Safran Magazine December 2012

description

Transcript of Safran Magazine December 2012

p. 25 mARKETS: MaxiMuM dispatch reliability for Military aircraft engines / p. 28 InSIghT: shooting for the stars

dEcEmbER 2012 – # 13the safran group magazine

The Brazilian Boom

SpEcIAl REpoRT

Safran supports the country's growth

marchésContents

02 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 03

marchésEditorial

safran is facing considerable challenges in all of our businesses. We have to address the huge appetite for mobility, especially by air. And we have to meet the growing need for technologies that can make our world a safer place. At the same time, we must meet these goals in line with our economic and environmental responsibilities.

Two factors are absolutely essential in meeting these challenges, starting with innovation. By developing the new LEAP engine, we have provided a worthy successor to our best-selling CFM56. Of course, we are fully aware that we can’t take anything for granted. In businesses like ours, as we all know, today’s choices determine tomorrow’s successes. Carrying on

our long tradition and ingrained culture, we are continuing to focus on innovation across the board: by developing breakthrough products and distinctive technologies, and

applying best practices. All of these efforts are needed to stay at the cutting edge of technology and maintain our competitive advantage.

The second imperative is social unity. We cannot move forward if we don’t give all of our people a stake in Safran’s future. In particular, we have to successfully integrate the new talents we need to maintain our critical skills base and pursue our growth in international markets. Of course, our healthy backlog of orders guarantees many years of growth. But if we are unable to either attract or integrate the new generation, we will not succeed. It’s as simple as that.

We have therefore made a firm commitment to several critical objectives: get out the word so that students know about us, construct effective orientation and integration paths, and offer all new employees career development opportunities attuned to their goals and their capabilities.

Innovation and new talents: the keys to our future

22 PropulsionYou can also check out the latest safran news on: • www.safran-group.com • www.facebook.com/Groupesafran• twitter.com/safran

Dominique-Jean ChertierDeputy chief Executive Officer, corporate Office

News break p. 04

Special report p. 08The Brazilian Boom Safran supports the country’s growth.

panorama p. 16Discovery Day 2012 The largest orientation day ever organized by Safran.

Markets p. 2020 Farnborough: a giant LEAP

forward for Safran22 Successful market entry for

Silvercrest bizjet engine25 Maximum dispatch reliability for

military aircraft engines

Insight p. 2828 Safran: shooting for the stars32 Spearheading innovation34 A facility dedicated to composite

materials35 GE and Snecma: teaming up for

success

Interview p. 36Commercial aviation: the Russian ren-aissance Interview with Mikhail A. Pogosyan, President of United Aircraft Corporation.

“Today’s choices determine tomorrow’s successes”

The Silvercrest jet engine has been chosen by Cessna to power its new Citation Longitude business jet and is now kicking off its test cycle.

SilvercreSt takeS off with ceSSna

© E

dwar

d Li

nsm

ier /

ca

Pa P

ictu

res

/ saf

ran

© r

ober

to F

rank

enbe

rg /

saf

ran

The Safran group magazine - 2, bd du Général-Martial-Valin 75724 Paris -

France - Cedex 15 - E-mail : [email protected] - Publication Director: Pascale Dubois - Editorial Director: Marie-Laure Dufour - Executive Editor in Chief: Céline Groult - Editor in Chief: Martin Bellet - Written by: A. Attali, D. Baudier, M. Bellet, E. Dumoulin, F. Lert, P. Michaud, M. Pyadouchkine - Translation: Don Siegel, ID Communications - Production: - Printed by: Imprimerie Vincent, certified imprim’vert on PEFC accredited paper - ISSN 1960-7164 - The articles and illustrations published in this magazine may not be reproduced without prior authorization. Cover: © Ricardo Funari

wTraining

marchésNews Breaks

04 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 05

orders and options for the LEaP engine as of October 31, 2012.

4,252

a busy weekend for safran museum

During European Heritage Days* on September 15

and 16, 2012, the Safran Aerospace Museum welcomed over 3,000 visitors of all ages to discover its outstanding collection, ranging from aircraft and rocket engines to motorcycles. They not only learned about the history of aerospace, but also had a lot of fun at the same time! One of the biggest hits was a children’s workshop,

enabling them to build and launch their own model rocket. Several

simulators were also set up so young and old alike could experience the thrill

of flying an aircraft, in particular an Airbus A320. A temporary exhibition was dedicated to Jean Bertin. A former Snecma engineer, Jean Bertin was a visionary inventor who in the late 1960s developed the Aerotrain, an innovative high-speed train that floated on a cushion of air over a guide rail.

* European Heritage Days was created in 1984 by the Ministry of Culture, and takes place every year in France during the third weekend of September.

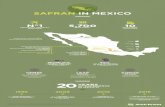

new training center opens in Mexico

s ince May 2012, helicopter operators in Mexico and neighboring countries

have had access to a joint training center operated by Eurocopter Mexico (EMSA) and Turbomeca Mexico (Safran). They receive complete training in four basic disciplines: mechanics, avionics and engine maintenance, as well as flight training. Courses are consolidated in a single venue and given in Spanish. Participants learn about

the parts and tools needed for the maintenance of Turbomeca Arriel and Makila helicopter engines. Two flight simulators are also available to train pilots in emergency procedures and flying under difficult conditions.

w More

Interview with Jean-Louis mostajo, corporate training manager, in the media corner on the safran website, www.safran-group.com

On October 16, 2012 safran announced a definitive agreement with goodrich Corporation to acquire its Electric Power systems business. The transaction should be finalized in late 2012 or early 2013 and will make safran no. 2 worldwide in aircraft electric power systems. it also marks a definitive breakthrough in safran’s “more electric aircraft” strategy. This newly acquired business fits perfectly with safran’s existing electrical businesses, and also supports the group’s development strategy, based on technological differentiation. it will drive savings in r&D and also open doors to key customers, by leveraging recognized expertise and excellence. The business acquired from goodrich should generate sales exceeding $200 million in 2012, half from maintenance services and spare parts.

