Section 6 Technical Specification & Drawings

-

Upload

pavankumar001 -

Category

Documents

-

view

225 -

download

0

Transcript of Section 6 Technical Specification & Drawings

-

7/30/2019 Section 6 Technical Specification & Drawings

1/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

SECTION-VI

TECHNICAL SPECIFICATIONS &

DRAWINGS

TENDER DOCUMENT SECTION VI VI.1

-

7/30/2019 Section 6 Technical Specification & Drawings

2/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

SECTION-VI: TECHNICAL SPECIFICATIONS

SUB SECTION - 1: SCOPE

1.1 SCOPE

The bidder shall quote for supply of two (2) units of TG sets of 2500 kW rated output each for theBANER SANGAM Hydro Electric Power Project, District Kangra, Himachal Pradesh, India. Thebidder shall quote covering design, material selection, manufacture, assembly, testing atmanufacturer's works including Type Test, packing and forwarding for shipment and delivery to ProjectSite (final destination) as well as Supervision Services for performing on site assembly, erection,commissioning & testing at site, load testing for 72 Hours (Trial Operation) and Test Run for 8 weeksas well as 30 (Thirty) days commercial operation and maintenance of all Electrical and MechanicalEquipments. The bidder has to include in the scope, all the equipments required for the project in fulland complete shape even though some equipment and services are not specifically mentioned (or)

detailed here or elsewhere under this specification.

S.

NO.

NAME OF SCHEME NO. OF UNITS AND RATED CAPACITYOF EACH UNIT

(IN kW)

1. BANER SANGAM HYDRO

ELECTRIC PROJECT, NEAR

VILLAGE SALEG, DISTRICT

KANGRA, HIMACHAL PRADESH,

INDIA.

2 (TWO) UNITS OF 2500 kW,

GENERATION VOLTAGE 6.6 kV AT 50 Hz,

Power Factor (Cos ) = 0.9 (LAG).

1.1.1 The bidder shall quote for the scope specified in the Contract including the Schedule of requirementsand shall include in the scope all the equipment and services required for the project in full andcomplete shape even though some equipment and services are not specifically mentioned (or)detailed here or elsewhere. The Contract envisages generation and evacuation of power on a waterto wire concept and accordingly, the Contractor shall perform all such work and/or supply all suchitems and materials not specifically mentioned in the Contract but that can be reasonably inferredfrom the Contract as being required for attaining completion of the project as if such work and/or itemsand materials were expressly mentioned in the Contract.

1.2 The Facilities and Services shall meet the stipulations of the Technical Specifications and otherrequirements of the Contract

1.3 Detailed scope has been described in various sections of the Technical Specifications.

1.4 The final destination for Facilities to reach is:

PROJECT SITE: BANER SANGAM HYDRO ELECTRIC POWER PROJECT,

ON THE LEFT BANK OF BANER KHAD,

NEAR JALARI VILLAGE, DISTRICT KANGRA,

HIMACHAL PRADESH, INDIA.

TENDER DOCUMENT SECTION VI VI.2

-

7/30/2019 Section 6 Technical Specification & Drawings

3/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

SECTION-VI: TECHNICAL SPECIFICATIONS

SUB SECTION - 2: PROJECT INFORMATION

2.1 INTRODUCTION

BANER SANGAM Hydro Electric Power Project is a run-off-the river scheme. The project is locatedon the Left Bank of Baner Khad in District Kangra, Himachal Pradesh, India.

It is proposed to install two (2) numbers TG sets of 2500 kW each. The Power shall be generated at6.6 kV and evacuation shall be done through 33 kV line on Wolf conductor to be connected with the33 kV sub-station at Darkata (Ranital) Kangra of HPSEB Limited.

2.2 LOCATION

COUNTRY : INDIA

STATE : HIMACHAL PRADESH

DISTRICT : KANGRA

ACCESS

ROAD

: Road up to intake of Baner Sangam HEP FROM KANGRA 10 km, 123

km FROM PATHANKOT AND 241 km FROM SHIMLA BY ROAD

RAIL : Nearest Broad Gauge Station at Pathankot (Punjab) Narrow Gauge at

Kangra (HP)

AIRPORT : NEAREST AIRPORT IS AT GAGAL

GEOGRAPHICAL COORDINATES OF PROJECT SITE:

LATITUDES : 32 02 50 North

LONGITUDES : 76 1445 East

2.3 HYDROLOGY

PROJECT TYPE : RUN OF THE RIVER SCHEME

RIVER CATCHMENT

CATCHMENT : BANER

RIVER : BANER KHAD

TRIBUTARY : TRIBUTARY OF BEAS RIVER

DIVERSION SITE

CATCHMENT AREA (BANER KHAD) : 406 sq. km.

CLIMATIC DATA : MAX. MIN.

ATMOSPHERIC TEMPERATURE : 30 DEG C 0 DEG C

TENDER DOCUMENT SECTION VI VI.3

-

7/30/2019 Section 6 Technical Specification & Drawings

4/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

FLOODS

DESIGN FLOOD DISCHARGE

(a) FOR 50 YEAR RETURN PERIOD :

(b) FOR 100 YEAR RETURN PERIOD : 3000 cumecs

2.4 GEOLOGY

BANER-SANGAM hydroelectric project in Kangra Distt. of Himachal Pradesh, is proposed to be locatedon the left bank of Baner Khad near village Jalari. The present scheme envisages diversion of BanerKhad water by a Trench weir at an EL 564 m near village Nandrul & leading it successively along a1727 m long power tunnel, forebay & 100 m long penstock to the surface power house on the left bankof Baner Khad to generate 5 MW power.

The Project area has been geologically reconnoitered and the geo-technical feasibility & locations of

different project components have been finalized on the ground.The area encompassed by the project falls on mountains terrain having high ranges and vertical cliffsat places. The rock units observed in the area are sand stone , schists with thin quartzitic bands (atplaces). The rocks are exposed mainly along the ridges, steep slopes and either bank of the Nalas.The low-lying areas along and below hill slopes comprise of debris / silty soil cover. The rocks areNW SE to N70o W-S70o E with dips from 26o to 70o in northeasterly direction. The power house islocated on the consolidated river bed material.

2.5 PROJECT PROPOSAL

A) DIVERSION STRUCTURE (HEAD WORKS)

I. DIVERSION WEIR ON BANER KHAD

i) TYPE : Raised crested type weir.

ii) LENGTH : 35.0 m

iii) HEIGHT :

iv) TOP WIDTH : 6.0 m

v) MAX. DISCHARGINGCAPACITY

: 14.10 cumecs WITH 2.8 m DEPTH OF FLOW

GATES INTAKE & Shingle flushing gates

(a) NUMBER OF GATES : 2 NOS. - 1 NO. AT INTAKE & 1 NO. AT Shingle flushing

(b) TYPE OF GATES : VERTICAL LIFT GATES

(c) SIZE OF GATES : INTAKE: 3 0 m (WIDE) x 4.5 m (HIGH),

Shingle flushing 2.5 m (WIDE) x 3.0 m (HIGH)

WATER CONDUCTOR SYSTEM

I. BANER KHAD

1. FEEDER Channel (RD 4.72 M TO RD 20.59 M)

TENDER DOCUMENT SECTION VI VI.4

-

7/30/2019 Section 6 Technical Specification & Drawings

5/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

i) TYPE : RCC box

ii) SIZE : 2.5 m (WIDE) x 2.5 m HIGH)

iii) Bed Level : EL 561.4 m

iv) NWL : EL 563.9 m

v) HFL : EL 567.5 m

2. DESILTING CHAMBER (RD 20.59 M TO RD 99.32 M) i/c U/S & D/S Transitions

i) TYPE : DUFOUR TYPE

ii) LENGTH (including u/s &d/s transition)

: 54.00 m

iii) WIDTH : 14.00 m

iv) DEPTH : 6.3 m

3. POWER TUNNEL (RD_____ M TO _____ M)

i) LENGTH : 1727.00 m

ii) SHAPE : D SHAPED TUNNEL

iii) SIZE : 3.0 m (WIDE) x 3 m m (HIGH)

iv) THICKNESS OF LINING : 150 mm

v) DESIGN DISCHARGE : 14.10 cumecs

C) FOREBAY

i) TYPE : RCC oval shaped

ii) SIZE OF FOREBAY : LENGTH = 65.0 m

WIDTH = 16.0 m

iii) BED LEVEL OFFOREBAY

: EL 552 m

iv) FULL FOREBAY LEVEL : EL 559.39 m

viii) MINIMUM DRAW DOWNLEVEL (MDDL)

