Scheduling for on-time completion in job shops using feasibility function

-

Upload

attila-lengyel -

Category

Documents

-

view

216 -

download

3

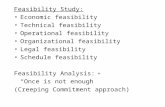

Transcript of Scheduling for on-time completion in job shops using feasibility function

Scheduling for on-time completion in job shops

using feasibility functionq

Attila Lengyela,*, Itsuo Hatonob, Kanji Uedac

aMI-2 Laboratory, Faculty of Engineering, Kobe University 1-1, Rokkodai, Nada, Kobe 657-8501, JapanbInformation Processing Center, Kobe University1-1, Rokkodai, Nada, Kobe 657- 8501, Japan

cRACE (Research into Artifacts, Center for Engineering), The University of Tokyo, Komaba, 4-6-1,

Meguro-ku,

Tokyo 153-8904, Japan

Accepted 20 March 2003

Abstract

This article focuses on job shop type manufacturing systems where a high variety of products of different

volumes are requested to be produce on a tight due date. The feasibility function (FF) is addressed in this article to

schedule jobs in multi-machine random job shop, where the purpose is to minimize unit penalty by achieving a

balance between the number of tardy and early jobs, and reducing the difference between the maximum and the

minimum lateness of jobs. A job shop simulation model based on multi-agent architecture developed by the

authors provides an environment for comparing the FF to commonly used dispatching rules. The results show

the benefit of using the FF. Discussions reveal that this concept is more reliable in case of due dates with different

tightness level.

q 2003 Elsevier Science Ltd. All rights reserved.

Keywords: Job shop; Due date based scheduling; On-time completion; Feasibility function; Multi-agent architecture

1. Introduction

Reliable delivery dates have been of capital importance in make-to-order manufacturing environment

since the beginning of production. Before the industrial revolution a craftsman, a member of a guild

created a unique product by himself fully satisfying the costumer’s requests, planning and scheduling

were based on intuitions. Quality and reliable delivery dates represented the trademark of the craftsman.

0360-8352/03/$ - see front matter q 2003 Elsevier Science Ltd. All rights reserved.

doi:10.1016/S0360-8352(03)00042-1

Computers & Industrial Engineering 45 (2003) 215–229www.elsevier.com/locate/dsw

q This manuscript was processed by Area Editor Maged Dessouky* Corresponding author. Fax: þ81-78-803-6155.

E-mail address: [email protected] (A. Lengyel).

Present manufacturing companies with make-to-order environment yearn for flexibility, quality and

ability of customizing these according to the customer’s requirements. The modern market of high

standard requires high variety of qualitative products, on-time delivery, minimal work in process, short

costumer lead times, and maximum utilization of resources. Unfortunately, these goals are conflicting.

The goal of the modern production scheduling is to strike a profitable balance among these conflicting

objectives (Hopp, Wallace, Spearman, & Mark 1996). The more complex the product and the

manufacturing system are the more complex planning and control techniques are needed, intuitions are

not effective enough anymore.

One of the basic objectives of production scheduling in make-to-order environment is to meet

the due dates. Due-date based scheduling of manufacturing systems has been widely examined in

the related literature. There are several empirical and mathematical models to schedule jobs in shop

floor to obtain better due date performance. Dynamic priority rules are the most used scheduling

algorithms in case of due date related real-time scheduling. Scheduling problems can be defined by

three separate elements: the machine environment, the optimal criterion, and a set of side

constraints and characteristics. In single machine environment earliest due date (EDD) is an exact

algorithm for minimizing the maximum lateness (Jackson, 1955). Dertouzos (1974) proved that in a

context of queuing system, the EDD algorithm is optimal in a following sense: if any algorithm

can schedule a particular task set without missing any deadline, the EDD algorithm can schedule it

as well. Mok (1983) proved that the last slack time (LST) algorithm could also complete the above.

