Sd Article 12

-

Upload

pritish-mohan -

Category

Documents

-

view

226 -

download

0

description

Transcript of Sd Article 12

-

Energy Conversion, Vol. 16. pp. 181-198. Pergamon Press, 1977. Printed in Great Britain

SOLAR POWER SYSTEMS

JESSE C. DENTON

Energy Associates, P.O. Box 355, Belton, TX 76513, U.S.A.

(Received 15 October 1976)

Abstract--A review of the principal solar power systems is presented. The nature of the solar energy source is discussed starting from the energy output of the sun and covering briefly the important atmospheric effects to characterize the available solar energy on the earth's surface. The various methods for capturing solar energy are presented: flat-plate, concentrating, photovoltaic, and other collectors. Energy storage methods are presented briefly for thermal, chemical, electrical, and mechanical storage approaches. An application of solar power systems in interaction with a conventional electrical utility system is presented in terms of mode of operation (base, intermediate, and peaking), reliability, capacity displacement, and energy displacement. An economic evaluation of selected solar power systems com- pared to conventional electrical generation plants is presented. Conclusions are drawn as to the condi- tions under which solar power systems may become economically competitive. A preliminary indication of market capture potential is discussed.

Solar power systems Solar energy source Flat-plate collectors Concentrating collectors Photovoltaic collectors Thermal energy storage Chemical energy storage Solar electric power Solar power econo- mics

INTRODUCTION

The sun is a gigantic thermonuclear reactor in the gravitational center of the solar system. The total solar radiation energy emission is 3.86 1033 ergs every sec, or a power level of 3.86 1023 kW. The mean distance from the sun to earth is taken equal to the semi-major axis of earth's orbit, which is 149.4 106 km. Thus the solar energy which would be intercepted by a planar surface oriented at right angles to the sun's rays outside the atmosphere of the earth is 1.36kW per m z. Working backwards from this latter number by applying the Stefan-Boltz- mann Law, one can determine that the effective tem- perature of the sun's surface is 5750 K. The solar spec- tral intensity curve, however, does not agree with that of a black body at 5750 K.

The total solar energy arriving in the vicinity of earth is truly immense, yet its intensity is quite small. Furthermore, the intensity may be severely attenuated by the passage of the radiation through the earth's atmosphere. The resulting low intensity of solar energy on the earth's surface means that relatively large areas of collector surface must be exposed to the sun to capture the solar energy. The collector sur- face represents a major element of the cost of solar energy systems.

Solar energy collectors do not operate continuously because of several factors such as cloud cover, strong winds, diurnal effects, etc. Furthermore, the output of solar energy collectors cannot be expected to match the demand schedule for energy that is required to meet the society's needs. Thus, energy storage systems are required to smooth the intermit- tent nature of the energy collection system and to match the energy supply to the instantaneous energy demand. The energy storage equipment represents a significant element of the cost of solar energy systems.

It is pointless to think in terms of an electric power system based entirely on solar power systems. It is, therefore, necessary to investigate the ways in which a solar power system can be operated in interaction with a conventional electrical utility system without adversely affecting the reliability of operation of the utility system. Standard conversion equipment is assumed for this purpose. Important questions are concerned with the questions of capacity displace- ment (of conventional generating capacity) and energy displacement (of conventional source forms of energy). Several systems will be discussed in terms of these factors.

Having defined the energy collection systems, the energy storage systems, and how the solar power sys- tems interact with a conventional electric utility sys- tem, one can estimate the state of economic competi- tiveness of solar power systems compared to conven- tional electrical generating plants. In this estimate the cost of the energy conversion equipment is estimated on the basis of available equipment, turbine-genera- tors, etc. Finally, given an economically competitive solar power system, one can speculate with respect to the maximum market capture potential that such a system could have.

Solar power systems research has expanded tre- mendously since 1970, and new proposed systems appear frequently. This paper attempts to present those systems that have been investigated extensively as opposed to new systems with a limited history of investigation.

SOLAR ENERGY SOURCE

The rate at which the sun emits energy is 3.86 1023 kW I-l], a truly immense number. Of this amount 1.36 kW/m 2 can be intercepted by a planar surface oriented at right angles to the sun's rays out-

181

-

182 DENTON: SOLAR POWER SYSTEMS

side the atmosphere of the earth at a mean distance from the sun of 149.4 106 km [2]. Although, by applying the Stefan-Boltzmann Law, the effective tern-

2.0 perature of the sun's surface is 5750 K, the solar spec- tral intensity curve does not agree with that of a black body at 5750 K. Figure 1 gives the solar spectral in- ~ z.s tensity curve. Furthermore, the solar flux varies sea- sonally up to 6.8~o due to the ellipticity of the earth's

1.0 orbit [3].

Although it is relatively easy to define a standard solar spectrum outside the earth's atmosphere, even 0.5 considering the seasonal variation resulting from the ellipticity of the earth's orbit, the spectrum at sea level is quite another matter because of the variability of the received radiation as a result of atmospheric effects, reflection, absorption, and scattering. The spectrum is altered as a result of the interaction of the radiation with molecules in the atmosphere, prin- cipally ozone, water vapor, and carbon dioxide. Ozone completely absorbs sunlight below 0.30/~m in the ultraviolet and reduces the flux in the entire green region. Water vapor absorbs the infrared in certain regions below 2.7 #m and completely beyond 2.7 #m; however, there is little energy beyond this wave length. The spectrum is also affected by suspended particles called aerosols, which do not absorb the energy, but instead scatter it. The scattering by aero- sols is approximately constant over a wide range of wave lengths, as compared with the Rayleigh scatter- ing by molecular oxygen and nitrogen, which pro- duces the blue sky color. Nevertheless, it is possible to define a standard atmosphere and determine a sea level solar energy spectrum. Figure 2 compares the spectrum of solar energy outside the atmosphere with that at sea level with an atmosphere containing 20 mm of precipitable water. The net effect of the atmospheric absorption is to remove much of the in- frared energy. Nevertheless, after standard atmos- pheric effects are taken into account, ca . 2;/3 of the solar energy entering the atmosphere at zenith actually arrives at sea level, yielding about

2.5

2 .0

1.5

1.0

0.5

J l

0 i 0,5 1.0 1.5 2.0 2.5 3.0

Wavelength ~ um

Fig. 1. Solar energy spectrum--above atmosphere [4].

~ Out side Atmosphere

/Se20L~ve l20 SUporat Zenith

0.5 1.0 1,5 2.0 2.5 3,0

Wavelength - ~m

Fig. 2. Solar energy spectrum--sea level [4].

0.91 kW/m 2. Clearly, this amount varies with atmos- pheric conditions and with altitude.

The solar energy arriving at sea level also varies with the time of day and with season. These diurnal and seasonal variations are caused by geometrical fac- tors and .the change in altitude of the sun and the corresponding change in atmospheric path length tra- versed by the sunlight and, therefore, in the total atmospheric absorption. When the standard sea level data are converted to time of day for a 33 north latitude, the curves shown in Fig. 3 result. These curves are drawn for a "standard desert atmosphere" in which 69.7~o of the normal incoming radiation reaches the surface, i.e. the solar flux on a horizontal surface at sea level is ca . 0.95 kW/m 2. The discussion above has concerned the direct radiation from the sun. As a result of atmospheric scattering, the total hemispherical radiation received is larger than the di- rect radiation. Figure 4 shows the incident flux for the total hemispherical radiation as a function of time of day and season. The direct radiation is applicable to concentrating collectors, whereas the total hemi- spherical radiation is applicable to planar collectors [43.

