Sandvik Breakers - Parts & Tools (2011)

-

Upload

massenterprises-bangalore -

Category

Documents

-

view

653 -

download

7

description

Transcript of Sandvik Breakers - Parts & Tools (2011)

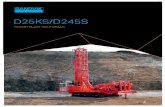

Sandvik breakers Parts and tools

2

Sandvik Mining and Construction, the world-leading manufacturer of hydraulic

breakers, has been setting the standards for breaking for over three decades. Sandvik,

through its former Rammer brand, was the first manufacturer to offer large and heavy-

duty hydraulic rock breaking hammers for tough conditions. Sandvik has continued

this tradition of technological advancement and innovation by leading the way on

productivity, reliability and customer solutions.

Our state-of-the-art factories produce a comprehensive range of breakers, cutter-

crushers, pulverizers and breaker boom systems to meet the needs of our customers in a

variety of fields such as demolition, recycling, mining, construction and quarrying.

Sandvik breakers are sold and supported through a global dealer and distributor

network that provides a comprehensive parts and after sales support service. The

expertise of the distribution network is always available to support the products and

assist our customers.

Regardless of your industry, application or geographic location, Sandvik has a complete

range of advanced hydraulic breakers, demolition attachments backed by an unrivalled

after sales support service to meet your specific needs.

Sandvik breakers in Action

3

ContentsInTROduCTIOn 5.

CHOOSInG THE RIGHT TOOL 6.

THE RIGHT TOOL FOR THE RIGHT APPLICATIOn 7.

COMPACT And SMALL RAnGE 8.

MId RAnGE 10.

MId MOduLAR RAnGE 11.

LARGE RAnGE 12.

PROPER TOOL MAInTEnAnCE 13.

TOOL AnALySES 14.

RAMLubE 15.

VIdAT 16.

PART AnALySES 17.

AuxILIARy PROduCTS 18.

dEMOLITIOn TOOLS 19.

4

Sandvik breakers Parts and tools

Sandvik Mining and Construction recognises that all our breakers and attachments are

only ever as good as the parts and tools they use.

Which is why our genuine parts and tools utilize the best raw materials and heat

treatment characteristics to ensure optimum durability across a broad range of

industries, materials and applications.

These parts and tools are available through a highly experienced global dealer network

that is unparalleled within our industry and which ensures that you get the right part or

tool, to the right place, at the right time.

during recent years Sandvik has researched tool design that will provide our customers

longer service life and better value. Sandvik's innovative tool design and world wide

testing programs have resulted in improved wear characteristics and greater durability

for our tools for a broader range of applications. Several new tools have been designed

with job specific requirements in mind.

Breaking application - Impact breaking

Impact breaking applications include boulder breaking and heavily reinforced concrete

breaking. The tool will typically not penetrate the material, as the material is broken

by destructive stress waves generated by the breaker, being transmitted through the

tool into material, for example granite boulders, diorite, quartzite, heavily reinforced

concrete, etc.

Breaking application - Penetrative breaking

Penetrative breaking applications include general concrete demolition, removal of soft

rock, and frozen and hard ground. The material is broken by a combination of impact

energy and a `wedging' effect which forces the material to be separate as the tool

penetrates, for example concrete, pudding stone, marl, etc.

5

6

Choosing the right toolSeveral factors must be identified in the process of choosing the correct tool for

any specific job application. First one must determine if the job is an `impact' or

`penetrative' breaking application. Sandvik has introduced several tool models designed

with `job specific' work requirements, providing excellent value, long life and maximum

performance.

In the `impact' applications, one must identify the level of abrasive characteristics in the

material. The Sandvik Super blunt tools provide excellent wear characteristic and long

life in applications breaking highly abrasive oversize materials, for example.. high silica

content boulders.

Primary breaking of hard rock will require the Sandvik Hard Rock Chisel. This tool is

geometrically designed for the highest production possible and long service life. In the

event the rock is very hard and homogenous, re-sharpening of the contact point may be

required.

Penetrative applications such as the breaking of limestone and non-reinforced concrete

require the Sandvik Limestone Chisel. Compared to standard chisel tools, the Sandvik

Limestone Chisel is specially designed for faster penetration while reducing the idle

blow effects caused by soft materials applications.

Correctly matching the right tool to the job application is critical to achieving the

highest level of production with lowest possible operating costs.

use always original Sandvik tools.

Training

Sandvik also offers product specialist training on all its products as well as operator

training to ensure that you and your investment are achieving the best results.