If we have more than one machine, scheduling problems become more complicated. This article is

focused on due-date based dynamic scheduling in job shop type manufacturing systems. Job shops

produce small lots with high variety of routings through the plant with different machines. Each job

has its own route to follow and unique requirements. Recent research results in the field of job

shop scheduling for due date performances point out that the combination of the shortest process

time first (SPT) and the critical ratio with allowance (ALL þ CR þ SPT) scheduling algorithms

gives the best performances (Cheng & Jiang, 1997). Due to the complexity of job shop type

manufacturing systems benchmark problems are still under development. The first expedient

benchmark concept for minimizing maximum lateness was introduced by Demirkol, Mehta, and

Uzsoy (1996). Later discussion will point out that in case of dynamic scheduling a realistic

simulation model with long-term simulation runs may represent a job shop behavior more

genuinely than benchmark problems.

The commonly used due date performance measures are unit penalty, mean tardiness,

maximum and minimum lateness. It is known that tardy jobs may incur tardiness costs, such as

contractual penalties, depending on how late they are. According to the new production

technologies, early jobs may incur earliness costs as well, such as inventory holding costs

(Yeunga, Oguz, & Cheng, 2001). Thus, minimizing average earliness of jobs has become more

important in production scheduling research (Baker, & Scudder, 1989; Lee, Liman, & Lin,

1991). For this performance the minimizing mean absolute and square lateness measurements are

used.

The purpose of the presented research work is to develop a scheduling algorithm that minimizes unit

penalty by balancing between the number of tardy and early jobs and reducing the difference between the

maximum and the minimum lateness of jobs by its nature. This article first introduces a new due date

related performance measurement, and then brings out a new scheduling algorithm, called feasibility

function (FF). The environment of comparing the FF with the other real-time scheduling algorithms is a

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229216

job shop simulation model based on multi-agent architecture. Several simulation runs are analyzed, with

up to 5500 jobs and 15 machines. To represent the behavior of scheduling algorithms a simulation run

with tight due dates is introduced in detail. The evaluation of the simulation results shows the benefit of

using the FF concept if on-time completion is of importance. Discussions reveal that this concept is more

reliable in case of tight due dates.

2. Due date performance measures

2.1. General measures

Due date related performance measures are well-known. Defining dj as the due date and cj as the

completion time of job j; lateness of job j is given by Eq. (1)

Lj ¼ cj 2 dj ð1Þ

The lateness can be positive (indicating a late job) or negative (indicating an early job). Therefore if the

earliness is of importance, then mean absolute lateness or mean squared lateness is considered. Job

tardiness, a related criterion, is defined based on lateness by Eq. (2)

Tj ¼ maxð0; LjÞ ð2Þ

These measures suggest several objectives that one can use to formulate scheduling problems. Two of

them that have become classics are minimizing the summarized tardiness and minimizing the maximum

lateness.

2.2. Completion ratio

In job shops where each job can have unique requirements, length of process times and tightness of

due dates can be different as well. For instance, if we compare two jobs, where the first job has 10 h

process time, due date is 1 day and 2 days tardiness, and the second job has 5 days process time, due date

is 7 days and 2 days tardiness, then the above mentioned measurements cannot reflect a comparable due

date performance of these jobs. Therefore, the proposed performance measurement, completion ratio ðRÞ

is defined by Eq. (3)

Rj ¼dj 2 rj

cj

ð3Þ

where rj denotes the release date of job j: If Rj is less than 1 then the job j is late; if it is equal to 1 then the

completion is on time; if it is more than 1 then the job is finished earlier. Completion ratio has been used

in the research work to evaluate long-term simulation runs.

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 217

3. The scheduling model

3.1. The feasibility function

The proposed dynamic scheduling algorithm is based on the FF. Let us assume that a job has as many

stages in the job shop as the tasks. The job follows its route and waits in the input buffers of machines for

being processed at each stage. A matter of course if there are no other jobs, then the job does not need to

wait, but if there is, then the machine has to sequence the waiting jobs. In the model the machine handles

overdue jobs separately from the other jobs, putting them in a different set. If this set contains elements,

then the machine sequences the overdue jobs and chooses the job with the highest priority given by their

FF. In case the set of overdue jobs is empty then the machine takes the next job to be processed from the

waiting jobs using the FF as well to define their priority. The following notation is used:

t time when the scheduling decision needs to be made,

k the kth task (stage) of job j which is waiting to be processed,

gj total number of stages of job j,

pij processing time of task i of job j,

dj due date of job j.