1.0

0.8

x ~ 0.6 i

=x 0.4

0.2

Direct Radiation 33 N Latitude Desert Atmosphere

~ ....... Winter

" \ ~ \ \

' , , \ \

",,,ix . . . . ',,. \ \ i 2 3 4 5 6 7

Hours from Noon

Fig. 3. Diurnal and seasonal variation of solar flux-~lirect radiation [4].

-

DENTON: SOLAR POWER SYSTEMS 183

Total Hemispheric Radiation 33 N Latitude Desert Atmosphere

b ~ Equinox 1.0 ______~,~~~~---- '~~ \\ S .....

Winter 0.8

0.6

I 0.4

0.2 I

. . . . 0 \, 1 2 3 4 5 6 7

Hours from Noon

Fig. 4. Diurnal and seasonal variation of solar flux--total radiation [4].

1.0

Visibility = 23 km Water Vapor - mm

0

5 i 0.5

0 I I I .4 0.6 0.8 1.0 1.2 1.4 1.6

Wavelength - ~m

Fig. 5. Calculated insolation spectrum--clear day [5].

The discussion above has indicated only an atmos- pheric impact on the quantity and variation of solar flux at a sea level site. In fact, the situation is much more complicated and, indeed, is only subject to an empirical approach utilizing information which is ex- tremely site-specific. The climatology of the site is governing. Factors to consider include the various cloud conditions, atmospheric haze (pollution) condi- tions, the geographical and annual distribution of sunshine, and the seasonal distribution of rainfall and diurnal cloudiness. Figure 5 presents calculated spec- tra for the solar flux on a clear day (visibility of 23 km) with two different values of precipitable water vapor (0 and 51.5 mm) using a tropical atmospheric model. Clearly the atmospheric water vapor content plays a large role in modifying the ground level inso- lation spectrum. The range of precipitable water vapor for the continental United States is from 5 to ca . 50 mm. If one increases the aerosol concentration near the surface, using the same size distribution, to the point where the sea level visibility is reduced to 5 km then the curves presented in Fig. 6 apply.

In working with solar power systems which pro- duce electrical energy from thermal energy, it is not

1.0

0.5 o

Visibility - 5 km

Water Vapor - mm

51.5

.4 0.6 0.8 1.0 1.2 1.4 1.6 Wavelength- ~m

Fig. 6. Calculated insolation spectrum--hazy day [5].

necessary to have the detailed solar flux spectrum, but all of the same considerations come into play in determining the amount of energy reaching the col- lector. Figure 7 presents the annual mean daily solar energy availability in the southwestern portion of the United States. Aerospace Corporation [5,6] has done a very complete analysis of the insolation character- istics of the southwestern United States. The average daily total hemispherical and direct insolation is

Total Insolation

i ~ I 1 (A 1 Mean Daily) ....

/ 5200 WATT-HRS/M2/DAY (215 WATTS/M 2 ) -~

Fig. 7. Solar energy availability--Southwestern United States [6].

-

184 DENTON: SOLAR POWER SYSTEMS

i i

zo

~9

~7

6

4

<

- i!iiiiii iiiiiii~

_ iiiiii!i iiiiiiii

-iiiiiiii _ iiiiiiil

~iiiiiii - ~iii

; i i i !

:::=! h~ . ~ . . . . - . - -

CAL IFORNIA

Fig. 8. Average daily

--]

ili[iiil iiiiii ! i!iii!!

ioii

ARIZONA

LEGEND

- - JUNE ..... ANNUAL .... DECEMBER

k ia.

m~ N~

~TA4NEV I NM 3OL 4

total insolation (1963)[6].

iiiiiiii iiiiiiii

[![iiiii i!iiii![

oli

TEXAS

i!iiiill !!Fi!!

iiiii !!!iiii

~iii iii~i! ........ KA [NEB]

shown in Figs. 8 and 9, respectively, for 1963 for 20 different locations in the Southwest based on their study.

In summary, ground level insolation is not predict- able from theory. Empirical data must be used and the data must be site-specific. Even then, one must expect that the actual insolation will be different from that estimated at a particular time depending upon the temporal variations in climatology and general atmospheric conditions. Only the direct component of the solar flux is focusable, whereas non-focusing collectors utilize the total hemispherical solar flux. The performance of photovoltaic devices is sensitive to the wave length of the incoming radiation. There- fore, for working with the full gamut of collectors, one needs three types of site-specific insolation data: 1. Spectral distribution of solar flux; 2. Total hemi- spherical radiation; 3. Direct radiation.

SOLAR ENERGY COLLECTION

The energy contained in the solar flux can be col- lected if it is allowed to fall on a suitable collector. One must consider both thermal and non-thermal collectors. The former group can be conveniently sub- divided into focusing and non-focusing collectors. Photovoltaic collectors are of the non-thermal type. In addition, there are attempts to use a hybrid photo- voltaic-thermal collector. Discussions of a limited nature are also found dealing with electromagnetic collectors, Winston collectors, thermoelectric collec- tors, Fresnel lens, etc. This review will cover only focusing and non-focusing collectors of the thermal variety and photovoltaic collectors of the non-thermal variety on which a substantial literature exists.

Focusin9 thermal collectors. Generally, a tracking mechanism is provided with focusing collectors; how-

11

= F ~i0 -

v 9 -

H 8 -

o 7 -

H

5 - H

4 -

o liii!ii)it l!ill

I

LEGEND

- - JUNE ..... ANNUAL ----- DECEMBER

E~ i ~'~ i<

iiiiifil li!!!!i[l I~iii!ii i i]iiil CAL IFORNIA

ic

AR IZONA UTAH

iii~i F !z~ c~ " : "

us : :~ i

~, =: = i

NE~ NM ICOL d

c

Fig. 9. Average daily direct insolation (1963) [-6].

i iiii[ ~i'~

iii!ii iiiili

TEXAS "AINEBI

-

DENTON: SOLAR POWER SYSTEMS 185

ever, in a trade-off between cost and performance, some configurations have been proposed which do not track the sun. Rotation may be accomplished either by moving the reflecting surface or the energy absorbing surface.

The University of Minnesota-Honeywell research team have done extensive research on a cylindrical parabolic trough focusing thermal collector [7], which is rotated about the focal line of the concen- trator in order to track the sun. The collector is com- posed of two cylindrical parabolic trough concen- trators, each having an aperture of 1.2 x 2.1 m. The collected sunlight is concentrated on a 2.54cm dia- meter absorber tube which is enclosed by a borosili- cate glass envelope for protection. The space between the absorber tube and the glass envelope can be eva- cuated to reduce the heat loss from the absorber. The parabolic contour has a rim angle of 115 , a focal length of 19.4 cm, and an f number of 0.159. The ref- lecting surface is an Alzak anodized aluminum reflec- tor sheet on a substrate which is a sandwich assembly composed of two epoxy skins and an aluminum honeycomb core. Three absorber tubes are employed. The first is a black painted tube with water flowing through it to evaluate calorimetrically the optical per- formance of the collector. The second absorber tube is a heat pipe in which the evaporator section is coated with an AlzO3-MoOx-A120 3 (AMA) selective solar absorber coating. The third absorber tube is a heat pipe with its absorber section painted black. The collector is designed to produce fluid temperatures up to 300~C with the selective coating absorber. Figure 10 presents the efficiency of this collector in the east-west orientation versus the apparent solar time as measured near Phoenix, Arizona. These data were taken with the first absorber and represent a calorimetric evaluation of the optical performance of the concentrator. The efficiency was calculated as the heat delivered to the cooling water divided by the product of aperture area and incident flux measured normal to the sun. The peak efficiency in Fig. 10 is

ca . 61.5% which is consistent with the product of the efficiencies of the various processes which contribute to the overall efficiency. The product of the com- ponent efficiencies is 63%. Figure 11 presents the solar radiation intensity as a function of time of day for 21 June, 1974 at the test site near Phoenix. The data is from instantaneous readings taken at 10-rain intervals during the day. The global radiation was measured with a Spectrolab SR-75 pyranometer, and the direct radiation was measured with an Eppley NIP pyrheliometer. About one-half hour of early morning measurements were blocked by the instru- ment trailer. A relatively dense cloud obscured the sun at 0806 and the effect of thin broken cirrus clouds can be seen in the data until about 1330. The sky appeared clear from 1330 to sundown. The ratio of the direct to hemispherical radiation intensity was 0.82 from 1200 to 1430, decreasing to 0.76 just prior to sundown. On other days this ratio varied from over 0.90 to less than 0.75 depending on humidity and dust conditions.

