Scorpion Motor Noise - JE BB (part)-1

-

Upload

peter-zhou -

Category

Documents

-

view

86 -

download

1

Transcript of Scorpion Motor Noise - JE BB (part)-1

Excellence in motors since 1959 Page : 1

Project Title : Automotive Motor Noise

Prepared By:

Peter Zhou

Excellence in motors since 1959 Page : 2

Define PhaseDefine Phase

Team Charter

Project Leader : Peter Zhou

Name Functional Area Reporting to 1. Paul Tsang HA Q&R xxxx2. CL Chiang C&S Shaft xxxx3. JN Ta Corp. Engg xxxx4. Howard IP Corp. Engg xxxx5. Peter Lai HA Engg xxxx6. LapLeong Ma HA Q&R xxxx7. Pierre Wong JENA xxxx

Excellence in motors since 1959 Page : 3

Define PhaseDefine PhaseProblem Statement :End customer from N.A. complained about NVH issue (i.e. abnormal noise) by shaft gear mating when installed inside the pump unit. All inventory in N.A. has been rejected for sorting in China. For this brand new designed pilot product there was no objective noise measurement standard developed at both sides for grinding noise inspection at certain sensitive frequency (e.g. 1K and 2K Hz)

Goal/Objective Statement :To reduce the current grinding noise defect rate from current 20000 PPM to 5000 PPM with well established shop floor outgoing inspection standard

Projected Business Benefits :Increased market share with further business business expansion; Significant savings on both customer field returned/sorting and shop floor process scrap; Industry NVH application standard development, etc

Excellence in motors since 1959 Page : 4

Define PhaseDefine Phase

Defect DefinitionDefect DefinitionCustomer Complained Two Typical Defects From Field Application- Noise Level Too Loud from Specific High Speed Range (i.e. Speed 10)

- Abnormal Grinding Noise From Specified Frequency Bands Defined

as Human Being Comfortable Zone (i.e. 1 KHz and 2 KHz ). A New

Product Characteristic Has Been Developed As “ Sound Quality” For

Measurement

Before the customer complaints there were no specific technical spec. available.

All field rejection was based on customer subjective judgement.

Excellence in motors since 1959 Page : 5

Define PhaseDefine Phase

Defect Graphic Demonstration By Sound MeasurementDefect Graphic Demonstration By Sound Measurement

Excellence in motors since 1959 Page : 6

Practical Problem Statement:

Customer CTQ (Y): Sound Quality of Gear Mating

Measurable y’s: Noise dBA Level and Sound Quality Index

Continuous or Attribute y? Continuous

Unit: dBA

Sound Quality

Defect: 20000 PPM

Customer Specification: To Be Developed By the Team

Define PhaseDefine Phase

Excellence in motors since 1959 Page : 7

Define Phase

Process Trend Chart - BaselineProcess Trend Chart - Baseline

20000

0

5000

10000

15000

20000

25000

30000

Nov Jan Mar Apr May June JulyMeasureMeasure AnalyzeAnalyze ImproveImprove ControlControl RealizationRealization

BASELINEBASELINE

GOALGOAL

Excellence in motors since 1959 Page : 8

Rating ofImportance to

Customer7 9 8 9 9 7

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15

Mot

or T

otal

Leng

thM

otor

Sha

ft T.

I.R.

Inpu

t/Out

put

Bal

anci

ng

Mot

or G

rindi

ngN

oise

Mot

or V

ibra

tion

Ass

'y M

otor

Sha

ftC

once

ntric

ity Total

Process Step Process Input

1 LaminationHeight

9 0 0 0 0 0 63

2 Shaft Burrs 0 0 0 9 0 0 81

3 Shaft TeethT.I.R.

0 0 7 3 0 90

4Shaft TeethCrowning Value 0 0 0 9 0 0 81

5 Shaft T.I.R. 0 3 3 3 7 127

6 Input BracketConcentricity

0 0 0 0 1 7 58

7 Output BracketConcentricity

0 0 0 0 1 7 58

8 Input BearingConcentricity

0 0 0 0 1 5 44

9 Output BearingConcentricity

0 0 0 0 1 5 44

10ProductBalancing Spec 0 0 9 0 1 0 81

11Lam. ScrewHoleConcentricity

0 0 0 0 0 9 63

12 013 014 015 016 017 018 019 020 0

0

Total 63 0 96 252

99 280

0 0 0 0 0 0 0 0 0

Lower Spec

TargetUpper Spec

Cause and EffectMatrix

This table provides the initial input to the FMEA. When each of the output variables (requirements) arenot correct, that represents potential "EFFECTS". When each input variable is not correct, thatrepresents "Failure Modes".

1. List the Key Process Output Variables2. Rate each variable on a 1-to-10 scale to importantance to the customer3. List Key Process Input Variables4. Rate each variables relationship to each output variable on a 1-to-10 scale5. Select the top input variables to start the FMEA process; Determine how each selected inputvarable can "go wrong" and place that in the Failure Mode column of the FMEA.

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 9

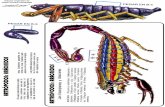

Sub-Assembly ComponentsSub-Assembly Components

Process Capability MeasurementProcess Capability Measurement

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 10

Customer Requirement(Output Variable) Measurement Technique %R&R or P/T

Ratio

UpperSpecLimit

TargetLowerSpecLimit

Cp Cpk SampleSize Date Actions

Shaft Crowning Shaft Teeth Mahr Mchine 77% 7.5 5 0 * -1.34 150 Nov-03 Need to Train Operator for CorrectMeasurement Method

Shaft T.I.R. T.I.R. Indicator 52.88% 0.05 0.025 0 0.8 0.77 37 Nov-03 Need to Change the MeasurementGate Immediately

Input Balancing Input Balancing Meter 8.90% 800 400 0 0.91 0.72 32 Nov-03 Good Gage

Output Balancing Balancing Meter 9.27% 800 400 0 1 0.7 32 Nov-03 Good Gage

Output Hub T.I.R. Hub T.I.R. Indicator 6.09% 0.1 0.05 0 1.17 0.92 31 Nov-03 Good Gage

Key Process Output VariableCapability Status Sheet

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 11

-6 -4 -2 0 2 4 6 8 10

LSL USL

Process Capability Analysis For Shaft eeth Crowning Value

USLTargetLSLMeanSample NStDev (Within)StDev (Overall)