: EL 556.89 m

ix) C.L. OF PENSTOCKINLET at forebay

: EL 554 m

x) OVERFLOW STRUCTURE (ESCAPE DUCT)

(a) LENGTH : 20 m

(b) BED LEVEL : EL 559.39 m

xi) MAXIMUMDISCHARGINGCAPACITY

: 14.10 cumecs

xii) TOTAL STORAGE : 3 minutes storage

TENDER DOCUMENT SECTION VI VI.5

-

7/30/2019 Section 6 Technical Specification & Drawings

6/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

D) PENSTOCK

i) TYPE & NUMBER : 1 (ONE) NO., CIRCULAR, STEEL BURIED PENSTOCK

BIFURCATING NEAR POWERHOUSEii) INSIDE DIA. BEFORE

BIFURCATION: 2700 mm , Thickness varying between 8 mm to 18 mm

iii) LENGTH OF PENSTOCKBEFORE BIFURACTION

: 100.0 m

iv) BIFURCATION : ONE (1) HAVING AN INCLUDED ANGLE OF 60

v) INSIDE DIA. AFTERBIFURCATION

: 1900 mm (1.9 m)

vi) LENGTH OF EACHPENSTOCK AFTERBIFURACTION

: 20 m (Two Nos.)

vii) DIAMETER ANDTHICKNESS

: 16 mm 1.9 m DIA

viii) TOTAL LENGTH OFPENSTOCK

: 100.0 m

ix) BIFURCATION ATLOWER END

: BIFURCATION'S YIELDING TWO PIPES OF 1900 mmDIA EACH

x) INVERT LEVEL AT INLET : EL _____ m

xi) DESIGN DISCHARGE : 14.10 cumecs

xii) MAX. DISCHARGE FOR20% OVERLOAD

: 17.00 cumecs

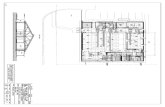

E) POWERHOUSE

i) TYPE : SURFACE POWERHOUSE

ii) SIZE OF POWERHOUSE

(a) LENGTH : 28.00 m

(b) WIDTH : 10.00 m

(c) HEIGHT : 9.50 m

(d) TUBINE : Horizon Axis Francis turbine

iii) INSTALLED CAPACITY : 2 x 2500 kW with 10% overload

iv) GROSS HEAD : 44.39 m

v) DESIGN HEAD : 42.50 m

F) TAILRACE DUCT (LENGTH = 50.00 m)

i) TYPE & SIZE : RCC box section, 3 m x 3 m

ii) LENGTH : 50.00 m

TENDER DOCUMENT SECTION VI VI.6

-

7/30/2019 Section 6 Technical Specification & Drawings

7/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

iii) MAXIMUM TAIL WATERLEVEL

: EL 515.00 m

G) TURBINE

i) TYPE : Horizon Axis Francis turbine

ii) NUMBER : TWO (2)

iii) CAPACITY : 2500 kW EACH WITH 20% OVERLOAD CAPACITY

iv) RATED TURBINEOUTPUT

: 2500 kW (EACH / PER MACHINE)

v) TURBINE SPEED : 500 rpm

H) GENERATOR

i) TYPE : HORIZONTAL SYNCHRONOUS

ii) NUMBERS : TWO (2)

iii) CAPACITY : 2777.77 kVA EACH WITH 20% OVERLOAD CAPACITY

iv) EXCITATION SYSTEM : AUTOMATIC (BRUSHLESS EXCITATION WITH AVR)

v) REGULATION SYSTEM : AUTOMATIC

vi) GENERATION VOLTAGE : 6.6 kV at 50 Hz

I) POWERHOUSE CRANE

i) TYPE : ELECTRICALLY OPERATED OVERHEAD TRAVELING(EOT) CRANE

Ii) NUMBER : ONE (1)

iii) CAPACITY : 25 / 5 T - 25 T CAPACITY OF MAIN HOOK, 5T CAPACITYOF AUXILIARY HOOK (TO BE CONFIRMED BY E&MCONTRACTOR)

J) TRANSMISSION : THE POWER AT 33 kV SHALL BE EVACUATEDTHROUGH A 33 kV LINE ON WOLF CONDUCTORUPTO THE 33 kV sub-station of HPSEB at Darkata(Kangra).

i) VOLTAGE : 33 kV SINGLE CIRCUIT

ii) FEEDING POINT INTOGRID

: 33 kV sub-station of HPSEB at Darkata (Kangra)

K) POWER

i) INSTALLED CAPACITY : 2 x 2500 kW

TENDER DOCUMENT SECTION VI VI.7

-

7/30/2019 Section 6 Technical Specification & Drawings

8/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

ii)TOTAL ANNUALENERGY- 75% DEPENDABLEYEAR

: 26.63 million kWh

L) SWITCHYARD

i) VOLTAGE LEVEL / BASICUNDULATION LEVEL

: 6.6/33 kV

ii) NO. OF BAYS : ONE (1)

iii) SIZE

(a) LENGTH : 20 m

(b) WIDTH : 20 m

TENDER DOCUMENT SECTION VI VI.8

-

7/30/2019 Section 6 Technical Specification & Drawings

9/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

SECTION-VI: TECHNICAL SPECIFICATIONS

SUB SECTION - 3: TECHNICAL REQUIREMENTS OF THE PROJECT

3.1 LAYOUT DRAWINGS

The bidder shall submit layout plan and cross-section of the Power House and tailrace pool giving sa-lient levels, width and lengths at each of these elevations. The Bidder shall submit along with his bid,drawings showing plans at different levels, longitudinal section and cross section of the powerhouseindicating all the equipment. The drawings shall contain following details:

i. Lowest elevation, length & width to which excavation is to be made for Turbine sump, tailrace, etc.corresponding to machine setting as recommended by the supplier.

ii. Bottom most elevations to which the area of power tunnel, Forebay, powerhouse and tailrace have to

be dug and the width and lengths at various elevationsiii. Transverse and longitudinal section through the centerline of the turbine as recommended by the

supplier.

iv. The equipment loads (including the points of their application) due to turbine, gearbox (if required),generator and other auxiliary equipment in dry and wet conditions.

v. While arriving at equipment loads the forces acting due to static loads, torque loads, axial thrust loads,short circuit torque loads and any other loads acting in both dry and wet conditions shall beconsidered and indicated on the drawings.

vi. The direction of load and its resolved X and Y components and distance of force acting point from areference point shall be indicated.

vii. The layout of the powerhouse and switchyard equipment.

viii. Charts / Shell curves showing performances including Discharge Vs turbine output and turbine outputVs turbine efficiency; Power output Vs efficiency of Turbine; Head Vs efficiency and power output ofTurbine

ix. Values of critical sigma as determined from cavitation model tests as per IEC 173A in the form ofcurves for different heads of operation.

x. Plant sigma curves as recommended by the Bidder clearly showing the safety margin available.

xi. General layout and assembly drawings showing overall dimensions of the generators indicating stator,rotor, shaft and bearings and positions of main and neutral terminals, main and neutral groundingcable boxes etc.

xii. Description of Lubrication System

xiii. Graphs showing predicted characteristics of the generator viz. Output Vs Efficiency, power factor

xiv. Drawings for connection of winding temperature detectors and bearing temperature detectors

xv. Schedule of tests

xvi. Layout of the main equipment and auxiliary equipment in machine hall, control room and switchyard,indicating positions and dimension of equipment and service bay.

xvii. Single line diagram indicating generation voltage scheme of switchgear and methods of starting.

xviii. Control schematic diagrams for unit control boards / TG panel, instrumentation and safety devices.

xix. Erection procedure to be followed in installation of generating units

xx. Characteristic curve / graphs showing the performance of various equipments.

TENDER DOCUMENT SECTION VI VI.9

-

7/30/2019 Section 6 Technical Specification & Drawings

10/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

3.2 METEOROLOGICAL CONDITIONS

The general weather conditions are as follows:

(A) MAXIMUM AIR TEMPERATURE - 30 degrees C

(B) MINIMUM AIR TEMPERATURE - 0 degrees C

3.3 SEISMICITY

The project area is bounded on the north by Jutogh/Murree thrust and on the south by MBF. Theproject site is located in Kangra valley, which lies in the epicenter tract of devasting Kangraearthquake of 1905. The magnitude of this earthquake was recorded as 8 on Richters scale. Thearea is prone to repeated earthquake of rarely high intensities as indicated by recurrence ofDharamshala earthquake of 1978. The magnitude of this earthquake was 5 Richters Scale and itsepicenter lies in the vicinity of Dharamshala.