The importance of starting to process the job j at kth stage before and after its due date is defined in the

proposed model by Eq. (4). This function is the reciprocate formula of the critical ratio (CR) dispatcher

rule. Thus, the function fjðt; kÞ would provide the same performance as the CR but the further analysis of

this function will lead us to the development of the FF used for dynamic scheduling

fjðt; kÞ ¼

Xgj

i¼k

pij

dj 2 tð4Þ

The function fjðt; kÞ has a jump at t ¼ dj point. In case the decision is being made at this point, which is

practically almost inconceivable, the scheduling model considers the job as an overdue job and the value

of fjðt; kÞ function as infinity, see Eq. (5). If t passes dj; the job is overdue, and is taken to the set of

overdue jobs. After this point the values of the function are negative, but as mentioned above the set of

this type of jobs is handled separately

fjðt; kÞ ¼

1 if t ¼ dj

Xgj

i¼k

pij

dj 2 totherwise

8>>>><>>>>:

ð5Þ

Values of fjðt; kÞ are driven by the remaining time till the due date and the remaining process time of job

j: As mentioned in Section 1, in a job shop jobs can have different process time length and due date

tightness. If scheduling was done by using only fjðt; kÞ; then a job with long process time would always

have higher priority than a job with short process time, and the latter would surely be late in most cases.

The already existing algorithms use only slack and remaining process time related formulas. The later

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229218

introduced simulation results show that in case these algorithms are used for dynamic scheduling,

discriminated jobs appear in the shop and stay in queue without being processed. To be able to compare

the due date related priority of these types of jobs the partial differential by t of their fjðt; kÞ function is

taken, because the time-derivate will show the intensity of the changes of the priority values defined by

the fjðt; kÞ function independently from the magnitude. The differential by t is proposed to be called in the

model the FF of job j; see Eq. (6)

FFjðt; kÞ ¼

1 if t ¼ dj

›

›tfjðt; kÞ ¼

Xgj

i¼k

pij

ðdj 2 tÞ2otherwise

8>>>><>>>>:

ð6Þ

The graphs of Figs. 1 and 2 show examples of possible FF values during production process. In Fig. 1

the k value of the job showed in the figure does not change over the time. As it can be seen that the FF of

the job is monotone increasing till the due date and monotone decreasing after t passes the due date.

Therefore, in the set of the overdue jobs the job, which has the lowest FF value, will have the highest

priority.

Fig. 1. The job j without changing its stage.

Fig. 2. The job j passing through the shop floor.

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 219

3.2. The real-time scheduling algorithm

The FF shows how important it is to start processing the jobs and not let them miss their due dates. Let

L denote the set the overdue jobs in the input buffer of a machine and W the set of the remaining waiting

jobs, then the machine chooses the next job to be processed using the algorithm defined by Eq. (7), where

kj denotes the stage of the job j:

max½FFjðt; kjÞ�; j [ W if lLl ¼ 0

min½FFjðt; kjÞ�; j [ L otherwise

(ð7Þ

Baker and Kanet (1983) and Cheng and Jiang (1997) declared that a due date based scheduling algorithm

works better if it is combined with the SPT algorithm or another algorithm to minimize mean flow time

in job shops. The model uses a component of Baker’s modified operation due date (MOD) algorithm

described by Eq. (8)

ajðkÞ ¼

Xgj

i¼k

pij

pkj

ð8Þ

Eq. (8) gives higher priority to a job having a short operation task at stage k with a long remaining

process time. Due to the behavior of the FF giving decreasing value to a job spending time in the shop as

overdue, for the set of overdue jobs the reciprocate formula of ajðtÞ is applied. The modified feasibility

function (MFF) based scheduling algorithm defined by Eq. (9)

max½ajðkjÞFFjðt; kjÞ�; j [ W if lLl ¼ 0

min1

ajðkjÞFFjðt; kjÞ

" #; j [ L otherwise

8>><>>: ð9Þ

Both FF and MFF have been implemented into a job shop simulation model based on multi-agent

architecture to compare their behavior to other common used algorithms.