Z.BenchZ.USLZ.LSLCpk

Cpm

Z.BenchZ.USLZ.LSLPpk

PPM < LSLPPM > USLPPM Total

PPM < LSLPPM > USLPPM Total

PPM < LSLPPM > USLPPM Total

10.0000 *

5.0000 -1.3379

1501.570871.64989

-4.03 7.22-4.03-1.34

*

-3.84 6.87-3.84-1.28

1000000.00 0.00

1000000.00

999972.66 0.00

999972.66

999938.84 0.00

999938.84

Process Data

Potential (Within) Capability

Overall Capability Observed Performance Exp. "Within" Performance Exp. "Overall" Performance

Within

Overall

2.00.5-1.0-2.5-4.0-5.5

95% Confidence Interval for Mu

-1.05-1.15-1.25-1.35-1.45-1.55-1.65-1.75

95% Confidence Interval for Median

Variable: History

-1.70000

1.47945

-1.60368

Maximum3rd QuartileMedian1st QuartileMinimum

NKurtosisSkewnessVarianceStDevMean

P-Value:A-Squared:

-1.10000

1.85800

-1.07218

1.90000 0.00000-1.40000-2.50000-6.10000

150-3.6E-01-1.3E-012.71302

1.64713-1.33793

0.3030.431

95% Confidence Interval for Median

95% Confidence Interval for Sigma

95% Confidence Interval for Mu

Anderson-Darling Normality Test

Descriptive Statistics

Incoming Shaft Crowning Value CapabilityIncoming Shaft Crowning Value Capability

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 12

0.0450.0350.0250.0150.005

95% Confidence Interval for Mu

0.0300.0250.020

95% Confidence Interval for Median

Bare Shaft TIR

2.00E-02

8.70E-03

2.23E-02

Maximum3rd QuartileMedian1st QuartileMinimum

NKurtosisSkewnessVarianceStDevMean

P-Value:A-Squared:

3.00E-02

1.39E-02

2.94E-02

5.00E-023.40E-022.50E-021.80E-025.00E-03

37-4.7E-010.2352281.14E-041.07E-022.58E-02

0.5400.310

95% Confidence Interval for Median

95% Confidence Interval for Sigma

95% Confidence Interval for Mu

Anderson-Darling Normality Test

Descriptive Statistics

0.060.050.040.030.020.010.00-0.01

USLLSL

Process Capability Analysis for Bare Shaft TIR

PPM TotalPPM > USLPPM < LSL

PPM TotalPPM > USLPPM < LSL

PPM TotalPPM > USLPPM < LSL

PpkPPLPPUPp

Cpm

CpkCPLCPUCp

StDev (Overall)StDev (Within)Sample NMeanLSLTargetUSL

20695.9512458.49 8237.47

17111.9110395.49 6716.43

0.00 0.00 0.00

0.750.800.750.77

*

0.770.820.770.80

0.01077380.0104519

370.02583780.0000000

*0.0500000

Exp. "Overall" PerformanceExp. "Within" PerformanceObserved PerformanceOverall Capability

Potential (Within) Capability

Process Data

Within

Overall

Incoming Shaft T.I.R. CapabilityIncoming Shaft T.I.R. Capability

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 13

Misc:Tolerance:Reported by:Date of study:Gage name:

0

13

12

11

21

Xbar Chart by OP

Sam

ple

Mean

Mean=11.60UCL=11.92

LCL=11.28

0

1.5

1.0

0.5

0.0

21

R Chart by OP

Sam

ple

Range

R=0.315

UCL=0.8109

LCL=0

10 9 8 7 6 5 4 3 2 1

12.8

11.8

10.8

Part_No

OPOP*Part_No Interaction

Ave

rage

1 2

21

13

12

11

10OP

By OP10 9 8 7 6 5 4 3 2 1

13

12

11

10Part_No

By Part_No%Contribution %Study Var

Part-to-PartReprodRepeatGage R&R

100

50

0

Components of Variation

Perc

ent

Gage R&R (ANOVA) for Shaft Teeth Mahr M/CTwo-Way ANOVA Table With Interaction

Source DF SS MS F P

Part_No 9 11.5875 1.2875 5.1344 0.01148OP 1 11.5282 11.5282 45.9730 0.00008OP*Part_No 9 2.2568 0.2508 5.1881 0.00011Repeatability 40 1.9333 0.0483Total 59 27.3058

Shaft Teeth CH Value Gage R&R

%ContributionSource VarComp (of VarComp)

Total Gage R&R 0.49172 74.00 Repeatability 0.04833 7.27 Reproducibility 0.44339 66.72 OP 0.37591 56.57 OP*Part_No 0.06748 10.15Part-To-Part 0.17279 26.00Total Variation 0.66451 100.00

StdDev Study Var %Study Var %ToleranceSource (SD) (5.15*SD) (%SV) (SV/Toler)

Total Gage R&R 0.701229 3.61133 86.02 72.23 Repeatability 0.219848 1.13222 26.97 22.64 Reproducibility 0.665875 3.42925 81.68 68.59 OP 0.613118 3.15756 75.21 63.15 OP*Part_No 0.259760 1.33776 31.87 26.76Part-To-Part 0.415680 2.14075 50.99 42.82Total Variation 0.815176 4.19816 100.00 83.96

Number of Distinct Categories = 1

GR&R Study For Shaft Teeth CH Mahr M/CGR&R Study For Shaft Teeth CH Mahr M/C

Operator w/ incorrect Measure Method

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 14

In-Process Assembly DataIn-Process Assembly Data

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 15

800700600500400300200

95% Confidence Interval for Mu

550500450400

95% Confidence Interval for Median

Balancing Input

399.463

114.947

430.791

Maximum3rd QuartileMedian1st QuartileMinimum

NKurtosisSkewnessVarianceStDevMean

P-Value:A-Squared:

540.537

190.619

534.178

799.000581.625481.750376.000211.500

32-1.8E-010.36406920557.4143.379482.484

0.6620.268

95% Confidence Interval for Median

95% Confidence Interval for Sigma

95% Confidence Interval for Mu

Anderson-Darling Normality Test

Descriptive Statistics

10008006004002000

USLLSL

Process Capability Analysis for Balancing Input

PPM TotalPPM > USLPPM < LSL

PPM TotalPPM > USLPPM < LSL

PPM TotalPPM > USLPPM < LSL

PpkPPLPPUPp

Cpm

CpkCPLCPUCp

StDev (Overall)StDev (Within)Sample NMeanLSLTargetUSL

14441.1814019.40 421.79

15805.5315297.00 508.52

0.00 0.00 0.00

0.731.110.730.92

*

0.721.100.720.91

144.539146.841

32482.484 0.000

*800.000

Exp. "Overall" PerformanceExp. "Within" PerformanceObserved PerformanceOverall Capability

Potential (Within) Capability

Process Data

Within

Overall

Input Balancing Process CapabilityInput Balancing Process Capability

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 16

Misc:Tolerance:Reported by:Date of study:Gage name:

0

35.3

35.2

35.1

35.0

34.9

34.8

BA

Xbar Chart by Operator

Sam

ple

Mean

Mean=35.00UCL=35.04LCL=34.96

0

0.10

0.05

0.00

BA

R Chart by Operator

Sam

ple

Range

R=0.021

UCL=0.06861

LCL=0

10 9 8 7 6 5 4 3 2 1

35.2

35.1

35.0

34.9

34.8Serial

OperatorOperator*Serial Interaction

Ave

rage

A B

BA

35.3

35.2

35.1

35.0

34.9

34.8Operator

By Operator10 9 8 7 6 5 4 3 2 1

35.3

35.2

35.1

35.0

34.9

34.8Serial

By Serial%Contribution %Study Var %Tolerance

Part-to-PartReprodRepeatGage R&R

140120100

80604020

0

Components of Variation

Perc

ent

Gage R&R (ANOVA) for Stator Lam. Height Two-Way ANOVA Table With Interaction

Source DF SS MS F P

Serial 9 0.65816 0.0731289 127.550 0.00000Operator 1 0.00169 0.0016900 2.948 0.12013Operator*Serial 9 0.00516 0.0005733 1.318 0.28850Repeatability 20 0.00870 0.0004350Total 39 0.67371

U9845 Stator Lamination Heigt Gage R&R%ContributionSource VarComp (of VarComp)

Total Gage R&R 0.000539 2.88 Repeatability 0.000478 2.56 Reproducibility 0.000061 0.32 Operator 0.000061 0.32Part-To-Part 0.018163 97.12Total Variation 0.018701 100.00

StdDev Study Var %Study Var %ToleranceSource (SD) (5.15*SD) (%SV) (SV/Toler)

Total Gage R&R 0.023206 0.119513 16.97 23.90 Repeatability 0.021862 0.112587 15.99 22.52 Reproducibility 0.007785 0.040092 5.69 8.02 Operator 0.007785 0.040092 5.69 8.02Part-To-Part 0.134769 0.694061 98.55 138.81Total Variation 0.136753 0.704276 100.00 140.86

Number of Distinct Categories = 8

GR&R Study For Lamination Height CaliperGR&R Study For Lamination Height Caliper

Good Gage

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 17

Misc:Tolerance:Reported by:Date of study:Gage name:

0

0.06

0.05

0.04

0.03

0.02

BA

Xbar Chart by Operator

Sam

ple

Mean

Mean=0.04025UCL=0.04307LCL=0.03743

0

0.010

0.005

0.000

BA

R Chart by Operator

Sam

ple

Range

R=0.0015

UCL=0.004901

LCL=0

10 9 8 7 6 5 4 3 2 1

0.06

0.05

0.04

0.03

0.02

Serial

OperatorOperator*Serial Interaction

Ave

rage

A B

BA

0.06

0.05

0.04

0.03

0.02

Operator

By Operator10 9 8 7 6 5 4 3 2 1

0.06

0.05

0.04

0.03

0.02

Serial

By Serial%Contribution %Study Var %Tolerance

Part-to-PartReprodRepeatGage R&R

100

50

0

Components of Variation

Perc

ent

Gage R&R (ANOVA) for Output Bracket Hub (T.I.R) Two-Way ANOVA Table With Interaction

Source DF SS MS F P

Serial 9 0.0075725 0.0008414 43.8986 0.00000Operator 1 0.0000025 0.0000025 0.1304 0.72631Operator*Serial 9 0.0001725 0.0000192 2.5556 0.03864Repeatability 20 0.0001500 0.0000075Total 39 0.0078975

Output Bracket Hub T.I.R. Gage R&R

%ContributionSource VarComp (of VarComp)

Total Gage R&R 1.33E-05 6.09 Repeatability 7.50E-06 3.43 Reproducibility 5.83E-06 2.66 Operator 0.00E+00 0.00 Operator*Serial 5.83E-06 2.66Part-To-Part 2.06E-04 93.91Total Variation 2.19E-04 100.00

StdDev Study Var %Study Var %ToleranceSource (SD) (5.15*SD) (%SV) (SV/Toler)

Total Gage R&R 3.65E-03 1.88E-02 24.68 18.81 Repeatability 2.74E-03 1.41E-02 18.51 14.10 Reproducibility 2.42E-03 1.24E-02 16.32 12.44 Operator 0.00E+00 0.00E+00 0.00 0.00 Operator*Serial 2.42E-03 1.24E-02 16.32 12.44Part-To-Part 1.43E-02 7.38E-02 96.91 73.84Total Variation 1.48E-02 7.62E-02 100.00 76.19

Number of Distinct Categories = 6

GR&R Study For Output Hub T.I.R. IndicatorGR&R Study For Output Hub T.I.R. Indicator

Good Gage

Measure PhaseMeasure Phase

Excellence in motors since 1959 Page : 18

Measurement Device : BK 4188 Sound Meter w/ MicrophoneAcoustic Room : 40 dBA Environment Chamber Installation Distance : 26.5 cm Above the PartPC Software : B&K Sound Quality 7698 SystemSound Frequency : 1000 Hz 2000 Hz

Measure PhaseMeasure Phase

Sound Level MeasurementSound Level Measurement

Measured Sound Level (dBA) Will Be Transformed Into Discrete Data In the Specified Frequency, Which Will Be

Added Up Together as the Sound Quality Index.