From seismic zoning map of India (IS 1893-1975) it is seen that project area lays in seismic zonewhere earthquake of intensity, greater than IX MM scale are expected. As such it is suggested that asuitable seismic factor has to be calculated for designing of various projects components after gettingevaluated from the competent agency.

The project area lies in highly seismic belt and within seismic zone V of the seismic zoning map ofIndia. Suitable seismic coefficient commensurate with the seismic zone V may have to be adopted inthe designing of the proposed structures.

3.4 WATER QUALITY

The water in Baner Khad is generally clean and does not contain any significant silt for most of the

year. However, during rainy season all the Himalayan streams do carry a lot of rolling bed loadcomprising of shingle, stones & boulders and suspended silt.

Design of the scheme ensures that rolling bed load as well as silt does not enter the water conductorsystem. De-silting tank has been designed so as to exclude silt particles greater than and upto 0.25mm size with about 96% efficiency.

3.5 TRANSPORT LIMITATIONS

Weight of each package should be such that it can be handled by the proposed lifting and hoistingarrangements by the Bidder. The Bidders are advised to visit the site to have detailed informationabout roads, railways and bridges enroute to BANER-SANGAM.

3.6 INTERCHANGEABILITY

All similar component parts of similar equipment supplied shall be interchangeable with one another.

3.7 APPROVAL OF DRAWINGS

Drawings shall be furnished in hard as well as soft copies on AutoCAD 2007

(i) The drawings furnished by the supplier may be either approved or clarifications asked for bythe Employer within 14 (Fourteen) days from date of receipt.

(ii) After approval of the drawing by the Employer, each drawing becomes contract drawing andsuch 5 (five) copies of approved drawings shall be sent within 15 (fifteen) days of receipt of

TENDER DOCUMENT SECTION VI VI.10

-

7/30/2019 Section 6 Technical Specification & Drawings

11/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

approval and commencement of manufacture plant. The Contractor shall not depart fromcontract drawings except by the written permission of the Employer.

(iii) Successful Bidder shall submit all relevant drawings for fabrication along with design

calculations of components of E & M equipment within 2 (two) weeks from the issuance ofNotification of award of contract, for approval. The approval of the drawings shall beaccorded within 1 (one) Weeks of receipt of the drawings. After approval of the drawing bythe Employer, each drawing becomes contract drawing and such 5 (five) copies of approveddrawings shall be sent within 1 (One) Week of receipt of approval to commence manufactureof the Facilities. The Contractor shall not depart from contract drawings except by the writtenpermission of the Employer. The Employer will maintain secrecy and confidentiality of allProprietary Drawings provided by the Contractor

(iv) Any manufacture performed prior to the approval of drawings will be at the Supplier's risk.

(v) When revised drawings are submitted for approval, the changes from the previous submitteddrawings shall be clearly identified on drawings, with every revision made during the life timeof the contract shown by number, date and subject in a revision block and notation shall be

given in the drawing margin. The drawings shall be clear and legible in all respects.

(vi) The drawings shall be clear, facilitating easy identification of all parts with part number forordering of spares by the Employer without referring to Supplier.

(vii) Approval of the drawings will not relieve the supplier of his responsibility for the correctness ofthe design and construction of the plan, guarantees and warranties on the performance of theequipment as per the terms and conditions of the specification

(viii) One set or reproducible shall be supplied with all correspondence. All drawings must beprepared on AutoCAD 2007 and supplied in floppy / CD.

3.8 MISTAKES IN DRAWINGS

The contractor shall be responsible for and shall at his cost carry out the alternations of the work due

to any discrepancies or errors or commissions in the drawings or other particulars supplied by him,whether or not such drawings or particulars have been approved by the Employer, provided that suchdiscrepancies, errors or omissions are not due to inaccurate information or particulars furnished to thesupplier by the Employer. If any dimensions figured upon a drawing or a plan differ from thoseobtained by scaling the drawings or plan, the dimension as figured upon the drawing or plan shall betaken as correct.

3.9 DEPARTURE / DEVIATIONS FROM SPECIFICATIONS

(i) Should the Bidder wish to depart from these specifications, he shall submit a complete and itemizedlist of such departures together with full particulars of the reasons for the departures in a separateschedule with reference to section and paragraph numbers of these tender specifications along with

this Bid. (Schedule-7 of Technical Specification)

(ii) Unless this is done the plant / Facilities offered shall be deemed to comply in every respect with thisBid document. The statement of departures should be made in a separate Schedule to the tender.

3.10 PAINTING

3.10.1 Generator, switchgear and all the auxiliary plant shall be given two coats of finishing paints ofapproved colour over a coat of fuller paint. The turbines including its parts that come into contact withwater and all the allied plant and outdoor equipment shall be given two primary coats of approved rustresisting paint in plain colour before packing. Parts not so painted shall be protected againstdeterioration during shipment. All bright steel parts shall be given a thick coat of approved rustresisting paint in plain colour to prevent rusting during shipment. All gunmetal or brass parts shall be

TENDER DOCUMENT SECTION VI VI.11

-

7/30/2019 Section 6 Technical Specification & Drawings

12/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

coated with a removable dark paint as precaution against pilferage during transit. All unfinishedsurfaces in contact with oil shall be cleared and painted with special oil resistant paint.

3.10.2 All the gears and joints, which shall be riveted together to site, shall be given a coat of rust resisting

paint before dispatch from contractors works. The interior metallic surfaces of oil filled apparatus shallbe treated with oil resistant paint after thorough cleaning.

3.10.3 For steel structures, in contact with water, two coats of bituminous black acid-free paint shall beapplied at site after thoroughly cleaning them by shot blasting.

All equipment shall be painted with two coats of approved colour at site after final assembly beforehanding over of the project.

3.11 STANDARDS AND CODES

3.11.1 All material and equipment shall comply in all respects with the requirements of the latest edition ofthe relevant Indian Standards, International Electro Technical Commission (IEC) Standards or British

Standards or American Standards Association (ASA) or ATM or NEMA or DIN standards or any otherrelevant equivalent standards. The standard applicable and code number of the standard shall begiven for all the equipment. It shall be invariably understood that the provision of the latest edition ofthe relevant standards shall apply in every case. It is however understood that the plant andequipment / Facilities offered shall comply with one consistent set of standards except in so far asthey are modified by the requirements of these specifications.

3.11.2 Wherever reference is made in the Technical Specifications to specific standards and codes to be metby the Facilities and materials to be furnished or tested, the provision of the latest current edition orrevision of the relevant standards or codes in effect shall apply, unless otherwise expressly stated inthe contract. Where such standards and codes are national or relate to a particular country or origin,other authoritative standards that ensure substantial equivalence to the standards and codesspecified will be acceptable.

3.12 MANUFACTURING STANDARDS

3.12.1 The general principle on which these specifications are drawn up is to permit the adoption of modernmanufacturing standards. The bidders are requested to tender for their own standard equipment asfar as possible provided these comply with the requirements of these specifications. However, shouldthe contractor wish to depart from the provisions of these specifications either on account ofmanufacturing practice or for any other reasons, he shall drawn the attention of the Employer to theproposed points of departure and shall submit such full information, drawings and specification as wellto enable the relative merit of his proposal to be fully appreciated.

3.12.2 In the event of these specifications, or a part thereof and the contractor's drawings, specifications etc.being found to disagree during the execution of the contract, these specifications shall be held asbinding unless the departures have been duly approved in writing by the Employer.

EXTRA WORK

The Contractor shall when asked in writing by the Employer, to perform extra work and furnish extramaterial not covered by the specification or included in the schedule but forming an inseparable partof the work contracted for. The terms of payment for such extra work or material shall be mutuallyagreed upon in advance.

TENDER DOCUMENT SECTION VI VI.12

-

7/30/2019 Section 6 Technical Specification & Drawings

13/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

3.13 ELECTRICITY RULES

All works shall conform with the rules in force under the latest versions of the Indian Electricity Act andIndian Electricity Rules and other applicable legislation.

3.14 NAME PLATES

All equipment shall have metal name plates fixed at a suitable position, with full technical particularslike Maximum, Minimum & Rated Output and the standards adopted.