The paraboloid of revolution focusing collector operates like the cylindrical parabolic trough collec- tor above except, of course, the theoretical focus is a point rather than a line. Consequently, it is gener- ally capable of higher temperatures with the same aperture area. The Black and Veatch-Honeywell research team has carried out an extensive analysis of alternative solar thermal power systems [8], one of which is a paraboloid of revolution circular mirror mounted on a two-axis, gimbaled tracking system and a fixed hemispherical receiver. The receiver can be contained within a "bell jar" glass envelope with a vacuum between the receiver and the inner glass sur- face. Figure 12 presents a view of this collector. The collector was analyzed for a site at 33 north latitude with insolation of 0.85kW/m 2 (15 June, 10:00a.m.) which is characteristic of the Phoenix, Arizona area for which cylindrical parabolic trough collector data were provided above (see Fig. 11). The aperture area chosen was 39m 2, the same as the aperture area

60

Co l lec tor Or iented East -West

~ Data f rom 5-28-74

@ Data f rom 6-4 -74

Co l lec tor Po in t ing = . ~ 1200 4 0700 to

- -50

40

.~ 30

t~ ~ 20

i0

70

i i i i i i i i i i i

0700 0800 0900 i000 i i00 1200 1300 1400 1500 1600 1700

Apparent So la r T ime

Fig. 10. Efficiency vs time of day for East-West collector orientation [7].

-

186 DENTON: SOLAR POWER SYSTEMS

1.0

0.9

0.8

0.7

0.6

0.5

0.4

0.3

0.2

0. i

0

Norma

o

i:

!

i i i i i i i

0400 0600 0800 i000 1200 1400 1600 1800 2000

Apparent So la r T ime - June 21, 1974

Fig. 11. Solar intensity as a function of time of day [7].

of a trough collector analyzed earlier by Honeywell [9] similar to the one presented above, but with a slightly lower ratio of width to length. The paraboloidal collector has a six-in, wide slot from the rim to the

"center of the dish to accommodate the receiver mounting as well as the shadow of the receiver sup- port structure. The receiver is stationary and the dish rotates to focus the sun's rays on the receiver surface which was a fiat black surface with an emittance of 0.9 at all wave lengths. The collector was designed to yield a receiver temperature of 537.8C with a 109 rim angle. The best concentration ratio is about 800 for the perfect optics case, 400 for a 0.25 rms uncer- tainty in the angular position of the mirror normal, and 180 for a 0.50 rms uncertainty. The analysis assumes a 0.25 rms tracking uncertainty. Figure 13 shows the load duration curve for this collector, i.e. the absorbed thermal power versus the number of

Fig. 12. Paraboloid of revolution collector [8].

hours annually for which the power output is at least equal to the indicated power. This is a very useful format of presentation for use by the power industry. For comparison purposes Fig. 14 shows the load duration curve for the cylindrical parabolic trough collector with the same aperture area.

Another variation of the focusing collector approach is one which utilizes a central receiver, onto which the solar energy is reflected by an array of independently steered flat mirrors, or heliostats. The University of Houston research team has been investi- gating this concept since ca . 1970. An analogous sys-

! 0 .9 ~ S lope Br ror T rack ing Er ror = 0 .25

0 .4 ~ 0 .8 ~ 3 0 25 Rece iver Temp. = 1000 l: ~0.7 ~ i F la t B lack Rece iver

x ~ 2 a= ~.9

0.5 ~ 21

0.2 ~ 0.4 2 is

i0 .1 - ~0.: ? 0~ ~ ~ e

0 . ~ C J

0 4 8 12 16 20 24 28 52 36 40 44

Durat ion 10 2 hrs

Fig. 13. Load duration curve paraboloid of revolution collector [8].

0.8

0.7

0.6

< 0.5

0.4

0.3

0 .2 o

0 .1

East -West Or ienta t ion

50 T rack ing Er ro r

Ground Cover Rat io

i000 2000 3000 4000 5000

Hours

Fig. 14. Load duration curve--cylindrical parabolic trough collector [8].

-

DENTON: SOLAR POWER SYSTEMS 187

_ . . . . . .

~ ~ / < (450TmeWtr r s--~) $ H;I io;a t s ;~~/~

i. 8 km ;-[

Fig. 15. Cross-section of power tower configuration [11].

tem was investigated in the Soviet Union in 1956 by Baum [10]. The configuration employs an array of heliostats arranged so that the central receiver is illu- minated without undue shading of one heliostat by another or blocking the redirected radiation from reaching the receiver. To accomplish this, one must elevate the receiver 1/4-1/2 the diameter of the helio- stat field. The University of Houston group chose to study a central receiver of 450 m height placed in a heliostat field of 2.5km 2 [11]. Figure 15 shows a cross-section of the heliostat field. Each of the helio- stats is to be individually steered, hydraulically or electrically, to reflect the sun's rays onto a receiver which is on top of the tower. Each heliostat is con- trolled separately with an optical guidance device. A parabolic surface is approximated by positioning the nominally flat mirrors. The heliostats are spaced to shade ca. 45~o of the area of the heliostat field and may range from 10 to 100m 2 in area. The mirrors can be made of either silvered float process glass or front surfaced aluminum or plastic sheet with a thin

protective coating. Figure 16 presents the solar energy redirected by the field of heliostats per square meter of mirror surface vs time of day for the solstices and equinoxes. The incident flux is taken from Zaren and Erway [12]. Also shown are curves of the inten- sity of solar radiation on a horizontal surface at ground level in mid-winter and mid-summer. The tower is offset from the center of the heliostat array to improve winter performance and the array is arranged to optimize performance at three hours on either side of noon. Clearly, the mid-winter perform- ance is improved at the expense of the mid-summer performance (compare with the horizontal ground level intensity). The performance is relatively constant for three hours on either side of noon. Both of these effects reduce the peak energy handling requirements on the central absorber, thereby alleviating some of its design problems. The optimized performance pre- sented in Fig. 16 illustrates the results of procedures employed to help match the solar power system to the power demand requirements.

800

600

.~ 400

200

Configuration of Mirror Field ~i6~ = 0 .45 ~5," a'c e~

I qe ~- i I ~ N I/~--T .... Height = h

1,.h /

Mi .... A 6.8 h 2 // /~/O ~ / .//~ / .