Excellence in motors since 1959 Page : 19

Speed 10

Frequ

ency

949290888684

3.0

2.5

2.0

1.5

1.0

0.5

0.0

Mean88.89StDev2.793N 16

Histogram (with Normal Curve) of Speed 10

Spee

d 10

95.0

92.5

90.0

87.5

85.0

Boxplot of Speed 10

Descriptive Statistics: dba-10 Variable N N* Mean SE Mean StDev Minimum Q1 Median Q3

dba-10 32 0 88.856 0.535 3.024 84.800 86.100 88.400 90.800

Variable Maximum

dba-10 95.000

Measure PhaseMeasure Phase

Sound Level Data at High Speed 10Sound Level Data at High Speed 10

No Customer Spec. Available Now!

Excellence in motors since 1959 Page : 20

Measure PhaseMeasure Phase

b. Abnormal Noise Defect From Shop floor Per Subjective Standardb. Abnormal Noise Defect From Shop floor Per Subjective Standard

Sound Quality Index Will be Referred If There Was Any ConfusionSound Quality Index Will be Referred If There Was Any Confusion

DPMO Z-Score Cpk Sigma Level

14000 2.20 0.73 3.7

Excellence in motors since 1959 Page : 21

QFD - Noise (1)QFD - Noise (1)

Sta

ckin

g P

ositi

on

Lam

inat

ion

Hei

ght

Fitti

ng D

imen

sion

Ang

le

Wire

Ten

sion

Spi

ndle

Spe

ed

Tric

klin

g A

mou

nt

Tric

klin

g Ti

me

Sur

face

Fin

ishi

ng

Rou

ndne

ss

T.I.R

.

Bal

anci

ng In

put

Cut

ting

Dep

th

Cut

ting

Leng

th

Inpu

t T.I.

R.

Lam

inat

ion

heig

ht

Sur

face

Lev

elin

g

Scr

ew ID

Wire

Ten

sion

Spi

ndle

Spe

ed

Coi

l Hei

ght

Pre

ssur

e

Pus

h-of

f For

ce

Con

cent

ricity

Pre

ssur

e

Pus

h-of

f For

ce

Con

cent

ricity

Shaft Diameter, Crowning value, T.I.R.,Knurling Height, Roundness5Magnet wire Diameter, Coating 2Commutator Roundness, Bar-to-bar, Surface finishing 3Cooling fan ID, Roundness 2Lamination Height, Surface Finishing, Resistance 3Magnet wire Diameter, Tension Strength, Coating 2

Lamination Height, Surface Finishing, Resistance4

Carbon brush Hardness, Resistance 2Ball bearing -input ID, OD, Roundness, Oil Content 3Ball bearing - output ID, OD, Roundness, Oil Content 3Bracket-input ID, OD, Surface Finishing, Roundness, Eccentric, Height5Bracket -output ID, OD, Surface Finishing, Roundness, Eccentric, Height5

57.8

+0.2

/- 0

mm

34.5

+ 0

/- 0.

5 m

m

24.9

+/-

0.1

mm

7.5

+/- 0

.2 d

eg

1000

~ 1

200

g

4.6

~ 5.

6 m

l eac

h

95-9

6 / 1

10-1

11 s

ec

3.5

- 5.5

um

3.0u

m m

ax

0.01

mm

Max

1.8

mm

Max

20 m

m M

ax

0.01

mm

Max

35.0

+/- 0

.25

mm

0.20

Max

3000

g

17.5

mm

Max

700

- 300

0

20kg

Min

60 k

g M

in

72 27 72 72 18 18 36 36 27 27 42 9 27 27 24 36 36 36 12 12 27 12 141 12 141

Matrix

StrongMedium

Weak

Weight

931

Process CapabilityHow Importance

Armature Ass'y

Coi

l Win

ding

Stator Ass'y

Stat

or W

eldi

ng

Part Characteristic Values

Process Parameters (Hows)Bracket Ass'y

Impo

rtan

ce Stac

king

Com

mut

ator

Fitt

ing

Coi

l Win

ding

Tric

klin

g

Com

m. T

urni

ng

Arm

atur

e B

alan

cing

Inpu

t Bra

cket

Fitti

ng B

earin

g

Process Parameter Values

Rot

or

Stat

or

Bra

cket

Part Characteristics (Whats)

Onp

ut B

rack

et

Fi

tting

Bea

ring

1st Priority - Bracket Ass’y

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 22

Qua

lity

Con

trol

Mai

nten

ance

Mis

take

Pro

ofin

g

Trai

ning

Stacking Position 2 2 2 2 1 16Lamination Height 3 1 1 2 1 6Fitting Dimension 3 3 2 3 2 108Angle 3 2 1 3 2 36Wire Tension 4 3 3 2 2 144Spindle Speed 2 2 2 1 1 8Trickling Amount 4 3 3 5 2 360Trickling Time 4 1 2 4 2 64Surface Finishing 3 1 1 3 2 18Roundness 3 3 2 3 2 108T.I.R. 3 2 1 3 2 36Balancing Input 5 1 1 4 1 20Cutting Depth 4 1 1 3 2 24Cutting Length 4 1 1 3 2 24Input T.I.R. 4 3 2 3 1 72Lamination height 3 2 2 2 1 24Surface Leveling 3 2 1 2 1 12Screw ID 4 3 3 3 3 324Wire Tension 4 3 3 2 2 144Spindle Speed 2 2 2 1 1 8Coil Height 3 2 2 2 1 24Pressure 3 2 1 2 1 12Push-off Force 3 2 1 2 1 12Concentricity 4 3 2 3 3 216Pressure 3 2 1 2 1 12Push-off Force 3 2 1 2 1 12Concentricity 4 3 2 3 3 216

Fitting Armature To Output Bracket Shaft Turning Freedom 4 3 3 3 2 216

Screw Fastening 3 2 2 3 1 36Shaft Output T.I.R 4 3 3 3 2 216

Fitting Carbon Brush 0Dimension 3 2 2 2 1 24Push-off Force 3 2 2 2 1 24

Fina

l Ass

'y

Final Ass'y

Cooling Fan Fitting

Arm

atur

e As

s'y

Stacking

Commutator Fitting

Coil Winding

Trickling

Comm. Turning

Armature Balancing

Stat

or A

ss'y

Stator Welding

Coil Winding

Bra

cket

Ass

'y

Input Bracket Fitting Bearing

Onput Bracket Fitting Bearing

Remark

Planning Requirement

Seve

rity

Diff

icul

ty

Freq

uenc

y

Process Parameters (WHAT)