3.15 NOISE

All rotating machinery shall be desired to work without undue noise and limiting the noise level asspecified in Technical Specifications. Special precautions shall be taken to provide machines that

shall run smoothly.

3.16 BALANCING

All revolving parts of the machinery shall give their motors thoroughly well balanced statically anddynamically at the manufacturer's works. Any out of balance that may occur upon erection at siteshall be rectified. The bidder shall state whether the rotating parts will be balanced both statically anddynamically at the manufacturer's works.

3.17 PIPING

3.17.1 All pipes and fittings supplied by the contractor shall conform to the appropriate standards and as per

IS - 4711 of 1968.3.17.2 Each piping system, shall be provided with an adequate quantity of valves, drain plug / cocks, sight

flow indicators, meters etc., which have to be approved by the Employer so as to ensure flexibility ofoperation coupled with reliability and ease of maintenance of the system.

3.17.3 All piping shall be clean inside and where ending in open connecting for other work, the piping shallhave the ends capped for protection. Valves shall be easily accessible and gauges and otheroperating or indicating devices shall be located so shall be suitable for the services intended. Either ablind companion flanges for a pipe plug shall be provided, where necessary to protect valves. Wherethe piping systems must be disconnected for servicing, flanges or unions shall be provided and thepiping valves and joints shall be arranged for minimum disturbance or interference with other partsduring such operation.

3.17.4 As far as possible the pipes shall not be embedded, but shall be run in trenches or shall be suitablysupported by hangers, brackets, pedestals or any other support suited to the requirements and careshould be taken to avoid vibration at the supports. An adequate allowance for the expansion of pipesunder service conditions shall be made. Each pipe shall be painted with colours as per standard codeof practice. The material of piping for different services shall be stated in the tender.

3.17.5 Flexible pipe connection to apparatus shall be provided wherever necessary such as in the case ofconnections from the permanent piping systems to a transformer etc.

3.17.6 For ready identification of different piping systems and their foundations standard colour code shall beadopted.

3.18 AUXILIARY SUPPLY

TENDER DOCUMENT SECTION VI VI.13

-

7/30/2019 Section 6 Technical Specification & Drawings

14/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

The various auxiliaries and controls shall be suitable for 415 / 240 V AC and 110 V DC respectively.

3.19 PUMPS & MOTORS

3.19.1 Unless otherwise specified all pumps and motors shall be such that their type, capacity andperformance shall be best suited to the requirements. The efficiencies shall be as high as practicableand consistent with good design. As far as possible the pumps shall be of a standard size to facilitatereplacement of parts. The pumps shall be of the primary type, if, however, any external means ofpriming are employed, these shall be stated in tender and shall be subject to the approval of theEmployer.

3.19.2 All pumps and motors shall be designed and constructed to ensure quiet and satisfactory operation.Suitable gaskets shall be provided for all pipe joints to ensure that the pipe joints are leak proof. Ifany strainers are required with the pumps, these shall be included in the tender.

3.19.3 The impeller material of all pumps shall be bronze material. All pumps shall be completed with thenecessary piping, both on the suction and delivery sides, and with all fittings, suited to the size and

duty of the pump. Adequate number of valves shall be furnished with each pumping unit so suit itsoperation and maintenance. Wherever necessary pumps shall be provided with suitable flow metersor flow indicators and pressure gauges and pressure switches to measure the discharge and thepressure delivered by the pumps. Suitable eye-bolts or lifting lugs shall be provided on each pumpingset to facilitate handling.

3.20 ELECTRIC MOTORS & MOTOR CONTROL GEARS

3.20.1 The motor shall generally conform to the Indian standards specification. Indoor motors shall conformto IP 54 and outdoor to IP 55. The class of insulation shall be entirely suitable for operation in thetropical, high humidity climatic conditions prevailing at site.

3.20.2 The capacity, speed and torque characteristics of the motors shall be suitable for the starting and

operating requirements of the associated apparatus like start and stop by means of DG set supply etc.

3.21 MEASURING INSTRUMENTS

3.21.1 All instruments and motors shall be suitable for operation under the tropical climatic conditionsprevailing at site. The instrument cases shall be dust proof and specifically constructed to adequatelyprotect the instruments against damage or deterioration due to high ambient temperatures andhumidity; special care should be taken in the protection of instruments for outdoor service. The dials,pointers etc. shall be designed to facilitate accurate reading, by minimizing parallax and glare frominstrument window, and by providing clear, bold dial markings. The sizes of dial and length of thescales of indicating instruments shall be large enough to suit the requirement and shall be subject tothe approval of the Employer, in each case. The scale plates of panel mounted indicating instrumentsshall have a permanent white matty finish with black graduations. The pointers or the pointerindicating contact setting (in-contact working instruments) shall be distinguished from the main pointerby a distinct colour and / or shape.

3.21.2 Instruments mounted on panels shall be of the semi-flush type, and shall be back connected. Allinstruments on a switchboard or instrument panel shall be of matching pattern, shape and finish so asto present a pleasing appearance consistent with the functional requirement. The furnish of theinstrument case shall be subject to the approval of the Employer. All instruments shall be designedfor accurate operations and any errors due to change in the ambient temperature, over the entirerange of temperatures obtainable.

3.21.3 Metric units shall be used for marking the instrument dials. The range shall generally be such that thenormal operating values are indicated in the middle third of the scale.

TENDER DOCUMENT SECTION VI VI.14

-

7/30/2019 Section 6 Technical Specification & Drawings

15/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

3.21.4 All electrical instrument coils shall be designed for continuous operation on at least 120 % (Onehundred & twenty percent) of the full rated current and for potential of the instruments. Theinstrument coil ratings shall be coordinated with those of associated instrument transformers.

3.21.5 The VA burden of instrument coil shall be as low as possible, consistent with the best modern design.

3.21.6 Electrical indicating instruments shall comply generally with the requirements off the Indian Standardor any other equivalent standard and shall be of the accuracy specified in relevant sections with alldigital annunciations.

3.21.7 Recording instruments shall be of the strip chart type with chart scales having suitable width. Thecharts shall be gear-driven by a self starting synchronous motor would spring device having ampletorque even at a reduced voltage and with at least 8 (eight) hours spearing reserve. The device forproducing the record on the chart shall be reliable ink-recording or printing type, and shall produceclear legible record under all normal conditions of operation. Sufficient number of chart rolls,recording ink and any special tools, required for the maintenance of the instruments shall be furnishedwith each recorder.

3.21.8 Integrating watt-hour meters shall comply generally with the requirements of the "Indian Standards"Electricity Meters, and shall be first grade class 0.2 accuracy.

3.21.9 Contact making instruments have contacts suitable for 240 volts, A.C., 50 Hz and 110 volts D.C.circuits.

3.21.10 All instruments shall have as high accuracy as possible, consistent with best modern design. Theconstruction of instruments shall be mechanically sound and shall ensure permanence in theaccuracy. The limits of error for different instruments shall be stated in the tender and their accuracyclassifications, where otherwise not specified shall be subject to the approval of the Employer. Allinstruments shall be test in accordance with the requirements of the standards, where specified. Incases where no specific standards are mentioned, the Supplier shall submit the standards inaccordance with which the instruments are proposed to be manufactured and tested and these shallbe subject to the approval of the Employer, in every case.

3.22 WIRING

3.22.1 All electric wiring of the various equipment panels etc. shall be completed at the manufacturer's worksas far as possible. All small wiring shall be arranged neatly into flat or rectangular groups and shall beadequately supported with cleats etc. The small wiring shall be so arranged as to reduce the numberof bonds or crossings to a minimum. There shall be no splices in the wire, and all connections shallbe made at the terminal studs, or terminal blocks. Similar circuits shall be arranged to terminate, asfar as possible, on adjacent terminals to facilitate grouping and to minimize the number ofinterconnecting cables. The secondary or control wiring including leads from the current transformer,temperature detectors alarm contacts, speed and pressure switches etc. shall be enclosed in conduitsand shall be carried to dust and water proof and oil tight cabinets located conveniently for connectingthe control cables. Pressure circuits shall not cause the progressive failure of adjacent circuits.

Alternating current circuits, direct current circuits, and circuits operating at different voltages shall begrouped separately and the wiring for each of these groups shall preferably be segregated.