For more information on the training courses on offer by Sandvik please contact your

local dealer or nearest Sandvik office.

The right tool for the right application

Sandvik standard chisel tool

- For nonabrasive but tough rock or concrete

- For material which has low or medium

penetration rate

Sandvik limestone/concrete chisel

- Very soft and easily breaking, nonabrasive

rock or concrete

- For rock which has high penetration rate

Sandvik moil point tool

- Where chisels have excessive retaining pin

groove wear

- Soft and nonabrasive rock

- General demolition of concrete

Sandvik pyramid point tool

- Soft, nonabrasive and tough rock and especially

concrete

- Materials requiring high penetration rate

- Where chisels have excessive retaining pin

groove wear

Sandvik compacting tool

- Ground compacting

Sandvik hard rock chisel

- Hard and abrasive rock with fractures

- For application where drilling and blasting

cannot be used

- Materials with low penetration rate

Sandvik blunt tool

- Hard rock with low or medium abrasive

content

- boulder breaking or concrete demolition

- Application where tool wear rate is low

Sandvik super blunt tool

- Hard and abrasive rock

- Only for boulder breaking

- Has 1.5...3 Times more wear life than standard

blunt in very abrasive applications

- In non-abrasive applications life maybe shorter

than standard blunt

Sandvik compact range tool

- breaking concrete

- hard or frozen ground

- road surface or asphalt

Sandvik asphalt cutting tool

- Frozen or compact ground

- Asphalt

7

8

COMPACT RANGE BR108

(in6/in8)

BR211

(in9/in11)

BR315

(in12/in15)

BR522

(in22)

Diameter mm 1600 2350 2790 3300

Pyramid

Part number No. N6351 N9351 N12351 N22351

Total length mm 420 470 520 590

Working length mm 270 300 330 380

Weight kg 9 14 19 27

SMALL RANGEBR111 BR222 BR333

Diameter mm 36 42 50

Chisel

Part number No. BH401 BH601 BH801

Total length mm 360 405 490

Working length mm 220 230 260

Weight kg 2.7 4.1 7.1

Moil point

Part number No. BH403 BH603 BH803

Total length mm 360 405 490

Working length mm 220 230 260

Weight kg 2.6 3.9 6.8

Spade, parallel to boom

Part number No. BH405 BH605 BH805

Total length mm 380 420 490

Working length mm 230 250 260

Weight kg 3.2 4.1 6.8

Spade, transverse to boom

Part number No. BH406 BH606 BH806

Total length mm 380 420 490

Working length mm 230 250 260

Weight kg 3.2 4.1 6.8

Compacting plate

Part number No. BH807

Total length mm 437

Working length mm 210

Weight kg 11.7

SANDVIK TOOLS

CHISEL BLUNT MOIL ASPHALT CUTTING COMPACTING

9

SMALL RANGE PICCOLO BR321

(S 21)

BR422

(S 22)

BR623

(S 23 N)

BR825

(S 25 N)

S26 BR927

(S 27)

BR1129

(S 29)

Diameter mm 40 45 50 63 70 90 84 95Chisel

Part number No. 181 211 2201 231 251 261 271 291Total length mm 400 480 530 380 730 850 840 900Working length mm 230 270 260 365 355 410 420 460Weight kg 4 5 8 15 20 36 34 46Long chisel

Part number No. 212 2202 232 252 262 272 292Total length mm 560 620 780 830 1000 950 1050Working length mm 350 350 465 455 560 530 610Weight kg 6 8 18 23 45 37 55Moil point

Part number No. 183 213 2203 233 253 263 273 293Total length mm 400 480 530 680 730 850 840 900Working length mm 230 270 260 365 355 410 420 460Weight kg 4 5 7 15 20 36 33 43Long moil point

Part number No. 218 2208 238 258 268 278 298Total length mm 560 620 780 830 1000 950 1050Working length mm 350 350 465 455 560 530 610Weight kg 6 8 18 23 48 37 53Blunt

Part number No. 294Total length mm 800Working length mm 360Weight kg 39Asphalt cutting

Part number parallel No. 185 215 2205 235 255 265 275 295Part number traverse No. 186 216 2206 236 256 266 276 296Width mm 100 100 115 130 150 280 200 200Weight kg 4 5 7 13 19 55 34 39Compacting

