SAMPLE PLAN - New Hampshire€¦ · mse wall notes and details mse wall notes 2 foundation notes 2"...

Transcript of SAMPLE PLAN - New Hampshire€¦ · mse wall notes and details mse wall notes 2 foundation notes 2"...

1610161116121613

914915916

917

918

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO. STATE PROJECTTOWN

LOCATION

REVISIONS AFTER PROPOSAL

SHEET SCALE

DESIGNED

DRAWN

QUANTITIES

REV. DATE

ISSUE DATE FEDERAL PROJECT NO. SHEET NO. TOTAL SHEETS

FILE NUMBER

OF

BRIDGE SHEET

DATEBY

CHECKED

CHECKED

CHECKED

DATEBY

LONGITUDINAL SECTION @ > WOODBURY AVE.

PAL

PAL

PMP

PMP

11238-L

12

270

DOVER

2/10

2/10

2/10

2/10113-2-3

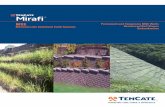

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

4/10AT PAL 4/10

SCALE: 1" = 30’-0"

N

TITLEBRIDGE SHEET

INDEX OF BRIDGE SHEETS

DESCRIPTIONITEM NO. QUANTITIES UNIT

NORTHING EASTING OFFSETSTATION

WP 1

WP 2 WP 3WP 4

WP 5

51+00

52+00

53+0054+00 55+00

56+0057+00

58+0059+00

WOOD SOUNDWALL

PT 917+41.98

PC 50+83.37

PT 55+17.41PC 58+89.55

PC 913+98.54

918+00

917+00

916+00

915+00 914+00ALIGNMENT

MAINLINE

CONTRACT L

110’-0"

110’-0"

110’-0"

107’-2�"

261’-1�"

2 OR 3 PLANS)

(SEE VOLUME

BRIDGE ABUTMENT

NEW SB LITTLE BAY

1

DOVER POINT ROAD

MSE WALL WORKING POINTS

WP B1

WP B2

WP B3WP B4 WP B5

WP B6

97

A

9

NOTES:

PC 1613+29.09

POT 1613+29.09, 37.0’ LT, NH ROUTE 16

POT 913+29.09 SB INTERIM =

1613+00 1612+00 1611+00 1610+00

CONSTRUCTION ¯

WALL, ITEM 592.103

MSE RETAINING

P #50 P #45

P #40 P #35P #30 P #25 P #20 P #15

P #10 P #5

P #1

DRAINAGE STRUCTURES (TYP.)

REINFORCEMENT TO AVOID

FABRICATOR TO DESIGN SOIL

SITE PLAN

SITE PLAN AND BORING LAYOUT

WP 5

WP 4

WP 3

WP 2

WP 1

227010.35

227206.95

227290.29

227374.91

227460.79

1208137.23

1207965.42

1207893.63

1207823.36

1207754.62

58+96.80

56+33.31

55+23.34

54+14.26

53+05.74

31.95 LT.

24.07 LT.

21.45 LT.

22.96 LT.

31.24 LT.

SUMMARY OF RETAINING WALL QUANTITIES

592.103) OUTLET IN SLOPE

(SUBSIDIARY TO ITEM

PERFORATED PIPE (TYP.)

APPROXIMATE LAYOUT OF 6"

TO ITEM 592.103)

AT WP 5. (SUBSIDIARY

PRE-CAST CORNER ELEMENTOF RETAINING WALL.

SHEETS FOR CONTINUATION

SEE LITTLE BAY BRIDGE

DESIGN LOADS, MATERIALS, AND SPECIFICATIONS

LIMIT STATE

STRENGTH III

HORZ. (K/FT) VERT. (K/FT)

EXTREME EVENT I

1.15 9.2

2.96 10.06

19.95

23.75

NH RTE 16

BY MSE WALL MANUFACTURER.

LIMITS TO BE DETERMINED

REINFORCEMENT (TYP.) ACTUAL

APPROXIMATE LAYOUT OF TENSILE P #53

12

11

10

9

8

7

6

5

4

3

2

1

LOADS FROM RAIL SUPPORT SLAB

P

M

PHORZ.

VERT.

NORTHING EASTING OFFSETSTATION

WP B6

WP B5

WP B4

WP B3

WP B2

WP B1

227032.01

227208.56

227291.88

227376.47

227462.32

227547.21

1208121.57

1207967.28

1207895.50

1207825.26

1207756.55

1207691.05

58+67.59

56+33.24

55+23.30

54+14.36

53+05.99

52+01.48

33.77 LT.

26.52 LT.

23.91 LT.

25.42 LT.

33.69 LT.

48.19 LT.

INVERT, EL. = 21.3’

DRAINAGE SYSTEM

6" PIPE OUTLET INTO

WOOD PANEL SOUNDWALL 2 OF 2

WOOD PANEL SOUNDWALL 1 OF 2

RAIL SUPPORT SLAB DETAILS 2 OF 2

RAIL SUPPORT SLAB DETAILS 1 OF 2

LOG OF BORINGS 3 OF 3

LOG OF BORINGS 2 OF 3

LOG OF BORINGS 1 OF 3

PLAN & ELEVATION VIEW 3 OF 3

PLAN & ELEVATION VIEW 2 OF 3

PLAN & ELEVATION VIEW 1 OF 3

MSE WALL NOTES AND DETAILS

SITE PLAN AND BORING LAYOUT607.642

592.103

585.4

534.3

504.101

209.5

CHAIN LINK FENCE WITH ALUMINUM COATED STEEL FABRIC, 4 FEET HIGH

MECHANICALLY STABILIZED EARTH RETAINING WALL

STONE FILL, CLASS D

WATER REPELLENT (SILANE-SILOXANE)

COMMON BRIDGE EXCAVATION

GRANULAR BACKFILL FOR MSE WALLS

LF

SF

CY

GAL

CY

CY

FOR SOUNDWALL QUANTITIES, INCLUDING RAIL SUPPORT SLAB, SEE BR. SHT. 12.

RAIL SUPPORT SLAB/BARRIER WORKING POINTS

DESCRIPTION2.

1.

DESCRIPTION

Seismic Zone: 1

Rail Support Slab (Class AA) f’c = 4,000 psi

Concrete: Precast MSE facing panels and copings (Class A-Modified) f’c = 5,000 psi

AASHTO M111 or ASTM A767.

Reinforcing in the MSE facing panels shall be galvanized in accordance with

epoxy coated, except as otherwise noted.

Reinforcing Steel: All reinforcing steel shall conform to AASHTO M31 (ASTM A615), GRADE 60,

Foundation Data: Refer to the 592 Special Provision for the MSE Wall design criteria.

Specifications for Road & Bridge Construction

Welding per AASHTO/AWS D1.5-08 & NHDOT Standard

NHDOT 2006 Standard Specifications as amended

Specifications: AASHTO 2007 with Interims

Design Method for the MSE Wall and Rail Support Slab is in accordance with LRFD design method.

Rail Support Slab Collision = TL-4

Design Live Loading: MSE Wall Live Load Surcharge = HL-93

7.