3.22.2 For the purpose of easy identification, tracing and reconnection, the wiring shall be colour coded andshall be fitted near the terminals with ferrules or such other gaps indelibly marked with theidentification number corresponding with that of the associated terminal blocks. When an electricalcircuit is extended to several pieces of equipment necessitating sectionalizing of circuit wiring at theterminal blocks of the corresponding equipment, common identification number shall be used for thedesignation of the circuits at all the terminal blocks and connections. The terminal and circuitdesignation for all wiring shall be subject to the approval of the Employer.

TENDER DOCUMENT SECTION VI VI.15

-

7/30/2019 Section 6 Technical Specification & Drawings

16/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

3.22.3 All wiring shall be arranged to terminate on suitable terminal blocks located preferably at the base ofthe equipment. Terminal block shall preferably be made of suitable mould plastic materials with baseand integral barriers and shall be provided with suitable terminal strips.

3.22.4 Terminal block shall have detachable section in case of removable equipment to separate the conduitand wiring from the equipment wiring for ease of assembly / disassembly. Adequate number of extraterminals should be provided on each block for terminating spare conductor in the inter-connectingcables and for future use. Terminal block compartments shall be separated from the equipment by oiland vapour proof barriers and seals where necessary. The seals shall be arranged to facilitateremoval or changing of any individual wire without interference with other wires terminating on theblocks.

3.22.5 All wiring shall have oil vapour proof insulation. All small wiring shall be done with single core cablecomplying with latest edition of Indian Standard or with Poly Vinyl Chloride (PVC) insulated cablescomplying with Indian Standard or with any other type of cables approved by the Employer. Standardconductors shall be tin or alloy coated, and the conductor sizes used with the different circuits in theswitch board and all other wiring shall have 600 volt class insulation and shall withstand all applicable

tests specified in their relevant Indian Standard.

3.23 GALVANIZING

3.23.1 All galvanizing shall be done after fabrication by the hot dip method. Threads of nuts and bolts shallbe so made that, after galvanizing the nuts will have a neat fit, and can be turned through the length ofthe threads of the bolts and shall be capable of developing the full strength of the bolts.

3.23.2 All galvanizing materials shall satisfactorily withstand the tests of the latest edition of specificationnumber: IS - 728 - 1956 and IS - 429 - 1950 or equivalent. If it is proposed to apply tests inaccordance with any other standard, the same may be clearly described in the tender, bringing out thedifference if any, from the IS specification.

3.24 COMMUNICATION SYSTEM

Powerhouse and HPSEB substation to which power is proposed to be fed shall be equipped with two-way wireless system for communication. The range of the individual equipment shall be at leasttwenty (20) kilometer radius. The Contractor shall provide 4 sets of equipments one to be kept withIntake, the second to be kept in Powerhouse, third to be kept in HPSEB sub-station and fourth to betreated as spare. Wireless communication system shall be capable of connecting 6 locations andupgradeable to multiple locations in future.

Each wireless set shall operate on a pre-determined frequency. The concerned governmentauthorities shall approve this frequency. Obtaining the approval of the frequency shall be inContractors scope.

3.25 TROPICAL / SPECIAL TREATMENT

3.25.1 Under the climatic conditions prevalent at the site, the equipment furnished under these specificationswill be subject to operation under ambient outdoor temperatures as much high as 30 - 35 degreesCelsius and as low as 0 degrees Celsius and very high relative humidity. All equipment shall,therefore, be suitably designed and treated for normal life and satisfactory operation under the tropicaland humid climatic conditions prevalent at the site, and shall be dust and vermin proof.

3.25.2 All parts and surfaces which are subject to corrosion, shall be made of such material, and shall beprovided with such protective finishes as would protect the equipment installed from any injuriouseffects of excessive humidity. All electrical auxiliary equipment shall be specially treated for tropicalconditions, and the materials and methods for this treatment shall be approved in advance by theEmployer.

TENDER DOCUMENT SECTION VI VI.16

-

7/30/2019 Section 6 Technical Specification & Drawings

17/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

3.26 MARKING OF PARTS

In order to facilitate identification at destination the several parts of the plant and equipment / Facilitiesshall be suitably marked and the scheme of marking notified to the Employer.

3.27 FOUNDATION AND FIXTURES

Foundation will be prepared by the Employer in accordance with the basic design data to be suppliedby the Contractor. All fixtures necessary for proper erection of embedded parts shall be supplied bythe Contractor.

3.28 STORAGE AT SITE

Complete instructions regarding storage of the equipment at site shall be furnished by the supplier /

contractor.

3.29 ENGINEERING DATA

All the engineering data and information required by the Employer shall be furnished by theContractor. The review of these data by the Employers Engineer will cover only the generalconformity of the data to the specifications and documents, interfaces with the equipment providedunder specifications external connections and of the dimensions which might affect plant layout. Thereview by the Employers Engineer may not indicate a thorough review of the dimensions, quantitiesand details of the equipment, materials, any devices or items indicated or the accuracy of theinformation submitted. This review and or approval by the Employers Engineer shall not beconstrued by the contractor as limiting any of his responsibilities and liabilities for mistakes and

deviations from the requirement so specified under those specifications and documents. Metric unitsand measures according to the latest editions of the relevant International Standards Organizationpublications shall be used for the contract and for the purpose of submission of design calculations tothe Employer.

3.30 LIMIT CONTRACT

Equipment furnished shall be complete with all mountings fittings, fixtures and standard accessoriesnormally provided with such equipment as required by applicable codes though they may not havebeen specifically detailed in respective specifications (unless included in the list of exclusions). Allsimilar standard components / parts of similar standard equipment provided shall be interchangeable

with one another.

TENDER DOCUMENT SECTION VI VI.17

-

7/30/2019 Section 6 Technical Specification & Drawings

18/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

SECTION-VI: TECHNICAL SPECIFICATIONS

SUB SECTION 4: SPECIFICATION FOR FRANCIS TURBINE AND AUXILIARIES

4.0 GENERAL

The site is located in the State of Himachal Pradesh and is along the alignment of Baner Khad.

The site is on the Left Bank and can be approached from nearest Railhead Pathankot (123 km).

The Bidder is expected to co-operate fully with other parties, involved in commissioning and executingworks on site. Any dissents do not entitle for any additional claim.

The scope of contract includes all supplies for Francis turbines and auxiliaries as well as completemounting ready to operate so that no performance of a third party is needed.

The Bidder must inspect and check all relevant details of the site and is expected to introduce all

necessary steps in time. All parts can be delivered directly on site. All workshop-manufactured partsshould be coated and be treated as per coating requirements and be equipped with transport lugs forease of mounting and handling. All lugs shall be retained to allow the future removal / installation ofturbines and auxiliaries.

The relevant codes have to be respected as well as ranked as given below:

Technical details of tender Docs and Specifications

Order form including all relevant supplements

Indian Standards, and with priority, relevant German Standards of DIN

All details requested by governmental bodies within approval documentation

Security codes for onsite manufacturing

IEC codes

Legal and governmental relevant rules

4.1 SCOPE

This section of the specification deals with / covers the design, material selection, manufacture,assembly, intermediate storage, test at manufacturers works before despatch, packing and forwardingfor shipment, supply, delivery at site (final destination), receipt and storage at site, services forperforming on-site assembly, erection, testing at site and commissioning in a complete shape of2 (TWO) NOS. HORIZONTAL FRANCIS TYPE HYDRAULIC TURBINES and associated auxiliaryand ancillary equipments including governing equipment, main inlet valve, equipment for auxiliary

systems such as compressed air, cooling water, centralized grease lubricating system, oil, water andair piping and cabling connected ready to operate with valves and fittings, instrumentation, control andsafety devices (as required) and speed increasing gearbox (if required), spares for five (5) yeartrouble free operation of the plant, special tools etc. as described and detailed in the TechnicalSpecifications (Section-VI) and listed in the Schedule of Requirements (Section-VIB) and asconsidered necessary by the Bidder.

The scope of supply shall also include all parts, accessories, spares etc. which are essential forassembly, erection, construction, trial operation, trial run, test run, commissioning, testing andmaintenance of the complete prime mover / unit even through these are not individually or specificallystated or enumerated. The corresponding components of both the turbines and associated

TENDER DOCUMENT SECTION VI VI.18

-

7/30/2019 Section 6 Technical Specification & Drawings

19/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

equipments and spares shall be of the same material, dimensions and finish and shall beinterchangeable.

The Supplier shall match the generator & speed-increasing gearbox which is to be coupled with theturbine in respect of speed, runaway speed, moment of inertia, overload capacities, coupling andother relevant requirements.