Part number No. 217 2207 237 257 267 277 297Total length mm 400 460 570 610 860 800 800Working length mm 250 250 250 330 330 330 350Weight kg 21 23 30 54 82 74 95

SANDVIK SPECIAL TOOLS

LIMESTONE CHISEL HARD ROCK PYRAMID SUPER BLUNT

1 0

MID RANGE S54 S56 BR2063

(E 63)

BR2064

(E64)

BR2155 BR2265

(E 65)

BR2266

(E 66)

BR2568

(E 68)

BR2577

Diameter mm 115 130 115 106 118 125 115 130 135Chisel

Part number No. 541 561 631 641 551 651 661 681 771Total length mm 1050 1100 1000 1050 1050 1050 1050 1100 1120Working length mm 655 675 560 610 560 575 575 620 636Weight kg 79 103 68 67 83 85 78 104 112Long chisel

Part number No. 542 562 642 552 652 662 682 772Total length mm 1150 1250 1150 1150 1150 1150 1250 1270Working length mm 755 825 710 660 675 675 770 786Weight kg 86 115 74 91 90 85 120 129Moil point

Part number No. 543 563 633 643 553 653 663 683 773Total length mm 1050 1100 1000 1050 1050 1050 1050 1100 1120Working length mm 655 675 560 610 560 575 575 620 636Weight kg 78 99 68 67 83 84 77 103 108Long moil point

Part number No. 548 568 648 558 658 668 688 778Total length mm 1150 1250 1150 1150 1150 1150 1250 1270Working length mm 755 825 710 660 675 675 770 786Weight kg 86 110 74 91 91 85 120 125

SMALL RANGEBR555 BR777 BR999

Diameter mm 72 80 90

Chisel

Part number No. BJ631 BJ701 BJ801

Total length mm 650 740 830

Working length mm 350 400 450

Weight kg 19.2 27.1 38.5

Moil point

Part number No. BJ633 BJ703 BJ803

Total length mm 650 740 830

Working length mm 350 400 450

Weight kg 19.2 27 38.4

Spade, parallel to boom

Part number No. BJ635 BJ705 BJ805

Total length mm 650 740 840

Working length mm 350 400 460

Weight kg 17.9 25 37.7

Spade, transverse to boom

Part number No. BJ636 BJ706 BJ806

Total length mm 650 740 840

Working length mm 350 400 460

Weight kg 17.9 25 37.7

Compacting plate

Part number No. BJ637 BJ707 BJ807

Total length mm 510 700 800

Working length mm 210 360 420

Weight kg 51.4 68 76.6

11

MID RANGES54 S56 BR2063

(E 63)

BR2064

(E64)

BR2155 BR2265

(E 65)

BR2266

(E 66)

BR2568

(E 68)

BR2577

Diameter mm 130 115 106 118 125 115 130 135Blunt

Part number No. 544 564 634 644 554 654 664 684 774Total length mm 850 900 800 850 850 850 850 900 920Working length mm 455 475 360 410 360 375 375 420 436Weight kg 69 94 58 58 71 74 68 90 98Long Blunt

Part number No. 634CI 644CI 554CI 654CI 664CI 684CI 774CITotal length mm 1000 1050 1050 1050 1050 1100 1120Working length mm 560 610 560 575 575 620 636Weight kg 72 78 88 87 82 111 121Limestone Chisel

Part number No. 631F3 551F3 651F3 681F1 771F3Total length mm 1000 1000 1000 1050 1120Working length mm 525 510 525 570 636Weight kg 70 81 81 91 115Hard Rock Chisel

Part number No. 681A2 771A2Total length mm 1100 1120Working length mm 570 636Weight kg 104 106Pyramid

Part number No. 633K3 643K3 553K3 653K3 663K3 683K3 773K3Total length mm 1050 1050 1050 1050 1050 1100 1120Working length mm 575 610 560 575 575 570 636Weight kg 66 66 83 76 76 104 108Super Blunt

Part number No. 564T2 684T2 774T2Total length mm 900 900 920Working length mm 475 420 436Weight kg 96 97 102

MID MODULAR RANGE BR2214 BR2518

Diameter mm 125 140Chisel

Part number No. M141 M181Total length mm 1100 1200Working length mm 565 615Weight kg 94 129Moil point

Part number No. M143 M183Total length mm 1100 1200Working length mm 565 615Weight kg 92 124Limestone chisel

Part number No. M141F3 M181F3Total length mm 1100 1150Working length mm 565 565Weight kg 100 127Hard rock chisel