6.

5.

4.

3.

2.

1.

40

9,320

48

52

5,500

9,150

MOMENT (KFT/FT)

For soundwall notes see Br. Shts. 11 and 12.

For MSE wall notes see Br. Sht. 2.

DATE:

SAMPLE PLAN

02-2010

24

24 23

22

21

192

0

18

17

16

15

14

13

B112

B111 B110

B109

AB-1

AB-2

25

1515

15

15

202020

20

2020

20

2020

20

20

25

25

25

25

25

25

25

25

252525

30

30

3030

35

35

40

wso

hyd

mhw

wg m

h

s

GV

polelt

3801

psnh

alum

ATTACHED TO BRIDGE

2"

WA

TE

R

ABANDONED 4" GAS

6" WATER

SEGMENT CUT

OFF

2 - 4" TELEPHONE

2" TELEPHONE

4" ABANDONED TELEPHONE

10"

GA

S

GV

ATTACHED TO BRIDGE

4" ABANDONED TELEPHONE

GV

ABANDONED GAS 4" GAS

ABANDONED GAS

8" GAS

6an

35"limit"speed

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

WALL 3-GEN PLAN.dgn Default 11/14/2013 8:57:46 AM �n18abh�

MSE WALL NOTES AND DETAILS

MSE WALL NOTES

2

FOUNDATION NOTES

2" 1" 6" EMBEDMENT

SCALE: 3" = 1’-0"

ANCHOR BOLT DETAIL

CHAIN LINK FENCE ANCHOR DETAILSSCALE: 3" = 1’-0"

PLAN

�FENCE POST

STAND-OFF FOR

�" x 2�" x�"

(TYP.)

1" BOLT HOLE

SCREWS (TYP.)

�" SS SETHOLE (TYP.)

�" DRAIN

8

A

8

B

6"

3"

3"

9"

3"3"

PRECAST COPING

1’-5" –

MSE WALL COPING SECTION AND REINFORCEMENTSCALE: 1" = 1’-0"

TYPICAL REINFORCEMENT

MSE FABRICATOR

DETERMINED BY

REINFORCING TO BE

AS REQUIRED

LEVEL-UP CONCRETE

LEVELING CONCRETE FILL)

REQUIRED TO CLEAR

TO TRIM DOWELS WHERE

CENTER (CONTRACTOR

#4 DOWELS 12" MAX. ON

9"

MI

N.

3"

4"

1’-

9"

*

LAYOUT LINE

AND WORKING

FACE OF MSE WALL

ITEM 607.642

FABRIC, 4 FT HIGH

ALUMINUM COATED STEEL

CHAIN LINK FENCE WITH

ADJUST HEIGHT AS NEEDED BASED ON STEP HEIGHT.

ON WALL STEP HEIGHT UTILIZED BY CONTRACTOR.

* ACTUAL DIMENSION MAY VARY DEPENDING

2" ASHLAR PATTERN

PRECAST WALL COPING

1’-5" –

(TYP.)

�" CHAMFER

MI

N.

4’-

6"

GROUND

PROPOSED

APPROXIMATE

WALL NOTE 3

WALL FINISH, SEE MSE

PANEL WITH ASHLAR PATTERN

PRECAST CONCRETE FACING

H

1’-

0"

25:1 MIN.

(SI

LA

NE-

SI

LO

XA

NE), I

TE

M

53

4.

3

WA

TE

R

RE

PE

LL

EN

T

SCALE:�" = 1’-0"

ITEM 209.5

FOR MSE WALLS,

GRANULAR BACKFILL

MSE WALLS, ITEM 209.5

GRANULAR BACKFILL FOR

1’-6"

SEE MSE WALL NOTE 10

L 0.7H OR 8’-0", WHICHEVER IS GREATER

1

21

2

DIRECTED

ELEVATIONS OR AS

SHOWN ON WALL

EXCAVATE TO GRADE

WHERE REQUIRED SEE PLAN

POST BLOCKOUT IN SLAB

3’-10"

ITEM 592.103

EARTH RETAINING WALL

MECHANICALLY STABILIZED

(SUBSIDIARY TO ITEM 592.103)

LEVELING PAD 6" MIN THICKNESS

UNREINFORCED CONCRETE

ITEM 504.101

EXCAVATION,

COMMON BRIDGE

ITEM 592.103) (TYP.)

(SUBSIDIARY TO

REINFORCEMENT

TENSILE

(SUBSIDIARY TO 592.103)

WRAP WITH GEOTEXTILE

6" PERFORATED PIPE

TO ITEM 592.103) (TYP.)

LAP DOWNGRADE (SUBSIDIARY

GEOTEXTILE, NON-WOVEN,

BARRIER WP

LOCATION OF

MSE WALL WP

LOCATION OF

TYPICAL SECTION

12" LOAM (ROADWAY ITEM)

SLOPE CURB (ROADWAY ITEM)

SPECIAL GRANITE

RO

AD

WA

Y I

TE

MS

RO

AD

WA

Y

ST

RU

CT

UR

E

SLAB FOR THE GUARD RAIL POSTS.

BLOCKOUTS IN THE RAIL SUPPORT

RAIL SUPPORT SLAB. INSTALL

TAPERS IN FROM CURB TOWARDS

GUARD RAIL (ROADWAY ITEM). RAIL

SECTION A

Scale:3" =1’-0" 8

��

�" MIN.

TO SET POSTS PLUMB,

GROUT AS NECESSARY

BEYOND

�" DRAIN HOLEÀ FENCE POST

FENCE POST

2�" O.D. PIPE

2" SCH. 40

2�" O.D. SLEEVE

2�" SCH. 40

BOLTS (TYP.)

�" ANCHOR

SECTION B

Scale:3" =1’-0" 8

(TYP.)

�" DRAIN HOLE

SET SCREW

�" SS

�" STAND-OFF

HOLE BEYOND

ANCHOR BOLT

�"

3"

6"

98

AND COPING

À FENCE

THIS SHEET

SEE DETAIL

CHAIN LINK FENCE NOTES

6" MIN.

WALL (ROADWAY ITEM)

EXISTING RETAINING

AFTER REMOVAL OF

EXISTING GROUND

APPROXIMATE

RAIL SUPPORT SLAB

AND WORKING LINE FOR

BACK FACE OF BARRIER

SEE BR. SHT. 9)

(FOR TYP. SECTION

ITEM 520.02021

RAIL SUPPORT SLAB,

1’-

0"

ITEM 534.3

(SILANE-SILOXANE),

WATER REPELLENT

6.

5.

4.

3.

2.

1.

(TYP.)

2’-0"

1’-0"

1’-0"

ITEM 594.2

SOUNDWALL

WOOD

11.

10.

9.

8.

7.

6.

5.

4.

3.

2.

1.

3.

2.

1.

�" ´

BAR (GALV.)