Goodrich electric Power SySteMS now Part of Safran

safran chosen for X4 helicopter

wPrOPuLsiOn

wEurOPEan HEriTagE Days

of sales reinvested by safran in r&D.

11%With the creation of Optrolead in July 2012, sagem (safran) and Thales are building a joint center of excellence for optronics. This new joint venture is equally-owned, and will draw on the industrial facilities and expertise of its two parent companies to sell newly developed optronic systems for defense applications. Optrolead will be competing to supply the new optronic pod for the French navy’s atlantique 2 maritime patrol aircraft, the imaging system for the future French-British MaLE (medium-altitude, long-endurance) drone, modular optronic systems for army combat vehicles, and optronics for tomorrow’s helicopters. The original Memorandum of understanding to create the joint venture was signed on December 20, 2011.

Safran and thaleS teaM uP

a concert to fight muscular dystrophy

On October 16, 2012, Safran and the Orchestre de l’Alliance organized their eighth “Seasons of Solidarity” concert

in the Gaveau concert hall in Paris. All receipts were donated to the French Muscular Dystrophy Association, AFM-Téléthon, to support the development of innovative therapies for rare diseases. Organized ahead of the traditional annual Telethon (Dec. 7 and 8, 2012), this concert also marked the start of Safran’s partnership with this association.

w More

To support the French muscular Dystrophy association: http://www.afm-telethon.fr/

wPHiLanTHrOPy

s afran was chosen this summer to supply both the engine and the wheels and

brakes for Eurocopter’s new-generation X4 helicopter. The TM800 turboshaft engine is rated at 800 kW (about 1,070 shp) and will significantly reduce fuel consumption compared to the current generation of engines. It will help improve the X4’s performance in terms of range, payload capacity, etc.,

while reducing its environmental footprint. It also features an optimized maintenance concept that will decrease operating costs. Electric brakes reduce weight, while also maintaining excellent friction properties and simplifying maintenance.

w More

Interview with Patrick moncoutié, Tm800 program manager, in the media corner on safran’s website, www.safran-group.com

© E

uroc

opte

r

© r

icar

do F

unar

i / c

aPa

Pic

ture

s

© D

anie

l Dec

lerc

q / s

afra

n

CorrectionIn the previous edition of safran magazine (No. 12, april 2012), the article “Vega lifts off!” referred to Vega as a “new rocket, developed by ELV, a joint venture of avio and EaDs.” ELV is in fact a joint venture of avio (70%) and the Italian space agency (30%).

Olivier savin,Director of safran’s Green Taxiing programs“Aircraft that don’t need their jet engines to taxi before takeoff or after landing: this revolutionary concept, dubbed “green taxiing”, will soon be a reality. The basic principle is in fact simple, with electric motors installed directly in the wheels on the plane’s landing gear. However, there are still a number of challenges to be met, in terms of technology, as well as reliability and performance. Several Safran companies have teamed up to meet these challenges, in conjunction with our program partner Honeywell, which offers complementary expertise. It will be largely worth it, since the economic and environmental benefits are considerable. The aircraft manufacturers, airlines and airports that we have talked to are eagerly awaiting this innovation. I’m very proud of my role as leader of this ambitious project.”

Olivier Savin was named director of Safran’s Green Taxiing programs at the end of 2011. Joining the Safran group in 1992, he held a series of management positions with Messier-Bugatti-Dowty, and was then named CFM56 program director for Snecma and Executive Vice President of CFM International (the 50/50 joint company of Safran and GE). In particular, he worked on the renewal of this partnership and the launch of the LEAP engine, already chosen for the Comac C919, Airbus A320neo and Boeing 737 MAX. He is continuing along this path with the creation of the joint venture between Safran and Honeywell dedicated to Green Taxiing. He was promoted to the rank of Knight in the National Order of Merit in 2011.

marchésNews Breaks

06 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 07

Decision-makers

safran, partner in the 2012 Women’s Forum

about 20 women from Safran participated in the 8th Women’s Forum

in Deauville, France, from October 10 to 12, 2012, taking part in the discussions and conferences concerning women’s vision of today’s pressing economic and society issues. The theme for this year’s forum was “Wanted: 360° Growth”. Safran organized a workshop called “Produce in Europe to grow Worldwide”, to promote its industrial strategy, which is based on maintaining its technology roots in France and Europe, while expanding internationally. Safran also

participated in a workshop series organized by Altran and Areva, entitled “Women in Engineering”, enabling it to show how women can play important roles in transforming both engineering and technological innovation. Safran’s businesses largely depend on the

development and integration of advanced technologies, and the Group hired some 6,000 new employees in 2012. It is also promoting gender equality, and the target is 30% women among the new hires. To help it achieve this goal, Safran has been a partner in the association Elles Bougent (“Women on the Move”) since 2006. This industry association encourages girls and young women to consider scientific and technical careers, telling them about the job opportunities opened through this type of education – especially as engineers.

wMEETings

support for Turbomeca-powered russian helicopters

Turbomeca (Safran) signed an agreement in June 2012 with Russian Helicopters

to ensure the best possible support services for its engines in Russia. Helicopter Service Company, a subsidiary of Russian Helicopters, will provide maintenance, repair and overhaul (MRO) services for Turbomeca engines powering the new Ka-226T light and Ka-62 medium twin-engine helicopters produced by Russian Helicopters

for the Russian army and government agencies. This is a major agreement for Safran, since it builds the foundations for a broad support network for Russian helicopters powered by Turbomeca engines. Russia is a vast country with a number of areas that are difficult to reach, making it a prime helicopter market. Even several decades ago, there were already an estimated 10,000 helicopters operating in Russia.

wMrO

© D

.r.

