Bridging the Gap to Sustainable Salmon Farming: Overcoming the

Salmon Farming Industry

-

Upload

tukangpel-lantai-rumahsakitjiwa -

Category

Documents

-

view

223 -

download

1

Transcript of Salmon Farming Industry

-

7/30/2019 Salmon Farming Industry

1/68

Salmon Farming Industry

Handbook 2010

The Marine Harvest Salmon Industry HandbookThe purpose of this document is to give financial analysts and

investors a better insight into the salmon farming industry and inMarine Harvests view the most important value drivers.

Our intention is to update and publish this document annually.

-

7/30/2019 Salmon Farming Industry

2/68

2

Contents

1. Introduction....3

2. Definition of segment..............4

Salmonids only make up 2.3% of global seafood supply..4Salmonids harvest 2009farmed Atlantic dominates..5Supply of farmed and wild salmonids6Harvest development all species...7Seafood as a protein source..8Seafood availability stagnating wild stocks..9

3. The attributes of salmon.10A healthy product...10Protein production efficiency11Feed volume vs. meat volume and water consumption.12

4. World market of farmed Atlantic salmon.13Historic total harvest of Atlantic salmon.13

Atlantic salmon trade and product flow (2009).....14Large farming potential in Chile...15Norway (supply constraints).16Future harvest volumes (indicators & source for statistics)17Development in standing biomass..18Supply and demand the market for Atlantic salmon.19Historic price development - FCA Oslo & FOB Miami...20Different sizes different prices (Norway).21Price indexes vs. FOB packing plant..22Historic price and volume development.23Salmon price relative to other proteins (1980-2009)24Salmonids has a small share of total protein25

5. Industry structure..26Top 10 players in each region (2009).26Number of players (80% of production).27

Secondary processing (VAP)...28Market segment.29The European market for smoked salmon30European seafood downstream industry...31European smoked salmon producers (2009)32

6. Production of salmon.....33Introduction.33The Atlantic salmon life cycle..34Input - Eggs and Smolt.35

Input Sea water temperatures..36Input - Labour and electricity37Establishing a salmon farm..38

Access to licenses.40

7. Cost dynamics42Economics of salmon farming.42Production costs comparison43Cost component mortality and disease..44Feed and feed ingredients45Salmon feed producers.46Raw material market.47Inflation adjusted price and production cost Norway48Typical production cycle in Norway (3 generations)49Cost of building biomass/production..50

Biomass capital needs...51Accounting principles for the biomass52New entry - financial assumptions..53New entry - economic results..54

8. Salmon diseases and mitigation and R&D55Disease risk55Most important disease risks56Vaccination and use of Antibiotics (Norway).57Research and Development.58

Appendix.59Some historic acquisitions and divestments.60Marine raw materials in salmon feed..61Sustainability..62

Key words and conversion ratios63Marine Harvest history..64Marine Harvest worldwide65Marine Harvest downstream (VAP)66Marine Harvest sales channels (2009)...67Useful sources for industry and market information.68

Updated as of 16 July 2010.

Disclaimer

While every reasonable precaution has been taken in the preparation of this document,neither the author nor Marine Harvest assumes responsibility for errors or omissions, or fordamages resulting from the use of the information contained herein.

The information contained in this document is believed to be accurate. However, no

guarantee is provided. Use this information at your own risk.

-

7/30/2019 Salmon Farming Industry

3/68

3

1. Introduction

Salmon

Salmon is the common name for several species of fish of the family Salmonidae (e.g.Atlantic salmon, Pacific salmon), while other species in the family are called trout (e.g. browntrout, seawater trout). While several of these species are both wild and farmed, all

commercially available Atlantic salmon is farmed. Salmon live in both the Atlantic and PacificOceans, as well as the Great Lakes and other land locked lakes.

Typically, salmon are anadromous: they are born in fresh water, migrate to the ocean, thenreturn to fresh water to reproduce.

Atlantic salmon farming started on an experimental level in the 1960s, but first became anindustry in Norway in the 80s and in Chile in the 90s.

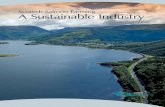

About 60% of the worlds salmon production is cultured. Cultivation takes place in large netsin sheltered quiet waters (fjords, bays) or in tanks on land. Most of the cultured salmon comefrom Norway, Chile, Scotland and Canada.

Salmon is a popular food. Consuming salmon is considered to be healthy because of thefish's high protein and high Omega-3 fatty acids content.

-

7/30/2019 Salmon Farming Industry

4/68

4

2. Definition of segment

Note: live weight because different species have different conversion ratios

Source: FAO/ Kontali Analyse

Salmonids only make up 2.3% of global seafood supply

Even with an increase in production of Atlantic salmon of more than 600% (1.25 milliontonnes wfe) between 1990 and 2008, total global supply of salmonids is still marginalcompared to most other seafood categories. The most important category is whitefish whichis about ten times larger, but consists of a much larger number of species. The non-foodcategory (Pelagic for reduction) is the largest with its 25% of global seafood production and ismade up of by-catch and catch for other purposes than human food, e.g. feed production foruse in aqua- and agriculture.

Comparing Atlantic salmon with some selected important species, Atlantic salmon is more

significant and somewhat larger than atlantic cod and pangasius. But compared to two of thelargest whitefish species, tilapia and alaska pollock, its only half the volume available.

-

5

10

15

20

25

30

35

MilliontonnesLW

Seafood categories 2008

Farmed

Wild

0,00

0,50

1,00

1,50

2,00

2,50

3,00

MilliontonnesLW

Selected species 2008

Farmed

Wild

-

7/30/2019 Salmon Farming Industry

5/68

5

2. Definition of segment

Source: Kontali Analayse

Salmonids harvest 2009 farmed Atlantic dominates

Atlantic salmon is, by volume, the largest species of salmonids in the world. This species is mainlyfarmed in North America, UK, Chile and Norway. These countries represent approximately 95 % ofthe total harvest. The total supply of Atlantic salmon was in 2009 approximately 1.36 million tonnes

HOG, while the total supply of all farmed salmonids was over 2 million tonnes. There is also aconsiderable catch of wild salmon in the world. There are three important wild catch species: pink,chum and sockeye. In volume, Pink is the largest specie, with a catch of approximately 540 thousandtonnes in 2009. The total catch quantity of wild salmon was 983 thousand tonnes in 2009.

Atlantic salmon: large fish used for several products as smoked, fresh, portions, sushi, sashimi,ready meals etc in all the large markets for salmonids as EU, Russia, Japan and USA.Sockeye: caught in Russia and Alaska. Most of these species are exported frozen to Japan, butsome is consumed locally in Russia and some is canned in Alaska. Sockeye is seen as a high qualitysalmonid and is used as salted products, sashimi and some smoked in EU.Pink: a less valued salmonid. The catch is in USA and Russia and is used for canning, pet food andfor roe production. Quality is lower than the other species as all catch happens in a very short timeperiod and the fish is small in size (1.5-1.7 kg).Chum: caught in Japan and Alaska. Most is consumed in Japan and China. In Japan it is available asfresh while in China it is processed for local consumption and re-export. Little chum is found in the EUmarket. Also in this species quality varies much and a part of the catch is not used for humanconsumption.Chinook: low volume species, but highly valued. Alaska, Canada and New Zealand are the mainsupply countries. Most volume is consumed locally. Chinook is more in direct competition to Atlanticsalmon than the other species and is available most of the year.Coho: Japan is the largest market for Coho which is produced in Chile. Coho is in competition withtrout and sockeye in the red fish market and is mostly used for salted products. Russia has increasedits import of this species the last years.

Seawater trout: produced in Norway, Chile and the Faeroes and the main markets are Japan andRussia. Trout is mainly sold fresh, but is also used for smoked production.Small trout: produced in many countries and most often consumed locally as a traditional dish as hotsmoked or portion fish. Small trout is not in direct competition with Atlantic salmon.

-

200

400

600

800

1 000

1 200

1 400

Atlantic

salmon

Large

trout

Coho Small

trout

Pink Chum Sockeye Chinook

ThousandtonnesHOG

Wild catch

Farmed

-

7/30/2019 Salmon Farming Industry

6/68

6

2. Definition of segment

Note: Small and large trout not included in farmed volumes

Source: Kontali Analayse

Supply of farmed and wild salmonids

The general supply of seafood in the world is turning more to farmed seafood as the supplyfrom wild catch is stagnating in several regions and for many important species. The sametrend is seen in the supply of salmonids. 1999 was the first year that the total supply ofsalmon was dominated by farmed. Since then the share of farmed has increased and peakedat approximately 67% of the total supply in 2008.