#8 STEEL REINFORCING

in accordance with Section 550.2.5 of the NHDOT Standard Specifications, 2006 as amended

Anchor bolts shall conform to AASHTO M31, ASTM A615/A, Grade 60 and be galvanized and fabricated

All steel plates shall conform to AASHTO M 270 Grade 50 (ASTM A709 Grade 50).

Complete anchorage assembly including anchor bolts shall be included in Item 607.642.

by the Fabricator (Subsidiary to Item 607.642).

Anchor bolts may be cast in the coping or contractor may field drill anchors if allowed

Post anchorage and all hardware shall be hot dip galvanized after fabrication.

Posts shall be set plumb.

ITEM 585.4

STONE FILL, CLASS D

as described in the Section 592 special provision.

Item 209.5 shall meet the material requirements for Item 304.4 (crushed stone-fine gradation),

Quantity estimates based on L= 1.0H or 8’-0", whichever is greater.

wall submission described in Note 2.

have a minimum dimension of 5 feet. All modifications shall be included with the MSE

wall typical section. Step angles shall be no steeper than 2H:1V and step lengths shall

modifications shall meet the top of the leveling pad requirements defined on the MSE

than the top of leveling pad elevations shown on the MSE wall elevation. Proposed

detailed on the contract drawings but in no case shall the top of leveling pad be higher

The contractor may propose modifications to the top elevations of the leveling pads

exposed MSE wall surfaces to 1’-0" below proposed ground.

Item 534.3 Water Repellent (Silane-Siloxane) shall be applied to entire coping and all

grout after installation. All costs included in item 592.103.

The Contractor shall fill all lifting device recesses in the precast coping with non-shrink

mechanically stabilized earth retaining wall.

perforated pipe, and all other appurtenances shall be included in item 592.103

wall including the leveling pad, wall copings, impervious membrane, geotextile and

All costs associated with the design, fabrication and construction of the MSE retaining

guardrail post locations.

MSE wall tensile reinforcement shall be adjusted as required to avoid conflicts with beam

of the guardrail posts in order to avoid being damaged during installation of the posts.

geotextile and impervious membrane shall be located a minimum of 6" below the bottom

shall extend 5’-0" beyond the end of the MSE wall. In locations of beam guardrail, the

a minimum of 4’-6" below the final grade. Limits of impervious membrane and geotextile

irregularities or stone protrusions. Geotextile and impervious membrane shall be located

Prior to placing the impervious membrane, the subgrade shall be graded smooth with no

detailed on the plans. Geotextile shall be placed on top of the impervious membrane.

Impervious membrane shall be provided within the MSE reinforced soil zone in areas as

face of wall.

Form liner finish shall extend to a minimum of 1’-0" below the proposed grade at

The cost of the form liner shall be included in item 592.103.

Industrial Blvd, St. Louis, MD 63122 (Tele: 1-800-325-9504) or an approved equal.

or ashlar stone no. 330 multi-cast, as manufactured by Greenstreak, 3400 Tree Court

Symons Corporation, 200 E. Touhy Avenue, Des Plaines, IL 60018 (Tele: 1-800-733-7654)

The form liner shall be old ashlar stone P/C 30664. Symons Dura-Tex, as manufactured by

Exposed MSE panels shall have an ashlar stone form pattern, as shown on the plans.

and shall bear the engineer’s seal and signature.

shall be prepared by a professional engineer licensed in the state of New Hampshire

calculations for approval in accordance with section 105.02. All plans and calculations

MSE retaining wall system. The Contractor shall submit MSE retaining wall plans and

The Contractor shall be responsible for the design and internal stability of the selected

changes to other components and dimensions to fit the MSE Wall design.

section 592. The Contractor shall be responsible to coordinate

shall be designed by the contractor in accordance with the requirements of

The actual size of the reinforced soil zone for all mechanically stabilized earth walls

Dimensions for the reinforced soil zone shown on the plans are minimum dimensions.

ITEM 592.103)

(SUBSIDIARY TO

PRECAST COPING

TO ITEM 592.103)

BELOW GRADE (SUBSIDIARY

SEAL ALL SEAMS, SET 4’-6" MIN.

30 MIL. IMPERVIOUS MEMBRANE.

disturbance of the marine deposit subgrade shall be repaired as described in Foundation Note 1.

lifts of Item 209.5) to avoid disturbance of the marine deposit at the bottom of excavation grade. Any

edged buckets, backfilling as the excavation proceeds, using non-vibratory compaction equipment for initial

use careful excavation and backfill procedures (e.g., excavation with excavators not dozers, using smooth

is considered acceptable for support of the MSE wall and shall be left in place. The Contractor shall

deposit. The remaining thickness of the marine deposit left in place below the required excavation depth

The required thickness of Item 209.5 below the MSE wall includes partial excavation of the soft marine

bearing materials during construction.

The Geotechnical Section should be contacted, if assistance is necessary in determining suitable

materials and replaced with Item 209.5 within the 1H:2V horizontal limits defined on the typical section.

the defined excavation depths shall be removed as directed down to the surface of acceptable bearing

MSE walls. Unsuitable materials such as wood, organic soil or miscellaneous debris encountered below

The bottom of Item 209.5 defined on the elevation views is the minimum depth of excavation below the

at no cost to the Department. All dewatering cost shall be subsidiary to Item 504.101.

inadequate excavation and dewatering procedures shall be removed and replaced with Item 209.5

or for other purposes at no additional cost to the Department. Bearing materials that are disturbed by

of clean stone structural fill for the bottom 12 inches of Item 209.5 below the wall to improve dewatering

of Section 504 to prevent disturbance of the bearing materials. The Contractor may substitute 12 inches

The Contractor shall excavate and dewater the excavation in close conformance to the requirements

2’-0"

DATE:

SAMPLE PLAN

02-2010

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO. STATE PROJECTTOWN

LOCATION

REVISIONS AFTER PROPOSAL

SHEET SCALE

DESIGNED

DRAWN

QUANTITIES

REV. DATE

ISSUE DATE FEDERAL PROJECT NO. SHEET NO. TOTAL SHEETS

FILE NUMBER

OF

BRIDGE SHEET

DATEBY

CHECKED

CHECKED

CHECKED

DATEBY

LONGITUDINAL SECTION @ > WOODBURY AVE.

PAL

PAL

PMP

PMP

11238-L

12

270

DOVER

2/10

2/10

2/10

2/10113-2-3

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

4/10AT PAL 4/10

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

WALL 3-NOTES.dgn Default 11/14/2013 9:02:37 AM �n18abh�

AT FRONT OF WALL

PROPOSED GROUND

EL. 19.31

2’-0"

2’-0"

EXCAVATION ITEM 504.101

LIMIT OF COMMON BRIDGE

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO. STATE PROJECTTOWN

LOCATION

REVISIONS AFTER PROPOSAL

SHEET SCALE

DESIGNED

DRAWN

QUANTITIES

REV. DATE

ISSUE DATE FEDERAL PROJECT NO. SHEET NO. TOTAL SHEETS

FILE NUMBER

OF

BRIDGE SHEET

DATEBY

CHECKED

CHECKED

CHECKED

DATEBY

LONGITUDINAL SECTION @ > WOODBURY AVE.