4. The simulation model

4.1. The job shop model

The job shop scheduling problem is widely acknowledged as one of the most difficult NP-complete

problems encountered in practice. Job shop type manufacturing systems consist of different machines

with unique capabilities. In case of dynamic scheduling problem the arrival of jobs is continuous, the

time interval between the arrivals is mainly set by statistical analysis of the modeled real manufacturing

system. Decreasing or increasing the time interval causes higher or lower demand and shop floor

utilization. When a job arrives at the system, a task list is assigned to it where the routing of the job is

defined. Each row of the task list denotes one task. A task consists of the required machine for the

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229220

operation and the expected operational time. Depending on job routing there are two types of job shops:

classic job shop and job shop with recirculation. In the latter a job may visit a machine more than once,

whereas in the former it does not. The type of the introduced simulation model is classic job shop. In case

of classic job shops a machine of the shop can be chosen to each task with the same probability, but one

machine can appear in the task list only once. Depending on how many machines the job shop consists of

the variation of the task list is limited, but combinatorially increasing by the number of machines.

The due date of the arriving jobs is set externally using static due date setting methods. In case of

externally set due dates the shop loading parameters are not considered in the due date setting method.

Two static due date setting methods have been used: the allowances proportional to work content (TWK)

method (Eq. (10)) and constant allowance (CON) method (Eq. (11))

dj ¼ t þ mXgj

i¼1

pij ð10Þ

dj ¼ t þ C ð11Þ

where m denotes the allowance multiplier and C the constant flow allowance (Veral, 2001). In the

simulation run series m and C are changed to set the due date tight, medium or loose, but during one

simulation run the due date setting method and the allowances are not changed. Thus, with one set of

jobs and one scheduling algorithm six different simulation runs have been examined.

4.2. Agent architecture of the model

The simulation model has been developed to meet the requirements of high flexibility and

compatibility. Multi-agent architecture has been found to be the most suitable for the purpose of

changing the layout, the shop parameters and the used dispatcher rules by the machines of the job shop

model with the highest effectiveness. However, in the model based on multi-agent architecture to verify

the later introduced simulation results any type of random multi-machine job shop simulation model

can be used. Further research directions of the authors led to the development of the multi-agent

architecture model. Three types of agents have been built: management agent, job agent and machine

agent (see Fig. 3).

The management agent creates jobs by the given time interval of job arrivals which has been set

randomly using uniform distribution between 1 h 30 min and 2 h. After the creation of a new job the

agent generates the task list. Due to the classic job shop type model the number of rows in the task list is

equal to the number of machines implemented in the job shop. The model consists of 15 machines. For

each task a machine is assigned randomly, and the operational time is set between 3 min and 3 h using

uniform distribution as well. When the generation of the task list is finished, the overall process time of

the job can be calculated and the due date defined. For one simulation run a due date setting method and a

due date tightness is chosen, the values of the allowances can be seen in Table 1. The new job with its

task list and due date is assigned to a job agent and the processing of the job starts.

The job agents manage the completion of the jobs. Each job has one job agent carrying all necessary

information about its job, thereby the information flow and the material flow handled in the model by this

agent. Following the task list the agent sends the job from machine to machine through the shop floor

finding the shortest way between them. However, the transportation time is always minimized, it is not

counted to the simulation time in order to make the reproduction of the simulation results independent of

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 221

the layout of the shop floor, therefore the transportation time is equal to zero in every case. When a job

enters the input buffer of a machine, the agent provides the expected operational time and the required

information for the dispatcher mechanism. This information consists of the due date and the remaining

process time of the job. When all tasks are completed the job is driven into the output of the shop floor

and the job agent collects the statistical data of the job completion and calculates the required due date

performance measurements. This information is gathered and summarized for the simulation run by

the management agent. The number of job agents is not limited; it depends on the number of jobs in the

shop at a time. The life cycle of the job agent starts at a new job arrival and ends on completion of the job.

