SCUDDING QmS Superior quality and speed in gear cutting ... · PDF fileRing Gear or Sliding...

Transcript of SCUDDING QmS Superior quality and speed in gear cutting ... · PDF fileRing Gear or Sliding...

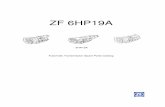

SCUDDING® QmS

Quality meets SpeedSuperior quality and speed in gear cutting

SCUDDING® QmS - Quality meets SpeedSCUDDING® is a continuous gear generating process. Technically, it is a process between gear „hobbing“ and gear „shaping“. The SCUDDING® process can be used for a wide range of symmetrical gear applications as well as for non-symmetrical gear or profile applications such as belt pulleys and synchronizer gears. Many other, non gear-related applications still have to be explored. With the Wera Profilator machine design, the same machine can be used for internal and external SCUDDING® applications.

Ring Gear or Sliding SleeveCompared with shaping, SCUDDING® is very economical because the high number of simultaneously engaged cutting edges eliminates unproductive idle strokes.

Annulus Gear, Internal HelixPreviously, this gear was produced by an internal, helical broaching process. In the future, this gear will be produced considering heat-treat distortions. The SCUDDING® process allows precise and independent corrections/offsets of the gear geometry, crown and taper. These are optimized for the later assembly process. The SCUDDING® process produces diagonally crossed over cutting lines which improve the noise performance of the gear.

Annulus Gear, Internal Straight Blind SplinePreviously, this spline was produced by a shaping process. Since the shaping process needs a certain amount of run-out/over-cut, an undercut was required at the end of a spline. SCUDDING® cuts straight up to the shoulder, no undercut is required! This impro-ves the functional strength of the component!

SCUDDING®

Internal Gear

SCUDDING®

External GearSynchro Gear with 1 Block-ToothFor the gear cutting of synchronizer parts with block-tooth features, SCUDDING® is the perfect process. The parallel incline of the tool and spindle axis allows an easy machining of non-symmetrical gear geometries. The cutting tool (number of teeth) for such an application is designed with a non-passing workpiece/tool-gear-ratio.

HubSCUDDING® is a continuous gear generating process. With the Wera Profilator „Fly-Cutter“ concept, internal and external gears can be produced.For SCUDDING® of helical gears, the tool is designed as a straight gear. The cross-axis angle is set in accordance to the workpiece. SCUDDING® can produce predetermined flank corrections. Taper and crown can be set via the machine parameters.

SCUDDING® QmS

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

1218534242

Datei:

20.0

20.0

500:1

55371911193755

55371911193755

500:1

/

/

mm

mm

-2.260-20.340

111.700108.700

bu/bo

df/da

3

-1

3

3

-1

3

3

0

3

3

-1

3

2

3

4

2

6

6

4

5

6

3

3

5

18

±28

32

4665

7124

7667

456416

2112±14

5522F

fH

ff

F

fH

ff

-11.30 -11.30 -11.30 -11.30 -11.30 -11.30 -11.30 -11.30

110.21 110.21 110.21 110.21 110.21 110.21 110.21 110.21

Auswertemodul:3.0.3.2310(involute)

Formularmodul:3.0.3.2412

6

7

7

5

5

5

2

1

3

Skalierung:Wälzweg

22

±14

16

32

±28

18

0.50

4.00

c:

c:

QaQn Qa6

4

7

9

9

9

Qn9

9

9

Qn9

9

9

Qn9

9

9

Bezugslänge fH : 22.600

µm

µm

µm

µm

µm

µm

mm

µm

mm

µm

65

Ø F fH ff F526 7 fH 3 ff 5

F fH ff3 -1 3Ø F 5 fH 4 ff 3

(DIN 3960)

1.00

1.00

v: 1 mm/s

v: 6 mm/s

11.08.08 - Standmenge Teil 153

DAIMLER Gleichlaufkoerper A 902 262 1135 komplett ohne Nut

QS Profilator GmbH / ZEISS Prismo Bediener Hochheim / Jungk

20.0:1

2.5:1

[...]

[...]

[...]

[...]

DIN_3962

DIN_3962

Zeiss

-GEAR

PRO

3.2.2.17

vom

28.04.2008

Abweichungen im Stirnschnitt

Abweichungen im Stirnschnitt

+ links - - rechts +

+ links - - rechts +

oben

unten

Qa Qa

Bezugslänge fH : 108.920 - 111.580

n 30.000 °z 72

mn 1.500

b 22.600

mm

mm

außen

0.000

x 0.737

db 93.531

°

mm

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

-20.340

-2.260

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

108.920

111.580

1218534242

Datei:

20.0

20.0

500:1

55371911193755

55371911193755

500:1

/

/

mm

mm

-2.260-20.340

111.700108.700

bu/bo

df/da

3

-1

3

3

-1

3

3

0

3

3

-1

3

2

3

4

2

6

6

4

5

6

3

3

5

18

±28

32

4665

7124

7667

456416

2112±14

5522F

fH

ff

F

fH

ff

-11.30 -11.30 -11.30 -11.30 -11.30 -11.30 -11.30 -11.30

110.21 110.21 110.21 110.21 110.21 110.21 110.21 110.21

Auswertemodul:3.0.3.2310(involute)

Formularmodul:3.0.3.2412

6

7

7

5

5

5

2

1

3

Skalierung:Wälzweg

22

±14

16

32

±28

18

0.50

4.00

c:

c:

QaQn Qa6

4

7

9

9

9

Qn9

9

9

Qn9

9

9

Qn9

9

9

Bezugslänge fH : 22.600

µm

µm

µm

µm

µm

µm

mm

µm

mm

µm

65

Ø F fH ff F526 7 fH 3 ff 5

F fH ff3 -1 3Ø F 5 fH 4 ff 3

(DIN 3960)

1.00

1.00

v: 1 mm/s

v: 6 mm/s

11.08.08 - Standmenge Teil 153

DAIMLER Gleichlaufkoerper A 902 262 1135 komplett ohne Nut

QS Profilator GmbH / ZEISS Prismo Bediener Hochheim / Jungk

20.0:1

2.5:1

[...]

[...]

[...]

[...]

DIN_3962

DIN_3962

Zeiss

-GEAR

PRO

3.2.2.17

vom

28.04.2008

Abweichungen im Stirnschnitt

Abweichungen im Stirnschnitt

+ links - - rechts +

+ links - - rechts +

oben

unten

Qa Qa

Bezugslänge fH : 108.920 - 111.580

n 30.000 °z 72

mn 1.500

b 22.600

mm

mm

außen

0.000

x 0.737

db 93.531

°

mm

Profilator GmbH & Co. KG MaschinenbauPostfach 14 41 22

D-42310 Wuppertal

Buchenhofener Straße 35

D-42329 Wuppertal

Phone: +49 (0)202 27 88-0

Fax: +49 (0)202 27 88-100

Internet: www.profilator.de

E-Mail: [email protected]

Gear quality DIN 5-7SCUDDING® produces non-comparable, opposed results:

High cutting force, high gear quality (DIN 5-7) and a low surface roughness (Rz 2-3). Superior quality and speed in gear cutting