PAL

PAL

PMP

PMP

11238-L

12

270

DOVER

2/10

2/10

2/10

2/10113-2-3

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

4/10AT PAL 4/10

B112

MA

TC

H

LI

NE -

SE

E

BRI

DG

E

SH

EE

T

4

3

SCALE: 1" = 10’

SCALE: 1" = 10’

107’-2�"

MA

TC

H

LI

NE -

SE

E

BRI

DG

E

SH

EE

T

4

N

WP1

107’-2�"

34’-1�"

2 SECTIONS @ 25’-6" = 51’-0"

11’-9" (

TY

P.)

SOUNDWALL PLANS)

WOOD SOUNDWALL (SEE

(SEE SOUNDWALL PLANS)

SOUNDWALL POST (TYP.)

(TYP.)

12’-9"

PLAN & ELEVATION VIEW 1 OF 3

EXP. JT.

EL. 29.87

EL. 30.30EL. 30.62

EL. 30.96

EL. 31.33

EL. 31.71

EL. 32.11

277’-1"

110’-0"

4 SECTIONS @ 25’-6" = 102’-0"

WP B1

WP B2

EL. 26.87

P #50

P #45

P #40

ITEM 520.02021

FACE OF BARRIER,

EXP. JT.

SEE MSE WALL SECTION

PERFORATED DRAIN PIPE

25’-6" TOE

25’-3� " HEEL

BE SET LEVEL (TYP.)

WOOD PANELS TO

110’-0"

BE SET PLUMB (TYP.)

SOUNDWALL POST TO

ITEM 592.103

MSE RETAINING WALL

ITEM 592.103

MSE RETAINING WALL

ITEM 592.103)

COPING (SUBSIDIARY TO

MSE RETAINING WALL

1

2

MSE WALL COPING

WALL TENSILE REINFOREMENT

ASSUMED LIMIT OF MSE

PLAN

ELEVATION VIEW

ITEM 520.02021

RAIL SUPPORT SLAB,

RAIL SUPPORT SLAB

AND LAYOUT LINE FOR

BACK FACE OF BARRIER

P #53

2. WALL AND BARRIER ARE TANGENT BETWEEN WORKING POINTS.

1. SEE BR. SHT. 2 FOR LOCATION OF LAYOUT LINE.

NOTE:

99

52

5354

1

2

AT FRONT OF WALL

APPROXIMATE EXISTING GROUND

FOR MSE WALLS ITEM 209.5

1’-6" GRANULAR BACKFILL

EXCAVATION ITEM 504.101

LIMIT OF COMMON BRIDGE

DOVER POINT ROAD

CONSTRUCTION LB

FOR MSE WALLS ITEM 209.5

3’-0" GRANULAR BACKFILL

SET 7.25FT BELOW TOP OF BARRIER ELEVATIONS SHOWN.

BOTTOM OF RAIL SUPPORT SLAB FOOTING SHALL BE

WALL AND BARRIER ARE TANGENT BETWEEN WORKING POINTS.

SEE BR. SHT. 2 FOR LOCATION OF LAYOUT LINE.

3.

2.

1.

NOTE:

DATE:

SAMPLE PLAN

02-2010

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

WALL 3-ELEVATION 1 OF 3.dgn Default 11/14/2013 9:06:34 AM �n18abh�

9

2’-9"

5’-

3"

1’-0"

10�"

5’-

3�

"

5%

(T

YP.)

3"

CL

R.

WP BEND

ADJUSTMENTS AT

BAR BENDS OR

NEED MINOR FIELD

SCALE:�" = 1’-0"

TYPICAL SECTION

25’-6"

9

TYPICAL SECTION

25’-6"

GRADE

PROPOSED

KEY

12"x 3" 2’-

0"

11’-9"

1’-

6"

105

LAP (TYP.)

2’-5" MIN.

LAP (TYP.)

2’-5" MIN.

#5#5

#5 #5

12 - #5 @ 12" TOP AND BOTTOM

#5 #5

#5#5

1’-

0"

B

9

(T

YP.)

1’-

0"

C

9

SCALE:�" = 1’-0"

A

SCALE: �" = 1’-0"

SECTION

9

B

SCALE: 1" = 1’-0"

SECTION

9

C

SCALE: 1" = 1’-0"

SECTION

9

NUMBER

RAIL POST

2’-0"

2’-0"

VARIES

1

2

A

WORKING LINE

JOINTS ONLY

KEY AT EXPANSION

FROM WALL 3

ITEM 209.5

PAY LIMIT OF

REINFORCEMENT

TENSILE

MSE WALL

NORTHING EASTING

KEY

3" x 12"

A

SCALE: �" = 1’-0"

SECTION

1

END OF SLAB

#5 @ 12"

DETAIL BR. SHT. 12

SEE POST CONNECTION

TYPICAL RAIL SUPPORT SLAB MASONRY SECTION

6 - #5

@ 12"

6 -

#5

@

12"

(TYP.)

2�" CLR.

BA

RRI

ER

11’-

9"

RAIL SUPPORT SLAB REINFORCEMENT - PLAN VIEW

EXPANSION JOINT DETAILS

3"

CORK

�"

(T

YP.)

�"

6"

FOOTING

TOP OF

OF FOOTING

1’-0" FROM EDGE

TERMINATE KEY

10�"

(TYP.)

�"

3"

CO

RK

�"

VARIES

OF BARRIER

VERTICAL FACE

(TYP.)

�" CHAMFER

OF BARRIER

1’-0" FROM TOP

TERMINATE KEY

OF BARRIER

BATTERED FACE

1’-

0"

2’-

0"

ITEM 562.1

JOINT SEALANT,

�" x�" SILICONE

ROADWAY ITEM

1’-0"

ITEM 562.1 (TYP.)

JOINT SEALANT

�" x�" SILICONE

RAIL SUPPORT SLAB DETAILS 1 OF 2EF = EACH FACE

FF = FAR FACE

NF = NEAR FACE

REINFORCING TERMINOLOGY

ITEM 520.02021

(QC/QA) (F),

RAIL SUPPORT SLAB

CONCRETE CLASS AA,

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

1208063.33

1208065.51

1208067.68

1208069.86

1208072.04

1208074.22

1208078.57

1208082.93

1208087.28

1208091.64

1208095.99

1208100.35

1208104.70

1208109.06

1208113.42

227109.59

227107.34

227105.10

227102.86

227100.62

227098.38

227093.90

227089.41

227084.93

227080.45

227075.97

227071.48

227067.00

227062.52

227058.04

#5 Ó @ 1’-0" NF

#6 Ó @ 1’-0" FF

#5 Ó @ 1’-0" NF

#6 Ó @ 1’-0" FF

CROSS SECTIONS

VARIES SEE ROAWAY

#6 @ 12"

#5 Ó @ 12"

#6 Ó @ 12"

LIMIT OF ITEM 534.3 WATER REPELLANT (SILANE SILOXANE)

ON BR. SHT. 3-5.