The two European specialists in military aircraft engines, snecma (safran) and rolls-royce, signed a contract with the British Ministry of Defense in July 2012 to carry out design studies for the next generation of engines powering French and British combat aircraft. Their joint company, rolls-royce snecma Ltd., will have unique access to the knowledge, technologies, infrastructures, supply chains and industrial facilities of the two engine-makers. it will be able to offer a range of propulsion systems for the upcoming generation of combat aircraft, whether these engines are derived from existing powerplants or are based on new concepts.

towardS a french-BritiSh coMBat aircraft enGine

© K

amov

© In

fopr

o c

omm

unic

atio

ns /s

afra

n

Women in industry award for innovation

sylvaine Picard, head of the biometric vein pattern research team at Morpho

(Safran), won the 2012 Women in Industry Award for Innovation in September. The Women in Industry Awards are organized by French magazine L’Usine Nouvelle. The award recognizes “a woman responsible for a spectacular innovation, whether scientific, technical, economic, financial or human.” Sylvaine Picard, 40, won this award because of her work on Finger On The Fly, the world’s first contactless biometric detector, capable of reading and processing the fingerprints on four fingers of a moving hand in just a

few seconds. After receiving her doctorate in image processing (INRIA), Sylvaine Picard started her career at Getris Images, then continued at remote sensing specialist Istar. This experience led to work for the French space agency CNES and its German counterpart DLR. In 2004 she joined Morpho’s Research & Technology unit, to work on biometric technologies. Today, Sylvaine Picard is in charge of both algorithmic research for vein pattern biometrics, and research on vein pattern detectors.

wHOnOrs

© a

Ba

ca

Pre

ss

sylvaine Picard receives the Women in industry award for innovation from former French culture minister, Christine albanel.

Brazil, one of the engines driving South America’s growth, has become a leading market for Safran. The Group has also invested heavily in this country.

The Brazilian Boom

204aircraft delivered in 2011 by embraer, the world’s third largest planemaker

$2.517trillion GDP in 2011

5th most populous country in the world, with 192 million inhabitants

08 _ December 2012 _ safran magazine safran magazine _ December 2012 _ 09

marchésSpecial report

© G

etty

imag

es/s

amba

Pho

to/c

assi

o V

asco

ncel

los

marchésSpecial report

Brazil’s primary asset is undoubtedly its vast national territory, bursting with raw materials, in particular minerals. But that’s far from the country’s only advantage. Brazil

also has the world’s largest reserves of fresh water and large quantities of offshore oil – and it’s one of the world’s leading producers of eth-anol. With all of its natural resources, Brazil has also developed a powerful agro-industry, which takes a very aggressive stance in inter-national markets. Furthermore, Brazil’s bank-ing industry was restructured in the 1990s, and it is now very healthy and competitive. The Brazilian economy is one of the most dynamic in the world, driving the emergence of a large middle class with hefty purchasing power.

Of infrastructures and menHowever, the country still faces an enormous challenge if it wants to meet its ambitious eco-nomic goals: an educational shortfall means a significant lack of mid-level managers and qualified workers. “But there are still good managers to be found in Brazil, and grants for young people to receive training abroad,” says Stéphane Monclaire, political sciences professor at the Sorbonne. “In fact, all infra-structures have to be improved, although the

Brazil has become a major economic power. Along with this growth, strong demand has emerged for technological expertise, in particular to boost the export competitiveness of Brazilian companies, within the scope of a strengthened government support policy.

EcONOmY

Brazil, land of unBounded amBitions

government has made an exceptional effort over the last few years by building roads, bridges and airports.”

OBjective: internatiOnal marketsAnother pivotal growth driver is Research & Development. Brazilian companies did not invest much in R&D. But times are chang-ing, and the current administration plans to nurture the development of the country’s knowledge base to include high-value-added technologies.

“If you want to do business in Brazil these days, you need to invest, transfer technolo-gies, form partnerships with local companies and give them management control,” adds Stéphane Monclaire. “Foreign companies can only submit bids if they meet all these criteria.”

The defense market also follows this trend. Brazil fully intends to develop the defense capabilities worthy of a global power, and is calling on major multinationals to help. But the country also intends to develop its own defense industry, even if it has to import cer-tain areas of expertise. “The Brazilian mili-tary is ready to purchase equipment, provided that it retains operational independence,” explains Monclaire. ■

million inhabitants

largest economy in the world, Brazil is just behind france and ahead of the united kingdom

million square kilometers (3.3 million square miles)

195

6th

8.5

more than half of all Brazilian helicopters are powered by engines from Turbomeca do Brazil, an exemplary perform-ance by this company, which

was founded in 1977,” notes François Haas, the Safran group’s National Delegate in Bra-zil. “Until 2002, Turbomeca’s presence in Brazil was limited to a small five-person team to provide technical and sales support. But that year, the company decided to set up a turbine engine maintenance center in Rio. Since then, it has overhauled more than 1,500 turbine engines for customers in Brazil and all of Latin America, making Turbomeca a leading exporter in Brazil.”

