SCinTE-142-A03-043

description

Transcript of SCinTE-142-A03-043

International Conference ‘Science in Technology’ SCinTE 2015

Evaluation of LNG Bunkering Concept for Greek Sea Territory

G.A. Livanos1*, S. Dimitrellou1, E. Strantzali1, G. Theotokatos1,2

1Technological Educational Institute of Athens, Egaleo, Greece, *[email protected]

2Currently at University of Strathclyde, Glasgow, UK

Keywords: LNG, bunkering methods, small-scale terminal, fuel consumption.

Abstract

This paper presents an LNG bunkering infrastructure concept in the Greek Sea territory for the

distribution of LNG to Greek islands electricity power plants and for ship bunkering. The LNG

consumption is estimated accordingly to the power plant installed capacities in six Greek

islands and the installed power of five passenger vessels operating at the ports of Piraeus and

Patras. The concept of small-scale LNG terminals is proposed that is a feasible and efficient

solution for countries with areas of little or no pipeline infrastructure.

Introduction

The demand for environmental protection has led International Maritime Organization to set

limits on NOX and SOX emissions from ship exhausts, and prohibit deliberate emissions of

ozone depleting substances (IMO, 2008). Special areas designated as Emission Control Areas

(ECA), where emission limits are more stringent, have been already defined. More areas within

the Mediterranean Sea are planned to become future Emission Control Areas. To prepare for

this possible regulatory development, the use of different fuels with less environmental impact

needs to be studied. Using Liquefied Natural Gas (LNG) as a fuel is a very efficient way to

reduce emissions. All SOx emissions are eliminated, the NOx emissions are reduced up to

85%, whereas the CO2 emissions decrease by 25%-30%.

The significant infrastructure in terms of pipeline projects and LNG terminals that have been

developed, are under development or have been proposed in the region of east Mediterranean,

makes LNG a viable solution for Greek ships and also for other LNG needs. In specific, four

gas transport and trading projects (Nabucco, Interconnector Turkey-Greece-Italy, Trans

Adriatic Pipeline, South East Europe Pipeline) are ongoing (Natural Gas Europe, 2013,

Gurbanov, 2014). Moreover, one existing Greek import terminal with current LNG storage

capacity of 130,000 m3 and two proposed Greek import terminals with LNG storage capacities

of 285,000 m3 can support the further distribution of LNG by the common LNG bunkering

methods.

LNG Distribution/Infrastructure Concept

Greek Islands Power Plants. The majority of Greek islands, especially those in Aegean Sea,

are not connected to the mainland electricity grid. Their insular electricity system comprises

oil-fired power plants that cover their demands. The examined Greek islands are: Rhodos,

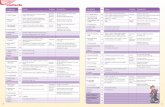

Crete, Samos, Kalymnos and Lesvos and Kos. Table 1 summarize the total annual consumption

of the HFO needed to cover the energy demands for the years 2013 and 2014 and the total cost

of the HFO needed (making the assumption that the current price of HFO is 600€/mt).

Extend Evaluation of LNG Bunkering Alternatives for Greek Sea Territory

2013 2014

Fuel Consumption [mt] 825,868.46 848,544.27

Fuel Cost [€] 495,521,075.37 509,126,564.37

Table 1. HFO total consumption and cost

This study investigates the conversion of the existing power plants in Rhodos, Samos,

Kalymnos and Lesvos, and the installation of new power plants in Crete, Lesvos and Kos.

Table 2 shows the results of the calculation of the LNG consumption for each island power

plant (Johnsson, 2015).

Plant Rhodos Crete Samos Kalymnos Lesvos Kos Total

Total Installed Capacity [MWe] 145 207 24.6 16.4 153 83 629

Average load 80% [MWe] 116 165.6 19.7 13.1 122.4 66.4 503

LNG Cons. at 100% load/day [m3] 1,411.36 1,843.04 226.43 150.95 1,377.00 740.54 5,749.34

LNG Cons. at 80% load/day [m3] 1,129 1,474 181 121 1,102 592 4,599

Annual LNG Cons. 80% load [m3] 412,118 538,169 66,118 44,079 402,084 216,239 1,678,806

Table 2: LNG consumption for power plants

According to the energy demand of 2013 and 2014 the LNG needed for the same years was

calculated. If the energy demand is higher than the energy produced from the LNG

consumption then it is used HFO as additional fuel. Making the assumption that the price of

HFO is 600€/tn and the price of LNG is 35€/MWh, then the total cost for these six islands had

been, also, calculated and it is shown in Table 3. In the last column of Table 3, the fuel cost

savings are given, calculated by the difference of the total costs in Tables 1 and 3.

LNG [tn] HFO [tn] LNG cost [€] HFO cost [€] TOTAL [€] Cost Difference

2013 537,300.83 96,270.49 250,740,386.63 57,762,295.11 308,502,681.73 -187,018,393.64 €

2014 536,934.47 119,443.79 250,569,417.33 71,666,273.37 322,235,690.69 -186,890,873.67 €

Table 3: The total consumption and fuel cost for the six islands

Port LNG nodes. Different types of vessels are sailing at the Greek territory as Ro-Ro, ferries,

bulk carriers, container and general cargo vessels. However, this study is focused on five LNG

fueled passenger vessels. Five of them operate between the main islands at Aegean Sea (sailing

from Piraeus port) and two of them connect Patras port to Italy. The estimation of LNG

consumption is shown in Table 4. We assume that vessel main engines operate at 75% load.