0

200

400

600

800

1000

1200

1400

1600

2001 2002 2003 2004 2005 2006 2007 2008 2009E

ThousandtonnesHOG

Wild

Farmed

-

7/30/2019 Salmon Farming Industry

7/68

7

2. Definition of segment

Source: Kontali Analayse

Harvest development all salmonid species (02-09)

Global supply of salmonids has increased by about 36% since year 2002, from 2.2 milliontonnes to approx. 3 million tonnes in 2009. The majority of the increase has come fromincreased farming of Atlantic salmon and pink. Farmed Atlantic salmon is the only specieswhich has seen a growth in supply every year. The third species which is farmed in large

volumes, Coho, has been relatively stable in supplied volume since 2002.

-

500

1 000

1 500

2 000

2 500

3 000

3 500

2002 2003 2004 2005 2006 2007 2008 2009E

ThousandtonnesHOG

Chinook

Sockeye

Coho

Large trout

Small trout

Chum

Pink

Atlantic salmon

-

7/30/2019 Salmon Farming Industry

8/68

8

2. Definition of segment

Source: FAO

Seafood as a protein source

Aquaculture is the fastest growing animal food-producing sector and outpaces populationgrowth, with per capita supply from aquaculture increasing from 0.7 kg in 1970 to 7.8 kg in2006, an average annual growth rate of 6.9 percent. From a production of less than 1 milliontonnes per year in the early 1950s, production in 2006 was reported to be 51.7 million tonneswith a value of USD 78.8 billion, representing an annual growth rate of nearly 7 percent.

On average, fish provides about 20-30 kilocalories per person per day globally. The dietary

contribution of fish is more significant in terms of fish proteins, which are a crucial componentin some densely populated countries where total protein intake level may be low.

In 2006, fish provided more than 2.9 billion people with at least 15 percent of their averageper capita animal protein intake. Global per capita fish consumption has increased over thepast four decades, rising from 9.0 kg in 1961 to about 15.3 kg in 2005.

-

7/30/2019 Salmon Farming Industry

9/68

9

2. Definition of segment

Source: FAO

Seafood availability stagnating wild stocks

The UN Food and Agriculture Organization (FAO) has estimated the global 2007 seafoodsupply to 140 million tonnes, whereof about 95 million tonnes is wild catch. FAOs estimatefor year 2030 is a reduction in wild catch to about 90 million tonnes while farmed seafood will

increase from 45 million tonnes to 85 million tonnes. Aquaculture will then supply nearly 50%of all available seafood in the world. Most of the growth will come before 2015.

A major international scientific study released in November 2006 in the journal Science foundthat about one-third of all fishing stocks worldwide has collapsed (with a collapse beingdefined as a decline to less than 10% of their maximum observed abundance), and that ifcurrent trends continue all fish stocks worldwide will collapse within fifty years.

The FAO State of World Fisheries and Aquaculture 2004 report estimates that in 2003, of themain fish stocks or groups of resources for which assessment information is available,approximately one quarter was overexploited, depleted or recovering from depletion and

needed rebuilding.

Northern Europe and the Mediterranean Sea have the highest degree of depleted andoverexploited stocks and there are very few underexploited stocks in the world.

-

7/30/2019 Salmon Farming Industry

10/68

10

3. The attributes of salmon

A healthy product

Omega-3Farmed salmon is a good source for the marine omega-3 polyunsaturated fatty acidseicosapentaenoic acid (EPA) and docosahexaenoic acid (DHA) that reduce the risk forcardiovascular disease.

More data accumulates indicating that EPA and DHA also cut the risk for several otherconditions, for example:

inflammatory diseases

impaired brain developmentdepressioninsulin resistance

Salmon is a source of many important nutrients

Seafood is nutritious, rich in micronutrients, minerals, marine omega-3 fatty acids, very highquality protein and several vitamins, and represents an important part of a varied and healthydiet. The Food and Agriculture Organization (FAO) highlights Fish is a food of excellentnutritional value, providing high quality protein and a wide variety of vitamins and minerals,

including vitamins A and D, phosphorus, magnesium, selenium and iodine in marine fish.(www.fao.org/focus/e/fisheries/nutr.htm).

The substantial library of evidence from multiple studies using nutrients present in fish andseafood in general, indicates that including salmon to your diet will improve your overallnutrient status and may even yield significant health benefits. In the face of increasing obesityand decreasing health standards, governments and food and health advisory bodies inEurope and the USA are actively encouraging their populations to consume more fish as partof their diet.

-

7/30/2019 Salmon Farming Industry

11/68

11

3. The attribute of salmon

Source: Marine Harvest, Wikipedia, British Pig BPEX Yearbook 2007, www.pork.org, article in Fiskaren March 20 2009

Protein production efficiency

There are five main sources for animal protein: cattle, poultry, sheep, pork and seafood. Thefirst four are farmed, while more and more of the available seafood is also farmed.

One method to measure how productive the different protein productions are is therepresentative feed conversion ratio (FCR). In short this means how many kilo feed isneeded to produce one kilo live animal. If we compare the farmed salmon with the four othermain species we find a variation in the FCR between 1.2 and 8.0, where the salmon scoresbest and cattle scores worst. Wild salmon has an FCR of approximately 10.0.

The feed for the different species consists of different ingredients. While the fish feedingredients include fish oil and fish meal mainly produced from pelagic fish, the other specieshave feed consisting of mainly corn, grain and soybean. Over time the share of marineingredients in the fish feed has been replaced more and more with vegetable ingredients.

-

7/30/2019 Salmon Farming Industry

12/68

12

3. The attribute of salmon

Feed volume vs. meat volume and water consuption

100 kg feed gives 65 kg edible salmon meat

Source: FHL

Salmon has a very low feed factor compared to other sources of meat, like chicken, pork andsheep. Most of the fish is edible meat while other sources of meat have a higher level ofwaste or non edible meat. The combination of these two factors gives salmon a favourablyhigh volume of edible meat per kg of feed fed.

Salmon consumes no fresh water - 1 kg beef consumes 14,000 litres of fresh water

Freshwater is a renewable but limited natural resource. Freshwatercan only be renewed through the process of the water cycle, wherewater from seas, lakes, rivers, and dams evaporates, forms clouds,

and returns to water sources as precipitation. However, if morefreshwater is consumed through human activities than is restored bynature, the result is that the quantity of freshwater available in lakes,rivers, dams and underground waters is reduced. This can causeserious damage to the surrounding environment.

Fish need no fresh water consumption while to produce 1 kg beef14,000 litres of fresh water consumption is needed.

0

10

20

30

40

50

60

70

Salmon Chicken Pork Sheep

Ediblemeatinkg

-

7/30/2019 Salmon Farming Industry

13/68

13

4. World market of farmed Atlantic salmon

Source: Kontali Analayse

Historic total harvest of Atlantic salmon

Farming of Atlantic salmon has always been dominated by a few producing countries asthere are several natural conditions that have to be in place for optimal production, like seawater temperature range and a sheltered coast line.

After many years when Chile increased its global market share, the situation has again

shifted, and for the two last years Norway has increased its global market share again. Theproduction in Canada, UK and to some extent the Faroe Islands has been more or lessstable the last five years, but has some potential to grow in the future.