-

188 DENTON: SOLAR POWER SYSTEMS

Non-Jbcusin9 thermal collectors. The fundamental problem of non-focusing solar collectors is the attain- ment of a sufficiently high temperature in a collection fluid to drive a thermal power conversion system. At the present time these collectors do not deliver a tem- perature that makes them attractive for electrical generating systems. There are techniques for improv- ing the temperature performance of flat-plate collec- tors involving radiation selective coatings. The prob- lem is one of simultaneously maximizing the solar energy absorbed and minimizing the thermal energy re-radiated. Because both the absorptivity and emissi- vity of surfaces are wave length dependent, it is poss- ible to enhance the temperature performance of a flat- plate collector by applying a coating which has a high absorptivity in the wave length regions of interest in the incident solar spectrum but has a low emissivity in the wave length regions of interest in the spectrum of re-radiated thermal energy. It will be recalled that the solar spectrum is similar to the spectrum of a black body radiator at 5750K, whereas the re- radiated thermal energy spectrum is similar to the spectrum of a black body radiator at the temperature of the radiating surface, say 575 K, a factor of 10 lower. Selective coatings simply attempt to capitalize on the spread between these two spectra.

The Honeywell-Black and Veatch research team has analyzed simple flat plate collectors for absorbing solar energy and employing pressurized water to transport the collected energy from the solar collec- tors [-8]. Figure 17 illustrates the flat-plate solar col- lector which was analyzed. The analysis determined the thermal performance of 10 serially connected flat- plate collectors. The pressurized water flowed in series through the collectors, each unit adding an incremen- tal amount of energy to the water. The thermal effi- ciency was obtained as a function of the temperature of the water leaving the last collector, which was varied by altering the water flow rate. The thermal

F lu id Tubes

Insu la t ion

Absorber P la te

Fig. 17. Flat plate solar collector [8].

70 T z = 120 F = F lu id In le t

Temperature

60 150

J 50 180

~ 40 0 210 -4

30 240

2o

U i0

0 I I I I | i

i 00 150 200 250 300 350

F lu id Ex i t Temperature - F

Fig. 18. Thermal efficiency of fiat plate solar collectors [8].

efficiency is the ratio of the net rate of heat leaving the collector to the solar flux incident on the collec- tor. The incident solar energy was taken as 0.98kW/m 2 and different inlet water temperatures were assumed. Figure 18 presents the results of this analysis for 1.22 m square collectors having 12 tubes in an aluminum absorber plate coated with a material having an absorptivity of 0.90 and an emissivity of 0.06. The collector was covered with one pane of glass 0.38cm thick and tilted at 33 with the horizontal. Ambient conditions were taken at one atmosphere pressure, a temperature of 21C, and a wind velocity of 16km/h. With the low temperatures and corre- spondingly low pressures of water available from the flat-plate system (maximum temperature of 150C), vapor cycles are relatively inefficient for generating electric power. Based on these results, the flat-plate collector system is marginal for a solar power system.

Selective coatings research at the University of Ari- zona [4] has investigated optical thin-film coatings that can absorb sunlight hut prevent heat loss in the infrared. Figure 19 illustrates the technique of layer- ing these films and the relationship between the per- formance of the thin-film and the physical behavior of the selective coating. These coatings are only about 1/250,000 cm thick and are deposited on the substrate within a vacuum tank or a chemical vapor deposition furnace. In the selective coating shown in Fig. 19 the absorbing layer is ordinary silicon, which is opaque to sunlight but quite transparent in the infrared. If a highly reflective metal coating is placed between the silicon and the steel substrate, sunlight never pene- trates to it because of the silicon. In the infrared, both the silicon and the overlying non-reflecting layers (added to improve collection efficiency) are in- visible. Thus the metal coating attempts to emit as if it were a highly reflective metal, and because bright metallic coatings have very low infrared emissivities, the surface traps the heat. The actual curve of reflec- tance as a function of wave length is shown in the lower portion of Fig. 19. The effectiveness of a selective coating is measured by the ratio of the solar

-

DENTON: SOLAR POWER SYSTEMS 189

X, l l / Visible Region ~O~_ Energy Incident " ~ Infrared Region on Selective //I \~ Energy Escape Coating /~ Inhibited

~ ,~ N .... flecting Layers ~[ , I ? I I I ~ i h i R fle ti , Transparent g y e c ng ,,I I Absorblng Layer ~ I ~ > 1.5 ~m Metal Coating

rh / , / / . . , z >a // Z / tool

io0 i 8o

~ 60 ~ 40

2o

~o 0.4 0.6 1.0 2.0 3.0 i0.0

Wavelength - ~m

Fig. 19. Optical thin film coatings and performance [4].

absorptance to the infrared thermal emittance, ale. System studies, such as the one quoted above [8], have assumed that the state-of-the-art will provide an ale of 15 at moderate temperatures, whereas the high temperature system studies usually employ an ale of 10. The University of Arizona group estimates that the limit of ale attainable by interference coating tech- nology will be ca. 30 at 500C and 60 at 300C. The limit by means of bulk absorption technology is estimated to be 24 at 500C. In order to reach an operating temperature of 500C, one needs an effective ale of ca. 100. Clearly, these selective coatings cannot provide such high values and one will have to resort to optical concentration, of moderate values, to reach 500C. A vital question concerns the opera- tional lifetime of these coatings at high temperatures.

Photovoltaic collectors. The basic technologies for photovoltaic solar energy conversion have been devel- oped and applied extensively in space flight systems. The question of large scale terrestrial use is one of cost and life-time under terrestrial conditions. A pho- tovoltaic collector is simply a flat array of solar cells exposed to the sunlight and, normally, oriented per- pendicular to the incoming rays. The solar cells may be any one of a number of photovoltaic devices, such as silicon or cadmium sulfide cells. Maximum per- formance is obtained with arrays that track the sun. The efficiency of a photovoltaic device is simply the ratio of the output power to the input power. Some- times, a maximum efficiency under load is quoted, in which case the output power is just the product of the voltage and current for maximum power deli- vered. Of course the power is direct current rather than alternating. In other cases, an ultimate efficiency is quoted in which the output power is taken as the product of the short-circuit current and the energy gap (in V). As we have seen above, the solar energy flux is wave length dependent (see Fig. 5). In addition, the response of a photovoltaic device is wave length dependent. Therefore, the electrical energy produced by a solar cell is determined by the integral of the spectral response curve of the cell combined with the

solar input spectrum. Figure 20 presents the silicon spectral response curve and the solar cell output for a clear day, tropical atmosphere with no water vapor as a function of wave length. This figure also repro- duces Fig. 5, in the case of no water vapor, which shows the solar input spectrum. Of course, the power produced is the integral of the solar cell output curve over the wave length range of the silicon spectral re- sponse curve. Figure 21 presents the same informa- tion for a hazy day with no atmospheric water vapor. Naturally, the presence of water vapor in the atmos- phere decreases the solar cell output because of its effect on the solar insolation spectrum. The literature on photovoltaic devices discusses the output in terms of the number of air masses between the device and the solar rays as they enter the earth's atmosphere. Thus, an air mass of zero (AMO) curve represents the performance of the device outside the earth's at- mosphere; an air mass of one (AMI) represents the performance with the sun at zenith; and an air mass larger than one is used when the sun is off-zenith.

In studies directed toward setting cost goals for sili- con solar cell arrays for large scale terrestrial appli- cations [13], an array efficiency of 10~o is used (with no anti-reflective coating), which is realizable with present day typical production cells. Cadmium sulfide

i 0.5

Visibility = 23 km Water Vapor - 0

~~/~Spect ra l Response 1.0 r / / / /~ ~[a~i~ n

/ ~ In~ted)

Solar Cell Output

0.4 0.6 0.8 1.0 1.2 1.4 1.6 Wavelength - um

Fig. 20. Silicon solar cell output~lear day [5].