Piraeus Port Patras Port Olympic

Spirit Blue Star

Paros Knossos

Palace Cruise

Europa Super

Fast XI Installed Power MW 4 x 12,6 4 x 4,1 4 x 16,8 4 x 12,6 4 x 12,6

Power @ load kW 37,800 12,300 50,400 37,800 37,800

Running hours /day h 8 14 10 22 22

Energy kWh 302,400 172,200 504,000 831,600 831,600

Fuel consumption MJ 2,531,693 1,441,658 4,219,488 6,962,155 6,962,155

LNG volume m3 119 68 198 326 326

LNG consumption m3/h 15 5 20 15 15

Hours between bunkering h 16 14 20 44 44

LNG cons. between bunkering m3 237 68 396 653 653

Bunkering frequency days 2 1 2 2 2

LNG consumption/ year m3/year 43,316 24,666 72,193 119,118 119,118

LNG consumption/ day m3/day 119 68 198 326 326

Table 4. LNG consumption estimation

International Conference ‘Science in Technology’ SCinTE 2015

Small Scale Terminal Design. The small scale LNG concept shares much of the technology

with traditional large scale LNG. Large scale is about intercontinental transport of millions of

tons LNG from a LNG production unit to an import terminal where the commodity product is

fed into a national pipeline grid system. Small scale LNG on the other hand is more of a

regional business moving hundreds of thousands of tons from the LNG source, using various

modes of transport ranging from ships to semitrailers and ISO containers, directly to end-users.

The most feasible solution for the Greek Sea case is the installation of small scale LNG

terminals in Piraeus Port and Patras port, for the bunkering of the corresponding vessels, and in

each island for the power plant installations.

To determine the storage tank capacity of each small-scale terminal we assume a fill-up interval

of 10 days with a safety inventory of 5 days. The requirement for the heel is 10%. Heel is the

small amount of liquefied natural gas remaining on storage after discharge of the regular LNG

cargo, and is the minimum quantity of LNG necessary to be retained in holding tanks. In each

terminal type C storage tanks to cover the required LNG volume are used, as shown in Table 5.

The tanks shall be filled with LNG up to 85%.

Terminals Required LNG

storage capacity (m3)

LNG tank size (with

25% tank vacuum)

No of

tanks

Single tank

capacity (m3)

Rhodos 18,630 21,918 9 2,450

Crete 24,328 28,621 12 2,400

Samos 2,989 3,516 3 1,200

Kalymnos 1,993 2,345 2 1,200

Lesvos 18,176 21,384 9 2,400

Kos 9,775 11,500 10 1,150

Piraeus Port 6,353 7,474 8 0,950

Patras Port 10,758 12,656 8 1,600

Table 5. Small scale LNG terminals sizing

Fig. 1 illustrates the LNG distribution chain. The import terminal is the existing LNG terminal

of Revithousa Island. For the proposed study a large LNG tank of 100,000 m3 and an export

bunkering reload facility has to be constructed. A LNG carrier of 100,000 m3 capacity will

transfer LNG to Revithousa’s LNG tank once every 10 days.

Figure 1. Small-scale LNG concept and LNG feeder vessel route in Aegean Sea

To distribute LNG between Revithousa import terminal and the small-scale terminals, two

LNG feeder vessels will be used. The first one, with LNG tank capacity of 82,244 m3, will sail

Extend Evaluation of LNG Bunkering Alternatives for Greek Sea Territory

from the import terminal and upload LNG at the small-scale terminals of Piraeus port and

islands. The second feeder vessel, with LNG tank capacity of 10,758 m3, will sail from the

import terminal and upload LNG at the small-scale terminal of Patras Port. Fig. 1 shows the

LNG feeder vessel route from the import terminal to the small-scale terminals (transportation

interval of 10 days).

LNG bunkering (DMA, 2012) can then be subdivided into ship-to-ship bunkering (STS), at

quay or at sea, tank truck-to-ship bunkering (TTS) and/or LNG intermediary terminal-to-ship

via pipeline (TPS). The suitability of a bunkering method to a particular vessel depends on a

number of factors such as, port turn-around time, bunkered volume, voyage range, etc.

Conclusions

In this paper an LNG infrastructure concept in Greek territory is presented, focused on the LNG

demand a) for the Greek islands electricity power plants and b) for five LNG fueled passenger

vessels. The small-scale LNG concept is an effective solution for making natural gas available

to energy users not currently connected to pipeline networks. The concept increases the market

for natural gas by distributing LNG from either a LNG plant, LNG import terminal or directly

from a LNG carrier using a combination of both sea and land based transport directly to the

end-user.

Acknowledgements

This work is conducted in the framework of the project LNG COMSHIP (Greek General

Secretariat of Research and Technology Code: 12CHN400), which is funded by the European

Regional Development Fund (ERDF) and National Resources.

References

DMA, 2012. North European LNG Infrastructure Project - A feasibility study for an LNG filling station

infrastructure and test of recommendations, Copenhagen: The Danish Maritime Authority.

IMO, 2008, Amendments to the Annex of the Protocol of 1997 to Amend the International Convention for the

Prevention of Pollution from Ships, 1973, as Modified by the Protocol of 1978 Relating thereto(Revised

MARPOL Annex VI), Resolution MEPC.176(58).

Johnsson, T., 2015, LNG Action Plan for Europe & Africa 2015, Wärtsilä.

Gurbanov, I., 2014. Implications of the demise of South Stream for southern gas corridor, Strategic Outlook,

December 2014.

Natural Gas Europe, Greek gas sector eyes flexible LNG infrastructure, Date of access: 10/2013.

http://www.naturalgaseurope.com