Part number No. M181A2Total length mm 1200Working length mm 615Weight kg 123

MID MODULAR RANGE BR2214 BR2518

Diameter mm 125 140Pyramid

Part number No. M143K3 M183K3Total length mm 1100 1200Working length mm 565 615Weight kg 92 124Blunt

Part number No. M144 M184Total length mm 900 1050Working length mm 365 465Weight kg 82 120Super blunt

Part number No. M184T2Total length mm 1050Working length mm 465Weight kg 123Long blunt

Part number No. M184C1Total length mm 1200Working length mm 615Weight kg 137

12

LARGE RANGEG80 BR3088/

BR3288

(G 88)

BR3890

(G 90)

BR4099 BR4510

(G 100)

BR4511

(G 110)

BR7013

(G 130)

S83 S84 S86

Diameter mm 140 142 160 166 170 175 203 140 160 170Chisel

Part number No. 801 881 901 991 101 111 131 831 841 861Total length mm 1200 1200 1405 1450 1450 1450 1550 1200 1350 1450Working length mm 615 610 750 755 700 700 780 660 750 800Weight kg 137 132 206 226 230 241 343 137 198 230Moil Point

Part number No. 803 883 903 993 103 113 133 833 843 863Total length mm 1200 1200 1405 1450 1450 1450 1550 1200 1350 1450Working length mm 615 610 750 755 700 700 780 660 750 800Weight kg 127 128 206 217 225 236 327 137 187 230Blunt

Part number No. 804 884 904 994 104 114 134 834 844 864Total length mm 1050 1050 1255 1265 1300 1300 1500 1050 1200 1300Working length mm 465 460 600 570 550 550 730 510 600 650Weight kg 123 124 196 208 225 232 362 122 185 230

LARGE RANGE SPECIAL

G80 BR3088/ BR3288

(G 88)

BR3890

(G 90)

BR4099 BR4510

(G 100)

BR4511

(G 110)

BR7013

(G 130) S83 S84

Diameter mm 140 142 160 166 170 175 203 140 160Limestone chisel

Part number No. 801F3 881F3 901F3 991F3 101F3 111F3 131P3 831F3 841F3Total length mm 1200 1200 1405 1450 1450 1450 1400 1200 1350Working length mm 615 610 750 755 700 700 630 660 750Weight kg 136 140 208 234 240 250 303 134 198Hard rock chisel

Part number No. 801A2 881A2 901A2 991A2 101A2 111A2 131A2 831A2 841A2Total length mm 1200 1200 1405 1450 1450 1450 1550 1200 1350Working length mm 615 610 750 755 700 700 780 660 750Weight kg 132 123 206 226 245 257 323 137 198Pyramid

Part number No. 803K3 883K3 903K3 993K3 103K3 113K3 133K3 833K3 843K3Total length mm 1200 1200 1405 1450 1450 1450 1550 1200 1350Working length mm 615 610 750 755 700 700 780 660 750Weight kg 132 131 197 226 215 226 332 137 187Super blunt

Part number No. 804T2 884T2 904T2 994T2 104T2 114T2 834T2 844T2Total length mm 110 110 1250 1265 1350 1350 110 1250Working length mm 515 510 600 570 600 600 560 650Weight kg 134 138 220 218 248 255 134 214

13

Proper Tool MaintenanceThe tool of a breaker is a wear part and tool consumption is the main causative for

wear part costs. These are the facts which are familiar for us. On the other way with

the proper tool maintenance we could make savings easy. And who is the key person for

maintenance – The Operator.

Safety

Always when doing tool maintenance proper safety clothes are mandatory to wear.

Please remember tool’s very high temperature after breaker working.

Proper tool maintenance could be divided into daily and weekly maintenance.

DAILY MAINTENANCE

Tool maintenance is a part of operator daily routines. When tool maintenance is

regular, it is possible for the operator to observe; is tool greasing period at proper level,

is quality of tool grease high enough, is operating method correct, is used tool type

correct for application, etc.

Correct greasing practice

The greasing practice depends on application and operating method. Tool grease

consumption is higher in applications where tool is penetrating and movements are

longer than in impact breaking applications where tool is steadily against thrust ring.

Greasing is needed to increase in dusty applications too.

In every Sandvik breakers operator’s manuals there are instructions for the correct

greasing practices. Operator adjusts suitable practice for prevailing application on a

daily bases. The proper procedure is reached when wet grease is visible about the length

equal to tool diameter on tool just under housing bottom plate.