-

190 DENTON: SOLAR POWER SYSTEMS

1.0

0.5

Visibility = 5 km Water Vapor = 0

Insolation

o ~ S O l a r Cell

0.4 0.6 0.8 1.0 1.2 1.4 1.6 Wavelength - ~m

Fig. 21. Silicon solar cell output--hazy day [5].

cells that have been operating for about eighteen months on a roof-top in Newark, Delaware have been reported 1-14,15] to have an efficiency of ca. 2.5%. The Delaware group predicts that they will attain effi- ciencies greater than 14% for their CdS/Cu2S cells [14]. In the case of silicon solar cells, a reasonable goal for efficiency is 17-20~o [14].

ENERGY STORAGE

The available energy from the sun is of low inten- sity and is both intermittent and variable in its instan-

i taneous availability. In order to use solar energy as a viable source of power, one must incorporate energy storage into each solar power system in order to match the power supply with the instantaneous power demand. Even if this were not so, it would still be necessary to accumulate the solar energy in a storage unit in order to reduce the variability of operating conditions required of the generating equipment. Energy storage systems can be classified conveniently as thermal, chemical, electrical, and mechanical. Each of these will be discussed briefly.

Thermal energy storage. This mode of energy stor- age consists of using the thermal energy from the col- lectors to increase the thermal energy content of the storage medium. Both sensible heat (temperature change) and latent heat (phase change) storage media are available.

Water is the most popular medium for sensible heat storage because of its relative abundance, low cost, and well-known properties. The stored energy is the product of the specific heat and the temperature rise of the water. Energy may be stored as sensible heat in water in a temperature range from just above its freezing point up to ca. 350C. At the higher tempera- tures the vapor pressure is high and the storage con- tainment will require heavy equipment. Consequently, water may be better suited for the lower temperature range, say up to 230C. At the higher temperatures one turns to liquid metals, molten salts, etc.

The steam accumulator has been used to store ther- mal energy in a combined sensible heat-latent heat manner. High pressure steam is mixed with water and allowed to condense in a pressure vessel. As more

steam is added, the mass of water eventually reaches its boiling point at the charging pressure. To produce steam from the storage unit the pressure is dropped and the water flashes back to steam with the amount of steam available being dependent upon the pressure drop. Only saturated steam can be withdrawn from the accumulator (corresponding to its pressure), there- by posing problems for the steam turbine.

An aquifer can be used for sensible heat storage in water. One drills a number of pairs (one deep, one shallow) of widely spaced holes into a suitable depth aquifer. Water is withdrawn from the deeper holes, heated by energy from the solar collectors, and in- jected into the shallow wells. Withdrawal of energy is accomplished by taking hot water from the shallow holes, cooling it by the energy conversion system, and injecting the cooled water into the deeper wells. The natural thermal stratification of large bodies of water inhibits the mixing of the hot and cold water. Water losses to the total volume of the aquifer present prob- lems of containment of the stored energy. An alterna- tive to aquifer storage which has been proposed is to drill a deep well into hard, nonporous rock (granite) and produce a large cavity by exploding a 100 kt atomic device in the well to fracture the rock a,u proauce a cavity into which the hot water can be injected. A second well is "slant" drilled into the lower part of the cavity. The normal thermal stratifi- cation occurs and the operation is the same as for the aquifer. The concept utilizes the natural insulation and containment provided by the surrounding rock.

Latent heat storage is based upon the energy absorbed or released upon a phase change of the stor- age medium, which occurs at a constant temperature substantially. The energy stored is simply the heat of fusion of the material for the particular phase change. Generally, the phase change employed is a liquid solid or solid-solid transition because of the small volumetric changes which occur with these changes of phase. A large variety of phase change media have been proposed, eutectic salts, metals, organic compounds, etc. For very high temperature thermal storage, a combination of a molten salt and a stratified tank of liquid metal is possible. Table l presents pertinent data on some latent heat storage media.

Table 1. Melting points of selected eutectics [18]

Melting Composition Eutectic point (C) (mole %)

AICIa-NaC1 112 62-38 FeC13-KC1 202 53~,7 ZnC12 ZnSO4 300 90-10 KC~MnC12-NaCI 400 37.7-37.3-25 CaC12-NaC1 500 52.847.2 FeS-Na2S-PbS 600 25.5-52.9 21.6 KC1-KMnF3 700 88.5-11.5 Fe203-NaPO3 800 15-85 MgO~NaaA1F6 905 3(~70 MgF2-NaF 1000 36-64

-

DENTON: SOLAR POWER SYSTEMS 191

Chemical energy storage. This mode of energy stor- age involves using the output of the solar collectors to produce a chemical which can be stored until the energy is required. Upon demand for energy from storage, the chemical is allowed to undergo a reaction to release the energy. Depending upon the chemical and the mode of use, the reaction may be of a com- bustion nature: it may occur in a fuel cell: or it may be some other appropriate chemical reaction.

Hydrogen and oxygen may be produced by electro- lysis of water with the electricity being provided either by the output of a photovoltaic solar collector or the operation of a thermal generating plant. Upon demand the hydrogen and oxygen (or air) can be recombined in a combustion reaction to drive a ther- mal generating plant or in a fuel cell to produce elec- tricity directly.

There have been several chemical reaction systems proposed to produce hydrogen. By using concentrat- ing solar collectors which deliver very high tempera- tures, one could contemplate several of these systems. In a study of a hydrogen-oxygen closed cycle MHD system [16] several such multi-step thermochemical decomposition processes are presented, e.g. Mar- chetti's Mark-I process (requiring a maximum tem- perature of 730 C) [17], the Mark-9 process requiring 650 C, and the G.E. Catherine process requiring 700C. Of course, any production of chemicals ther- mally, which can be recombined to yield high tem- perature products of reaction or in a fuel cell to pro- duce electrical power directly, are possible candidates for chemical energy storage applications.

Electrical energy storage. The storage of electrical energy normally employs batteries, of which there are numerous types. Most available batteries do not have the high energy and power density characteristics which are desirable, greater than say 0.2 kWh/kg and 0.2 kW/kg. Nevertheless, two types of batteries which are presently under development, do have desirable characteristics. The sodium sulfur battery has a theor- etical energy density of 0.68 kWh/kg; the lithium sul- fur battery has a theoretical energy density of 1.54kWh/kg: and the theoretical energy density for

34,000 - -

the lithium-chlorine battery is 2.31 kWh/kg. Allowing for severe degradation of the energy density in a prac- tical battery, there is enough potential in each of these batteries to make them attractive candidates for elec- trical energy storage in solar power systems.

Another system of electrical energy storage that has been proposed is a superconducting magnet with alu- minum conductors and epoxy insulation which would be emplaced in native rock, probably granite.

Mechanical energy storage. This type of energy stor- age includes flywheels, compressed air, and pumped hydroelectric systems. Among flywheels, only the new superflywheels offer enough energy density to be attractive. Compressed air systems would employ a natural underground cavity, such as a depleted oil, gas, or water reservoir. The compressed air is simply pumped into the formation and withdrawn upon demand. Loss of pressure and air presents a problem. Pumped hydroelectric systems are presently employed by electric utility firms in favorable locations.

ELECTRIC POWER UTILITY CONSIDERATIONS

It appears futile to contemplate a stand-alone solar powered electric utility system. At least for the fore- seeable future it is necessary to integrate solar pow- ered plants with an established electric utility system involving a mix of different types of power plants and several different modes of operation to meet its level of demand for power. A given utility system may be composed of fossil-fired, nuclear, and hydroelectric facilities. In addition, it may supply steam to some of its customers. The different generating plants may operate as base, intermediate, or peak load generating units in response to the instantaneous demand for power by the customers.