Turbomeca do Brasil now has 240 employ-ees. In recent months its business has shifted into higher gear, largely due to a strategic deci-sion to bolster local customer support, plus the requirements of the 2009 contract with the Brazilian ministry of defense to acquire 50 EC 725 helicopters, each powered by twin Makila 2 turboshaft engines. “We also signed our first through-life support contract [MCO – see page 25] in this country in 2011, cover-ing the 100 Makila 2 engines for the Brazil-

Safran has been operating in Brazil for well over three decades. Today, its development is largely channeled through two subsidiaries, Turbomeca do Brasil and Morpho do Brasil.

safran in BrazilFacILITIEs

ian armed forces,” adds Haas. Turbomeca do Brasil manages over 1,000 engines deployed in Latin America, ranking it 5th among Tur-bomeca’s 14 entities around the world.

spectacular grOwthMorpho do Brasil is Safran’s other main sub-sidiary in Brazil. Operating in the identifi-cation, detection and e-document markets, this company has nearly 700 employees. The e-document division alone counts 630 persons at the Taubaté plant, which turns out 100 mil-lion smart cards a year. Morpho do Brasil also invested in a dedicated chip assembly line in 2011, in response to a government recommen-dation for foreign companies to increase their share of local production. “This new produc-tion line places us in an ideal position to meet new government requirements for electronic documents,” says Paolo Villasco, Morpho’s sales director for the Americas.

The country’s four main mobile phone operators, along with all public and private banks, are Morpho do Brasil customers. In particular, the company has become a favored supplier to Banco Itaú (see page 15).

Another major customer, this time for iden-

four pivotal years

aviation championEmbraer is now the world’s third leading aircraft manufacturer. Founded in 1969 at the instigation of the Brazilian government, Embraer is the world’s leading manufacturer of regional aircraft. The company also offers a complete range of business aircraft. For the defense industry, Embraer is developing a new-generation military transport, the Kc-390, and is active in combat aircraft modernization programs. It also provides drones, c4Isr* systems and satellites to the Brazilian armed forces. safran holds a 1.1% stake in Embraer.

* c4Isr: command, control, communications, computers, Intelligence, surveillance and reconnaissance

“1977creation of the company that would become Turbomeca do Brasil

2002maintenance center for helicopter turbine engines set up in Xerem

2005morpho do Brasil acquires a smart card production plant in Taubaté, são Paulo state

2008Brazilian ministry of defense acquires 50 Ec 725 helicopters, powered by Turbomeca engines

© E

mbr

aer

© r

icar

do F

unar

i / c

aPa

Pic

ture

s

10 _ December 2012 _ safran magazine safran magazine _ December 2012 _ 11

XeremTurbomeca do BrasilIndustria e Comercio Ltda

TaubatéMorpho Cards do Brasil

OsascoSagem Defesa e Aeronautica

Sao Josedos CamposSafran

marchésSpecial report

the recent acquisition by Safran com-pany Sagem of Optovac, a small Bra-zilian company specialized in optron-ics and night vision equipment, clearly reflects Safran’s strategy in

Brazil. Through this transaction, the latest in a long line of alliances with local partners, Safran can now set up a Brazilian center of excellence in optronics, and also establish a local base for avionics through Sagem Defesa e Aeronautica. These advantages will underpin Safran’s objec-tive of becoming a partner in Brazil’s ambitious defense procurement program. “Optovac is a very innovative small business, and it is rec-ognized by the ministry of defense,” explains Hervé Bouaziz, Vice President for Strategy at Sagem. “This company is therefore in a perfect position to attack the Brazilian market either directly or through partnerships, while contrib-uting local added-value.”

One of the opportunities to be seized in this market is in the border patrol segment, which demands advanced night vision systems. “The government recently started a pilot program for the surveillance of land borders, and is working on a similar project for coastal zones. Sagem and Optovac are obviously candidates,” notes Valérie Redron, CEO of Optovac. Another key sector is the country’s fighter fleet. Safran

OUTLOOK

provides the engines for 12 Brazilian Mirage 2000 fighters, and is part of the GIE Rafale consortium that has proposed the advanced Rafale multirole fighter. As part of this consor-tium, Safran was asked to set up a specialized maintenance training center in Sao José dos Campos, State of São Paulo. “This is an impres-sive project, and symbolizes our commitment to Brazil,” says Jean-Pascal Gaudy, deputy director of Safran Corporate University.

sky kingSafran’s major success in the Brazilian market in 2011 was its selection by Embraer to supply five major systems on the new KC-390 military transport, the largest aircraft ever developed

supporting Brazilian growth

Safran is strengthening its positions in Brazil in its core businesses of aerospace, defense and security by applying an industrial strategy aligned with the country’s own objectives. The near-term outlook is promising indeed.

safran’s facilities in Brazil.

tification systems, is the federal police. It is currently deploying a database that will cen-tralize all biometric information on Brazilian citizens, including fingerprints, and facial and iris recognition data. A custom-designed facil-ity has been set up in the State of Bahia.

“Morpho do Brasil is probably Safran’s fast-est-growing company in Brazil,” notes Paolo Villasco. “The company developed at just the right moment to seize some outstanding opportunities, doubling its revenues twice in the last four years.” Morpho recently opened a new office in Rio de Janeiro, covering all three business sectors. In 2012 Morpho do Brasil exported 10% of its production in terms of value, and 15% in volume.

“I work at the Xerem plant, near rio, where I’m in charge of final inspection of technical publications and engines before delivery to customers.

I’m part of the first group of mechanics hired by Turbomeca do Brasil. The company has grown quite a bit in these ten years, and has also

invested heavily in staff training. For example, I took a training program in France in 2002, then a second one, lasting several months, in France again early in 2010. This training was for the makila 2 engine, which began to be assembled in Xerem at the end of July 2012. my job is very demanding, but it’s also very gratifying because we work on projects that have an excellent future.”