TOOL LUBRICATION

A breakers tool is subject to extreme wear that requires proper lubrication and care if it

is to achieve a long, trouble free life.

Tool lubricant must have properties to withstand high temperature and extreme

pressure. Special tool lubricants and automatic tool lubrication systems which have

been especially designed to work with Sandvik products are available from your breaker

dealer.

TOOL SHARPInG

Genuine Sandvik tools can be reconditioned by milling turning or by plaining. It is

important when sharpening, that the working temperature does not exceed 200°, never

use gas cutting tools as they soften the tool and causes micro-cracks that may lead to

breakages.

Part no. Specification Weight

902045 Sandvik tool grease 400g902046 Sandvik tool grease 18kg951370 Special tool grease Ramlube II 500g951371 Special tool grease Ramlube II (Meissel paste) 500g

14

Tool analyses - what a broken tool tells us:

PROBLEM LIKELY CAUSE REMEDY

Failure of the retainer pin groove

Usually caused by idle blows

Soft tool (beware of pirate tools and pirate retainer pins!).

Ensure that the operator is fol-lowing the instructions as detailed in the operators manual.

Use only Sandvik genuine parts and tools.

Newer model Sandvik breakers have idle blow protection

Deformation of piston end of tool

High impact energy due to wrong setting of oil flow and pressure.

Soft tool (beware of pirate tools!)

Check oil flow and pressure settings on the carrier .

Use only Sandvik genuine parts and tools

Mushrooming of tool Overheating of tool

Working on a hard material with-out pause for a long period of time.

Re-positing the tool every 15 seconds during operation.

Sandvik breakers hit harder and are the designed to break hard rock. Thus accelerated wear is only natural in extremely hard rock.

Lip formation in (fatigue) fracture

Breaking caused by excessive bending. This type of stress is caused by using the wrong work-ing angle or use ot the tool for mechanical leverage.

Adopt correct working angle and follow operating instructions as outlined in the operators manual.

Fatigue failure that starts from the inside of the tool.

Material failure (beware of pirate tools!)

The material of Sandvik tools is ultrasonic-tested for large inclusions, and such failure occurs very rarely, but contact your local dealer for more information

Seizing in tool bushing

Fatigue failure that starts from the tool surface.

Strong side loads and striking at the same time causes the surface of the tool bushing to be damaged, this is caused by using the wrong working angle or insufficient lubrication.

Adopt correct working angle and follow operating instructions as outlined in the operators manual.

Sandvik offers a complete range of tool grease as well as it's range of Ramlube automatic lubricators to ensure constant and sufficient lubrication.

15

RAMLUBELubricating of the tool and the tool bushings of Sandvik breakers is very easy with the Ramlube automatic lubrication system mounted on the excavator or directly on the breaker itself.

RAMLUBE IIThe Ramlube II kit can be fitted to most all Sandvik Mid and Large Range (E- and G-series) breakers. Mounted on the breaker housing, the system features no external electric cables or hydraulic hoses for optimum wear and impact protection. Available as a retro fit option, Ramlube II is ideally suited to applications in which the breaker is required to work with more than one carrier.

RAMLUBE IIIAn integrated lubrication device mounted inside the breaker’s housing on the power cell itself provides maximal lubrication whilst only using minimum grease amount, prolonging the tool and bushing life.The location of Ramlube III also provides it with full protecting from the elements, keeping it free of moisture and dust. In colder climates the location also acts as an advantage because the grease heats along with the breaker.Ramlube III is available as a retrofit option for bR 2155.

Ramlube lubrication products

Part no. Description

850500 Ramlube kit

Part no. Description Model

155193 Ramlube II kit BR 2063, BR 2064, E 63, E 64154933 Ramlube II kit BR 2265, BR 2266, E 65, E 66 N154934 Ramlube II kit BR 2568, E 68, G 80 N162539 Ramlube II kit BR2577 (Demolition/Trenching)165318 Ramlube II kit BR2577 (Boulder breaking)166429 Ramlube II kit BR3288165351 Ramlube II kit BR4099154935 Ramlube II kit BR3890, BR4510, BR4511, G 90, G 100, G 110

Part no. Description Model

162802 Ramlube III BR2155

16

update your Sandvik (Rammer) breaker with the latest in tie rod technology. Sandvik

has introduced this latest advance in breaking technology, to upgrade and better

maintain it's existing feet of breakers. Each kit, includes 4x VIdAT tie rods for the

following breaker models:

Sandvik recommends that when upgrading to the VIdAT tie rods for the first time

that you also replace the upper tool bushing, piston and carry out a full service. If the

breaker has been previously equipped with VIdAT tie rods, then it is possible to replace

two tie rods at a time providing that they are diagonally opposite each other and the

remaining two are in fit condition.