The power demand for a utility varies markedly over a daily period, a weekly period, and seasonally. Figure 22 shows the forecasted electric power demand in 1990 for the Southern California Edison Co. by daily profile over three weeks of the year [6]. The curves show the hourly variation for each day, the

30,000

~26,000

22,000

18,000

14,000

Aprilw' T, F, si s M, TIw TIAu ust FJ sis IMIT'DecemberW' I 'S I Fig. 22. Electric power demand forcast [6].

-

192 DENTON: SOLAR POWER SYSTEMS

daily variation through each week, and the weekly variation for a typical week in April, August, and December to illustrate the seasonal demands in the spring (and fall), summer, and winter, respectively. Clearly, these power demands will vary from com- pany to company. In the conventional generation model assumed for 1990, there were 18,000 MWe of base load capacity (1000MWe unit plant size), 10,000 MWe of intermediate load capacity (500 MWe units), and 9,000MWe of peak load capacity (200 MWe units) [6].

An electric utility is vitally concerned with the relia- bility of its plants because it is required (by charter) to serve its customers needs upon demand regardless of the timing of the demand. In order to ensure that the demand does not exceed its available generating capacity, the utility builds its system capacity in excess of the anticipated peak loads. This excess generating capacity above peak load is the utility's reserve, or margin, for meeting peak loads under con- ditions of forced outages at some of its generating stations. The amount of reserve which is required to insure a given level of reliability of service to the cus- tomers is determined by a margin analysis. Unsche- duled outages for conventional plants are due to com- ponent failures; whereas, for solar plants one encounters unscheduled outages both from com- ponent failures and from insolation outages. These unscheduled outages are separate from scheduled plant outages for maintenance or seasonal deratings of plants.

When solar plants are substituted for conventional plants into a total power grid, a margin analysis must be made to ensure that the resulting system provides service equally reliable as the conventional system. If the increased outages of solar plants dictate backup generating capacity to satisfy the reliability require- ment, this backup capacity must be taken into account when making comparative economic assess-

ments. Consequently, one seeks to establish the potential of solar power plants to provide both gener- ating capacity displacement and energy displacement with the solar plants operating in a system which functions with the required reliability of service. Mar- gin analysis is probabilistic in nature and is based on a loss-of-load probability on an hourly basis extended over an entire year (because of seasonal demand variations). By combining the total utility system available generating capacity probability dis- tribution with the projected electrical load distribu- tion, a probability is developed that the load will not exceed the available capacity (loss-of-load condition). The system loss-of-load calculations are performed on an hourly basis over the entire year of operation. By varying the number of plants assumed in the grid, the total generation capacity required to satisfy a given reliability criterion, say a loss-of-load condition of only one day in ten years (2.4 hr per yr), can be established. Each generating unit contributes to the total power grid as a function of its generating capa- city and its outage rate. The forced outage rates for conventional power plants are a function of type, size, and age of the plant. The same behavior is expected of solar power plants, but, in addition, insolation outages at night or due to cloud cover will occur. The effective insolation outage for the solar plants is a function of the amount and type of energy storage provided and must be determined hr-by-hr over an entire year of operation. In addition, insolation outages for a single utility system are expected to be statistically dependent between solar plants located at different points in the grid.

In order to determine the generating capacity dis- placement for solar power plants, it is necessary to determine a conventional plant base-line generation configuration of plants that provides the required reliability of service. Figure 23 presents the baseline generation capacity for Southern California Edison

40

38

36

34

o o

o 32

30

o

28

26

22

Baseline Conventional Installed Generation Capacity (Margin 15.6%)

83 (Nr. of Plants) 6!I! I 59~58: ~lO%scheduledplantMaint~ ...... ~ I ~ i * - - ~ ~ I Generation 58

~52 ~ 52 46 [ - -

~ 44 | 42

| 39 39 38 39

1 36 [ ~ S C E P e a k

Load Profile (1990)

Jan F b M r A r Ma Jun J 1 A Se Oct Nov Dec

Fig. 23. Conventional plant base-line generation capacity [6].

Loss of Load: 1.78 Hrs/Yr

(Method l) 2.38 Hrs/Yr

(Method 2)

-

DENTON: SOLAR POWER SYSTEMS 193

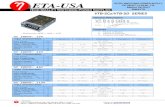

Table 2. Margin analysis [6] SCE peak demand (1990)--32,000 MW,. Generation model--conventional (idealized)

Size Capacity Component Plant type (MW~) No. of units (MW,,) (%) outage (o~)

Base load 1000 18 18,000 49 4 I nterm ediate 500 20 10,000 27 4 Peaking 200 45 9,000 24 4 Total 83 37,000 100

Solar thermal plants (substituted for conventional units)

Size Capacity Component Solar* Plant type (MW~) Nr. of units (MW~,) outage (%) outage (%)

Intermediate 500 2, 4, 6~ 8. 10 1000 5000 4 0-100 ,~ 250 4, 8, 12, 16, 20

100 10. 20, 30, 40, 50 ,L

Reliability criterion. Loss of load ~ 1 day/10 yr. Conventional back-up capacity required. * Determined from system simulation.

for 1990 [6]. The total capacity is sufficient to permit a 5-week scheduled maintenance period for each power plant and satisfy the reliability criterion that loss of load periods will not exceed 2.4hr per yr. Assuming a uniform 4% unscheduled outage at each plant as a result of component failures, the margin is 15.6%. Table 2 presents the data which was employed in the margin analysis [6]. Different sizes of solar plants (100-500 MWe) were substituted for intermediate load conventional plants. The total con- ventional capacity which was displaced by solar plants was varied between 1000 and 5000 MWe. Indi- vidual plant outage rates of 4% as a result of com- ponent failure were assumed for both solar and con- ventional plants. Insolation outages were determined

by simulations of alternative solar plant configur- ations. Because of the insolation outages the solar plants require conventional plant backup capacity to achieve the same overall system reliability of service. The larger the capacity displacement, the smaller the conventional plant backup capacity required for equal system reliability as long as the total capacity displacement is a relatively small fraction of the total system capacity.

Figure 24 presents typical results of the margin analysis to determine the potential capacity displace- ment of solar power plants and the conventional plant backup capacity required as a function of solar plant insolation outage [6]. The amount of backup capacity required to maintain the system loss-of-load

1.00-

~ 0 .80-

0 .60-

0.40-

TURBINE-GENERATOR RAT ING ~ i 00 MW e (DT G

LOCATION ~ INYOKERN, CAL IFORNIA

DEMAND DATA ~ SCE

T IME PERIOD ~ 1990

0 .45 ~ 0 .50

~ 0.36- [ 0.40

~o.29H 0.30

0.18 ~ 0 .20

= .36)

32

o 16

<

INTE~4EDIATE

22 ,000 - 22 ,100 MW e

SUN SAT

/ / / ! ! /

L l I \ _ ~ . . . / ~ ~-- - . . . . .

i

Fig. 24. Intermediate solar thermal conversion power plant--ventral receiver [6].

-

194 DENTON: SOLAR POWER SYSTEMS

reliability criterion depends on a number of par- ameters, such as order of substitution of plants, total capacity of solar power plant penetration, size of solar power plants employed, size of conventional plants replaced, and size of the conventional backup plants. For the case shown, ten individual 100MWe solar plants were substituted for 1000 MWe of conventional plant capacity. Three different conventional plant sizes are shown to indicate the sensitivity of the solar plant substitution to the size of the displaced conven- tional plant. Small insolation outages do not require conventional backup capacity because the substitu- tion of several small plants for a single plant spreads the relative effect of component outages. For 100~'~,; insolation outages, the conventional backup capacity is not 1000MWe because the conventional backup plants are of 100 MWe capacity or smaller.