mechanic, Turbomeca do Brasil

w ricardo paiva

“turbomeca has invested heavily in training”

priOrity develOpment zOneAccording to Olivier Piepsz, Safran Senior Vice President, Latin America, “Brazil is a priority development zone for Safran, because of its large domestic market, major moderniza-tion projects in our areas of expertise, includ-ing airports, biometric systems, border control and defense, the presence of a world-class air-craft manufacturer and the only helicopter-maker in Latin America.” Safran developed national structures calling on its technologies to make sure it is aligned with the Brazilian government’s policy and expectations, and teams up with local experts, building key industrial partnerships with Brazilian heavy-weights.” ■

safran chairman and cEO Jean-Paul herteman visited Brazil in October 2012 to meet with the country’s main aerospace players (FaB, Gol, Embraer, helibras, Infraéro, etc.), as well as

senior government officials. he was also invited to visit the Brazilian Parliament and sent a strong message to all, clearly stating, “safran is here in Brazil to stay, and we will play an even

stronger role in the future.” During this trip, safran signed a letter of intent with Queiroz Galvão, a major conglomerate active in construction, energy and other sectors, confirming a closer

relationship in defense and security in Brazil. They should be well positioned to win upcoming major contracts, based on the combination of Queiroz Galvão’s knowledge of the country and experience in

large-scale projects, and safran’s mastery of key deterrence technologies, industrial expertise and high-performance products, through sagem for defense and morpho for security.

a forward-looking visit

“Optovac is a small company, but it’s the first one in Brazil to have developed and built a thermal imager. We’re also the first company to be

certified by INPs, the national space research institute, for space projects. There is a pressing demand in Brazil today for high-end optronics,

including portable optical cameras and more sophisticated imagers, and for custom-tailored solutions. By combining the reputation and expertise of Optovac with the high-performance products available from sagem, we can meet both our customers’ expectations and government requirements. In fact, the government is actively encouraging projects that bring new areas of technological know-how to Brazil.”

Technology director, Optovac

w henrique noBre

“a position that corresponds to our customers’ expectations”

services Industrialsite

Offices

sagem supplies four series 30 sms optronic masts for each new scorpène class submarine deployed by the Brazilian navy

4

leap engines ordered by gOl airlines of Brazil to power its upcoming Boeing 737 maX jetliners

120

© F

lavi

o Li

ma

/ mor

pho

© a

ntoi

ne L

eves

que

© r

icar

do F

unar

i / c

aPa

Pic

ture

s

© O

ptov

ac

12 _ December 2012 _ safran magazine safran magazine _ December 2012 _ 13

14 _ December 2012 _ safran magazine safran magazine _ December 2012 _ 15

shore drilling projects in the country will require a large number of helicopters,” notes Haas. “We’re expecting demand to increase by about 50% in the coming years, and Safran will be ready.”

Brazil also has a space industry, and Safran is already a partner in the country’s VLS1 launcher through Pyroalliance, a subsidiary of Herakles. According to Olivier Piepsz, “We’re keeping a close eye on this program’s propul-sion requirements, as well as pyrotechnics and inertial guidance systems.”

amBitiOus OBjectives in the security marketTwo major upcoming global events will further boost Brazil’s already strong security require-ments: the Football World Cup in 2014 and the Olympic Games in 2016. Safran hopes to take an active role in setting up security systems at the country’s airports, an area in which it has solid credentials, as well as in the Brazilian Civil Identity Registry program, abbreviated RIC. “The government has launched the ambi-tious RIC program, which will give all Brazil-ians a biometric ID card,” notes Richard Schin-dler, Latin America sales director for Morpho’s Identification division. “We’re one of the three companies selected for the first phase of this project.” ■

w moresee the interview with jérôme tourdiat, kc-390 program manager at hispano-suiza, in the media corner of the safran website, www.safran-group.com

“safran provides an array of equipment for our Kc-390 cargo plane. We were very favorably surprised by their flexibility during contract negotiations, including messier-Bugatti-Dowty, which

was able to add the braking control and landing gear extension-retraction systems to their proposal. another example was hispano-suiza, which developed a ram air

turbine* specially for us, and acquired an american company to add that capability! Last but not least, the new organization they recently set up at são José Dos campos [aircraft program and engineering support entity] shows how deeply safran is committed to working with us to develop business and strengthen relations with the Brazilian aircraft industry.”

*part of the backup electrical generation system

“Turbomeca’s contribution was a key to the success of this contract, involving the delivery of 50 Ec 725 helicopters to the Brazilian armed

forces. We wanted to thank our partner for having fully met their commitments. and we’re counting on Turbomeca to continue to provide

excellent support through the end of the contract, in 2018. This also applies to the Panther helicopter upgrade program, which will undergo an operational evaluation from march to may 2013. We currently have a number of projects underway with safran companies, and we consider this to be a very strategic partnership.”

1. Eurocopter’s Brazilian subsidiary

the customer identification system that morpho do Brasil is developing for Banco

itaú is the world’s largest biometric program for banks. why did your bank decide to pioneer this

technology at such a large scale?Years of studies showed us that biometrics could meet two of our key objectives: reduce fraud and satisfy customers. Furthermore, we’re firmly convinced that digital biometrics is the most mature technology now available, especially in terms of interoperability with other solutions.

why did you choose morpho do Brasil as your partner, and what do you expect from the partnership? We looked into biometrics in depth before choosing a partner. We need a system that can not only identify our customers, but also detect inconsistencies, such as two customers with the same fingerprints!

morpho has very solid credentials, and is developing very powerful technologies that offer impressive speed and accuracy. We are counting on this partnership to underpin our growth. and we will work together to develop solutions that will continue to make our bank the benchmark in terms of customer satisfaction and sustainable performance.

chief Operating Officer, Embraer Defesa e segurança/Defense and security

Vice President, Programs, helibras1

Banking automation Technology Director, Banco Itaú

w eduardo Bonini

w didier cormary

w edson matunaga

“we really appreciate safran’s flexibility”

“they met their commitments”

“morpho develops very powerful technologies”

marchésSpecial report

safran is a key supplier to embraer’s new kc-390 cargo plane.

by the Brazilian plane-maker. The first flight is slated for 2014. These systems will come from four different Group companies: Hispano-Suiza for the primary and secondary electrical dis-tribution systems, overall electrical integration and ram air turbine backup generator; Messier-Bugatti-Dowty will supply wheels and brakes,

plus the braking control, steering and landing gear extension-retraction systems; Sagem the horizontal stabilizer trim system; and Techno-fan all ventilation systems.