ELEVATION VIEWS

ELEVATIONS. SEE

TOP OF BARRIER

APPLY HERE

RAIL POST LOCATIONS

4

25

5%

#5 (BOTTOM) (TYP.)

#6 (TOP) (TYP.)

FOR MSE WALLS

GRANULAR BACKFILL

1’-6" MIN. ITEM 209.5

�" CHAMFER (TYP.)

TO AVOID BLOCKOUTS (TYP.)

MOVE TRANSVERSE BARS

TO CLEAR BLOCKOUTS (TYP.)

CUT LONGITUDINAL BARS

RAIL POST BLOCKOUT LOCATIONS

FOR RAIL POST LOCATIONS SEE BR. SHT. 5

JOINT

TYPICAL CONSTRUCTION

JOINT

TYPICAL EXPANSION(SEE TABLE FOR LOCATIONS)

BLOCKOUTS FOR RAIL POSTS (TYP.)

DATE:

SAMPLE PLAN

02-2010STATE OF NEW HAMPSHIRE

DEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO. STATE PROJECTTOWN

LOCATION

REVISIONS AFTER PROPOSAL

SHEET SCALE

DESIGNED

DRAWN

QUANTITIES

REV. DATE

ISSUE DATE FEDERAL PROJECT NO. SHEET NO. TOTAL SHEETS

FILE NUMBER

OF

BRIDGE SHEET

DATEBY

CHECKED

CHECKED

CHECKED

DATEBY

LONGITUDINAL SECTION @ > WOODBURY AVE.

PAL

PAL

PMP

PMP

11238-L

12

270

DOVER

2/10

2/10

2/10

2/10113-2-3

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

4/10AT PAL 4/10

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

WALL 3-SLAB SECTIONS.dgn Default 11/14/2013 9:13:04 AM �n18abh�

10

SCALE:�" = 1’-0"

SCALE:�" = 1’-0"

25’-6"

SOUND WALL

BEAM RAIL

PROPOSED GRADE

OF CONCRETE BARRIER

TAPERED PORTION

1

18

FOR RAIL POSTS (TYP.)

12" X 18" BLOCK OUT

FO

OTI

NG

11’-

9"

TO

E

1’-

0"

LAST SECTION OF SLEEPER SLAB

34’-1�"

10

A

A

10SCALE: �" = 1’-0"

SECTION

SECTION

10

C

B

10SCALE: �" = 1’-0"

SECTION

#5

#6

5’-

3"

2’-9"

10

B

ITEM 209.5

FILL HOLES WITH

TO BEAM

14’-2�"

106

SHEAR KEY

12" x 3"

FO

OTI

NG

2’-

0"

11’-9"

5’-3"

2’-

0"

2’-9"

10�"

1’-0"

RO

AD

WA

Y I

TE

M

1’-6"

C

10SCALE: �" = 1’-0"

SECTION

#5 @ 12"

#5 @ 12"BOTTOM

2- #5

BOTTOM

2- #5

(TYP.)

2�" CLR.

#5

BA

RS

@

1’-0"

#5

BA

RS

@

1’-0"

TO SINGLE SLOPE

VERTICAL FACE

TRANSITION FROM

10�"

(TOP AND BOTTOM)

#5 BARS @ 1’-0" = 11’-0" (TYP.)

(T

YP.)

3"

CL

R.

RAIL SUPPORT SLAB DETAILS 2 OF 2

3’-9"

7’-0"

5’-0�"

PLAN

ELEVATION

AT END OF TAPER

OF TAPER TO 2’-9"

7’-4" AT START

WIDTH VARIES FROM

#5 Ó

#6 Ó

#4 å @ 12"

#4 å @ 12"

AT BEAM CENTER

PLACE MIDDLE BAR

3 #6 @ 10".

BA

RRI

ER

WI

DT

H

7’-

4"

6’-

4�

"

4’-

11"

BA

RRI

ER

AT

TO

P

2’-

9"

BA

RRI

ER

AT

BO

TT

OM

3’-

7�

"

18 TO 1 TAPERED FACE

MEASURED ALONG

7’-0"

3’-9"

AT BEAM CENTER

PLACE MIDDLE BAR

3 #6 @ 10"

JOINT

CONSTRUCTION

JOINT

CONSTRUCTION

JOINT (TYP.)

FOOTING EXPANSION

JOINT (TYP.)

FOOTING CONSTRUCTION

TO BARRIER

9’-9�"

TO BEAM

9’-3�"

FOR RAIL POSTS

1’-6" BLOCKOUT

AT END OF TAPER

SINGLE SLOPE FACE

DATE:

SAMPLE PLAN

02-2010

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO. STATE PROJECTTOWN

LOCATION

REVISIONS AFTER PROPOSAL

SHEET SCALE

DESIGNED

DRAWN

QUANTITIES

REV. DATE

ISSUE DATE FEDERAL PROJECT NO. SHEET NO. TOTAL SHEETS

FILE NUMBER

OF

BRIDGE SHEET

DATEBY

CHECKED

CHECKED

CHECKED

DATEBY

LONGITUDINAL SECTION @ > WOODBURY AVE.

PAL

PAL

PMP

PMP

11238-L

12

270

DOVER

2/10

2/10

2/10

2/10113-2-3

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

4/10AT PAL 4/10

IN

FO

OTI

NG

1’-6"

OP

EN

SL

OT

1’-0"

1’-6"

2’-0"

VOID IN FOOTING

12’-0"

VOID IN FOOTING

12’-0"

2’-0"

2’-

0"

STIFFENING BEAM (TYP.)

SOUND WALL

TOP OF BARRIER

FINISHED GRADE

TOP OF FOOTING

BOTTOM OF FOOTING

3’-9"

2’-0"

1’-6"

EACH POST (TYP.)

1’-0" BLOCK OUT FOR

GRADE

FINISHED

JOINT (TYP.)

10

A

2’-7�"

TO

VOI

D

2’-

11�

"

TO

VOI

D

3’-

6�

"

TO BEAM

2’-8�"

2’-6�"

(TYP.)

2’-0" BEAM

CONCRETE BARRIER

END OF TAPERED

TO

E

1’-

0"

BA

RRI

ER

3’-

7�

"

HE

EL

7’-

1�

"

À BEAM À BEAM

(T

YP.)

3"

CL

R.

(TYP.)

3" CLR.

(TYP.)

12" MAX.

2’-

0"

2’-0"

2’-

0"

2’-0"

2’-0"

#6 @ 12"

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

WALL 3-slab void details.dgn Default 11/14/2013 9:17:20 AM �n18abh�

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO.TOWN

LOCATION

STATE PROJECT

BRIDGE SHEET

OF

FILE NUMBER

TOTAL SHEETSSHEET NO.FEDERAL PROJECT NO.