The discussion above addresses an important con- sideration for utility firms contemplating the use of solar power plants, the reliability of service. Other important questions have to do with the technical characteristics of the solar plant, its operational characteristics, and the optimal use of the plant in the total power grid. The Aerospace Corporation group [6] has examined solar plants based on the central receiver system, the parabolic cylindrical trough collector, and the paraboloidal dish collector for operation in an electric power grid as base load, intermediate load, and peak load plants. On an over- all basis the central receiver system operating as an intermediate load plant appears to be best [6]; there- fore, the discussion below will be restricted to this case. Figure 22 presented the electric power demand forecasted for 1990 for the Southern California Edison Co. For this utility system the Aerospace group studied the operation of a 100 MWe plant to carry the system load in the range of 22,000 to 22,100 MWe, in the intermediate load range for the system. The collector area was varied from 0.5 to 2.5 km 2 and the thermal storage capacity was varied from 0 to 9 hr of capacity. The technical character- istics of the central receiver solar power plant are shown in Table 3. Figure 24 presents parametrically the technical performance characteristics for an inter- mediate load, central receiver solar power plant based upon a full year of hourly simulation. For the 100MWe rated solar plant, the collector area was varied from 0.5 to 2.5 km 2, and the thermal storage capacity was varied from 0 to 9 hr of capacity. Shown are the solar capacity factor, the plant capacity factor, and the energy displacement when the 100MWe plant is operated in the system intermediate demand range between 22,000 and 22,100MWe. The solar capacity factor is the actual turbine/generator energy output, integrated over the entire year, divided by the maximum theoretical total output for the year. The plant capacity factor is 90,o of the solar capacity fac- tor based on the assumption of a 5-week per year scheduled maintenance period. The energy displace- ment within the 22,00(~22,100MWe intermediate-

Table 3. Central receiver plant subsystem efficiencies and technical characteristics [6]

Collector Tracking Aiming Shading 0.703 Blocking First reflectivity 0.880

Receiver Absorptivity 0.990 Emissivity 0.950 Thermal losses 0.970 Surface temperature 538C

Distribution pump Losses 0.985 Pump constant ~ 66 x 10 3

Distribution Line thermal losses 1.000

Turbine/generator 0.360 Steam temperature 482:C Efficiency

-

DENTON: SOLAR POWER SYSTEMS 195

i00

~ 80 z

6R

2(/

100%

DIREC'I 70 .3% INSOLATION

LESS: 61 .9%

" 'IRACK1NG AIMING, LESS:

WINTER PERTURBED I )R IENIAT ION INTERblEDIATE DEHAND COLLECTOR AREA - ] ,0 Kbl 2 STORAGE CAPACITY = 6 hr

TURBINE GENERATOR RAI'ING ~ 100 ~IB e (rITE = ( I .36) LOCATION ~ INYOKERN, CALIFORNIA o DEblM~D DATA ~ SEE I IME PERIOD ~ 1990

SHADING, AND BLOCKING

" LOSSES

fNERGY AVMI,ABLE EOR BASE LOAD FUEL D ISPLACEMEN'I

55.7% 54 .0% 53 2% 50. 490

REFLECq 48 .8% I,OSSES LESS :

ABSORP. LESS: lESS : ~iz...F LOSSES RECEIVER PUMP LESS: V/

'['lIE RbLM IOSSI S SIORAGE 4 . - 4 . ~.. LOSSES LOSSES ; ~

I , ISS : WASTE IIEAT I,OSSES

|

Fig. 25. Central receiver system performance I-6].

17.6%

LESS : TURBINE GENERATOR

the Aerospace group performed a cost sensitivity analysis of those items which have either a large im- pact on the total cost or a substantial uncertainty associated with their estimates.

Table 4 presents the basic economic data which is employed in the Aerospace study [6]. It is recog-

Table 4. Data standards [6]

Base year 1973 Inflation 3%/yr Plant life 30 yr Depreciation Straight line Cost of capital 7.4% (after tax) Debt/equity 50%/500 Tax rate 40% Land and solar

materials Non-depreciable Escalation rates

Investment costs Operation and maintenance Fuel Revenues Insurance/property tax

O-6.1%/yr 4.0%/yr 5.5-12.8%/yr 2%/yr O%/yr

nized that the 3% per year inflation rate may be too low; however, since all of the escalation rates are con- sistently expressed in terms of the assumed inflation rate, the comparative economic analyses (solar versus conventional) remain valid even though the magni- tudes may turn out to be incorrect. The capital struc- ture, tax rate, and cost-of-capital used reflect values representative of the electric utility industry. The economic analysis is based on the discounted cash flow method and the total methodology is shown in flow chart form in Fig. 26 [6].

The total busbar energy costs for the 100 MWe cen- tral receiver solar power plant for intermediate load application are shown parametrically in Fig. 27 [6] in terms of collector area and thermal storage capa- city. A collector cost of $30/m 2 and a thermal storage cost of $15/kWhe are assumed. Included in the solar plant busbar energy cost is an allowance for backup capacity. This is the cost for maintaining sufficient conventional backup capacity to achieve equal utility system reliability as compared to the use of conven-

System L I 1973 Capital Description ~ Cost Data

I I H EieS ..... 1972 Capital of Investme~nt Cost Scale

I Escalation to I Determine Start of Project Cost-of-Capital

i i I H calcu1 te Determine Escalation Cash Flows & IDC

11 Estiiate I Other Fixed Charges H Determine ~ Fixed Charges

(DCF Method)

t H Capital

Investment Cost @ Yr of Cumin

Operation

Fig. 26. Economic analysis methodology [6].

Determine Total Busbar Energy Cost

Transmission &

Distribution

Retail Energy Cost

-

196 DENTON: SOLAR POWER SYSTEMS

[ I ]RB0 GEMRAI0]~ R,\I [NG - b>O '.Ih e (q lG 0 .36)

] t ) fA I [{',~, [NYOKI P,X, CAl.] }OR'~IA

I} I f f lAN I ] ] ) \b \ ~ 54l:1

* l ' ]H l P]RIOII ~ 199(I

COl L IC IOk ARfA ( I )S ' i $50/M 2

'[IIII~,IAI, S'IORA(;I [:OS'l $15/ki~/hr

z ~ [< 4{I - - m

c .-

20 --

(I SUN I

1 I I II l T L : ' -

i I

I N'I ERb!IiD IA'] [:

]2 ,000 22 , 1{){] k~,' e I I I I

SAT

Fig. 27. Intermediate solar thermal conversion power plant--central receiver [6].

tional plants. The backup capacity required was determined by the margin analysis discussed above. For intermediate load solar plants, in addition to the added fixed charge for conventional backup capacity required, an energy displacement credit is incorpor- ated to account for the additional base load energy displacement. No base load capacity displacement was assumed. A solar plant with a 1.0 km 2 collector area and a 6-hour thermal storage capacity, operating in an intermediate load application, has the lowest total busbar energy cost. The fossil fuel busbar energy costs for intermediate load plants are shown by the wide band across the bottom of Fig. 27. These costs estimates were based on a 400 MWe combined-cycle plant for intermediate load application assuming a 1991 fuel cost range of S1.65-~2.40 per MB,t.u. (1990 dollars), with an escalation rate of 5L per year. Comparing the busbar energy costs for a fossil-fired combined-cycle plant and for a central receiver solar plant, both operating as intermediate load generating units, it appears that the solar plant with a collector area of 1.0km 2 and a 6-hr thermal storage capacity

will be competitive in the 1990 time period, assuming that the collector cost of $30/m 2 can be realized.