“Safran has decided to create an entity in São José Dos Campos, which will act as liaison between Embraer and the Group staff working on the project, provide local program manage-ment, and also set up a local engineering team,” explains Gérald Farrenc, Safran Senior Vice President, Programs Brazil. At the same time, Embraer has started designing a second genera-tion of regional aircraft. Farrenc adds: “We’ll be working with them to support the definition, and of course hope to be chosen as partners on these programs.”

There are also a number of helicopter projects in the pipeline. Brazilian company Helibras, a subsidiary of Eurocopter, calls on several Safran companies, in particular Turbomeca do Brasil to handle the assembly, testing and, shortly, support services for the Makila 2 engines pow-ering the 50 EC 725 helicopters to be deliv-ered to Brazilian armed forces in the coming months. “This contract also provides for the construction of the first ‘non-French’ engine assembly line, located in Xerem, a suburb of Rio de Janeiro,” says François Haas, Safran National Executive in Brazil. Safran Engineer-ing Services is working on systems integration for the modernization of 36 Fennec helicopters deployed by the Brazilian army, while Sagem supplies autopilots and cockpit displays. “Off-

© h

elib

ras

© E

uroc

opte

r

© B

anco

Itaú

© E

mbr

aer

© E

mbr

aer

marchésPanorama

safran Magazine _ December 2012 _ 17

© B

erna

rd L

acha

ux /

saf

ran

The largest orientation day ever organized by Safran.

DIsCOVERY DAY 2012

16 _ December 2012 _ safran Magazine

On June 6, 2012, safran brought together more than 3,000 newly hired employees and newly promoted managers at the Le Bourget venue near Paris. This day-long orientation event allowed them to better understand the Group, its values, organization and career opportunities. safran corporate management was also involved, addressing the participants and taking part in roundtable discussions with considerable audience input. Following these presentations, all participants adjourned outside to form a “human logo” – an outstanding illustration of unity. according to Pascale Dubois, safran Vice President for communications, “This event reflects our employees’ collective pride and commitment. Thanks to Discovery Day, these 3,000 men and women became fully conscious of the role they play in safran’s future.” an aerial shot of the human logo was the centerpiece in a special advertising campaign bearing the “PrOUD!” tagline, complementing the recruiting campaign that is appearing all year long.

© B

erna

rd L

acha

ux /

saf

ran

© B

erna

rd L

acha

ux /

saf

ran

marchésPanorama

18 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 19

“I’m impressed by all the various know-hows that exist at Safran. The Group has developed very sharp skills in various fields. I feel proud to be part of such a team.”Walter Knecht, Switzerland

“I really discovered the scope of the Safran group, its international presence, and also the many career possibilities it offers over a broad range of business sectors.”Sophie Soulignac, France

“I appreciated that the Group’s leaders talked about women in management teams. It seems that there will be more opportunities for women in the Group, and it’s a good thing…”Jacqueline Drauschke, Germany

“To summarize what I learned today, I would choose three key words: multidisciplinary (technologies), dynamism (the Group’s) and authenticity (testimonials and speeches).”Alexandra Dumas, France

“Thanks to a testimonial from an employee, I learned that it was possible to work at three different Group companies in eight years. We don’t have this kind of culture yet in Brazil, but we have to develop it!”Giuliano Leonel Cabral, Brazil

© E

ric D

roui

n / s

afra

n©

Ber

nard

Lac

haux

/ s

afra

n©

Ber

nard

Lac

haux

/ s

afra

n

© B

erna

rd L

acha

ux /

saf

ran

© B

erna

rd L

acha

ux /

saf

ran

© a

ntoi

ne D

enoi

x / s

afra

n

“Safran is an amazing Group! I had read it, but not really seen it for myself, like here today.”Geokching Loh, Singapore

20 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 21

marchésMarkets

The new LEAP engine garnered an impressive number of orders at the 2012 Farnborough Airshow, reflecting its outstanding performance qualities.

Farnborough: a giant LEaP Forward For SaFran

aVIaTION

4,252 orders and options for LEAP engines at October 31, 2012, including 742 orders at Farnborough.

3 applications for LEAP: Airbus A320neo, Boeing 737 MAX, Comac C919

2016Entry into service

C FM International was in the spotlight at the Farnborough International Air-show in July 2012. The 50/50 joint company of Snecma (Safran) and GE recorded 922 engine orders, including

80% for the new LEAP engine that will replace today’s best-selling CFM56. “Barely two years after hitting the market, this new engine for next-generation single-aisle commercial jets has already logged more than 4,252 orders and options, an exceptional score,” enthuses Marc Ventre, Safran Deputy Chief Executive Officer, Operations.

A wOrthy hEir tO thE CFM56LEAP’s strong point is its impressive performance specs, including a 15% reduction in fuel consump-tion compared with the latest CFM56 Tech Inser-tion model, NOx (oxides of nitrogen) emissions cut

why did you opt for Boeing, with LEAP as the exclusive powerplant?The watchword here is confidence: we trusted cFm International’s ability to live up to its promises. They’re one of the world’s leading makers of aircraft engines, with many years of experience, extensive credentials and largely proven products. Furthermore, I believe that the LEaP marks a decisive turning point

in aircraft propulsion, since it combines sophisticated technology with energy efficiency and environmental friendliness.

what do you expect from CFM international in terms of service quality? We know that cFm International will be able to meet its commitments, including on-time delivery, excellent quality for the price

and of course engine reliability. This also applies to mrO: its dedicated support teams will be able to quickly resolve any problems and limit aOG (aircraft on ground) situations as much as possible – in other words, maximize aircraft dispatch reliability while keeping costs under control.

how would you describe your relations with CFM international, and how do you think they will evolve? We’ve established a solid, sustainable partnership. Over and above this initial order for 75 engines, I’m sure that there will be many other shared development opportunities in the years to come.