Fig. 3. The simulation model.

Table 1

The values of allowances in case of different due date tightness

CON C (days) TWK m

Due date tightness tight 4 3

medium 6 5

loose 8 7

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229222

Machine agents sequence the jobs in the buffers of the machines and choose the next job to be

processed when a machine is or becomes free. Each machine is assigned to one machine agent, as

mentioned above the model consists of 15 machines, thus the number of the machine agents is 15 as well.

Due to the multi-agent architecture the number of machines can be extended or reduced easily. When the

management agent generates the task list for the new job the agent broadcasts a message to be a part of

the task list to all active machine agents. The management agent puts all answers into a list and from this

list creates the tasks list assigning one task to one machine randomly. The job agents do the routing of a

job between the machines. When a job leaves a machine the job agent reads from the task list the next

destination and finds the position of the machine and the way to it by exchanging the routing information

with the machine agent of the destination. The routing information is created when a new machine and

machine agent are placed in the shop.

The machine agent can sequence the jobs by using several dispatcher rules, but for one simulation run

the agents use only one and the same type of rule chosen for the run in order to be able to compare the

performances of different scheduling methods. Eight dynamic scheduling algorithms are available for

the machine agents:

† FF—feasibility function,

† MFF—modified feasibility function,

† EDD—earliest due date,

† LST—least slack time,

† CR—critical ratio,

† MOD– modified operational due date: for each operation of job j the MOD generates a due date

denoted by dkj: The machine agent chooses the next job to be processed from the input buffer which

has the earliest operational due date (Armentano & Rigao, 2000). The calculation of dkj can be seen in

Eqs. (12) and (13).dkj ¼ max{dkj; t þ pkj} ð12Þ

dkj ¼ dk21;j þ djpkj

Xgj

i¼k

pij; d0j ¼ 0 ð13Þ

† ALL þ CR þ SPT—the combination of the critical ratio and the shortest process time first (ALL

stands for allowance): for this rule two separate queues are created for each machine, as in the case of

FF and MFF. The queue of the already overdue jobs has priority over the other. For this queue the SPT

rule is employed, but if this queue is empty the CR þ SPT rule is used for the secondary queue.

The CR þ SPT operates the same way as the MOD, but the calculation of dkj is different. See

Eqs. (14)–(16).dkj ¼ max{t þ bðtÞpkj; t þ pkj} ð14Þ

bðtÞ ¼ ajðtÞ

Xgj

i¼k

pij ð15Þ

ajðtÞ ¼ dj 2 t ð16Þ

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 223

† S/RPT þ SPT—the combination of the slack per remaining process time and the shortest

process time first: in this case the dkj of job j defined as

dkj ¼ max{t þ gðtÞpkj; t þ pkj}; ð17Þ

gðtÞ ¼ sjðtÞ

Xgj

i¼k

pij; ð18Þ

sjðtÞ ¼ ajðtÞ2Xgj

i¼k

pij: ð19Þ

The above introduced job shop simulation model based on multi-agent architecture is suitable

to form various types of random job shops. The number of machines, the due date setting

algorithms, the task list creation, the random number generation, the applied scheduling method

and the time interval between job arrivals can be changed effortlessly.

5. Simulation runs and results

One simulation run includes one year time period. The same set of jobs has been given to each

scheduling algorithm at one examined situation. The following due date performance measures were

considered:

SU summarized unit penalty,

ST summarized tardiness (days/h),

SW W of job j is 1 if the Cj is within ^20% of dj(due window),

Lmax maximum lateness (days/h/min),

Lmin minimum lateness (days/h/min),

MAL mean absolute lateness (days/h/min),

MSL mean square lateness [s2],

Rmax maximum completion ratio,

Rmin minimum completion ratio,

MR mean completion ratio.