DESIGNED

DRAWN

QUANTITIES CHECKED

CHECKED

CHECKED

BY DATEDATE BYREVISIONS AFTER PROPOSAL

REV. DATE

ISSUE DATESHEET SCALE

2�"

1�

"

25°

1�"

SOUNDWALL - PLAN

SOUNDWALL - ELEVATION SECTION A-A

PANEL ENDS

at

DETAIL

PRECAST CONCRETE LEVELING PANEL DETAIL

GENERAL NOTES

WOOD WALL CAP DETAIL

WOOD WALL PANEL DETAIL

NOTE TO DESIGNER:

AS NOTED

4/14

4/14

4/15

4/15

WOOD PANEL SOUNDWALL (1 of 2)11 12

WALL PANEL SHALL HAVE NO TONGUE.

NOTE: WALL CAP SHALL HAVE NO GROOVE. UPPERMOST

270

583

NC

NC

11238-LDOVER

107

ML/RB

ML/RB

SCALE: �" = 1’-0"

SCALE: �" = 1’-0"SCALE: �" = 1’-0"

SCALE: �" = 1’-0"

SCALE: 1" = 1"

SCALE: �" = 1’-0"

IN EACH HEIGHT ZONE)

Cc = 0.80. ("H" IS THE DISTANCE FROM AVERAGE LEVEL ADJOINING GROUND SURFACE TO CENTROID OF LOADED AREA

AND EXPOSURE CATEGORY C, WITH 0<H<14, OF SOUND BARRIERS 1989, WITH INTERIMS, FOR A WIND SPEED OF 90 MPH

WOOD PANEL SOUNDWALL DESIGNED IN ACCORDANCE WITH AASHTO GUIDE SPECIFICATIONS FOR STRUCTURAL DESIGN 1.

NOTE: DETAILS DEVELOPED FROM NHDOT BRIDGE DESIGN SOUNDWALL DETAIL SHEETS.

1"+

SEE BRIDGE SHEETS 1, 3-5 & 12.

FOR LAYOUT OF SOUNDWALL (INCLUDING POST NUMBERS, COORDINATES AND WALL ELEVATIONS) 7.

FOR SUMMARY OF SOUNDWALL QUANTITIES SEE BRIDGE SHEET 12.6.

SEE BRIDGE SHEET 12.

FOR PRECAST CONCRETE NOTES AND POST DETAILS AND STEEL BASE PLATE NOTES AND DETAILS5.

SIDES OF A POST THE MAXIMUM ALLOWABLE DISTANCE FROM THE TOP OF WALL TO TOP OF POST SHALL BE 8".

OF WALL TO TOP OF POST SHALL BE 4". IN THE CASE WHERE THE TOP OF WALL ELEVATION VARIES ON BOTH

OF WALL ELEVATION IS THE SAME ON BOTH SIDES OF A POST THE MAXIMUM ALLOWABLE DISTANCE FROM THE TOP

TRANSITIONS IN TOP OF WALL ELEVATION SHALL BE AS DETAILED ON THE PLANS. IN THE CASE WHERE THE TOP4.

EXCEED 20 DEGREES.

SHALL BE HORIZONTALLY ALIGNED TO ACHIEVE THE PROPOSED WALL ALIGNMENT WITH ANGLE POINTS NOT TO

THE ANGLE BETWEEN THE PRECAST CONCRETE POST AND WALL PANEL SHALL NOT EXCEED 10 DEGREES. POSTS3.

INCLUDING LUMBER REQUIREMENTS.

SEE SECTION 594 SPECIAL PROVISION FOR ADDITIONAL WOOD PANEL SOUNDWALL INFORMATION2.

HARDWARE NECESSARY FOR CONSTRUCTION OF THE SOUNDWALL AS DETAILED ON THE PLANS.

AND LEVELING PANELS, STEEL BASE PLATES, ANCHOR BOLTS, GROUT PAD UNDERNEATH POSTS, AND ALL

ITEM 594.2, WOOD PANEL SOUND ABATEMENT WALL SHALL INCLUDE ALL LUMBER, PRECAST CONCRETE POSTS1.

COMPREHENSIVE

ENVIRONMENTAL

INCORPORATED

EH

ER

PM

OC

IN C

L

AT

NE

MN

ORI

VNEEVIS

N

21 DEPOT STREETMERRIMACK NH, 03054

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

DATE:

SAMPLE PLAN

02-2010

GROUT PAD

2X8 WOOD WALL PANELS (TYP)

ITEM 594.2

PAY LIMITS OF

STEEL BASE PLATE

(TYP)

�" CLEAR

A

A

(TYPICAL PANEL)

12’-9" CTR-CTR POSTS

4" (

MA

X)

0" (

MI

N)

ELEVATIONS GIVEN HERE

MINIMUM TOP OF WALL

(MAX)

10°

(MAX)

10°

(M

AX)

8"

C POST

(MAX)

20°

TYP)

AT PANEL ENDS AND 1/3 POINTS,

(INSTALL FRONT AND BACK

2X4 WOOD STRONG-BACKS

PANELS

2X8 WOOD WALL

POST

PRECAST CONCRETE

(OMIT AT PANEL ENDS) (TYP)

�" CARRIAGE BOLT TOP AND BOTTOM

PRECAST CONCRETE POST. (ALL COSTS

INCLUDED IN ITEM 594.2) (SEE BRIDGE SHEET 12)

SEAL AROUND BETWEEN STEEL BASE PLATE AND

CONCRETE POST WITH SILICONE JOINT SEALANT.

(ALL COSTS INCLUDED IN ITEM 594.2.)

PRECAST CONCRETE LEVELING

PANEL (4" THICK)

(SEE BRIDGE SHEET 12)

STEEL BASE PLATE

(SEE BRIDGE SHEET 12)

ANCHOR BOLTS

CONCRETE BARRIER

FACE OF

IN ITEM 594.2)

SEALANT (TYP). (ALL COSTS INCLUDED

SEAL ALL GAPS WITH SILICONE JOINT

PRECAST CONCRETE

LEVELING PANEL

BARRIER

TOP OF CONCRETE

2X3 WOOD WALL CAP (THE CAP SHALL

BE NAILED 1’-0" o.c. IN PREDRILLED

HOLES TO ELIMINATE ANY SPLITTING)

2X4 WOOD STRONG-BACKS (CONNECT USING 3/8" GALVANIZED

CARRIAGE BOLTS AT TOP AND BOTTOM WALL PANELS. NAIL AT OTHER

PANELS USING 2 STAINLESS STEEL 10d NAILS PER PANEL. TOP OF

STRONG-BACKS SHALL BE CUT AT A 45 DEGREE ANGLE. THIS CUT

SHALL BE MADE PRIOR TO PRESSURE TREATMENT.)