0

200

400

600

800

1 000

1994

1995

1996

1997

1998

1999

000

2006

2007

2008

2009E

InthousandtonnesHOG

Norway (CAGR 9 %)

0

50

100

150

200

250

300

350

400

1992

1993

994

1997

1998

1999

2003

2004

2005

2009E

InthousandtonnesHOG

Chile (CAGR 18 %)

0

20

40

60

80

100

120

140

160

1995

1996

1997

1998

1999

2000

2001

2002

InthousandtonnesHOG

UK (CAGR 8 %)

0

20

40

60

80

100

120

140

1990

1991

1992

1993

2002

2003

2004

2005

2006

InthousandtonnesHOG

North America (CAGR 13 %)

0

20

40

60

80

100

1990

1991

1992

1993

1994

1998

1999

2000

2001

2002

2007

2008

2009E

InthousandtonnesHOG

Others (CAGR 8 %)

0

500

1 000

1 500

1990

1991

1993

1994

1995

1996

1997

1998

1999

2001

2002

2004

2005

2006

2007

InthousandtonnesHOG

Total harvest quantity Atlantic

salmon (CAGR 10 %)

-

7/30/2019 Salmon Farming Industry

14/68

14

4. World market of farmed Atlantic salmon

Atlantic salmon trade and product flow (2009)

The historically four main trade flows have been:

Norway to EU Chile to USA Canada to USA Scotland to EU

The logistic and perishability of the product have led to this supply trend. A new trend sincethe beginning of this millennium has been that Norwegian fresh salmon meet morecompetition from Chilean frozen salmon in the European market. This together with strongcompetition between mainly Norwegian and Chilean salmon in the Japanese market, and theincrease in export from Scotland and Norway to USA due to reduced supply from Chileshows that the market is becoming more and more globalized. But there will still be home

markets for the different production regions as it is only the frozen salmon that can beavailable in large volumes for distant markets and there is no reason to believe that frozenproducts will outstrip fresh products.

2007

Thousand tonnes HOG Norway Chile Scotland North America Other Total %

EU 455 61 101 0 15 632 50 %

North America 13 182 15 103 4 316 25 %

Russia 53 3 3 0 5 64 5 %

Asia 72 21 1 2 14 110 9 %

South America 0 42 0 0 0 43 3 %

Other markets 57 8 1 4 18 88 7 %

Total 650 316 121 110 56 1253

% 52 % 25 % 10 % 9 % 4 %

2008

Thousand tonnes HOG Norway Chile Scotland North America Other Total %

EU 479 60 104 0 19 663 50 %

North America 9 174 15 112 4 314 24 %

Russia 56 6 0 0 6 67 5 %

Asia 66 29 2 7 10 113 9 %

South America 0 61 0 0 0 61 5 %

Other markets 57 10 2 2 32 103 8 %

Total 667 340 122 121 70 1320% 51 % 26 % 9 % 9 % 5 %

2009

Thousand tonnes HOG Norway Chile Scotland North America Other Total %

EU 533 36 99 0 22 690 51 %

North America 39 110 25 116 15 305 22 %

Russia 63 5 1 0 2 71 5 %

Asia 77 27 3 2 17 126 9 %

South America 1 64 0 0 0 65 5 %

Other markets 57 6 2 1 33 99 7 %

Total 770 248 130 119 89 1356

% 57 % 18 % 10 % 9 % 7 %

Source: Kontali Analayse

-

7/30/2019 Salmon Farming Industry

15/68

15

4. World market of farmed Atlantic salmon

Source: Kontali Analyse

Large farming potential in Chile

In Chile there has been a tremendous growth in farming of Atlantic salmon thelast decade, before growth and production was reduced after 2006, caused by

biological challenges. The mortality in Chile increased rapidly as a result ofoutbreak of ISA, and the average harvest size of the fish went down whichresulted in a lower yield per smolt (in kg), as the graph above shows. While theaverage yield per smolt in Norway was 3.67 kg (HOG) in 2008, the samenumber was 1.33 kg (HOG) in Chile.

To improve yield the production area in Chile has to be expanded when thebiological situation is under control. The number of smolt released in region Xwill be reduced and increased in region XI and later on region XII. Thisdevelopment is necessary due to the density and the limited area capacity inregion X. This expansion will take place once the biological situation is under

control and new legislation is implemented and enforced.

Expansion to the region XI and XII will increase the Chilean production cost asthere will be longer transportation, less optimal industry cluster and lack ofinfrastructure. But the mortality related costs will be lower.

-0,50

1,00

1,50

2,00

2,50

3,00

3,50

4,00

4,50

5,00

01G 02G 03G 04G 05G 06G 07G 08G

Kgfish(HOG)/smoltreleased

Yield per smolt released

Norway

Chile

UK

Faroe Islands

-

7/30/2019 Salmon Farming Industry

16/68

16

4. World market of farmed Atlantic salmon

Production=harvest

Licenses can be used for both Atlanticsalmon and trout

o Calculation on total production

Number of sea water licenses for salmonand trout in commercial use

o 2007: 929o 2008: 916o 2009: 981o 2010: 981

Average production capacity per licenseo Max 1,200 tonnes per yearo Realistic 1,000 tonnes per year

Source: Fiskeridirektoratet

Norway (supply constraints)

Because of the regulation of standing biomass (MTB) per licence (780 tonnes) the productioncapacity per licence is limited. In 2008, the average harvest volume per licence in commercialuse was approximately 895 tonnes (lw). Maximum annual harvest volume per licence inNorway could be as much as 1,200 tonnes, but 1,000 tonnes would be more realisticachievable as not all sites are in use all the time. MHG has estimated the production in

Norway in 2010 to 830 thousand tonnes.

Producing closer to maximum can give better utilization of equipment leading to lower unitcosts, but it also involves producing at locations that may not be optimal which add to costs.It is difficult to calculate exactly how many smolts to set out because there are many factorswhich influence the fish growth. Producers do not wish to run the risk to slaughter fish toavoid exceeding the maximum level. Therefore there will always be a difference between therealistic production level and maximum capacity.

0

200

400

600

800

1000

1200

2007 2008 2009E 2010E

TotalannualharvestinNorway(HOG)inthousandtonnes

-

7/30/2019 Salmon Farming Industry

17/68

17

4. World market of farmed Atlantic salmon

Future harvest volumes (indicators & source for statistics)

The three most important indicators on future harvest volumes are: standing biomass, feedsales and smolt release. These three are good indicators on medium-term and long-termharvest, while the best short term indicator is standing biomass divided on size categories.As most fish is harvested on a size of 4+kg it is only the amount of large fish in the sea thatcan be used to estimate short term harvest.

If no actual numbers on smolt release are available, vaccine sales could be a good indicatorof number of smolt releases and when the smolt is put to sea. This is a good indicator onlong term harvest as it takes up to 2 years before the fish is harvested after smolt release.

Seawater temperature is difficult to use as an estimator, but have large impact on averageharvest weight and production time and can have a significant effect on total harvest.

Disease outbreaks can hardly be used to give an estimate on total harvest, but to adjustestimates based on the other factors.

-

7/30/2019 Salmon Farming Industry

18/68

18

4. World market of farmed Atlantic salmon

Source: Kontali Analayse

Development in standing biomass

Because of the variation in sea water temperatures over the year and the regulation ofmaximal standing biomass per license in Norway, the total standing biomass in Europe has aS-curve which is at its lowest in May and at its peak in October. The two external factors

make it hard to utilise capacity fully as it is only a short time of the year that biomass is closeto what is maximum. In Chile the situation is different. A more steady water temperaturegives the possibility to release smolt during the whole year and a more uniform utilization ofthe facilities. The falling line in Chile in 2008 and 2009 is due to the impact of the ISAdisease.

0

100

200

300

400

500

600

700800

Jan

Feb a

r

Apr

ay

Jun

Jul

Aug

Sep c

t

Nov

Dec

ThousandtonnesLW

Standing biomass in Europe

-

50

100

150

200

250300

Jan

Feb a

r

Apr

ay

Jun

Jul

Aug

Sep

Oct

Nov

Dec

ThousandtonnesLW

Standing biomass in Chile

-

20

40

60

80

100

120

Ja

n

Feb a

r

A

pr

ay

Jun

Jul

Aug

Sep

O

ct

Nov

Dec

ThousandtonnesLW

Standing biomass in North America

2004

2005

2006

2007

2008

2009E

-

7/30/2019 Salmon Farming Industry

19/68

19

4. World market of farmed Atlantic salmon

Supply and demand the market for Atlantic salmon

In economics, supply and demand describe market relations between prospective sellers andbuyers of a good. The supply and demand model determines price and quantity sold in themarket.

The model predicts that in a competitive market, price will function to equalise the quantitydemanded by consumers and the quantity supplied by producers, resulting in an economicequilibrium of price and quantity.

As most of the farmed salmon is marketed fresh, all salmon produced in one period has to beconsumed in the same period as the product is perishable. In short term, the production levelis difficult and expensive to adjust as the planning/production cycle is three year long.Therefore, the supplied volume is very inelastic in short term, while also demand is shiftingwith the season. This has a large effect on the price volatility in the market.