The first introduced case from the simulation runs is when the due dates are set by TWK with a small

m allowance generating very tight due dates, where the main comparison criteria is minimizing the mean

absolute lateness and mean squared lateness. In case of loose or medium due dates the performances of

the scheduling algorithms are very similar and the comparison difficult. Scheduling is the most needed in

chaotic situation, because if there are many jobs with tight due date then the decision making of the

scheduling mechanism influences due date performances the most. The simulation result can be seen in

detail in Tables 2 and 3. The number of finished jobs was 5500.

As can be seen, if all known due date performance measures are considered, the best algorithm cannot

be pointed out. The combined algorithms work better than the single due-date and slack-time based

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229224

algorithms with these parameters. The summarized unit penalty was decreased the most by MFF, but

many finished jobs are out of the due window. The mean absolute lateness is the best at

ALL þ CR þ SPT, but the maximum lateness is 84 days. At MFF the maximum lateness and mean

square lateness is conspicuously very low. The mean completion ratio is almost the same for the four

best. One can suppose that there is no suitable data view to get the real characteristic of these algorithms.

But if a graph from the completion ratio of all finished jobs is created, a closer data view can be

presented, (see Fig. 4).

Analyzing the graphs of Fig. 4, a view inside of the behavior of the best four algorithms can be

observed. The first 2000 jobs had achievable due dates, but after that point due to the randomly chosen

parameters the utilization of the machines became much higher than at the beginning, from the average

75% dropped to 92%. In the first section before the 2000th job, MFF completed most jobs before their

due date. This is the reason that the unit penalty is the lowest in the case of MFF. After this section the

situation turned to a chaotic one, the completion ratio values are always under 1, none of the jobs were

completed before the expected due date. In the graphs it can be seen why MFF has conspicuously the low

maximum lateness. However, the other algorithms have similar or better performances in summarized

tardiness, mean absolute lateness and mean completion ratio, the behavior of these algorithms is

Table 2

Simulation results of classical scheduling algorithms (classic, TWK, tight due date)

EDD LST FF CR

SU 4812 4780 4420 4298

ST 9456/03 8955/13 8674/08 7688/05

SW 1582 1666 1711 2111

Lmax 4/02/40 3/12/55 4/23/14 5/19/48

Lmin 23/23/35 23/19/12 23/19/12 23/21/55

MAL 1/20/01 1/17/54 1/17/15 1/12/14

MSL 3.31 £ 1010 3.01 £ 1010 3.11 £ 1010 2.66 £ 1010

Rmax 4.75 4.05 4.05 4.33

Rmin 0.41 0.43 0.42 0.41

MR 0.77 0.78 0.82 0.81

Table 3

Simulation results of combined scheduling algorithms (classic, TWK, tight due date)

ALL þ CR þ SPT S/RPT þ SPT MOD MFF

SU 4171 4071 3921 3437

ST 3733/12 3887/14 7583/2 4186/03

SW 4309 4298 4337 2983

Lmax 84/23/24 87/08/13 190/06/17 3/00/10

Lmin 24/00/53 2 3/08/13 23/23/35 23/21/18

MAL 00/20/00 00/20/33 1/12/44 00/23/18

MSL 4.85 £ 1010 5.12 £ 1010 5.88 £ 1011 9.74 3 109

Rmax 4.75 4.75 4.75 4.36

Rmin 0.047 0.046 0.023 0.55

MR 0.94 0.94 0.94 0.92

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 225

unusual. They left many jobs in the job shop for several weeks. Notice that all four handle the overdue

jobs separately from the other jobs as MFF does. This behavior can emerge due to the combination of the

SPT and slack-time based algorithms. If the combined algorithm gives higher priority to a job with

shorter process time then it can happen to the jobs with large process time never to be processed. This

explains the very large maximum lateness. Contrary to these algorithms the MFF tries to complete all

jobs with the same completion ratio. The other simulation runs with tight due dates confirm the above

introduced results. A summary of the all simulation run series can be seen in Tables 4 and 5.

If the tightness of the due date changes then the other algorithms perform better in MSL in case of the

TWK due date setting method. Because of the m allowance multiplier the jobs with short process time

Fig. 4. Completion ratio of finished jobs.

Table 4

Mean square lateness results of the simulation runs.