The total busbar energy cost is, of course, sensitive to deviations in technical performance from the values presented earlier as well as the component costs of the solar plant. Table 5 presents the results of a technical and economic sensitivity analysis for deviations of the subsystem performance from their nominal values. As can be seen from this table, the system technical performance and the associated cost performance is not overly sensitive to the anticipated changes in subsystem characteristics. Table 6 presents the results of a cost sensitivity analysis with respect to the impacts of changes in heliostat unit collector cost, thermal storage cost, operating and maintenance costs, and conventional backup capacity costs on the 1991 total busbar energy cost. Clearly, the busbar costs are quite sensitive to the heliostat cost and least sensitive to the thermal storage cost.

One of the ever-pressing problems of utility com- panies is raising the capital for new generating facili- ties, thus the capital cost of a solar plant might pre-

Table 5. Technical and economic sensitivity analysis--central receiver system [6] Intermediate demand Collector area ~ 1.0 kM 2 Storage ~ 6 hr

Subsystem

Subsystem Subsystem System sensitivity nominal performance Capacity Busbar cost

performance variations factor 1991 mills/kWh

Collector/receiver: 99yo( + 10,o) + 1.9)[, - 0.9 absorptivity* 90/O 81%( - 10%0) - 2.8~o + 1.3

Receiver: 1200 F( + 20~o) + 0.4~o - 0.2 surface temp: 538C (1000F) 800F(- 20~o) + 0.4/[, + 0.2

Distribution 1.0 MW~ ( + 100Yo) + 0.2/O - 0.1 o/ _ 0 .2o , , ; pump power 0.5 MW e (max) 0.25 MWe (-50/0) +0.1

Storage 100~o(+ 18~[,) + 1.1~ -0.5 input efficiency 85~o 70Yo(- 18yo) - 1.37/o +0.6

Turbine/generator 39.6~0( + 10Yo) + 1.9% - 0.9 efficiency 36Yo 32.4~o( - 107

-

DENTON: SOLAR POWER SYSTEMS 197

Table 6. Cost sensitivity analysis. Intermediate central receiver plant [6] (100 MW~)

A1991 Busbar cost Nominal value Change (Mills/'kWh)

Category (1973 dollars) (1973 dollars) (1991 dollars) %

Heliostat cost $30/m 2 +$10/m 2 +7.2 + 14.9o Storage cost $15/Kwh + $15/Kwh + 2.5 + 5.2% Operating and

maintenance costs $7.5/KW~ + $7.5/KW~ + 5.3 + 1 t.0",,

Conventional backup capacity required 0.0 MW~ +20 MW< +6.6 + 13.70~/,

clude its selection even though the ultimate busbar energy costs might be competitive with other alterna- tives or even cheaper. Table 7 presents the estimates of the 100 MWe central receiver solar plant capital cost components [6]. The capital investment esti- mates are shown by the various accounts in 1973 dol- lars for a total capital investment of $776/kWe. When these costs are escalated to the first year of commer- cial operation, the total cost becomes $1360/kWe in 1990 dollars. By comparison, the total capital invest- ment for a 400 MWe combined-cycle conventional plant is $179/kW e in 1973 dollars, or, when escalated to the first year of commercial operation, the total cost becomes $342/kWe.

Assuming the economic competitiveness of the in- termediate load, central receiver 100 MWe solar plant on the basis of total busbar energy costs as presented above and that the utilities will be able to raise the required additional capital, one can make some pre- liminary estimates of the market capture potential of this solar power system. Figure 28 presents the Aero- space group's conclusions with respect to market cap- ture potential. Factors contributing to this potential market that were considered include the projected growth in installed generation capacity, the allocation of the load by operational mode (base, intermediate, peak), manufacturing rate capabilities, construction

Table 7. Central receiver capital cost estimates 100 MW,, rated [6]

$./kW~

Collector area (km 2) 1.0 Storage time (hr) 6 Account

Land 2 Structures and facilities 44 Heliostats* 300 Central Receiver/towerf/heat exch. 95 Storage/tanks+ 90 Boiler plant Turbine plant equipment 80 Electric plant equipment 21 Misc plant equipment 4 Allowance for cooling towers 20

Total direct cost 656 Contingency allowance 39

Spare parts allowance 3 Indirect costs 78

Total capital investment (19731 776 Escalation to start of construction 296

Total at start of construction 1072 Interest during construction 119 Escalation during construction 169

Total cost at yr of comm'l opn. (1990 dollars) 1360

* Collector cost--$30/m 2. ~'Tower height 260m (3,2,1, 1 tower(s), respectively). ~. Thermal storage cost $15/kW/hr

lOOi:

-

198 DENTON: SOLAR POWER SYSTEMS

lead times, siting constraints, relative economics, en- vironmental factors, and conventional fuel avail- ability. The major barrier to implementation appears to be the comparatively high initial capital investment requirements projected for solar power plants even assuming that the cost goals for collectors, storage, etc. can be met, which remains to be demonstrated.

REFERENCES

[1] G. P. Kuiper, The Sun, Vol. I of The Solar System. Univ. of Chicago Press, Chicago (1953).

[2] The American Ephemeris and Nautical Almanac, U.S. Govt. Printing Office, Washington (1957).

[3] A. B. Cambel, Energy R&D and National Progress, U.S. Govt. Printing Office, Washington (1964).

[4] B. O. Seraphin, Solar Energy Conversion Study, Univ. of Arizona, Tucson (1973).

[5] Mission Analysis of Photovoltaic Solar Energy Sys- tems, Aerospace Corp., E1 Segundo (1975).

[6] Solar Thermal Conversion Mission Analysis, Volume I. Aerospace Corp., El Segundo (1975).

[7] E. M. Sparrow, Research Applied to Solar Thermal Power Systems, Report No. 4, Univ. of Minnesota, Minneapolis (1974).

[8] J. C. Powell, Dynamic Conversion of Solar Gener- ated Heat to Electricity, Honeywell, Inc., Minnea- polis [1974}.

[9]

[10]

[11]

[12]

[13]

[14]

[15]

[16]

[17]

[18]

E. M. Sparrow, Research Applied to Solar Thermal Power Systems, Report No. 2, Univ. of Minnesota, Minneapolis (1973). V. A. Baum, High Power Solar Installations, Solar Energy 1, 2 (1957). Solar Thermal Conversion Workshop Proceedings, Univ. of Maryland, College Park (1974). A. M. Zaren and D. D. Erway, Introduction to the Utilization of Solar Energy, McGraw-Hill, New York (1963). M. Wolf, Cost goals for silicon solar cell arrays for large scale terrestrial applications--update 1974, Energy Conversion 14, 2 (1975). Summary Report of the Second Semi-Annual NSF Photovoltaic Conversion Research Program Review, Univ. of Pennsylvania, Philadelphia (1975). H. M. Windawi, Performance of CdS/Cu2S Solar Cells Under Roof Top Insolation Conditions, Univ. of Delaware, Newark (1975). T. Nakamura and W. Riedmfiller, Hydrogen-Oxygen Closed Cycle MHD Power Generation System Based Upon Thermochemical Decomposition of Water, Energy Conversion 15, 1/2 (1975). G. de Beni and C. Marchetti, Proc. Symposium on Non-Fossil Chemical Fuels, Boston, American Chemical Society (1972). P. V. Clark, Fused Salt Mixtures: Eutectic Composi- tions and Melting Points, Sandia Corp. SC-R-68-1680, Albuquerque (1968).