C PANELL

L

C PANELL

GROUT PAD

2X8 WOOD WALL PANELS (TYP)

ITEM 594.2

PAY LIMITS OF

STEEL BASE PLATE

(TYP)

�" CLEAR

A

A

(TYPICAL PANEL)

12’-9" CTR-CTR POSTS

4" (

MA

X)

0" (

MI

N)

ELEVATIONS GIVEN HERE

MINIMUM TOP OF WALL

(MAX)

10°

(MAX)

10°

(M

AX)

8"

C POST

(MAX)

20°

TYP)

AT PANEL ENDS AND 1/3 POINTS,

(INSTALL FRONT AND BACK

2X4 WOOD STRONG-BACKS

PANELS

2X8 WOOD WALL

POST

PRECAST CONCRETE

(OMIT AT PANEL ENDS) (TYP)

�" CARRIAGE BOLT TOP AND BOTTOM

PRECAST CONCRETE POST. (ALL COSTS

INCLUDED IN ITEM 594.2) (SEE BRIDGE SHEET 12)

SEAL AROUND BETWEEN STEEL BASE PLATE AND

CONCRETE POST WITH SILICONE JOINT SEALANT.

(ALL COSTS INCLUDED IN ITEM 594.2.)

PRECAST CONCRETE LEVELING

PANEL (4" THICK)

(SEE BRIDGE SHEET 12)

STEEL BASE PLATE

(SEE BRIDGE SHEET 12)

ANCHOR BOLTS

CONCRETE BARRIER

FACE OF

IN ITEM 594.2)

SEALANT (TYP). (ALL COSTS INCLUDED

SEAL ALL GAPS WITH SILICONE JOINT

PRECAST CONCRETE

LEVELING PANEL

BARRIER

TOP OF CONCRETE

2X3 WOOD WALL CAP (THE CAP SHALL

BE NAILED 1’-0" o.c. IN PREDRILLED

HOLES TO ELIMINATE ANY SPLITTING)

2X4 WOOD STRONG-BACKS (CONNECT USING 3/8" GALVANIZED

CARRIAGE BOLTS AT TOP AND BOTTOM WALL PANELS. NAIL AT OTHER

PANELS USING 2 STAINLESS STEEL 10d NAILS PER PANEL. TOP OF

STRONG-BACKS SHALL BE CUT AT A 45 DEGREE ANGLE. THIS CUT

SHALL BE MADE PRIOR TO PRESSURE TREATMENT.)

C PANELL

L

C PANELL

6�

"

�"

1�"

�"

�"

(OMIT GROOVE IN LOWERMOST PANEL)

TONGUE FOR EASE OF INSTALLATION.

APPROXIMATELY �" LARGER THAN

WALL PANEL

OMIT TONGUE IN UPPERMOST

2X8 WOOD WALL PANEL

2X4 WOOD STRONG-BACKS�" CLEAR

8�

"

5"

(T

YP)

4�

"

(TYP)

NOTE: PANEL IS 4" THICK

1’-0"

(MI

N)

VA

RI

ES

4"X4" (W6XW6)

(EPOXY COATED)

WELDED WIRE FABRIC

1’-

1"

BE SET TRUE AND LEVEL BETWEEN THE POSTS)

SMOOTH TROWEL FINISH (THE TOP OF THE PRECAST LEVELING PANEL SHALL

(TYP)

12’-0"

11238LSWDetls_11.dgn Default 11/14/2013 9:48:57 AM �n18abh�

STATE OF NEW HAMPSHIREDEPARTMENT OF TRANSPORTATION * BUREAU OF BRIDGE DESIGN

BRIDGE NO.TOWN

LOCATION

STATE PROJECT

BRIDGE SHEET

OF

FILE NUMBER

TOTAL SHEETSSHEET NO.FEDERAL PROJECT NO.

DESIGNED

DRAWN

QUANTITIES CHECKED

CHECKED

CHECKED

BY DATEDATE BYREVISIONS AFTER PROPOSAL

REV. DATE

ISSUE DATESHEET SCALE

BASE PLATE AND ANCHOR BOLT NOTES

POST CONNECTION DETAILSCALE: 1"=1’-0"

PRECAST CONCRETE NOTES

FLUSH WITH GROUT.

STRENGTH, NON-SHRINK GROUT. THE SLOTTED HOLES IN BASE PLATES SHALL BE FILLED

5. AFTER POST INSTALLATION GROUT THE AREA UNDERNEATH THE POSTS WITH APPROVED HIGH

SECTION 594.

4. ALL STEEL COMPONENTS SHALL BE GALVANIZED AFTER FABRICATION IN ACCORDANCE WITH

ACCORDANCE WITH SECTION 550.

3. ANCHOR BOLTS SHALL CONFORM TO AASHTO M 31, GRADE 60, AND SHALL BE FABRICATED IN

TO AASHTO M 293, TYPE 1.

2. NUTS SHALL CONFORM TO AASHTO M 291, CLASS 10S (GRADE DH). WASHERS SHALL CONFORM

1. STRUCTURAL STEEL FOR BASE PLATES SHALL CONFORM TO AASHTO M 270, GRADE 50.

AS NOTED

4/14

4/14

4/15

4/15

WOOD PANEL SOUNDWALL (2 of 2)