The turbine manufacturer shall co-ordinate with the generator supplier so that the generator coupledto the turbine is matched in respect of speed, runaway speed, moment of inertia, over load capacities,coupling and other relevant requirements.

The offer shall include also one set of spares as indicated elsewhere under this specification(Schedule 13) corresponding to components of the turbine and associated equipment and sparesshall be of the same material, dimensions and finish and shall be interchangeable.

The turbine and gearbox shall be so designed and manufactured to match preferably with the normalspeed, runaway speed, moment of inertia, overload capacities and other relevant requirement of thegenerators.

4.2 TYPE AND RATING

4.2.1 Each turbine shall be of axial flow horizontal Francis wheel type and horizontal shaft suitable forcoupling to the synchronous generator through a speed increaser (if required). Each turbine shall bedesigned to deliver higher output than rated output to match the overload capacity of the generator.The rated output is 2500 kW at the terminals of synchronous generator at net rated head of 42.50 mand at rated discharge of 14.11 cumecs with optimum guide vane opening. Each turbine should be

capable of continuously delivering a maximum output of 3000 kW at rated head of 42.50 m and amaximum discharge of about 15.52 cumecs. The specific speed of the turbine shall be as per thebest modern practice and of proven design and operation. The speed and setting of the turbine andits design shall be such as to result in the installation of the best generating unit.

4.2.2 The turbine shall be such that it takes care of water hammer effect in case of sudden load rejection.The guide vane actuated by governor, shall be closed to stop flow of water through turbine, penstockgate at all forebay shall be closed first and turbine main inlet valve shall be closed only when penstockis totally empty.

4.3 HYDRAULIC SYSTEM AND BASIC DATA

The details of the hydraulic system and basic data for design of turbine are given below:

i) MAXIMUM FULL RESERVOIR / SUPPLY LEVEL (FRL /

FSL)

- EL 559.39 m

ii) MINIMUM DRAW DOWN LEVEL - EL 554 m

iii) GROSS HEAD (STATIC) - 44.39 m

iv) NET HEAD - 42.50 m

TENDER DOCUMENT SECTION VI VI.19

-

7/30/2019 Section 6 Technical Specification & Drawings

20/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

v) RATED HEAD - 42.50 m

vi) ELEVATION OF TURBINE RUNNER CENTER LINE - EL 515.00 m

vii) DIAMETER OF PENSTOCK (INTERNAL)

a) UPTO BIFURCATION FROM FOREBAY - 2700 mm

b) BEYOND BIFURCATION TOWARDS DISTRIBUTOR - 1900 mm

(each)

viii) LENGTH OF PENSTOCK

TOTAL LENGTH OF PENSTOCK - 100 m

a) UPTO BIFURCATION FROM FOREBAY - 100 m

b) BEYOND BIFURCATION TOWARDS DISTRIBUTOR - 20 m (each)

ix) HIGH FLOOD LEVEL (HFL) AT P.H. SITE - EL 517 mx) DESIGN DISCHARGE (TOTAL FOR 2 MACHINES)

INCLUDING i/c flushing

- 14.11 cumecs

xi) LENGTH OF TRC (FROM C/L OF UNITS) - 50.0 m

xii) PERMISSIBLE PRESSURE RISE IN PENSTOCK - 30 %

NOTE:

i) The turbine shall be capable of operating at rated head limit mentioned above.

ii) The minimum tail water level is to be arrived based on rated discharge of turbine for running machine

at no load.iii) The bidder shall state the maximum and minimum head limits under which the turbine can be

operated safely and the maximum and minimum discharge the machine can handle safely.

4.3.1 Power Plant Parameters

The Pelton turbines will be designed considering the following parameters:

Turbine type Horizontal shaftFrancis turbines

Number of units 2

Number of Guide Vanes To be indicated by thebidder

Maximum intake level (=FRL) EL 559.39 m

Minimum intake level (=MDDL) EL556.89 m

Maximum tail race water level (TWL) EL 515 m

Net head (2 units running at 100% load)42.50 m

TENDER DOCUMENT SECTION VI VI.20

-

7/30/2019 Section 6 Technical Specification & Drawings

21/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

Rated Output at Net Head = 42.50 m & RatedDischarge of each unit = 7.055 cumecs

2500 kW

Rotational Speed of the Unit500 rpm

Rated head for maximum output42.50 m

Rated Discharge for each machine for maximumoutput

7.055 cumecs

Runner center line elevation EL 515.00 m

Shaft coupling face elevation EL To be provided by themanufacturer

Direction of rotation To be indicated by themanufacturer

4.4 OUTPUT AND EFFICIENCY GUARANTEES

The efficiencies of the turbine, gearbox and generator unit shall be as high as possible. The efficiencyat rated head of 42.50 m for 120 %, 100%, 80%, 60% and 40% of Turbine - Gearbox - Generator unitshall be guaranteed. These figures shall be applicable for the purpose of penalties and rejection limitsas detailed in clause 4.4 to 4.6 of this section.

4.5 WEIGHTED AVERAGE EFFICIENCY

The Weighted Average Efficiency of the prototype Turbine - Gearbox unit shall be determined from thefield test values of efficiency at the rated head in accordance with the following formula for the purposeof penalty and rejection limits. The field tests on the turbine shall be carried out by the supplier asspecified in IEC or equivalent International Code or mutually agreed method. The field test on theGearbox and Generator will also be carried out as per appropriate IEC or equivalent International Codeor on mutually agreed method.

TEav = K1*E120 % +K2*E100% +K3*E80%+ K4*E60% %+ K5*E40%

Where TEav is the weighted average efficiency of the Turbine-Gearbox-Generator

TE120% =TN120 %

TB120 %TG120 % = Efficiency of the Turbine-Gearbox-Generator at 120 %of

Rated Output at Rated Head

TE100% =TN100%

TB100%TG100% = Efficiency of the Turbine-Gearbox-Generator at 100%of

Rated Output at Rated Head

TE80% =TN80%

TB80%TG80% = Efficiency of the Turbine-Gearbox-Generator at 80% of

Rated Output at Rated Head

TE60% =TN60%

TB60%TG60% = Efficiency of the Turbine-Gearbox-Generator at 60% of

Rated Output at Rated Head

TENDER DOCUMENT SECTION VI VI.21

-

7/30/2019 Section 6 Technical Specification & Drawings

22/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

TE40% =TN40%

TB40%TG40% = Efficiency of the Turbine-Gearbox-Generator at 40% of

Rated Output at Rated Head

The values of K1, K2, K3, K4 & K5 are dependent on operating conditions i.e., the percent of time themachine is running in that condition with that efficiency.

Weighted Average Efficiency: Values of K1, K2, K3, K4 & K5 for Francis Turbines:

K1 = 0.20 K2 = 0.25 K3 = 0.20 K4 = 0.20 K5 = 0.15

The weighted average efficiency of the turbine at rated head for 120 percent, 100 percent, 80 percent,60 percent and 40 percent at rated output shall also be guaranteed. These figures shall be applicablefor purpose of penalties, rejection limits and bid evaluation. In addition the outputs as per dischargeconditions used for calculation of generation shall also be guaranteed. Guarantee is fulfilled only if it is

in accordance to the IEC code 41, edition 1992 at given discharges.

4.6 PENALTIES

4.6.1 Penalty for shortfall in efficiency and rated output

For any shortfall in the tested values of rated output and average efficiency, penalty shall be applied @Rs. Six (6.0) lakh for each Kilowatt (kW) below the guaranteed output and @ Rs. Thirty (30.0) lakhs forevery half percent (0.5%) drop in efficiency below the guaranteed efficiency. The penalties for outputand efficiency shall be computed separately and the total amount of penalty shall be the sum of thesetwo with no upper limits. No tolerance shall be permissible over the test figures of rated output. In caseof efficiency, tolerance will be allowed as per appropriate International Standard IEC codes. Theefficiency for the purpose shall be measured according to the IEC code 41, edition 1992.

4.7 REJECTION LIMIT

The Employer reserves the right to reject the turbine-gearbox-generator unit if the test values of eitherweighted Average Efficiency as determined by Clause 4.4 or the rated or maximum output is less thanthe corresponding guaranteed values by 2 % (two percent) or more after allowing tolerance incomputation of efficiency.