Production Requirement (HOWS)

Abili

ty to

Det

ect

Tota

l Poi

nt

Process Parameter Values

Impo

rtan

ce

Proc

ess

Cap

abili

ty

QFD - Noise (2)QFD - Noise (2)

1st Priority to Monitor Noise

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 23

Pareto Analysis Of QFD Process PlanningPareto Analysis Of QFD Process Planning

0

50

100

150

200

250

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 24

Item# Process / Product ParameterKey process Inputs

Variables [KPIVs](X's)

Key Process OutputsVariables

[KPOVs} (Y's)

Levels of Interest (for each input)

[Process Limit] Specification (for

each input)

Appropriate Test(s) / Analysis

Is Input Vital

(Yes/No)?Comments

1 Armature Stacking Gear Teeth Crowning

Abnormal Noise (dBA/Sound

Quality)

Positive and Negative >5 Multi-Vari Yes

Samples from one

shift

2 Armature Balancing Input BalancingAbnormal Noise

(dBA/Sound Quality)

200 - 1200 mg.cm 500 mg.cm Multi-Vari Yes

Samples from one

shift

3 Armature Balancing Output BalancingAbnormal Noise

(dBA/Sound Quality)

200 - 1200 mg.cm 500 mg.cm Multi-Vari Yes

Samples from one

shift

4 Fitting Armature Into Bracket Bracket Shaft TIRAbnormal Noise

(dBA/Sound Quality)

0.010 - 0.018 mm Nil T-Test No

Samples from one

shift

KPIV Matrix

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 25

67.5 68.5 69.5 70.5 71.5 72.5 73.5

95% Confidence Interval for Mu

67.8 68.3 68.8 69.3

95% Confidence Interval for Median

Variable: dB

A-Squared:P-Value:

MeanStDevVarianceSkewnessKurtosisN

Minimum1st QuartileMedian3rd QuartileMaximum

67.7576

0.4020

67.7714

0.2710.529

68.4333 0.6439

0.4146670.436417-1.63033

6

67.700067.850068.300069.150069.3000

69.1091

1.5794

69.2286

TIR: 0.004

Anderson-Darling Normality Test

95% Confidence Interval for Mu

95% Confidence Interval for Sigma

95% Confidence Interval for Median

Descriptive Statistics

67.5 68.5 69.5 70.5 71.5 72.5 73.5

95% Confidence Interval for Mu

67 68 69 70 71 72 73 74

95% Confidence Interval for Median

Variable: dB

A-Squared:P-Value:

MeanStDevVarianceSkewnessKurtosisN

Minimum1st QuartileMedian3rd QuartileMaximum

66.8151

1.5271

67.6000

0.4050.206

69.9800 2.5489

6.4970.626605-2.47711

5

67.600067.900068.700072.700073.3000

73.1449

7.3245

73.3000

TIR: 0.006

Anderson-Darling Normality Test

95% Confidence Interval for Mu

95% Confidence Interval for Sigma

95% Confidence Interval for Median

Descriptive Statistics

67.5 68.5 69.5 70.5 71.5 72.5 73.5

95% Confidence Interval for Mu

67.5 68.5 69.5 70.5 71.5 72.5

95% Confidence Interval for Median

Variable: dB

A-Squared:P-Value:

MeanStDevVarianceSkewnessKurtosisN

Minimum1st QuartileMedian3rd QuartileMaximum

68.0654

0.9817

67.9000

0.1420.923

70.1000 1.6386

2.685-1.5E-01-3.8E-01

5

67.900068.550070.300071.550072.2000

72.1346

4.7086

72.2000

TIR: 0.002

Anderson-Darling Normality Test

95% Confidence Interval for Mu

95% Confidence Interval for Sigma

95% Confidence Interval for Median

Descriptive Statistics

0 1 2 3 4 5 6 7 8 9 10

95% Confidence Intervals for Sigmas

Bartlett's Test

Test Statistic: 6.505

P-Value : 0.039

Levene's Test

Test Statistic: 1.776

P-Value : 0.208

Factor Levels

0.002

0.004

0.006

Test for Equal Variances for dB

Kruskal - Wallis Test For Shaft T.I.R. - (1)Kruskal - Wallis Test For Shaft T.I.R. - (1)

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 26

Kruskal-Wallis Test: dB versus TIR

Kruskal-Wallis Test on dB

TIR N Median Ave Rank Z0.002 5 70.30 10.7 1.250.004 6 68.30 6.3 -1.410.006 5 68.70 8.9 0.23Overall 16 8.5

H = 2.35 DF = 2 P = 0.310H = 2.35 DF = 2 P = 0.308 (adjusted for ties)

P-Value: 0.889A-Squared: 0.186

Anderson-Darling Normality Test

N: 16StDev: 1.60834Average: -0.0000000

3210-1-2

.999

.99

.95

.80

.50

.20

.05

.01

.001

Prob

abilit

y

RESI1

Normal Probability Plot

Shaft T.I.R. is Not

KPIV

Kruskal - Wallis Test For Shaft T.I.R. - (2)Kruskal - Wallis Test For Shaft T.I.R. - (2)

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 27

2000 500

79

78

77

76

75

74

73

72

output balancing

S1_d

BA

5

-1

Multi-Vari Chart for Speed 1dBA by crowning/output/input balancing

input balancingvaluecrowning

2000 500

83.5

82.5

81.5

80.5

79.5

output balan

S5_d

BA

5

-1

Multi-Vari Chart for S5_dBA by crowning/output/input balancing

input balanc

valuecrowning

2000 500

91.8

90.8

89.8

88.8

87.8

86.8

85.8

output balan

S10_

dBA

5

-1

Multi-Vari Chart for S10_dBA by crowning/output/input balancing

input balanc

valuecrowning

Ch/Input/Outputare KPIVs

for dBA

Multi-Vari Study for KPIV - dBAMulti-Vari Study for KPIV - dBA

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 28

2000 500

41

36

31

output balancing

S1_lo

ud

5

-1

Multi-Vari Chart for S1_loud by crowning/output/input balancing

input balancing

valuecrowning

2000 500

60

55

50

output balancing

S5_lo

ud

5

-1

Multi-Vari Chart for S5_loud by crowning/output/input balancing

input balancing

valuecrowning

2000 500

90

80

70

output balancing

S10_

loud

5

-1

Multi-Vari Chart for S10_loud by crowning/output/input balancing

input balancing

valuecrowning

Ch/Input/Outputare KPIVs

for Loudness

Multi-Vari Study for KPIV - Sound LoudnessMulti-Vari Study for KPIV - Sound Loudness