ALL þ CR þ SPT S/RPT þ SPT MFF

TWK Tight 4.85 £ 1010 5.12 £ 1010 9.74 3 109

Medium 8.34 £ 109 8.30 3 109 9.68 £ 109

Loose 2.97 3 1010 3.02 £ 1010 3.31 £ 1010

CON Tight 3.85 £ 1010 3.98 £ 1010 2.33 3 1010

Medium 3.98 £ 1010 7.95 £ 1010 6.95 3 109

Loose 3.48 £ 1010 2.96 £ 1010 2.88 3 1010

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229226

get tighter due date than the other jobs. It is known from the results analyzed above that

ALL þ CR þ SPT and S/RPT þ SPT favor short process times. But in case of CON due date setting

method the jobs have very different tightness level, because they get the same time period to complete

jobs even though they have different process times. When the due dates are set by CON then the MFF

performs always better MSL than the other algorithms, including the single due-date based scheduling

algorithms, too. MFF minimizes not only MSL but unit penalty in all examined situations as well. This

confirms that MFF works with a good effectiveness in due-date based scheduling of classic job shop

problems. In case of CON with the tightest set the MSL value of MFF is the lowest compared to the

average value of the other two algorithms in different tightness level set by CON. It means that MFF has

a good control over the scheduling process rendering the job completion time as close as possible to the

due date in different tightness levels.

6. Discussions

6.1. On-time completion

The new production trends define earliness as a performance measure in manufacturing systems.

Therefore, the latest research works in due-date based scheduling try to balance between the earliness

and tardiness of jobs. After having examined and analyzed all simulation runs over 50 situations and

eight scheduling algorithms with the same detail as the first problem was it can be established that the

balance between earliness and tardiness depends on variable parameters and component of the

manufacturing system, first of all the due-date setting policy and the mean utilization of machines in

the shop. In case of low utilization and loose due dates it is not required to consider mean flow time,

moreover maximizing mean flow time may affect better tardiness–earliness balance, otherwise the mean

absolute earliness is too high. In this case the combined algorithms complete every job too early. In the

opposite situation where due dates are tight and utilization of machines is very high then the combined

algorithms can present their quintessence. There are a powerful lot of combinations of all parameters and

components. To define a scheduling algorithm that works the best in all these situations, cannot be done

in dynamic manufacturing environment by classical scheduling algorithm approach. Aydin and Oztemel

(2000) introduced an example for reinforcement learning based dynamic scheduling in job shops.

They implement a central scheduler using the reinforcement learning approach to minimize tardiness of

jobs that chooses SPT or CR depending on the manufacturing environment. However, their problem

Table 5

Summarized unit penalties of the simulation runs

ALL þ CR þ SPT S/RPT þ SPT MFF

TWK Tight 4171 4071 3437

Medium 2263 2068 30

Loose 79 42 0

CON Tight 4722 4726 4333

Medium 2503 2575 1420

Loose 102 104 0

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 227

frame is simple and their results promising. The new approaches for manufacturing optimization

problems are generally based on artificial intelligent methods. Ueda (2001) presents an overview on the

problem frames and their suitable problem solver approaches in manufacturing systems and clarifies

emergent synthesis for the most complex problem frames combination. These approaches provide a

wide area of possible methods to solve the earliness-tardiness balance problem in different types of job

shops.

6.2. Benchmarks vs. long-term simulation runs

In Fig. 4 long time simulation runs have been shown due to completion ratio data view

approach. The graphs of Fig. 4 represent more than 5000 job performances. The graphs can be

separated in different sections. In the first section (at the beginning of the simulation), the behavior

of job completion is different from the later sections, even though the parameter setting method has

not been changed. The complexity of job shop type manufacturing systems is very high. If the job

shop is empty and there is an amount of jobs available for the scheduling method at the same time

to be sequenced then the flow time of the first chosen jobs are always lower than the later chosen

jobs. Benchmark problems assume batch-scheduling problem with 10,100 or 1000 jobs, where the

arrival time is the same for all jobs and the due dates are randomly set with different tightness