4.8 RECTIFICATION TO MEET GUARANTEES

i) In case the specified tests prove unsuccessful in meeting the guaranteed values, theContractor will be given mutually agreed reasonable period to improve or modify or rectify

Turbine / Gearbox / Generator as may be required to meet the stated / standard guaranteedfigures without extra cost to Employer.

ii) If such attempts to improve or modify or rectify fails, taking remedial action by the Employer atContractor's risk & expenses without prejudice to other terms and conditions of contract orimposing of penalty or rejection of the equipment as the case may be, shall be applied

4.9 SPEED RISE & SPEED REGULATION

Essentially, the data on speed rise and speed drop etc., should be stated in the tender. The regulationshall be obtained from the unit operating along, independent of the effects of the rest of the system.The moment of inertia of the unit shall be so adjusted such that the maximum momentary speed rise ofthe unit shall be kept much below the runaway speed.

TENDER DOCUMENT SECTION VI VI.22

-

7/30/2019 Section 6 Technical Specification & Drawings

23/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

However the momentary speed rise shall not exceed 50% of the rated speed and pressure in thepenstock shall not exceed 35% of the maximum net head under any conditions of operation (ifapplicable).

Under exceptional circumstances, speed rise may go up to the maximum permissible limit as perinternationally accepted design practices, which in any case should not exceed the limits, set in USBR.The turbine manufacturer shall co-ordinate with the generator manufacturer for limiting the speed andpressure rise values.

4.10 RUNAWAY SPEED

The maximum runaway speed of the unit under any combination of head and load conditions shall bestated in the tender. The runaway speed may be as lowest as possible. Turbine, Gearbox andGenerator parts shall be so designed and coordinated to withstand maximum runaway speed withoutany damage to its parts for 15 minutes duration continuously for every occurrence with cooling watersupply on. The maximum runaway speed for on cam / off cam under any conditions off head / load

conditions shall be stated in the bid. The turbines shall be capable of running safely at the maximumrunaway speed without damage to its parts for not less than fifteen minutes continuously for everyoccurrence with cooling water supply on. The calculated first critical speed shall be at least 20% abovethe maximum runaway speed.

4.11 CAVITATION GUARANTEES

The Tenderer / Bidder shall guarantee the runner, nozzle spear and other hydraulic passage againstexcessive pitting caused by cavitation and erosion for 18 months from the date of commissioning or8000 hours of actual operation which ever is earlier.

Excessive pitting shall be defined as the removal of metal from the runner and other hydraulicpassages of a weight of:

W = 0.15 D2 per 1000 hours of operation

Where D = Discharge diameter of the runner in meter and

W = Weight in kg.

If the 18 months of guarantee period expires before completion of 8,000 hours of operation, theguarantee shall apply to the actual hours of operation.

In case of cavitation pitting exceeding the guarantee, the turbine Contractor shall at his cost takecorrective measures such as modification of design, finish, replacement, repair etc. and the turbineafter statement of fulfilled modification etc. shall be subject to cavitation guarantee as for the originalequipment. In addition, the Contractor shall also be liable to bear the revenue cost lost due to loss ofgeneration.

4.12 CRITICAL AND PLANT SIGMA

Values of critical sigma as determined from cavitation model tests as per IEC 173A shall be given bythe Bidder in the form of curves for different heads of operation. Plant sigma curves as recommendedby the Bidder shall also be plotted on it clearly to show the safety margin available. The Bidder shalldetermine and indicate the limiting levels for installation of the equipment in his offer.

TENDER DOCUMENT SECTION VI VI.23

-

7/30/2019 Section 6 Technical Specification & Drawings

24/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

4.13 NOISE LEVEL

Maximum noise level from any of the operating conditions shall not exceed 90 db (A) at any place1.0 m away from any operating equipment detected in the machine hall. Any vibration caused by themachine should not be in resonance with any part of the equipment delivered.

4.14 STRESSES AND FACTOR OF SAFETY AND GUARANTEE

All parts of turbine shall be designed and constructed to safely withstand the maximum stresses duringnormal running, speed rise, and runaway speed and short circuit conditions, out of phasesynchronizing and brake or grid fail application. The maximum unit stresses of the rotating parts shallnot exceed 2/3rd (two-thirds) of yield point stress of the material. For other parts the factor of safetybased on yield point stress shall not be less than 3 (three) at normal conditions.

For over-load and short circuit conditions, a factor of safety of 1.5 on yield point stress shall bepermitted.

4.15 BID EVALUATION

In the comparison of the tenders, the equalization on account of difference in the efficiencies of variousoffers will be made on the basis indicated in this Tender Document.

The basis for selection of the offers shall be the overall economy to the Employer. The speed andsetting of the turbine and its design shall be such as to result in the installation of the best generatingunit at the reasonable cost and least still stand. The life cycle period for major parts e.g. bearings,runner, speed increaser, syphon valve etc. shall be indicated and guaranteed by the Bidder.

4.15.1 MODEL TEST

The manufacture of any part of a prototype turbine shall be started only after the efficiency and otherguarantees and requirement of the turbine are established and fulfilled on the basis of model tests. Incase the Contractor has already performed model tests on homologous models and the Employer canbe satisfied that the tests were witnessed by independent experts, the Employer may at his discretion,permit the Contractor to proceed with the manufacture after approval by the Employer of the model testreport. The shell diagram provided by the Contractor can be based on model test results but will notreplace the onsite guarantee measurement procedure according to IEC. Any model test provided byBidder must fulfill the International Standards as given below:

4.15.2 The Employer shall have the option to get the model test performed by the manufacturer of turbine inthe presence of the Employer's representative before commencement of manufacturer of prototypeturbine at an extra cost (optional item) including charges for two members of the Employer to witnessthe model test. In that event manufacturer of any part of the prototype turbine shall be stated only after

the efficiencies and other guarantees and requirement of the turbine are established and fulfilled on thebasis of model tests

4.15.3 In case the manufacturer has already performed model test on homologous model the manufacturersshall supply results of the model test establishing the efficiency and other guarantees in conformity withthe date furnished with Bid and take approval of Employer within 15 days (Fifteen days) after award ofcontract. Along with the model test results, the tenderer is required to furnish the calculations forarriving at important parameters of the turbine like, (a) Guide vane opening & closing time (b) efficiencyat 120 %, 100%, 80% and 60% load and comparison of the same with guaranteed values (c) rateddischarge and maximum discharge (d) rated speed (e) specific speed (f) runner diameter (g) turbinesetting (h) speed rise (I) pressure rise (j) runaway speed (k) flywheel effect (l) water velocities atturbine inlet & exit.

The performance characteristic curves of the turbine shall also be enclosed with the above calculation.

TENDER DOCUMENT SECTION VI VI.24

-

7/30/2019 Section 6 Technical Specification & Drawings

25/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

4.16.3 The Employer will, at his discretion, approve the model test results and permit the supplier tocommence the manufacture of prototype turbine. The approval of model test results by the Employerwill not absolve the responsibility of the supplier for the satisfactory performance of the prototypeturbine.

4.16.4 The performance of the model tests either afresh or that had been done earlier shall be as per IEC 193and 193 A in all respects. Hydraulic performance tests shall be made with various Guide vaneopenings to determine the machine characteristics including regimes of safe vibration particularly atless Guide vane opening shall be specially investigated. These tests shall include the determination ofcapacity, hydraulic thrust, runaway speed, Guide vane opening outlet relationship and such otherdetails covered in IEC 193 and 193 A. Prototype efficiencies shall be derived from model tests by thestep up formula as applicable for the type of turbine contained in IEC 193. Model tests shall simulateall possible normal operating conditions of the prototype for entire range of heads and loads.

4.16.5 The Bidder shall clearly mention the time within which any model tests including manufacture of a newmodel, if required, will be complete. The delivery schedule given by the Bidder shall be reckoned fromthe date of approval of model tests or model test report or from the time of permission to proceed with

the prototype manufacture. If the model test is already available, this shall be submitted within 2Weeks after the date of issuance of notification of award. All relevant information relating to theperformance of such tests shall be provided along with the Report. Model test results will in any casebe replaced by prototype test procedure, which only shall be valid for performance guarantees.

4.17 GENERAL ARRANGEMENT AND CONSTRUCTION

The arrangement and construction of turbines shall be such that any removable part can beconveniently and easily dismantled & removed. The design shall also permits horizontal movement ofrunner shaft sufficient for adjustment of bearings and for cleaning the joints at the couplings of theturbines, speed increaser and generators. The arrangement of all the equipment should be easilyaccessible for operation and clearances, walkways etc. should be provided.