Part no. Description Model

K40080 VIDAT tie rod x 4 G80

K40090 VIDAT tie rod x 4 BR 3890

K40010 VIDAT tie rod x 4 BR 4510

K40011 VIDAT tie rod x 4 BR 4511

Sandvik breakers VIDAT

17

We here at Sandvik stands by it's products, and as further proof of this we are offering

a free lifetime warranty on all double digit breakers, bR2155, bR2577, bR3288 and

bR4099.

We recognise that our customers are seeking to safeguard their investment in capital

equipment, that is why we have designed this new Lifetime Warranty to provide them

with total security.

The Sandvik Lifetime Warranty does not only provide our customers with greater

reassurance, but also makes it easier to calculate their operating costs, whilst increasing

the resale value of their Sandvik breaker.

For more information about the Sandvik breaker Lifetime Warranty please contact

your nearest Sandvik breaker dealer.

Sandvik breakers Lifetime Warranty

18

SANDVIK WATER JETSandvik water jet suppresses dust effectively in any application! Essential especially in tunnelling and demolition applications there is a high need to reduce the amount of dust caused by the breaking.

SANDVIK RAMAIRAir flush system, produces compressed air for preventing dust entering the breaker mechanism, whilst cooling the breaker when working in hot conditions. The compressor is connected hydraulically the excavator and is compact and easy to install.The Ramair compressor enables better lubrication of the lower tool bushing when the breaker is working in horizontal position. Ramair reduces wear on the breakers consumable components including the piston, tool, tool bushing and wear plates, prolonging the breakers life cycle.

RAMONAThe Ramona system monitors the breaker’s pressure, blow frequency, temperature, maintenance intervals and working hours. Alerting the operator in the event of a malfunction or incorrect operation. data can be delivered via a cable connection to a laptop computer or via GSM to office or local dealer, resulting in increased productivity and reduced cost.

Auxiliary products

Part no. Description

95137 Ramair Kit

Part no. Description Model

105761 Water Jet Kit BR2266, BR2568, BR3890, BR4510,BR4511, BR7013, G80, G80 N, G90, G100, G110

Contact Order Desk Water Jet Kit BC 807, BC 1515, BC 2019, BC 2525, RD 7,

RD 15, RD 18, RD 19, RD 25

Contact Order Desk Water Jet Kit BC 3032, RD 32

Part no. Description

153978 Ramona153677 Ramona GSM

19

Demolition tools Wear parts

Just like the tool for a breaker, Sandvik's range of demolition tool attachments also have

wear parts.

The Sandvik bP range of pulverizer and Sandvik bC cutter-crusher range of demolition

tools are essential additions to any demolition application and Sandvik offers a complete

range of spare parts to ensure that your productivity is maintained at it's highest level at

all times.

With 4 different jaw types and various other teeth options that can be attached

Sandvik's bC multiprocessor range can cut, crush, pulverize and tear down even the

most reinforced structure, which is something that can be achieved by using the highest

quality wear parts.

For more information on Sandvik's full range of demolition tools and replacement wear

parts please contact your local dealer.

www.sandvik.com

Sandvik is a high-technology engineering group with world-leading

positions in selected areas – tools for metal working, advanced

materials technology, and mining and construction. We are

represented in 130 countries.

Sandvik Mining and Construction represents one third of the

overall Sandvik Group and serves a broad range of customers in

construction, mineral exploration, mining and bulk materials

handling. Our construction expertise covers quarrying, tunneling,

demolition and recycling, and other civil engineering applications.

Our mining products and services support customers on the

surface and under ground, in all mineral, coal and metal mining

applications from exploration to ore transportation.

Commitment and Responsibility

Sandvik is committed to improving conditions for people while

minimizing environmental impact. you can see it in everything

we do. From sustainable operations that recycle resources, cut

emissions and save energy. To promoting a strong safety culture,

and supporting local communities with resources and knowledge.

Put simply: Commitment and Responsibility.

EN/0

3/2

011/S

NDAVIS

Subj

ect

to c

hang

e w

ithou

t no

tice.