President and cOO, air Lease corporation

w John PLuEgEr

“LEAP marks a decisive turning point in aircraft propulsion”

© a

ir L

ease

cor

pora

tion

announced the new engine we were in fact ahead of the curve, since no new aircraft was announced at the time,” Marc Ventre recalls. “But we also understood that airlines were expecting a sub-stantial reduction in fuel consumption before they would make a commitment. Time has proven us right: when Comac launched the C919 in 2009 we were ready.” The two world leaders followed: in 2010 Airbus tabbed the LEAP as one of the two engines offered on the A320neo, and in 2010 Boeing chose it as the exclusive powerplant on its new 737 MAX. Orders have poured in since then, along with service contracts. When Snecma and GE renewed their partnership, they extended it to include aftersales service, so they could offer integrated packages, including both the original engine and support services. This proved to be an excellent idea, since 90% of customers choosing the engine have opted for this package.

While awaiting the LEAP service entry in 2016, CFM’s assembly lines are already running at full speed to handle the large backlog of orders for the CFM56. According to Marc Ventre, “We’re going to reach an unprecedented rate of about 1,600 engines per year. Our facilities are ready, and we are also making sure that our suppliers can sustain this accelerated pace.” At the same time, LEAP devel-opment is proceeding on schedule, with the first ground test of a complete engine slated for 2013. ■

in half and 15 dB less noise. At the same time, it maintains the well-known reliability and low maintenance costs of the CFM56. “Airlines want engines that are reliable, fuel-efficient and inex-pensive to operate”, notes Marc Ventre. “And that’s what we give them with LEAP. We’re also capi-talizing on the reputation of the CFM56, and we have retained the basic architecture of this proven engine. Furthermore, we renewed our partnership with GE until 2040 back in 2008, at the same time we launched the new engine, thus reassuring the market that the winning CFM team would still be in place for the next generation.”

MArkEt LEAdErshiPThe first selection of this new engine didn’t come from one of the legacy plane-makers, but a new entrant, Comac of China. “When we first

Other show highlightsOther safran group companies booked major orders at Farnborough.• Aircelle teamed up with rolls-royce to sign a 25-year maintenance contract for the nacelles on British airways’ airbus a380s.• Messier-Bugatti-dowty was selected by the Philippine airline cebu Pacific to supply wheels and carbon brakes for its airbus a319 and a320 fleet, and will also provide electric brakes to Norwegian air shuttle for the carrier’s Boeing 787s on order.

© E

ric

Dro

uin

/ saf

ran

© B

oein

g

22 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 23

marchésMarkets

t he year 2012 will go down in the his-tory of the Silvercrest engine, with its selection by American plane-maker Cessna for the new Citation Longitude business jet. Snecma, the

Safran group’s propulsion specialist, developed this brand-new engine for long-range, large cabin “super midsize” bizjets like the Citation Longitude. Cessna’s latest bizjet will be the larg-est in its family, offering a range of 4,000 nautical miles and a maximum speed of 490 knots (Mach 0.74). The engine selection was announced dur-ing the European Business Aviation Convention & Exhibition (EBACE) in Geneva in May 2012 and follows a first selection by one of the lead-ing manufacturers in this sector. It was followed by the start of ground tests of the first complete engine in October. This marks a dual milestone for the Silvercrest, which has made a striking market entry in just a few short years.

UnrivALEd PErFOrMAnCESilvercrest is the first business jet engine devel-oped by Snecma, but the world’s leading maker of engines for single-aisle jets (through CFM International, the equally owned company with GE) rose to the challenge. To win over the business aviation market, Snecma has set very ambitious goals for this new engine, in par-ticular a 15% decrease in fuel consumption and CO2 emissions, and a 50% cut in both noise and

SuccESSFuL markEt Entry For SiLvErcrESt bizJEt EnginE

PrOPULsION

The Silvercrest jet engine being developed by Snecma (Safran) has been chosen by Cessna to power its new Citation Longitude business jet. Building on this latest business win, which follows an initial selection by a customer who prefers to remain anonymous, the engine is now kicking off its test cycle.

NOx (oxides of nitrogen) emissions in relation to the current CAEP/6 standard. “Silvercrest will offer unrivaled performance,” says Laurence Finet, program director at Snecma. “Cessna has even described its performance specs as ‘excep-tional’.”

To uphold these promises, the engine calls on a number of innovations, including advanced 3D aero design, a new-generation axial-cen-trifugal compressor, low-emissions combustor and a single-stage high-pressure turbine with single-crystal blades … plus of course the wide-chord fan blades, ensuring very high efficiency and strong resistance to foreign object damage (FOD). Lastly, Silvercrest will of course feature a new-generation full authority digital engine control system (Fadec), which also monitors maintenance needs.

CUstOM-tAiLOrEd MAintEnAnCEGreen, quiet and economical, Silvercrest will also set the standard in reliability and maintain-ability. As Laurence Finet says, “We bring to the business aviation market our broad-based maintenance expertise from the CFM56. This is based on two complementary approaches, namely ‘on-condition’ maintenance, which means only servicing an engine according to its actual condition, not a preset schedule; and health monitoring, which means tracking engine readings in-flight, so we can detect the

slightest warning of an upcoming problem. The combination of these two approaches delivers real benefits to operators, because it reduces maintenance costs, keeps the aircraft in the air, and helps them schedule maintenance at timely moments, keeping service interruptions to a minimum.”