ITEM NO. ITEM DESCRIPTION UNIT

534.3

562.1

544.31

SUMMARY OF SOUNDWALL QUANTITIES

$

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

1208119.0536227036.9770

1208110.6638

1208102.2738

1208093.8838

1208085.4938

1208077.1038

1208068.7138

1208060.3238

1208051.9338

1208043.5438

1208035.1538

1208026.7638

1208018.3738

1208009.9838

1208001.5938

1207993.2038

1207984.8138

1207968.0361

1207959.7147

1207976.4238

1207951.3932

1207943.0718

1207934.7503

1207926.4289

1207918.1074

1207909.7860

1207901.4645

227046.5773

227056.1779

227065.7784

227075.3789

227084.9795

227094.5800

227104.1806

227113.7811

227123.3817

227132.9822

227142.5827

227152.1833

227161.7838

227171.3844

227180.9849

227190.5854

227200.1860

227209.7885

227219.4486

227229.1086

227238.7686

227248.4286

227258.0886

227267.7487

227277.4087

227287.0687

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

52.9342.51

52.5942.17

52.2541.83

51.9341.51

51.6241.20

51.3240.90

51.0340.61

50.7440.32

50.4540.03

50.1439.72

49.8439.42

49.5439.12

49.2538.83

48.9738.55

48.7038.28

48.4538.03

48.2037.78

47.9537.53

47.7237.30

47.5237.10

47.3236.90

47.1336.71

46.9236.50

46.6836.26

46.4236.00

46.1435.72

45.8635.44

NO.POST

NORTHING EASTING EL (FT)BARRIER

CONCRETETOP OF

EL. (FT)SOUND WALL MIN. TOP OF

NO.POST

NORTHING EASTING EL (FT)BARRIER

CONCRETETOP OF

EL. (FT)SOUND WALL MIN. TOP OF

520.02021

1010.42

209.5

594.2 WOOD PANEL SOUND ABATEMENT WALL

28

29

30

31

32

33

34

35

36

37

38

39

40

41

42

43

44

45

46

47

48

49

50

1207893.2151

1207885.0695

1207876.9239

1207868.7783

1207860.6327

1207852.4871

1207844.3415

1207836.1959

1207828.0503

1207820.0453

1207812.0782

1207804.1110

1207796.1441

1207788.1770

1207780.2099

1207772.2428

1207764.2757

1207756.3382

1207748.5499

1207740.7616

1207732.9733

1207725.1851

1207717.3968

227296.7897

227306.5984

227316.4072

227326.2159

227336.0247

227345.8334

227355.6422

227365.4510

227375.2597

227385.1831

227395.1374

227405.0917

227415.0460

227425.0003

227434.9546

227444.9089

227454.8631

227464.8407

227474.9355

227485.0303

227495.1251

227505.2199

227515.3147

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

10.42

45.5935.17

45.3134.89

45.0434.62

44.7734.35

44.5234.10

44.2733.85

44.0233.60

43.7833.36

43.5533.13

43.3232.90

43.0932.67

42.8732.45

42.6532.23

42.4532.03

42.2531.83

42.0531.63

41.8631.44

41.6731.25

41.4931.07

41.3130.89

41.1430.72

40.9730.55

40.8130.39

51

52

53

1207709.6085

1207701.8202

1207694.0319

227525.4095

227535.5043

227545.5992

10.42

10.42

10.42

40.6630.24

40.5230.10

40.3829.96

12 12

SOUND WALL POST LOCATIONS AND ELEVATIONS

DEVICES SHALL BE FILLED WITH NON-SHRINK GROUT.

7. AFTER INSTALLATION OF POSTS AND LEVELING PANELS, ALL RECESSED INSTALLATION

6. CLEAR COVER FOR REINFORCEMENT SHALL BE A MIN. OF 2".

WATER REPELLENT (SILANE-SILOXANE) IN ACCORDANCE WITH SECTION 534.

5. COAT ALL SURFACES OF THE PRECAST CONCRETE POSTS AND LEVELING PANELS WITH

AND SHALL BE EPOXY COATED.

4. WELDED WIRE FABRIC FOR THE LEVELING PANELS SHALL CONFORM TO SECTION 544

TO THE SIZE SPECIFIED ON THE PLANS IN ACCORDANCE WITH SECTION 550.

3. VERTICAL REINFORCING STEEL FOR THE POSTS SHALL HAVE THE LAST 4" THREADED

EPOXY COATED IN ACCORDANCE WITH SECTION 544.

ACCORDANCE WITH SECTION 594. TIE BARS FOR THE POST MAY BE GALVANIZED OR

REINFORCING STEEL FOR THE POSTS SHALL BE GALVANIZED AFTER FABRICATION IN

2. ALL REINFORCING STEEL SHALL CONFORM TO AASHTO M 31, GRADE 60. VERTICAL

CLASS AA CONCRETE UNLESS NOTED OTHERWISE.

COMPRESSIVE STRENGTH OF 4,000 PSI AND SHALL CONFORM TO SECTION 520 FOR

1. CONCRETE FOR THE POSTS AND LEVELING PANELS SHALL HAVE A MINIMUM 28 DAY

NC

NC

11238-LDOVER

270

583

REINFORCING STEEL, EPOXY COATED (CONTRACTOR-DETAILED)

SILICONE JOINT SEALANT (F)

QUALITY CONTROL QUALITY ASSURANCE (QC/QA) FOR CONCRETE

6,908 SF

LF

61,000 LB

1,030 CY

CY

GAL

200

QUANTITIES

150

65

GRANULAR BACKFILL FOR MSE WALLS

CONCRETE CLASS AA, RAIL SUPPORT SLAB (QC/QA), (F)

108

ML/RB

ML/RB

NOTE: DETAILS DEVELOPED FROM NHDOT BRIDGE DESIGN SOUNDWALL DETAIL SHEETS.

(FT)HEIGHT

MIN. WALL

(FT)HEIGHT

MIN. WALL

504.101 COMMON BRIDGE EXCAVATION 85 CY

RETAINING WALL #3: 53+05 TO 58+97 & RAIL SUPPORT SLAB/SOUNDWALL: 52+01 TO 58+68COMPREHENSIVE

ENVIRONMENTAL

INCORPORATED

EH

ER

PM

OC

IN C

L

AT

NE

MN

ORI

VNEEVIS

N

21 DEPOT STREETMERRIMACK NH, 03054

--

WATER REPELLENT (SILANE-SILOXANE)

FOR EACH PROJECT.DESIGNED AND MOMENT SLAB SHALL BE

NOTE: ANCHORAGE SYSTEM

USING DETAILS.CLOSELY REVIEW BEFORE

MAY NOT BE CURRENT.NOTE: DETAILS AND NOTES

DATE:

SAMPLE PLAN

02-2010

4"3"

3"

(T

YP)

R = �

"

1’-2"

5�

"

(T

YP)

(T

YP)

�"

1’-

4"

1’-6"

8"5"

10" 9"

4"

SCALE: 2" = 1’-0"

SCALE: 2" = 1’-0"

(TYPICAL OUTSIDE CORNERS)

�" CHAMFER

10"

1’-

8"

2"

(TYP)

3"

(T

YP)

4�

"

BASE PLATE 1�" X 1’-6" X 2’-0"

FOR ANCHOR BOLTS (TYP)

1�" X 2�" SLOTTED HOLE

7"

5"

2’-

0"

1�" OUTSIDE DIAMETER

(APPROXIMATE)

#9 STEEL REINFORCING BAR

(GALVANIZED)7" CUT OR

ROLLED THREADS

1"

NOT TO SCALE

EMBED

3’-8"

4’-3"

for WALL HEIGHT >10’ to 15’

ANCHOR BOLT DETAIL

(TYP)

4"

POST

OUTLINE OF

(THREADED TO 1" DIAMETER)

VERTICAL REINFORCEMENT #9 BAR (TYP)

@ 1’-0" VERTICALLY) (TYP)

#3 TIE BARS (SPACE

for WALL HEIGHT >10’to 15’

POST BASE PLATE DETAIL

for WALL HEIGHT >10’to 15’

POST SECTION DETAIL

POST REINFORCEMENT (TYP)

1�" HOLES FOR VERTICAL

GROUT PAD

7"

4�

"

STEEL BASE PLATE

PRECAST CONCRETE POST

* 3�

"

POST REINFORCEMENT WITH

NUT AND WASHER (TYP)

(EXTEND TO WITHIN 2�" OF TOP OF POST)

VERTICAL POST REINFORCEMENT

1�" FOR #11 BAR

1" FOR #9 BAR

THE THREADED DIAMETERS SHALL BE : �" FOR #7 BAR

3�" OF THE THREADS SHALL EXTEND BEYOND THE BOTTOM OF THE POST.

* THE LAST 4" OF THE VERTICAL POST REINFORCEMENT SHALL BE THREADED.

PLATE (TYP)

TIGHT AGAINST THE BASE

NUTS TO BE DRAWN UP

BARRIER

CONCRETE

(SEE DETAIL THIS SHEET)

TOP AND BOTTOM OF PLATE (TYP)

ANCHOR BOLT WITH NUT AND WASHER

11238LSWDetls_12.dgn Default 11/14/2013 9:56:02 AM �n18abh