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 29

Two-Sample T-Test and CI: S1_dBA, Shaft TIR

Two-sample T for S1_dBA

Shaft TI N Mean StDev SE Meana 8 75.34 2.63 0.93b 8 75.86 3.81 1.3

Difference = mu (a) - mu (b)Estimate for difference: -0.5295% CI for difference: (-4.03, 2.98)T-Test of difference = 0 (vs not =): T-Value = -0.32P-Value = 0.753 DF = 14Both use Pooled StDev = 3.27

1 2 3 4 5 6 7 8 9

95% Confidence Intervals for Sigmas

b

a

70 75 80

Boxplots of Raw Data

S1_dBA

F-TestTest Statistic: 0.478P-Value : 0.351

Levene's TestTest Statistic: 1.507P-Value : 0.240

Factor Levels

a

b

Test for Equal Variances for S1_dBA

a b

70

75

80

Shaft TIR

S1_d

BA

Boxplots of S1_dBA by Shaft TI(means are indicated by solid circles)

70 72 74 76 78 80 82

95% Confidence Interval for Mu

73 74 75 76 77 78

95% Confidence Interval for Median

Variable: S1_dBA

A-Squared:P-Value:

MeanStDevVarianceSkewnessKurtosisN

Minimum1st QuartileMedian3rd QuartileMaximum

73.1374

1.7400

73.5455

0.3580.355

75.3375 2.63166.92554

0.4712670.568964

8

71.300073.900074.950077.400079.9000

77.5376

5.3561

78.2158

Shaft TIR: a

Anderson-Darling Normality Test

95% Confidence Interval for Mu

95% Confidence Interval for Sigma

95% Confidence Interval for Median

Descriptive Statistics

a=0.010

b=0.018

Shaft T.I.R. is Not

KPIV

Two Sample T-test For Shaft T.I.R.Two Sample T-test For Shaft T.I.R.

Analyze PhaseAnalyze Phase

Excellence in motors since 1959 Page : 30

Improve PhaseImprove Phase

Problem Statement:Problem Statement:

To optimize assembly process setting with minimum sound level (dBA) and To optimize assembly process setting with minimum sound level (dBA) and sound quality indexsound quality index

Objective:Objective:

223 3 full factorial design to optimize the sound level and sound quality indexfull factorial design to optimize the sound level and sound quality index

Study Factor:Study Factor:

A Shaft teeth crowning value (Lo: -1, Hi: +5)A Shaft teeth crowning value (Lo: -1, Hi: +5)

B Armature input balancing (Lo: 500, Hi: 2000)B Armature input balancing (Lo: 500, Hi: 2000)

C Motor output balancing (Lo: 500, Hi: 2000)C Motor output balancing (Lo: 500, Hi: 2000)

Response Interest:Response Interest:

1) Sound level (dBA)1) Sound level (dBA)2) Sound Quality Index2) Sound Quality Index

Excellence in motors since 1959 Page : 31

Scorpion Motor Speed Range:Scorpion Motor Speed Range:

a.a. Speed 10 - High Speed Speed 10 - High Speed (Sound Level & Sound Quality)(Sound Level & Sound Quality)

b.b. Speed 5 - Medium Speed Speed 5 - Medium Speed (Sound Quality Only)(Sound Quality Only)

c.c. Speed 1 - Low Speed Speed 1 - Low Speed (Sound Quality Only)(Sound Quality Only)

All the three speeds are interested in this DOE study, All the three speeds are interested in this DOE study, Which means the process optimization should resolveWhich means the process optimization should resolveall three speeds abnormal noise issue.all three speeds abnormal noise issue.

Improve PhaseImprove Phase

Excellence in motors since 1959 Page : 32

Improve PhaseImprove Phase

crowningvalue

inputbalancing

outputbalancing Speed 10

-1 500 500 94.65 500 500 88.35 500 2000 93.8-1 2000 500 87-1 500 500 88.65 2000 500 85.95 2000 2000 85.35 2000 2000 86.9-1 2000 2000 86.7-1 500 2000 88-1 2000 2000 88.8-1 2000 500 925 2000 500 85.95 500 2000 89.25 500 500 90.2-1 500 2000 91

crowningvalue

inputbalancing

outputbalancing Speed 1 Speed 5 Speed 10

-1 500 500 40.5 51 82.15 500 500 30.9 50.8 70.25 500 2000 41.6 68.3 97.9-1 2000 500 34.9 51.8 71.7-1 500 500 31.3 51.1 715 2000 500 29.4 48.8 63.75 2000 2000 29.9 50.6 68.25 2000 2000 32.5 49.7 68.8-1 2000 2000 44.3 57.9 67.9-1 500 2000 43.6 56.2 68.9-1 2000 2000 36.3 55 67-1 2000 500 34.2 49.1 75.95 2000 500 32.3 44.7 65.45 500 2000 36 51.6 79.75 500 500 36.9 56.6 82.6-1 500 2000 38.8 57.1 85.5

Sound Level (dBA)Sound Level (dBA) Sound QualitySound Quality

Excellence in motors since 1959 Page : 33

Speed 10Speed 10 – High Speed Sound Level (dBA)– High Speed Sound Level (dBA)

Improve PhaseImprove Phase

Excellence in motors since 1959 Page : 34

0.0 0.5 1.0 1.5 2.0 2.5

C

BC

ABC

AB

A

AC

B

Pareto Chart of the Standardized Effects(response is Speed 10, Alpha = .05)

A: crowningB: input baC: output b

-2 -1 0 1

-1.5

-1.0

-0.5

0.0

0.5

1.0

1.5

Standardized Effect

No

rma

l S

co

re

B

Normal Probability Plot of the Standardized Effects(response is Speed 10, Alpha = .05)