level. The difference between tightness levels can be given by the coefficients of the due date

setting methods. Therefore scheduling algorithms in simulation runs with benchmarks, sequences

jobs by tightness levels. In case the tightness levels are defined, the scheduling algorithms perform

very similar. The differences of the measure values are not obviously large enough to distinguish

the performances of the scheduling algorithms. For instance, in benchmark problems it would not

have turned out that the existing combination of the shortest process time and due-date based

algorithms leave jobs in the job shop for relatively large time period generating giant lateness for

discriminated jobs. In batch scheduling these jobs would go through the plant and their lateness

would be influenced by the maximum completion time. The more complex the manufacturing

system is, the larger benchmark problems. A realistic simulation model with long-term simulation

runs may represent a job shop behavior genuinely.

7. Conclusion and future work

The presented research work verifies the establishment of the former research results in the field

of job shop due-date scheduling. The algorithms that combine minimizing mean flow time and on

time completion criteria work better in job shop scheduling problems. Single due-date based

algorithms are not effective enough, because they do not consider the aspect of rational job

sequencing in job shops, they use only slack time related sequencing. However, in case of loose

due dates they perform as good as the combined algorithms. Due to the longer mean flow time

they may approach the due dates in the due window more intensively.

The FF-based algorithm introduced in the presented research work operates the most effective in job

shop scheduling if ontime completion is of importance. The unit penalty and the mean square lateness

decreased with higher effectiveness compared to the other existing algorithms in case the tightness of

due-dates are high or different for each job.

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229228

The future work will focus on dynamic due-date setting method to be able to set the due date tightness

according to the fluctuation of the shop floor utilization. During the simulation runs the average FF of

jobs was monitored. When the on time completion was in a reassuring way then the average value was

determined directly. When the utilization of the machines was increasing then the average value started

to oscillating and when it turned to a chaotic situation then the value was very high. The aim of the future

research work is to develop a management agent with reinforcement learning method that sets tightness

of due dates dynamically adopting the fluctuation of the demand and the shop utilization.

References

Aydin, M. E., & Oztemel, E. (2000). Dynamic job-shop scheduling using reinforcement learning agents. Robotics and

Autonomous Systems, 33(3), 169–178.

Baker, K. R., & Kanet, J. J. (1983). Job shop scheduling with modified due dates. Journal of Operations Management, 4,

11–22.

Baker, K. R., & Scudder, G. D. (1989). Sequencing with earliness and tardiness penalties: a review. Operations Research, 38,

22–36.

Cheng, T. C. E., & Jiang, J. (1997). Job shop scheduling for missed due date performance. Computers & Industrial Engineering,

34(2), 297–307.

Demirkol, E., Mehta, S., & Uzsoy, R. (1996). Benchmarks for shop scheduling problems. European Journal of Operational

Research, 109, 137–141.

Dertouzos, M. L (1974). Control robotics: The procedural control of physical processes. Proceedings of the IFIP Congress

(pp. 807–813)

Hopp, Wallace J., Spearman, Mark L., (1996). Factory physics. Times Mirror Company

Jackson, J.R., (1955). Scheduling a production line to minimize maximum tardiness. Management Science Research Project

Report 43. University of California

Lee, C. Y., Liman, S. D., & Lin, C. S. (1991). Minimizing weighted number of tardy jobs and weighted earliness tardiness

penalties about a common due date. Computers and Operations Research, 18, 379–389.

Mok, A. K (1983). Fundamental Design Problems of Distributed Systems for the Hard-Real-time Environment. PhD thesis.

Massachusetts institute of technology

Ueda, K. (2001). Emergent synthesis. Artificial Intelligence in Engineering, 15(4), 319–320.

Veral, E. A. (2001). Computer simulation of due-date setting in multi-machine job shops. Computers & Industrial Engineering,

41, 77–94.

Yeunga, W. K., Oguz, C., & Cheng, T. C. E. (2001). Single-machine scheduling with a common due window. Computers and

Operations Research, 28(2), 157–175.

A. Lengyel et al. / Computers & Industrial Engineering 45 (2003) 215–229 229