-

7/30/2019 Salmon Farming Industry

20/68

20

4. World market of farmed Atlantic salmon

Source: Kontali Analyse

Historic price development FCA Oslo & FOB Miami

As in most commodity industries the producers of Atlantic salmon are experiencing muchvolatility in the price achieved for the product. While the average price for Norwegian wholesalmon the last decade has been about NOK 25/kg (HOG), there has been peaks at NOK45/kg and as low as NOK 15/kg.

Comparing FCA Oslo and FOB Miami there are clear indications of a global market as theprices correlate to a high degree.

Factors affecting market price are: Supply Demand (absolute and seasonal volatility) Globalisation of the market (fresh, frozen, whole, fresh supply)

Contracts and forward market

0,00

1,00

2,00

3,00

4,00

5,00

6,00

0,00

5,00

10,00

15,00

20,00

25,00

30,00

35,00

40,00

45,00

50,00

1997 1998 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009

USD/lb

NOK/kg

FCA Oslo FOB Miami

-

7/30/2019 Salmon Farming Industry

21/68

21

4. World market of farmed Atlantic salmon

Source: Kontali Analyse

Different sizes different prices (Norway)

The most normal market size for a salmon is 4-5kg and 5-6kg HOG, making up about 60% ofthe production in Norway. There are also produced significant volumes of 3-4kg and 6-7kgfish, and less 1-3kg and 7+ fish. The reason for the different sized fish is mainly that salmonfarming is a biological production process, where the fish has different growth cycles and thebiomass represents a normal distributed size variation. When produced, this is beingadjusted by sorting the fish once or twice into groups of equal size. However, this isexpensive and not optimal for the fish due to extra stress caused by handling.

The markets for the different sizes vary. While the processing industry in Europe mainly use3-6kg HOG, there are also niche markets for the small and large fish. As these markets areminor compared to the main market, they are easily disrupted if volumes become too high.

History shows no systematic gain on specific sizes, but a variation within each year, and adeclining premium on large fish compared to standard sized fish.

0,00

5,00

10,00

15,00

20,00

25,00

30,00

35,00

40,00

45,00

50,00

1997 1998 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009

NOK/Kg

2/3 kg

4/5 kg

6/7 kg

-

7/30/2019 Salmon Farming Industry

22/68

22

4. World market of farmed Atlantic salmon

*Average difference between SSB and return to packing plant

Price indexes vs. FOB packing plant

Several price indexes for salmon are publicly available. The two most important providers ofsuch statistics are FHL and SSB in Norway and Urner Barry in the US (Chilean andCanadian salmon). These can be used to calculate the average price the salmon farmer willachieve.

In Norway this is fairly simple by deducting freight cost from the farm to Oslo and the terminalcost from the FHL price (~0.50 NOK). If using the SSB custom statistics, you need to adjustfor freight to border, duty and taxes, and also to adjust for quality and contract sales to getthe achieved spot price back to producer. Average difference between SSB price and FCAOslo is ~1 NOK, which gives the average difference between SSB price and back to plant atNOK 1.50*.

Calculating Urner Barry Chilean fillets, back to HOG plant is more extensive. It is necessaryto use UB prices for both 2/3lb and lb and adjust for volume share, market handling (4cent), market commission (4.5%), premium fish share (92%), reduced price on downgradedfish (30%), airfreight (USD 1.50/kg) and HOG to fillet yield (70%).

* Historically this difference fluctuates from week to week and will normally be observed in the range of [-2 to +4]

-

7/30/2019 Salmon Farming Industry

23/68

23

4. World market of farmed Atlantic salmon

Source: Kontali Analyse

Historic price and volume development

The market for salmon has developed more and more into a global market. This hashappened as a result of mainly two factors; rapid growth of volumes in Chile resulted in moreChilean salmon in direct competition with European salmon in all markets; and consolidation

in the industry, creating more companies producing and selling salmon from several regions.

The Norwegian FHL price has been registered for many years and has been seen as areference price for most of the industry, especially the European part. But the US marketprice has strongly correlated with the FHL, making this price a good index for a global marketprice.

Growth in global supply of Atlantic salmon is estimated to 69% in the period 2000-2009,varying between 2% and 13% annually. Variation in growth rates has affected pricedevelopment and caused a volatile industry with annual average prices ranging between19.50 (2003) and 30.31 (2009) NOK.

Combining the data gives a linear correlation between change in global supply and change inthe Norwegian FHL price. This relation has an explanation power of almost 84% of theannual price development between 2000 and 2009.

-30 %

-25 %

-20 %

-15 %

-10 %

-5 %

0 %

5 %

10 %15 %

20 %

25 %

0 % 5 % 10 % 15 %

ChangeinaverageFHLprice

Global supply change

r=-0.84

Y-o-YGlobal supply

growthChange in av.

price FCA Oslo

2000-01 13 % -25 %2001-02 7 % -10 %

2002-03 8 % -3 %

2003-04 5 % 11 %

2004-05 4 % 17 %

2005-06 2 % 1 %

2006-07 10 % -4 %

2007-08 5 % 4 %

2008-09 3 % 18 %

-

7/30/2019 Salmon Farming Industry

24/68

24

4. World market of farmed Atlantic salmon

Source: International Monetary Fund

Salmon price relative to other proteins (1980-2009)

Compared to beef and chicken, salmon has become relatively much cheaper during the lastdecades. Especially compared to chicken, salmon has gone from being ten times asexpensive to be only about twice the price. Compared to pork, relative price has been veryvolatile over the period, varying mostly between 2-4 times as expensive.

Compared to IMFs Food and Beverages index salmon has also become significantlycheaper over the last three decades.

-

2

4

6

8

10

-

1

2

3

4

-

2

4

6

8

10

-

5

10

15

-

7/30/2019 Salmon Farming Industry

25/68

25

4. World market of farmed Atlantic salmon

Source: Rabo Bank; FAO animal production and health division

Salmonids has a small share of the protein market

The illustration above is an estimate of the European protein market.

Pork is the definite largest source for animal protein in Europe, while seafood is the firstrunner up. Salmon is estimated to make up about 4% of the seafood consumption in Europe,giving salmon only one percent share of the total animal protein consumption in Europe. Onlya small increase in this share means a market capable of consuming several hundredthousand tonnes more than today.

If all 800 million people in Europe and the US consumed one more meal with salmon permonth, the market size would increase by 1,920,000 tonnes, which is more than the doubleof todays market.

-

7/30/2019 Salmon Farming Industry

26/68

26

5. Industry structure

Top 5 - 10 Players in main producing regions, Harvest Quantity, all farmed salmonids 2009. tonnes HOG

Top 10 Norway H.Q. Top 10 UK H.Q. Top 10 North America H.Q. Top 10 Chile H.Q.

1 Marine Harvest 201 700 Marine Harvest 37 700 Cooke Aquaculture 42 300 Empresas Aquachile 56 700

2 Lery Seafood 108 500 Scottish Seafarms 26 500 Marine Harvest 36 500 Mainstream 44 000

3 Salmar 64 400 Lighthouse Cal. 20 100 Mainstream 22 400 Los Fiordos 36 900

4 Mainstream 30 700 Grieg Seafood 12 400 Grieg Seafood 10 200 Marine Harvest 31 700

5 Nova Sea 29 300 Marine Farms 11 700 Icicle 5 400 Multiexport 22 500

6 Nordlaks 27 000 * * Salmones Antarctica 20 700

7 Grieg Seafood 26 300 Pesquera Camanchaca 19 800

8 Sjtroll 25 200 Salmones Cupquelan 17 100

9 Alsaker Fjordbruk 20 300 Trusal 16 200

10 Bremnes Seashore 15 300 G.M. Tornagaleones 15 300

Top 10 548 700 Top 10 108 400 Top 10 116 800 Top 10 280 900

Others 294 300 Others 23 600 Others 5 900 Others 161 700

Total 843 000 Total 132 000 Total 122 700 Total 442 600

* Kontali Analyse finds that UK and North American industry are best described by top 5 producers, as volumes of top 5-10 are low.