A: crowningB: input baC: output b

Improve PhaseImprove Phase

DOE Study On Sound Level dBADOE Study On Sound Level dBA

Excellence in motors since 1959 Page : 35

crowning val input balanc output balan

87.4

88.2

89.0

89.8

90.6

Sp

ee

d 1

0

Main Effects Plot Speed 10 dBA Means

86

88

90

86

88

90crowning val

input balanc

output balan

-1

5

500

2000

Interaction Plot For Speed 10 dBA

Improve PhaseImprove Phase

DOE Study On Sound Level dBADOE Study On Sound Level dBA

Excellence in motors since 1959 Page : 36

543210-1-2-3-4-5

3

2

1

0

Residual

Freq

uenc

y

Histogram of Residuals

151050

86420

-2-4-6-8

Observation Number

Res

idua

l

I Chart of Residuals

Mean=-3.6E-15

UCL=6.755

LCL=-6.755

9190898887

5

0

-5

Fit

Res

idua

l

Residuals vs. Fits

210-1-2

5

0

-5

Normal Plot of Residuals

Normal Score

Res

idua

l

Residual Plot For dBA Mean

Improve PhaseImprove Phase

DOE Study On Sound Level dBADOE Study On Sound Level dBA

Excellence in motors since 1959 Page : 37

Hi

Lo1.0000D

New

Cur

d = 1.0000

MinimumSpeed 10

y = 85.90

500.0

2000.0

500.0

2000.0

-1.0

5.0input ba output bcrowning

[5.0000] [2000.0] [500.0]

Improve PhaseImprove Phase

Sound Level (dBA) Control OptimizationSound Level (dBA) Control Optimization

Input Balance Plays Dominant to Reduce dBA

Excellence in motors since 1959 Page : 38

86.10

85.90

91.50

89.25

87.75

89.50

89.50

91.60output balan

input balanc

crowning val

5-1

2000

500

2000

500

Cube Plot for Speed 10 dBA

Improve PhaseImprove Phase

The optimal set-up for a minimum sound level (dBA) should be:

Crowning value - 5, input balancing - 2000, output balancing - 500

Excellence in motors since 1959 Page : 39

Speed 1– Low Speed Sound QualitySpeed 1– Low Speed Sound Quality

Excellence in motors since 1959 Page : 40

210

A

C

B

AB

AC

ABC

BC

Pareto Chart of the Standardized Effects(response is Speed 1, Alpha = .10)

A: crowningB: input baC: output b

210-1-2

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

Standardized Effect

No

rma

l S

co

re

A

C

Normal Probability Plot of the Standardized Effects(response is Speed 1, Alpha = .10)

A: crowningB: input baC: output b

Improve PhaseImprove Phase

DOE Study On Sound Quality - Speed 1DOE Study On Sound Quality - Speed 1

Excellence in motors since 1959 Page : 41

output balaninput balanccrowning val

38

37

36

35

34

Sp

eed

1

Main Effects Plot for Speed1 Sound Quality

41

36

3141

36

31

crowning val

input balanc

output balan

2000

500

5

-1

Interaction Plot for Speed1 Sound Quality

Improve PhaseImprove Phase

DOE Study On Sound Quality - Speed 1DOE Study On Sound Quality - Speed 1

Excellence in motors since 1959 Page : 42

-6 -4 -2 0 2 4 6

0

1

2

3

4

Residual

Fre

quen

cy

Histogram of Residuals

0 5 10 15

-10

0

10

Observation Number

Res

idua

l

I Chart of Residuals

Mean=-3.8E-15

UCL=11.12

LCL=-11.12

31 32 33 34 35 36 37 38 39 40

-5

0

5

Fit

Res

idua

l

Residuals vs. Fits

-2 -1 0 1 2

-5

0

5

Normal Plot of Residuals

Normal Score

Res

idua

l

Residual Plot For Sound Quality Mean

Improve PhaseImprove Phase

Excellence in motors since 1959 Page : 43

78.95

76.30

72.30

72.05

75.00

78.20

75.05

76.95

-1 5

crowning val

input balanc

output balan

500

2000

500

2000

Cube Plot (data means) for Speed 1

Improve PhaseImprove Phase

The optimal set-up for a minimum sound quality should be:

Crowning value - 5, input balancing - 2000, output balancing - 2000

Excellence in motors since 1959 Page : 44

Speed 5– Medium Speed Sound QualitySpeed 5– Medium Speed Sound Quality

Improve PhaseImprove Phase

Excellence in motors since 1959 Page : 45

210

C

B

AB

A

ABC

BC

AC

Pareto Chart of the Standardized Effects(response is Speed 5, Alpha = .10)

A: crowningB: input baC: output b

2.52.01.51.00.50.0-0.5-1.0-1.5-2.0

1.5

1.0

0.5

0.0

-0.5

-1.0

-1.5

Standardized EffectN

orm

al S

co

re

B

C

Normal Probability Plot of the Standardized Effects(response is Speed 5, Alpha = .10)

A: crowningB: input baC: output b

Improve PhaseImprove Phase

DOE Study On Sound Quality - Speed 5DOE Study On Sound Quality - Speed 5

Excellence in motors since 1959 Page : 46

output balaninput balanccrowning val

55.8

54.6

53.4

52.2

51.0

Sp

ee

d 5

Main Effects Plot for Speed 5 Sound Quality Mean58

53

4858

53

48

crowning val

input balanc

output balan

2000

500

5

-1

Interaction Plot for Speed5 Sound Quality Mean

Improve PhaseImprove Phase

DOE Study On Sound Quality - Speed 5DOE Study On Sound Quality - Speed 5

Excellence in motors since 1959 Page : 47

2000

500

2000

5005-1

output balancing

input balancing

crowning value

68.50

88.8077.20

67.45

64.55

76.4076.55

73.80

Cube Plot (data means) for Speed 10

Improve PhaseImprove Phase

The optimal set-up for a minimum sound quality should be:

Crowning value - 5, input balancing - 2000, output balancing - 500

Excellence in motors since 1959 Page : 48

31.20

30.85

38.80

33.90

40.30

34.55

41.20

35.90output balan

input balanc

crowning val

5-1

2000

500

2000

500

Cube Plot for Speed1 Sound Quality Mean

50.15

46.75

59.95

53.70

56.45

50.45

56.65

51.05output balan

input balanc

crowning val

5-1

2000

500

2000

500

Cube Plot for Speed5 Sound Quality Mean

68.50

64.55

88.80

76.40

67.45

73.80

77.20

76.55output balan

input balanc

crowning val

5-1

2000

500

2000

500

Cube Plot for Speed10 Sound Quality Index

Improve PhaseImprove Phase

The Optimal Process Set-up In Each Speed is :

Crowning value - 5,

Input balancing - 2000,

Output balancing - 500

Excellence in motors since 1959 Page : 49

70.5 73.0 75.5 78.0 80.5

200015001000500

2000

1500

1000

500

input balancing

outp

ut b

alan

cing

Contour Plot of Speed 10

Hold values: crowning:-1.0

52.5 55.0 57.5

200015001000500

2000

1500

1000

500

input balancing

outp

ut b

alan

cing

Contour Plot of Speed 5

34 36 38 40

543210-1

2000

1500

1000

500

crowning value

outp

ut b

alan

cing

Contour Plot of Speed 1

Improve PhaseImprove Phase

Excellence in motors since 1959 Page : 50

Improve PhaseImprove Phase

KPIV Set Up Optimization From DOE Study KPIV Set Up Optimization From DOE Study

Key Process Input Variables

(KPIV - Xs)SoundLevel(dBA)Speed

10Speed

1Speed

5Speed

10Shaft Teeth Crown 5 5 5 5Armature Input Balance 2000 2000 2000 2000Motor Output Balance 500 2000 500 500

Sound Qual i ty

Output (Y)

Crowning value – 5 Input balancing – 2000 Output balancing - 500

Excellence in motors since 1959 Page : 51

Improve PhaseImprove Phase

a. Restricted Noise dBA Spec.: USL<a. Restricted Noise dBA Spec.: USL<9090 dBAdBA, LSL>40 dBA , LSL>40 dBA

9184777063564942

LSL USLProcess Data

Sample N 16StDev(Within) 1.47754StDev(Overall) 1.74767

LSL 40Target *USL 92Sample Mean 85.5312

Potential (Within) Capability

CCpk 5.87Overall Capability

Pp 4.96PPL 8.68PPU 1.23Ppk

Cp

1.23Cpm *

5.87CPL 10.27CPU 1.46Cpk 1.46

Observed PerformancePPM < LSL 0.00PPM > USL 0.00PPM Total 0.00

Exp. Within PerformancePPM < LSL 0.00PPM > USL 5.99PPM Total 5.99

Exp. Overall PerformancePPM < LSL 0.00PPM > USL 107.23PPM Total 107.23

WithinOverall

Process Capability of Speed 10

Excellence in motors since 1959 Page : 52

Control PhaseControl Phase

BeforeBefore AfterAfter

Assembly Line Scrap – Abnormal NoiseAssembly Line Scrap – Abnormal Noise

Excellence in motors since 1959 Page : 53

Control PhaseControl Phase

b. Abnormal Noise Defect From Shopfloorb. Abnormal Noise Defect From Shopfloor

DPMO Z-Score Cpk Sigma Level

4000 2.65 0.88 4.15

Excellence in motors since 1959 Page : 54

Control PhaseControl Phase

T.I.R. Meter ImprovementT.I.R. Meter Improvement

Before

After

BK Sound Meter DeviceBK Sound Meter Device

Hardw

areSoftw

are

Excellence in motors since 1959 Page : 55

Control PhaseControl Phase

Excellence in motors since 1959 Page : 56

Sample

Sam

ple C

o un

t

60544842363024181261

20

15

10

5

0

_ _NP=4.47

UCL=10.79

LCL=0

Before After

111

1

N P Chart of Defect _ 1 by N ature

Tests performed with unequal sample sizes

Assembly Line SPC – Abnormal NoiseAssembly Line SPC – Abnormal Noise

Control PhaseControl Phase

Excellence in motors since 1959 Page : 57

Control PhaseControl Phase

JE Qual i ty Document Revi sion Ti tl e Responsibl e Due Date Status

DBDQC-CL-HC010-14 Rev.4 WPUN88C0127A Bracket Comm-Quality Control Checklist Simon Tan Nov-03 Done

DBDQC-CL-HC010-12 Rev.3 WPUN88C0126C Bracket Comm-Quality Control Checklist

Simon Tan Dec-03 Done

9708197 Rev.03 Teeth Helica Gear Drawing Peter Lai Dec-03 Done

DBDQC-HA-QC010-01 Rev.02 Scorpion Motor R35000 (U9835)PFMEA Peter Zhou Mar-04 Done

DBEBC-PC-R101006 Rev.03 WPUN98B02005D W.I. Ping Zhao Jan-03 Done

DBEBC-EN-R350001 Rev.01 Noise Measurement Standard JN Ta Jan-03 Done

Corrective Activities Implementation Corrective Activities Implementation

Excellence in motors since 1959 Page : 58

Process Trend Chart - AchievementProcess Trend Chart - Achievement

20000

15000

8000

5500 5000 4600

0

5000

10000

15000

20000

25000

30000

Nov Jan Feb Mar Apr May June JulyMeasureMeasure AnalyzeAnalyze ImproveImprove ControlControl RealizationRealization

BASELINEBASELINE

GOALGOAL

Control PhaseControl Phase

Excellence in motors since 1959 Page : 59

JEHA Customer Situation Settlement

13 13

0

5

10

15

20

25

30

35

40

45

50

Jan Feb Mar Apr May Jun Jul Aug Sep Oct Nov Dec

#CS

0.0

20.0

40.0

60.0

80.0

100.0

120.0

SCT/DCT

Sev erity 2-X Sev erity 1

# of CS cases Ent. DCT

SCT DCT Entitlement

JEHA Customer Situation Settlement

21 19

0

5

10

15

20

25

30

35

40

45

50

w5 w6 w7 w8 w9 w10 w11 w12 w13 w14 w15 w16

#CS

0.0

20.0

40.0

60.0

80.0

100.0

120.0

SCT/DCT

Sev erity 2-X Sev erity 1

# of CS cases Ent. DCT

SCT DCT Entitlement

BeforeBefore AfterAfter

Control PhaseControl Phase

Customer Field Return – High Noise Customer Field Return – High Noise