Second Poster for EU CELLUWOOD Project

-

Upload

portillo63 -

Category

Documents

-

view

23 -

download

1

description

Transcript of Second Poster for EU CELLUWOOD Project

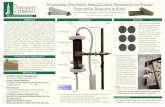

EU 'CELLUWOOD' PROJECTLAMINATED STRONG ECO-MATERIAL FORBUILDING CONSTRUCTION MADEOF CELLULOSE-STRENGTHENED WOODSThe CELLUWOOD project aims to develop a new range of structural elements madeof wood by introducing innovative production elements and includes the use of celluloseinstead of petroleum-based glue in the lamination of the timber products.The 'physical' results will be the strong eco-beams and columns and their most sustainablemanufacturing technologies, in addition to significant environmental and cost benefitsof the innovation. These are achieved through:

* The introduction of the (new) technologies from other sectors (e.g. cellulose velvet,bio-composite reinforcement and bio-resin) for innovative uses in the defect removaland repairing, and lamination of strong building materials.

* Facilitating innovation in the use of nano/micro cellulose and bio-resin technologiesin timber re-engineering.

* The development, testing and demonstration of the novel initiative products.

This new product and technology approach would bring significant reduction in thecarbon footprint of construction within the EU and, eventually, worldwide, as theproposed engineered timber became a viable and cost-effective substitute for conventionalstrong construction materials that are high CO2 emitters during manufacture. Theproposed technology will anticipate the massive reduce of the embodied energy inbuilding carcasses, create new opportunities for carbon capture and storage, minimisethermal bridging through insulation layers and improve the possibilities for low-impactrecycling of waste materials arising following a building's eventual demolition.

STRUCTURAL TIMBER BOARDING

Utilization of small diameter and underutilized European grown timber has beeninvestigated in detail. Processes and performance in use of small diameter wood onEuropean, national and regional levels from a practical and technical point of view havebeen described. The tree types under discussion for the project are sweet chestnut(Castanea sativa), Douglas fir (Pseudotsuga menziesii), European larch (Larix deciduaMill), spruce, Norway spruce (Picea abies), and Sitka spruce (Picea sitchensis). Additionally,preliminary processing for timber boarding is defined.

BIO- RESIN AND REINFORCEMENTS

Different adhesion systems for CELLUWOOD materials have been analyzed:* Systems of condensed tannin extracted from Quebracho Colorado (Schinopsis Lorentzii)

trees.* Systems of condensed tannin from pine trees.* Kraft Lignin from hardwood and softwood.* CNSL (Cashew nut shell liquid).These natural raw materials were tested for their ability to perform cold or hot curingprocesses. The various adhesion systems were firstly evaluated with the lap shear testingin accordance with relevant EN or ISO standards and then applied to the timber boardingmaterials used in this project.

CORE MATERIAL FOR ECO-BEAMS AND ECO-COLUMNS

The core material for Eco-beams and Eco-columns is made of natural fibres and gypsumfor the building application.Four parts of complicated work were carried out with the aim to develop a new lightweight in parallel with high mechanical performance of gypsum/natural fibre composite.By compared with three kinds of natural fibres, it was found that sawdust is the bestselection. Three chemical agents were used to modify sawdust by using spray coatingtechnology. Compared with the traditional immerse method, spray coating could improvethe modification significantly. Among these agents, Na2SiO3 displayed the highestimprovement on the final composite. The hemihydrate gypsum binder was modifiedwith systematic experiments which included the extender, retarder, water reducer, andreinforce material.

ALTERNATIVE BIO-ADHESIVES

Two kinds of nanocellulose reinforced wood adhesives have been fabricated: nanocellulosereinforced epoxy and nanocellulose reinforced casein. It has been found that bothadhesives can be used in the room temperature under a low pressure and display highperformance. By using the nanocellulose reinforced epoxy, the shear strength could beincreased by more than 40% when the addition of nanocellulose was 5%. It has beenfound that the addition of nanocellulose can improve the bonding performance. Howeverthe low water resistance and the shear strain of the natural polymers adhesive is stillunder investigation. The resins are applied to the defect repairing and lumber lamination.

DEVELOPMENT OF NEW BEAMS AND COLUMNS

The development of new beams and columns is based on modelling results. The repairedand scarf jointed lumber is to be used to develop a number of novel, low carbon,sustainable, viable, low cost beam and column products with good environmental profiles.

IMPACT ASSESSMENT AND LIFE CYCLE ANALYSIS (LCA)

Eco-efficiency describes how environmental friendly and economical a product or processis. Through determination of the total impact on the environment and all costs frommanufacture to disposal the complete value-added chain is covered. The eco-efficiencyaims to achieve a balance between environmental and economic factors. This means

to manufacture cost-effective products with the smallest possible amount of raw materialsand energy, and to minimize emissions.The analysis of the environmental term includes a life cycle assessment of the newmaterials developed in the project, versus the traditional glulam manufacturing process.This LCA is being developed currently.

CELLUWOOD beam production.

Nanocellulose CELLUWOOD core.

Miguel Angel Abian

Author: Miguel Ángel Abián