Top 10 players in each region (2009)

The Marine Harvest Group represents the largest total production and holds about onequarter of the volume in Norway, and about one third of the volume in North America and UK.

In North America and the UK production is more consolidated. It is estimated that in the UKmore than 80% and, in North America about 95% of the volume is produced by fivecompanies in each region.

In Norway and Chile there are several more companies with a significant production volumeof Atlantic salmon. In Chile, several of the companies also produce other salmonids like cohoand seawater trout.

-

7/30/2019 Salmon Farming Industry

27/68

27

5. Industry structure

Source: Kontali Analyse

Number of players (80% of production)

Historically, the salmon industry has been represented by many, small firms. This hasdefinitely been the case in Norway, and to a lesser degree in Scotland and in Chile. If we gothirteen years back, to 1997, there were a total of 117 companies in these three countriesproducing 80% of the volume, whereof 70 of them were located in Norway.

The large difference between Norway and Chile was based on the governmental level ofinvolvement in the industry from the start. The government in Norway put restrictions early onhow many licences a company/person could own, while the Chilean approach, from thebeginning, was to build a new industry.

During the last decade the salmon farming industry has been through a period ofconsolidation and the number of companies producing 80% of the Atlantic salmon has beenreduced by 44% to 51 in 2009.

The increasing number in Chile is probably explained by big companies having lostproduction volumes in 2008 due to the ISA disease. The number of companies producing80% of the Atlantic salmon in Chile is expected to decrease when normal production hasagain been achieved.

The consolidation trend is expected to continue.

See appendix for some historic acquisitions and divestments.

2009

2006

2003

2000

1997

0

10

20

30

40

50

60

70

NorwayChile

ScotlandCanada

25

18

53

31

10

53

45

15

78

55

18

8

70

35

12

-

7/30/2019 Salmon Farming Industry

28/68

28

5. Industry structure

Secondary processing (VAP)

In salmon processing we divide between primary and secondary processing.

Primary processing is slaughtering and gutting. This is the point in the value chain standard

price indexes for farmed salmon are related to.

Secondary processing is head off, filleting, fillet trimming, portioning, different cuttings likechoplets, smoking or making ready meal or packing with Modified Atmosphere (MAP).

The products that are secondary processed are called value-added products (VAP).

-

7/30/2019 Salmon Farming Industry

29/68

29

5. Industry structure

Market segment

In EU in 2009 over half of the Atlantic salmon went to retailers, while 45% went to hotels,restaurants and catering (HORECA).

Of whole salmon and salmon fillets almost two third were sold as fresh fish and about onethird as frozen.

In EU salmon fillets and smoked salmon have an equal market share of 32% each, whilewhole fish has about 19%. In this graph other VAP consist of all value added processedproducts except smoked salmon which is represented separately, and include ready meals,canned fish, etc.

55 % 45 %

Retail vs. Horeca

Retail Horeca

61 %39 %

Fresh vs. frozen

Fresh Frozen

19 %

32 % 32 %

16 %

Different products

Whole Fillet Smoked Other VAP

-

7/30/2019 Salmon Farming Industry

30/68

30

5. Industry structure

The European market for smoked salmon

Source: Kontali, ABG Sundal Collier

The most common secondary processed product based on Atlantic salmon, is smoked. TheEuropean market for this product was 125,000 tonnes product weight (pw) in 2009, whereofFrance and Germany were the major markets with a total market size of approximately45,000 tonnes product weight. The amount of raw material needed for this production wasabout 208,000 tonnes HOG.

The market for smoked salmon in Europe shows good growth. In 2009 the growth in France,Germany, UK and Spain was 9-26%.

0 % 5 % 10 % 15 % 20 % 25 %

Other EU 27

Poland

Italy

Spain

Scandinavia

Benelux

UK

Germany

France

-

7/30/2019 Salmon Farming Industry

31/68

31

Others

19 %

Shellfish

and

mussels

15 %

Fish

66 %

5. Industry structure

European seafood downstream industry

A total value of > EUR 18 billion

Employees > 135,000

Extremely fragmented more than 4,000companies

About 50% of all companies have less than 20employees

Traditionally the EBIT-margins have been between 3% and 6%

The average company employs 33 people and has a turnover of EUR 4.2 million

Source: Marine Harvest, Intrafish, EU

The seafood industry in Europe is extremely fragmented with more than 4,000 players. Mostof the companies are fairly small, but there are also several companies of significant sizeinvolved in the processing industry: Marine Harvest, Icelandic Group, Youngs Bluecrest,Royal Greenland, Alfesca, Lery Seafood and Morpol.

Most of the largest players are basing their processing on Atlantic salmon, producing smoked

salmon, portions or ready meals with different packing as vacuum or modified atmosphere(MAP).

The trend is that people are willing to pay for quality and value-added so convenienceproducts like ready meals and ready to cook are believed to increase together with a packingtrend which is believed to move to MAP as this increase the freshness of the product.

-

7/30/2019 Salmon Farming Industry

32/68

32

5. Industry structure

European smoked salmon producers (2009)

Source: ABG Sundal Collier

The ten largest producers of smoked salmon in Europe have a market share of about 55-60% together. The production is mainly done in four countries/regions: France, Benelux,

Germany and Poland.

After the acquisition of the German company Laschinger, Morpol is the largest producer ofsmoked salmon in Europe. Morpol is based in Poland, selling most of its production to theGerman market.

Alfesca is the second largest and sells its products under own brand names like Labyrie andDelpierre. Alfesca sells mostly to France, but are also found in UK, Spain, Italy and Belgium.Marine Harvest is the third largest producer, having production in France (Kritsen) and inBelgium (La Couronne). Marine Harvest sells its smoked salmon in France, Italy andBelgium.

0 5 10 15 20 25 30

Friedrich (Germany)

Foppen (Netherlands)

Martiko (Spain)

Suempol (Poland)

Mer alliance (France)

Macrae (UK)

Marine Harvest (Norway)

Alfesca (France)

Morpol (Poland)

Smoked salmon production output in MT (000s)

-

7/30/2019 Salmon Farming Industry

33/68

33

6. Production of salmon

Introduction

Fish farming is the principal form of aquaculture. It involves raising fish commercially incages, ponds or tanks, usually for food, by regular release of juveniles, feeding andprotection against predators etc. Fish species raised by fish farms include salmon, catfish,tilapia, cod, carp, trout, cobia and many others.

Increasing demands on wild fisheries by commercial fishing operations have causedwidespread overfishing. Commercial fishery catch is considered to be at or above thesustainable level and the harvest volumes are considered to be flat or declining goingforward. Fish farming offers an alternative solution to the increasing market demand for fishand fish protein.

-

7/30/2019 Salmon Farming Industry

34/68

34

6. Production of salmon

Photos: EFF, Laksefakta, Marine Harvest

The Atlantic salmon life cycle

The total production cycle takes approximately 10-16 months in freshwater plus 14-22months in sea water = 24-36 months. This is about the same in all regions except for Chilewhere the sea water temperatures are more optimal and average harvest weight is less,resulting in fewer months needed in sea water before harvested.

-

7/30/2019 Salmon Farming Industry

35/68

35

6. Production of salmon

Input Eggs

There are several suppliers of eggs to the industry. Aquagen AS, Fanad Fisheries Ltd,Lakeland and Salmobreed AS are some of the most significant by volume. Egg suppliers can

tailor their production to demand by obtaining more or less fish for breeding during thepreceding season. Production can easily be scaled. The egg market is international.

Input Smolt

The majority of smolt are produced in-house by vertically integrated salmon farmers. Thisproduction is generally captive, although a proportion may also be sold to third parties. Asmolt is produced over a 6-12 months period from the eggs are fertilized to a mature smoltwith weight of 60-100 grams.

-

7/30/2019 Salmon Farming Industry

36/68

36

6. Production of salmon

Source: Marine Harvest, racerocks.com

Input sea water temperatures

The sea water temperatures vary much throughout the year in all production regions. Whilethe production countries on the Northern hemisphere see low temperatures in the start of theyear and high temperatures in autumn varying with as much as 10 degrees Celcius, thetemperature in Chile is more stable varying between 10 and 14 degrees Celcius. Chile hasthe highest average temperature of 120C, while Ireland has 110C and the three other regionshave an average temperature of about 100C.

