Table 8: Multicomponent sorption – Effect of pH on the sorption capacity for Hg(II) Co(II),

Cu(II), Fe(II), Ni(II), Zn(II) and Mg(II) (initial concentration of 1.0 mmol metal L-1

for each

metal ion).

*: negative values for Fe(II) are associated to metal release due to magnetite partial

dissolving.

Initial

pH

Sorption capacity (mmol Hg g-1

)

HgCl2 HgNO3 HgSO4

MCGMA-I MCGMA-II MCGMA-I MCGMA-II MCGMA-I MCGMA-II

0.95 1.51 2.07 0.15 0.16 0.048 0.054

2.12 1.45 2.07 1.00 1.41 0.153 0.164

3.2 1.36 1.95 1.33 2.14 - -

Adsorbent Initial

pH

Uptake (mmol g-1

)

Final

pH Metal ion

Hg(II) Co(II) Cu(II) Fe(II)* Ni(II) Zn(II) Mg(II)

MCGMA-I

0.4 0.82 0.280 0.016 0.001 -0.209 0.002 0.034 0.000

0.8 1.12 0.342 0.006 0.000 -0.118 0.011 0.021 0.001

1.2 1.26 0.350 0.016 0.005 -0.008 0.015 0.008 0.004

1.6 1.80 0.301 0.014 0.004 -0.005 0.016 0.000 0.000

MCGMA-II

0.4 0.90 0.310 0.014 0.000 -0.192 0.004 0.027 0.000

0.8 1.22 0.372 0.000 0.003 -0.109 0.005 0.008 0.000

1.2 1.29 0.380 0.001 0.006 -0.007 0.000 0.000 0.005

1.6 1.86 0.331 0.000 0.013 -0.004 0.000 0.000 0.002

42

Table 9: Comparison of sorption capacity for Hg(II) ions with various sorbents

Adsorbent material

Initial pH Contact

time (min)

Temperature

(oC)

Initial

concentration

(mM)

Sorbent

dosage (g L-1

)

Sorption capacity

(mmol Hg g−1

) References

Thiourea modified Hg(II)

ion-imprinted cellulosic cotton fibers 5.00 180 30 1.99 0.30 0.54 [42]

Schiff-base modified guar gum 5.00 120 25 0.24 1.00 0.20 [43]

Hydrolyzed acrylamide-grafted PET

films 4.5 40 25 0.49 4.00 0.07 [44]

ZnCl2-MCM-41 6.00 30 20 0.24 0.33 0.43 [45]

Chitosan foam 4.00 2880 20 0.49 0.45 1.74 [40]

Thiol modified activated coke 5.00 480 25 0.49 0.10 2.29 [41]

Glycidylmethacrylate grafted on

cellulose 5.00 50 - 0.24 20.00 0.18 [6]

Sheep bone charcoal 3.0 360 25 0.39 4.00 0.06 [46]

MCGMA-I 4.0 300 20 5.00 2.50 1.43 This work

MCGMA-II 4.0 300 20 5.00 2.50 2.02 This work

43

OH

NH2

H2NO

O

O

O

O

n

HO

OH

O CH2 CH2CH

OH

NH2

H2N

HO

OH

polymerization

NH2

NHNH2

CHHO

CH2

NH2

NHNH2

NH2

NHNH2

CH

CH2

HO

(MCGMA) O CH2 CH2CH

OH

NH2

H2N

HO

OH

Cl CH2 HC CH2

OHN

CH2H2C CH

O

OHO

O

O

(MCGMA)

NH

CH2 HC CH2

OHO

CH2CH

OH

O CH2

HO

HN

CH2H2C CHNH2

NHNH

OH

OHO

NH2

NHNH2(MCGMA-ECH)

NH2

NHNH2

CHHO

NH

CH2H2C CH

OH

NH2

NHNH

CHHO

CH2

NH2

NHNH2

CH2CH

OH

O CH2

(MC) + (GMA) + (magnetite) (MCGMA)

(MCGMA-I)

(MCGMA-ECH)

(MCGMA-II)

Scheme 1: Scheme for the synthesis and modification of magnetic-macromolecular hybrid

material

44

OO

O

OHO NH2

CH2

HC OH

H2C

O

C O

CCH3H2C

H2C CH

CO

NH

CH2

NH

CO

CHH2C

OO

O

OHO NH2

CH2

HC OH

H2C

O

C O

C

CH3

CH2

CH

CO

NH

CH2

NH

CO

CH

CH2

Chitosan-GMA (MBA) Macromolecular hybrid material

(MCGMA)

Scheme 2: proposed chemical structure of chitosan–glycidyl methacrylate - N,N’methylene-

bis-acrylamide (macromolecular hybrid material)

45

Figures captions

Figure 1: Scanning electron micrographs of; (a) unloaded MCGMA-I, (b) unloaded

MCGMA-II, (c) Hg(II)-loaded MCGMA-I and (d) Hg(II)-loaded MCGMA-II.

Figure 2: Energy dispersive X-ray analysis (EDX) of MCGMA-I and MCGMA-II sorbents:

(a) unloaded MCGMA-I, (b) unloaded MCGMA-II, (c) Hg(II)-loaded MCGMA-I and (d)

Hg(II)-loaded MCGMA-II.

Figure 3: Magnetization curves for MCGMA-I and MCGMA-II sorbents.

Figure 4: FT-IR spectra of MCGMA-I and MCGMA-II sorbents.

Figure 5: pH effect on Hg(II) sorption using MCGMA-I and MCGMA-II: (a) sorption

capacity, (b) pH change (T: 20 oC; C0: 10 mmol Hg L

-1).

Figure 6: Hg(II) uptake kinetics using MCGMA-I and MCGMA-II (a: relative concentration