TURBINE CONSTRUCTION FEATURES

Each horizontal axis Francis turbine will consist of the following principal parts:

TURBINE RUNNER

TURBINE SHAFT

TURBINE GUIDE BEARING

SPIRAL CASING

DRAFT TUBE

GUIDE VANE AND OPERATING MACHENISM

SERVO MOTORS

STAY RING, FRONT COVER AND REAR COVER

INSTRUMENTS, GAUGES AND TRANSDUCERS

TENDER DOCUMENT SECTION VI VI.25

-

7/30/2019 Section 6 Technical Specification & Drawings

26/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

4.17.1 RUNNER AND REGULATION SYSTEM

TURBINE RUNNERa) General

The runner shall be made of cast stainless steel having a material composition of 13% chromium and4% nickel. The contractor shall assure that a higher degree of quality finish and control is maintainedduring the manufacture of the runner, including bar test specimens, non-destructive flow detectinginspection, stress relieving of the casting and balancing. All surfaces of the runner shall be finishedsmooth without any humps or hollows, depressions, cracks and projections. The crown sealingsurface shall be furnished to suit the stationary head cover and bottom ring.The contour of the runner blades shall be accurate and shall be finished it required so that the bladeprofile precisely conforms to the model design within the tolerance set out in IEC Publication-60193-1999. The blade shall be evenly and symmetrically spaces. Before shipment/despatch, manufacturershall check the hydraulic surfaces with templates and submit proof that the finished runner contoursand shape meet with the tested model and the design requirement. Templates for guidance inrestoring blade shapes to original contour shall be supplied with turbine.

b) Design

The runner shall be designed to safety withstand the stresses due to operation at runaway speedunder condition of maximum head with no load on generator and any position of the wicket gates.Special attention shall be paid to reduce stress concentration at the filet of the blade outlet edge withthe band and crown

c) Machining

The runner has to be of modern design and will meet the relevant IEC Standards. The hydraulicsurfaces of the runner blade shall be carefully machined and smoothly finished to the required shapewith programmable NC boring mills.

The disc be machined and bored to center a male projection at the end of the main shaft and to fittightly to the coupling flange, thus ensuring proper centering and alignment of the runner.

d) Balancing

The runner shall be statically balanced at the works and shall be designed and constructed towithstand safely the stresses developed due to operation at the runaway speed under conditions ofmaximum head including pressure rise due to water hammer.

e) Shaft Connection

The method of attaching the runner to the turbine and intermediate shafts need to permit convenient

and quick removal of the runner. The coupling should be of the friction type with prestressed couplingbolts, which will permit ready interchange of runners without drilling for adjustment, the coupling holesof the bolts on site. The coupling bolts and nuts to be protected from the operating water. Furtherinformation, e.g. reference list for turbines, for which the friction coupling is used.

f) Sealing Box

Sealing Box comprising of labyrinth type seal with white metal lining. Suitable arrangement fordrainage of leakage water shall be provided.

TENDER DOCUMENT SECTION VI VI.26

-

7/30/2019 Section 6 Technical Specification & Drawings

27/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

4.17.2 MAIN INLET VALVE

The main inlet valve shall be butterfly valve pressure type of suitable diameter placed at end of thepenstock pipeline within the Powerhouse. The valve shall be capable for all operating conditions oftransient & maximum water hammer. The valve shall be operated manually / by oil pressure throughservomotor and may have counter weight in system. The valve shall close automatically undernormal and emergency shutdown conditions. The valve shall be complete with inlet pipe, outlet pipewith dismantling joints, by pass arrangements required for equalization of pressure on either sideof the valve. The inlet valve shall be designed to open under balanced conditions and to closeagainst full discharge in emergency. The valve shall be fully assembled and tested in the works. Thevalve shall be capable of operation against two (2) times the full gross head of 44.39 m of water pluswater hammer.

4.17.3 SHAFT & COUPLING

TURBINE SHAFT

a) General

The turbine shaft has to include the main shaft section from the interface of the turbine runnerapproximately on level given to the interface of the generator motor shaft-coupling flange on level tobe determined in final offer-stage.

b) Design

The turbine shaft shall be designed for the maximum output of the turbine and to operate at full gateoutput without exceeding normal design stress. The bidder shall provide stress calculation on shaft toowner to review. In addition the shaft will be designed to operate without detrimental vibration or

distortion at any speed up to the maximum runaway speed including reverse runaway speed.

c) Critical Speed

Electrical/Mechanical Contractor will be responsible in case of an order for the shaft critical speed forthe combined generator / turbine unit. First critically speed shall be atleast 25% above the maximumrunaway speed.

d) Shaft Details

The shafts have a hole to be bored at the center throughout the length to permit usual inspection ofthe metal in the interior of the shaft.

The runner provided to be replaced, if necessary, by a hydraulic servomotor cylinder operated by oil,inserted in the shaft hole, which allows to bring the runner from the service platform to the shaftcoupling.

e) Shaft Length

The turbine shaft should be of the proper length to connect with the generator shaft at an elevation tofit the shaft length furnished by the generator manufacturer. The elevation has to allow dismantling ofthe coupling bolts in an easy manner. As the final design of the powerhouse makes it desirable ornecessary to change the distance from the centerline of the turbine runner to the generator floorelevation the price to be adjusted for resultant changes in shaft length in accordance with theadjustment prices to be stated in the price schedules.

TENDER DOCUMENT SECTION VI VI.27

-

7/30/2019 Section 6 Technical Specification & Drawings

28/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

f) Lifting Clearance

Vertical clearances to be provided in the turbine to a height as required for dismantling of thegenerator thrust bearing. Contractor will cooperate with the generator manufacturer in determining theclearance required.

g) Shaft Coupling

The coupling of the shaft shall be of friction type design. As regards to the turbine shaft manufacturerwill make the necessary arrangement with the generator manufacturer to provide a proper couplingand accurate fit.

- All coupling bolts have to be equal in size- Contractor will supply all coupling bolts and nuts- The coupling bolts will be made of steel suitable for prestressing

- Manufacturer will provide the necessary tools for prestressing the coupling bolts and will supply all

tools required for field assembly.- The shaft flanges to be equipped with backing out type jacking bolts to aid dismantling of theshafts.

h) Material

The shafts shall be made of forged carbon steel and shall be heat-treated. The shaft provided to besubject to ultrasonic inspection in accordance with manufacturer provisions. Manufacturer will provideresults of the material and shop tests in writing.

i) Shaft Alignment

The alignment of the shaft will be tested by rotating the assembled shaft on site after erection. The

tolerances for shaft runout will be based on the NEMA Standard Publication No. MG.5.1 "VerticalHydraulic Turbine-Generator Shaft Runout Tolerances-Shop Check" paragraph 3.04 A.

Runout tolerances for fabrication of the turbine shaft, when individually checked, shall not exceed thefollowing values in mm:

S.No.

Particulars mm

1. Cylindrical surface of guide bearing journals 0.05

2. Male or female portion of coupling 0.025

3. Face of coupling (inside and outside of bolt circle) at generator end ofturbine shaft

0.020

4. Face of coupling at runner end of the turbine shaft 0.025

5. Outside cylindrical surface of coupling 0.050

j) Alignment of the Combined Turbine and Generator Shafts

(1) General - The shaft alignment of the assembled turbine and Generator shaft has to be performed onsite after the erection is completed. The Generator manufacturer will attend the tests.

(2) Delivery - Manufacturer will ship the shaft finished machined and with all coupling boltholes drilled tosize.

(3) Alignment Test - Alignment tests will be performed by manufacturer based on the NEMA Standard.

TENDER DOCUMENT SECTION VI VI.28

-

7/30/2019 Section 6 Technical Specification & Drawings

29/168

BANER SANGAM SHEP ( 5 MW ) TECHNICAL SPECIFICATIONS & DRAWINGS

DEVELOPER : M/S YOGINDERA POWERS LIMITED BID REFERENCE : BSHPPL-2010 / EPC-E&M / 001

Manufacturer will be responsible to obtain proper alignment. Both will arrange the necessarycorrection of the turbine and generator shafts if the alignment tests reveal defects.

The assembly of the shaft coupling connections between turbine and generator shaft will be theresponsibility of the turbine contractor only.

k) Types of Shaft

Each turbine shall have a power shaft and stub shaft.

(i) POWER SHAFT FOR TURBINE

The power shaft shall be provided with flanges on eight sides and entire shaft and flanges shall bemade out of a solid forging of carbon steel. A through hole is to be bored inside the power shaft to