As the salmon is a cold-blooded animal (ectotherm), the temperature plays an important rolefor its growth rate. The optimal temperature range for Atlantic salmon is 8-14 degreesCelcius. Temperature is one of the most important natural competitive advantages that Chilehas compared to the other production regions and historically the production time in Chilehas been a few months shorter as a result of this.

With high seawater temperatures, disease risk increases. Superchill, with temperaturesbelow zero degrees Celcius, causes mass mortality.

-

7/30/2019 Salmon Farming Industry

37/68

37

6. Production of salmon

Source: NILF report 2007-3, Marine Harvest, Kontali Analyse

Input Labour

In 2008, around 4 800 people in Norway were directly employed in aquaculture, of whichmore than half was employed in salmon and trout production. In UK the figure was 1 430people directly employed in aquaculture while estimates on Canadian employment say thataround 8 000 people are directly employed in the business. In Chile, employment has been

significantly reduced as a consequence of the ISA situation that developed throughout 2008.Direct employment in Chilean aquaculture (incl. processing) is estimated to around 18 000people in 2009. In Norway, both salaries and levels of automation are highest, while theopposite is the case in Chile. Salaries in UK and Canada are somewhat lower than inNorway.

Input Electricity

Electricity is mainly used in the earliest and latest stage in the salmons life cycle. To producea good quality smolt they are often produced in tanks on land where the water is temperatureregulated and/or recirculated which requires energy (8-10% of smolt cost in Norway). When

the salmon is processed energy is consumed. However, this depends on the level ofautomation (3-5% of harvest cost in Norway).

-

7/30/2019 Salmon Farming Industry

38/68

38

6. Production of salmon

Establishing a salmon farm

License and location (Norway)

Since 1973, a licence has been required to operate a salmon farm in Norway. A licence givesthe right to farm salmon either in freshwater or in sea. In addition a site, where the licencecan be used, must be granted. One licence can be associated with up to four sites, and onesite may use several licenses at the same time. These licences are awarded by the Ministryof Fisheries and are administered by the Directorate of Fisheries. It is also possible to applyto the Directorate of Fisheries to change the size of a site and licenses can be traded

between companies in the industry. Since 1982, new licences have been awarded only inlimited numbers in 1985, 1988, 1999, 2001, 2002 and 2009. Currently there are 981seawater licences in Norway distributed on 996 locations. In addition to giving the location,each licence will also specify maximum allowable biomass (MAB) which dictates how muchfish can be produced at the site. One license is set to a MAB of 780 tonnes (900 tonnes inTroms & Finnmark). In general maximum production capacity is 1.5 times MAB on the site.Most Norwegian fish farming sites have between 2,340 and 3,120 tonnes allowed maximumstanding biomass.

License and location (Canada)

Several specific licenses must be approved by Provincial and Federal Ministries before afacility can operate. All parameters of production are regulated and provisions areincorporated within the licensing system to formulate amendments. A typical facility will rangein size from 700 tonnes to 5,000 tonnes of biomass produced on site, per cycle of fish.

Marine sites are located on Crown Land. Leases are awarded by the Provincial Governmentand are issued for a period of five to ten years. A yearly rental fee is calculated based upon agovernment preset value index, size of tenure and area used for aquaculture on the lease. Atypical lease of 20 hectares in size will cost approximately 7500 CAD per year.

-

7/30/2019 Salmon Farming Industry

39/68

39

6. Production of salmon

Establishing a salmon farm (cont.)

License and location (Scotland)

In Scotland the licensing system is very different. Instead of a license, there are severalinstitutions that that have to give permission before it is allowed to make use of an area.

Individual site biomass is governed by environmental concerns: namely the assimilativecapacity of the local marine environment. As a consequence individual site biomass is notuniform, but varies between 100 tonnes to 2,500 tonnes depending on individual sitecharacteristics.

License and location (Chile)In Chile the licensing is based in 2 authorizations. First, the authorization to operate anaquaculture facility is issued by Fishery Sub Secretary (Economy Ministry) which iscomparable to Norwegian Coast and Fishery department. The authorization is for unlimitedtime and can be traded. The second one is the Physic area to operate (or permission to usenational sea areas for aquaculture production). This is issued by the Sub secretary of theNavy, which belongs to the Defence Ministry. The use of the license is restricted to a specificgeographic area, to defined species and to a specified limit of production or stocking density.The production and stocking density limit are specified in the Environmental and SanitaryResolution involved for any issued license.

In Chile there is an annual fee per license. The fee is about 1.800 NOK per Ha. Estimatedtotal area used by the industry in Chile is 22.000 Ha., which give a total annual fee paid of 40million NOK. New fees were defined in the New Legislation.

Equipment

To equip a grow-out facility you need cages (steel or plastic), mooring, nets, cameras, feedbarge/automats and boat. For a normal facility in Norway (850,000 smolt release) theinvestment costs would be in range of 25-30 million NOK.

-

7/30/2019 Salmon Farming Industry

40/68

40

6. Production of salmon

Access to licenses

Norway

It is legal to trade licenses in Norway, but there are some restrictions: If the buyer throughtrade gets control of more than 15% of the total licensed biomass in the country, he has toapply for an approval from the Ministry of Fisheries and Coastal Affairs. The Ministry can notgive approval that implies that the buyer through the trade gets control of more than 25% ofthe total biomass in the country. No owner can control more than 50% of the total biomass inany of the regions. In 1993 a salmon farming licence was traded for NOK 200 000, while theprice today is normally about 20 - 30 million NOK. In the last round of new licences from thegovernment, the price was 8 MNOK.

When assignment for a licence is given, it has to be used within two years with a minimum ofone third of the allowed biomass. A license can be withdrawn if the owner has not beenapproved for a site no later than 6 months after he was granted the licence. A licence can bepledged. A license can not be hired out.

Access to licenses Canada

In Canada licenses for tenures can be assigned to a different operator through a GovernmentAssignment Process. The provision enables a company to transfer a tenure to anothercompany for reasons such as; moved processing to new area, distance is too great and not

feasible to operate or change in species (no longer culture shellfish) etc. Companies havetransferred licenses, the processes involve First Nations consultation and depending uponthe relationships between the parties this can sometimes be a lengthy procedure.

Time limits are part of all licenses, but in general licenses are renewed on request. Licensescan be lost for non- compliance issues and of course non-payments of bills.

Timelines vary from a year to several years to acquire a license. An estimate of cost toacquire a new license/site can range from 300,000 - 500,000 CAD.

A recent court decision, changed jurisdiction of aquaculture from a provincial mandate to

federal control. We remain confident that this shift will not significantly change many of thecurrent operational requirements.

-

7/30/2019 Salmon Farming Industry

41/68

41

6. Production of salmon

Access to licenses (cont.)

Scotland

In Scotland it is legal to trade licences and although no restriction on number is given there isa limit on production volume ascribed to any one company. This limit would be determined bythe Competition Commission Authorities. Licensing aquaculture operations in the UK iscurrently in a transitory state with all new applications requiring planning application forpermission to operate as well as an environmental and Crown estate licence. The granting ofthe planning permission is aligned to the Crown estate lease for 25 year period. All existingfish farm leases in Scotland are currently undergoing a review process which transfers themfrom the Crown estate to Local regional councils. These grants are automatically given a 25year lease.

The environmental licence can be revoked in some cases for significant and long-term non-compliance.

New licence applications take around 6-12 months for planning permission and around 4-6months for environmental discharge licence. Expansion of existing facilities is the mostefficient route in terms of cost and time, whilst brand new sites will take longer and willprobably have to go through an EIA (Environmental Impact Assessment) process. Theenvironmental licence is charged annually at 5,000 whilst the standing rent is levied to thecrown estate on production basis (between 15 and 17 / Tonne). The applications are alsocharged at 145 per 0.1 hectare of farm area whilst the environmental licence costs 2,600for a new site.

Access to licenses Chile

The trading of licenses in Chile is legal and is regulated by the Ministry of Economy.

Licenses granted up to March 2010 are issued for an indefinite period of time. The newlegislation, which has been established for new licenses or modifications to the alreadygranted licenses, allows for permissions for 25 years, and are renewable. Licenses can belost in case of specified violations to regulation and voluntary resignation. It can be lost if e.g.the license is used for a different purpose than the one for which this was granted,environmental violations among others. Main issues in the new legislation are:

General Law on Fisheries and Aquaculture (LPGA) was enacted 5 April 2010.Development of regulations expected to take several months

o Improved sanitary and environmental regulations. Details to be established throughdevelopment of regulations over the next months.

No impact on duration of current licenses.Future production capacity will be impacted by the new law, and specifically by thefollowing:

o No new licenses to be awarded during next 12 months.o Gradual opening of regions XII, XI and X after 12 months, two years and five years

respectivelyo Regulations of zones, availability of areas suitable for aquaculture and fallow periods will

limit production capacity and growth rate until new licenses can be approved and/or newareas opened.

-

7/30/2019 Salmon Farming Industry

42/68

42

7. Cost dynamics

Economy in salmon farming

The salmon farming industry is capitalintensive and volatile. This is a result of along production cycle, a fragmented industry,market conditions and a biological productionprocess which is affected by many externalfactors.

Over the history, production cost has beenreduced and productivity has increased asnew technology and new competence hasbeen achieved. This is believed to continue in

the future as commercial aquaculture still is ayoung industry.

Revenues

Reported revenues

A gross figure which can include freight invoiced to the customers, and where discounts,commissions and credits are deducted. Reported revenues can also include revenues fromtrading activity, sales of by-products, insurance compensation, gain/loss on sale of assetsetc.

Price

Reported prices are normally stated in the terms of a specific reference price e.g. the FHLprice for Norway (FCA Oslo) and UB price for Chile (FCA Miami). Reference prices are notreflecting freight, and other sales reducing items mentioned above. Reference prices are forone specific product (FHL = per kg head on gutted fish packed fresh in a standard box).Sales of other products (frozen products, fresh fillets and portions) will cause deviation in theachieved prices vs. reference price. Reference prices are for superior quality fish, whileachieved prices are for a mix of qualities including downgrades. Reference prices are spotprices, while most companies will have a mix of spot and contract sales in their portfolio

Volume

Reported volume can take many forms. Volume harvested = Fish harvested in a specificperiod in a standardized term e.g. head on gutted (HOG) or whole fish equivalent (wfe) thedifference being gutting loss. Volume sold can be reported using different weight scales:

Kg sold in product weightKg sold converted to standard weight unit (HOG or wfe)

Volume sold could also include traded volume.

-

7/30/2019 Salmon Farming Industry

43/68

43

7. Cost dynamics

Production costs comparison

The figures below illustrate the main cost components and their relative importance in the

farming of salmon in the three biggest regions. The cost level is chosen for illustrationpurposes.

Norway (NOK) Canada (CAD) Scotland (GBP)Feed 10,60 1,80 0,99Primary processing 2,29 0,53 0,25Smolt 1,79 0,46 0,26Salary 1,42 0,33 0,18Maintenance 0,87 0,13 0,06Well boat 0,72 0,14 0,13Depreciation 0,79 0,26 0,12

Sales & Marketing 0,31 0,04 0,04Mortality 0,27 0,05 0,05Other 1,95 0,75 0,41Total* 21,00 4,50 2,50

*HOG cost in box delivered at the processing plant

Cost elements

Feed: As in all protein production, feed makes up the largest share of the total cost. The

variation in costs between the countries is based on somewhat different inputs to the feed,logistics and the feed conversion ratio.

Smolt: Smolt production is done in two different ways; either in lakes or in closed/re-circulated systems in tanks on land. The smolt is produced in fresh water up to about 100gwhen the salmon through its smoltification phase gets ready to be put in sea water. UK hasthe highest costs as there has been low scale production in both land based systems andtanks. Chile has used lakes for this production and has had cheap labour, while in Norwaythere has been a transmission from production in lakes to large scale production in land-based systems.

Salary: Salary level differs among the production regions but in general the salary cost is lowbecause labour cost is a minor part of the total cost as much of the production is automated(e.g. feed blowers).

Well boat/processing: The cost of transportation of live fish, slaughtering, processing andpacking are all heavily dependent on volume, logistics and automation.Other operational costs: Other costs include direct and indirect costs, administration,insurance, etc.

-

7/30/2019 Salmon Farming Industry

44/68

44

7. Cost dynamics

Cost component mortality and disease

During the farming cycle some mortality will be observed. Under normal circumstances the

highest mortality rate will be observed during the first 1-2 months after the smolt is put toseawater while preceding months will have a lower mortality rate.

Elevated mortality in later months of the cycle is normally related to outbreaks of disease orpredator attacks.

There is no strict standard for how to account for mortality in the books, and there is nounified industry standard. Three alternative approaches are:

Charge all mortality to expenses when it is observedCapitalise all mortality (letting the surviving individuals carry the cost of deadindividuals in the balance sheet when harvested)Charge to expense mortality which is higher than what is expected under normalcircumstances

It is not possible to perform biological production without any mortality. By capitalizing themortality cost, the cost of harvested fish will therefore reflect the total cost for the biomasswhich can be harvested from one production cycle.

-

7/30/2019 Salmon Farming Industry

45/68

45

7. Cost dynamics

Source: Marine Harvest

Growth intervals 0.1 0.2 kg 0.2 1 kg 1 2 kg 2 3 kg 3 4 kg 4 5 kg

Feed consume* 0.12 kg 0.8 kg 1.05 kg 1.06 kg 1.06 kg 1.06 kgTime, months 1 4 4 4 4 2

*Estimates for Norway only

Feed and feed ingredients

Historically the two most important ingredients in fish feed have been fish meal and fish oil.The use of these two marine raw materials in feed production has been reduced and partlyreplaced by vegetable ingredients as soya beans, sunflower meal, poultry by products (Chileand Canada) and rape seed oil. This substitution is mainly done because of heavy

constraints on availability of fish meal and fish oil.

Fish meal and other raw materials of animal origin has a more complete amino acid profilethan protein of vegetable origin. It is therefore difficult to replace fish meal 100%.

Feed at the beginning of salmon aquaculture was moist feed (high water content) with highlevels of marine protein (60%) and low levels of fat/oil (10%), the industry went through adevelopment of pellet feeds with focus on protein and fat content. A typical recipe in the earlynineties consisted of 45% protein, whereof most of it was marine protein, i.e. fish meal.Today the marine protein level is still high, but the vegetable content has increased.However, the most interesting development has been the increasingly higher inclusion of fat.This has been possible through technological development and extruded feeds.

Due to market demands, legislation and different availability of raw materials, the ingredientsused in fish feed today are different from country to country, giving higher raw materialflexibility in certain regions as e.g. Chile and Canada. This will have an impact on the feedprice.

Feed and feeding strategies aim at growing a healthy fish fast at the lowest possible cost.There is an optimal feed level to achieve the lowest production cost. A too restrictive feedingregime may delay production, be uneconomic and in conflict with animal welfare issues. A

more aggressively feeding than optimal feeding level, can impact growth positively, but at theexpense of higher feed conversion ratio and cost optimisation.

-

7/30/2019 Salmon Farming Industry

46/68

46

7. Cost dynamics

Source: Skretting annual report, EWOS annual report, BioMar

Salmon feed producers

The salmonid feed industry has during the last decade become more and more consolidated,and in 2008 there were essentially three large producers controlling the majority of theoutput. These companies, BioMar (listed), Ewos (Cermaq) and Skretting (Nutreco) can becharacterised as global players as they are present in most of the regions with the highestproduction of farmed salmonids. Additionally, there are some producers who are only presentin their regional market. The aqua feed suppliers are an important source of advice and

support to salmon farmers and this is an important factor in the selection of feed suppliers.

One major issue in the salmon feed industry is the future supplies of the raw materials goinginto feed (see next page).

The major cost elements when producing salmonid feed are fishmeal, fish oil, pigment andproduction/capacity costs.

The feed producers have historically operated on cost-plus contracts, leaving the exposure ofraw material prices with the aquaculture companies.

Feed producers'

market share 1998

Skretting (44%)EWOS (22%)

BioMar (12%)

NorAqua (9%)

Biomaster (4%)

Other (9%)

Feed producers'market share 2008

Skretting (35%)

EWOS (34%)

BioMar 25%)

Other (6%)

-

7/30/2019 Salmon Farming Industry

47/68

47

7. Cost dynamics

Source: Marine Harvest

Raw material market

Fish oil: 2008 was a very turbulent year with regard to fish oil price. During the first half of2008 we saw the highest fish oil prices ever, close to 2000 USD. Since August 2008 the fishoil price has been reduced and in December 08 fish oil was purchased at around 1000 USD.Since then there has been a further decline in price.

Rape seed oil: Rape seed oil prices have very much the same price trend as fish oil. In

2008, when we saw the all time high fish oil prices rape seed oil could be purchased at alower price. At the moment there is a tendency to a higher rape seed oil price compared tofish oil. As there is an increasing demand for bio diesel, there will be continued pressure onprice, including other types of vegetable oil.

Fish meal: During2008 fish meal prices have been very stable, and have therefore been agood price buffer for fish feed up to now. During the first month in 2009 there has been aslight increase in fish meal price.

Soy:After having seen the soy prices climb to the highest level in 34 years in mid 2008 therehas been a decrease in price, but still with higher prices than in the past. The main reason for

this is less soy planted due to a shift from soy to corn in many regions, and a high demandfor vegetable oil in general. Corn is planted in higher volume due to increased demand forethanol produced from corn, i.e. former soy areas are used for corn production.

Vegetable protein: Soy and corn have traditionally been very important vegetable proteinsources in fish feed. As a consequence of less planting of soy and more corn for energypurposes, the price for these raw materials increases. Parallel to this there has been anincrease in genetic modified (GM) production of soy and corn. To be able to get non- GMproduction, a premium has been put on price, i.e. non -GM products are more expensive thanGM products.

Wheat: In 2007/ beginning of 2008 drought conditions and bad weather lead to a low harvestin major production areas as for instance in Australia and thereby the prices for wheat wentup significantly. During the last part of 2008 the harvest and thereby prices have normalised.

-

200

400

600

800

1 000

1 2001 400

1 600

1 800

2 000

Fish meal

Soy meal

Wheat

Rapeseed oil

Fish oil

-

7/30/2019 Salmon Farming Industry

48/68

48

7. Cost dynamics

Inflation adjusted price and production cost Norway

Source: Kontali Analyse

Commodity production

When historically achieved sales prices in Norway are adjusted for Norwegian inflation wesee the normal trend in a market of perfect competition - a clear correlation betweendevelopment in cost and price.

Production cost has also shown the normal falling trend as production volume has increasedrapidly.

Most of the time though, the inflation-adjusted sales prices have been above the productioncosts, but the difference has been very volatile and cyclical.

-10,00

0,00

10,00

20,00

30,00

40,00

50,00

1993 1994 1995 1996 1997 1998 1999 2000 2001 2002 2003 2004 2005 2006 2007 2008 2009

EBIT/kg Price/kg Cost/kg

Adjusted according to KPI (2009 = 100)

-

7/30/2019 Salmon Farming Industry

49/68

49

7. Cost dynamics

Typical production cycle in Norway (3 generations)

In the autumn, the broodfish are stripped for eggs and the ova inlay happens betweenNovember and March. The producer has the possibility to speed up the growth of thejuveniles with light manipulation to accelerate the smoltification process by up to 6 months.The light manipulated juveniles are called S0s and the normal grown juveniles are calledS1s.

In Norway smolt is mainly released into seawater twice a year, S0s in autumn/spring within12 months after ova inlay, and S1s in the autumn about 18 months after ova inlay. A verysmall part of the production is produced as S1 which are put to sea 2 years after the ovainlay. The harvest is spread all around the year. In Norway typical harvest is harvest of theS0s in the beginning of the year and S1s in the second half of the year. In the summertimethe supply to the market is significantly different to the rest of the year, as harvest go fromS0s to S1s and the large S0s and the small S1s dominate the supply.

After a site is harvested, the location is fallowed between 2 and 6 months before the nextgeneration is put to sea at the same location. Smolt may be released in the same locationwith a two year cycle. In the example above Generation 1 (G1) is put to Location 1 (L1), G2put to L2 and then G3 is put in L1 again as the fish from G1 have been harvested and thelocation has been fallowed.

Harvest volume is largest in the last quarter of the year mainly since most of the S1s areharvested in this period. Some of the last S0s and some early S1 could also be harvestedin this period.

-

7/30/2019 Salmon Farming Industry

50/68

-

7/30/2019 Salmon Farming Industry

51/68

51

7. Cost dynamics

Biomass capital needs

Capital needs when building biomass

The illustration above shows how capital needs develop when building production/biomassfrom scratch. In phase 1 there is only one generation of fish produced and the capital needs

is the production cost of the fish. In phase 2 the next generation is also put into productionwhile the on-growing on G1 continues, rapidly increasing the capital invested. In phase 3, G1has come to its last stage, while G2 is in its on-growing phase and G3 has begun to increaseits cost base.

At the end of phase 3 the harvest starts on generation 1, reducing the capital bound, but thenext generations are building up their cost base. If each generation is equally large andeverything else is in a steady state, the capital needed would have peaked at the end ofphase 3. With an increasing production the capital needed will also increase after phase 3 aslong as the next generation is larger than the previous (if not production cost is reduced).

-

7/30/2019 Salmon Farming Industry

52/68

52

7. Cost dynamics

Accounting principles for the biomass

Accounting for biological assets

Biological assets are recognized in the statement of financial position at fair value of thebiomass.

Live fish over approximately 1 1.5 kilo is measured at fair value less cost to sell. However,brood stock, smolt and small live fish are measured at cost less impairment losses.

The calculation of the estimated fair value of live fish is based on market prices for harvestedfish. The market price is derived from a spectre of prices. Normally a combination of achieved

prices last month, quoted forward prices and the most recent contract entered into. Theprices are reduced for harvesting costs, processing costs and freight costs to market, toarrive at a net value back to farm. The valuation take into account the stage in the life cycle,actual size and expected harvest weight of the fish and reflects the expected quality gradingand size distribution.

The change in estimated fair value is recognized in profit or loss in comprehensive income ona continuous basis, and is classified separately (not included in the cost of the harvestedbiomass). When harvested, the fair value adjustment is reversed on the same line in profit orloss.

Fixed price contracts

The company holds long term sale contracts related to salmon. Provisions are made foronerous fixed-price contracts that oblige the company to sell fish at a price lower thanrecognized fair value of the biomass.

The provision for onerous contracts is classified as a liability in the statement of financialposition, while the change is classified separately in profit or loss in comprehensive income.

Operational EBIT

Operational EBIT and other operational analyzes are reported based on the realized costs ofharvested salmon and do not include neither the fair value adjustments on biomass nor theprovision for onerous contracts.

-

7/30/2019 Salmon Farming Industry

53/68

53

7. Cost dynamics

New entry financial assumptions

Normal site consisting of 4 licenses:

Equipment investment NOK 25-30mNumber of licenses 4Licence cost (second hand market) NOK 80-120m (~NOK 20-30m per licence)Output per generation: ~4000 tonnes HOGNumber of smolt released: 1m

Smolt cost per unit: NOK 7.5Feed price per kg: NOK 8Economic feed conversion ratio: 1.2 (to live weight)Conversion rate from Live Weight to HOG: 0.83Harvest and processing cost per kg (HOG): NOK 3

Average harvest weight (HOG): 4.5kgMortality in sea: 10%

Sales price: NOK 25

Investments and payback time for new entries - assumptions

For new volume capacity to be established there are many regulations to fulfil.

In this model, we have used only one site for simplification purpose and because we arelooking at a new company entering the industry. Most companies use several sites at thesame time, which enables economies of scale and makes the production more flexible andoften less costly.

To simplify, smolt is bought externally. Smolt is usually less costly to produce internally, butthis depends on production volume.

The performance of the fish is affected by numerous factors as feeding regime, sea watertemperature, diseases, oxygen level in water, smolt quality etc.

Sales price chosen is the average sales price from Norway the last decade.

-

7/30/2019 Salmon Farming Industry

54/68

54

7. Cost dynamics

New entry economic results

Investments and payback time for new entries - results

Due to the simplifications in the model and low, non-optimal, production regime, productioncost in the model is higher than average production cost in the industry. But it is likely tobelieve that a new entry into salmon production will experience higher production costs thanlarger companies due to less volume and flexibility. During the production of each harvest theworking capital needed at this farm, given the assumptions, would be peaking at MNOK 75(given that the whole harvest is harvested at the same time).