Business aircraft operators demand impecca-ble local support. So Snecma is already estab-lishing a network of local representatives, and plans to set up customer support centers in North America and Asia.

thE GrOUP stEPs UP!Other companies in the Safran group are also involved in this program. For example, the cen-trifugal stage on the core demonstrator, ground tested in late 2007-early 2008, was designed by Turbomeca, the world leader in this technology,

what were your requirements for the Longitude powerplant?The Longitude will be a super midsize business jet with a range of 4,000 nautical miles. choosing the right engine is absolutely essential if we are to guarantee this range. We were looking for an engine that would combine low fuel consumption, the power needed by this class of bizjet and low maintenance costs.

what were the main factors behind your choice of the silvercrest? We looked very closely at all engines proposed by various manufacturers. The snecma silvercrest perfectly met our requirements, so it was a natural choice. I also want to add that snecma enjoys an excellent reputation for aircraft engines because of the highly successful cFm.

how would you describe your

relations with snecma? We’re very satisfied to be working with snecma, especially because their technical support is excellent. Our contacts have been so remarkable that we are now looking to do more business with other safran companies.

what are the main upcoming steps in integrating the silvercrest engine on Longitude? We are eagerly awaiting the results of the First Engine To Test (FETT) next month. We have absolutely no doubt that the engine will live up to its promise. at the same time, we’re continuing to work on airframe-engine integration, including very positive discussions between our teams. a snecma engineer is on permanent assignment at cessna and a second one will join him in 2013. By mid-2016 we will have two silvercrest engines installed on our first prototype.

senior Program manager, cessna

w kEvin Schmitz

“snecma is a reliable partner”

© c

essn

a

Cessna at a glance cessna aircraft company was founded in Wichita, Kansas in 1927 and has produced over 193,500 aircraft to date, including 6,300 business aircraft – the largest fleet of this kind in the world. cessna makes three families of aircraft: • citation business jets• Turboprop-powered airplanes• Piston-powered single-engine planes

Purchased by the Textron corporation in 1992, cessna now has 8,500 employees and logged nearly $3 billion in sales in 2011.

delivery of the first Citation Longitude is slated for 2017.

© c

essn

a

Full-scale model of the silvercrest engine presented at nBAA 2012 by Laurence Finet, silvercrest program director at snecma

© E

dwar

d Li

nsm

ier /

ca

Pa P

ictu

res

/ saf

ran

marchés

24 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 25

Markets

t he conundrum is clear: what can armed forces do to keep their engine maintenance, repair and overhaul (MRO) bills under control, when this equipment is increasingly high-

performance and sophisticated, and therefore more expensive to service? Safran has adapted its approach, especially for French government contracts, to address an issue that is more criti-cal than ever, given shrinking defense budgets.

Over the last dozen years, Safran has revamped its offering of life cycle support packages to address the evolving needs of armed forces. The contract signed by helicopter-engine specialist Turbomeca and the French government in 2001 was recently renewed for ten years, reflecting the success of this initiative.

maximum diSPatch rELiabiLity For miLitary aircraFt EnginES

sErVIcEs

“Previously, the government placed orders as needed, depending on fleet use and as techni-cal problems arose,” notes General Baudoin Albanel, military advisor to the Chairman of Safran. “There was often a gap between the requirement and the response, all the more so for engines, where the production of a part could take 18 to 24 months.” Safran therefore began to develop more complete packages, based on billing per hour of flight, along with contrac-

routinely used on helicopter turbine engines. Safran Electronics is developing the full author-ity digital engine control (Fadec) and Techspace Aero is supplying the low-pressure compressor, forward sump and lubrication unit. “We’re involved in the Silvercrest program as Safran’s center of excellence for low-pressure modules and lubrication equipment,” notes Jacques Smal, Vice President Strategy, Sales and Programs at Techspace Aero. “In particular, we draw on the work done in the European research program VITAL, for which we developed a smaller, lighter low-pressure compressor, with improved aerodynamics. All of these advances are now being applied to Silvercrest.” In July 2012 Tech-space Aero delivered the instrumented modules to Snecma for testing, and by the end of the year it will provide four more complete assemblies.

FAst MArkEt BrEAkthrOUGhWith all of these advantages, it’s hardly surpris-ing that Silvercrest convinced Cessna. “The excellent results of the core engine demonstra-tor, coupled with our 40 years of experience in commercial aviation, gave us considerable cred-ibility,” says Laurence Finet. “We have always enjoyed excellent relations with Cessna. And in October 2011 at the NBAA trade show, we gave Cessna a close look at our progress on the Sil-vercrest program, and they were very interested. A few months later we received the request for

proposals on their new Citation Longitude, and we submitted the winning bid.”

Another, non-negligible advantage of Sil-vercrest is that it’s competing in the strongest segment of the bizjet market. Larger, premium bizjets have in fact been less impacted by the economic crisis than entry-level and interme-diate models. “Larger models will do better in this market, especially in the BRIC (Brazil, Rus-sia, India, China) regions, because these are all large countries, with a lot of ground to cover,” adds Laurence Finet. “We anticipated this situ-ation, and we started investing back in 2006, when other engine-makers were freezing their development programs. Today, the market looks like it’s ready to take off again, and we’ll be ready when it does.”

A tiGht sChEdULEFor the moment, the program is moving forward. The engine design was launched in September 2010 and is now finished. Ground tests have started and will continue until 2014 on a total of eight engines. The first flight tests will kick off in the first half of 2013, along with certifica-tion tests. Cessna is just starting development of its new aircraft. Snecma seconded an engineer to the aircraft manufacturer’s headquarters, in Wichita, Kansas, to work on integrating the engine in the airplane. The Citation Longitude is slated for service entry in 2017. ■

lb of thrust

lower fuel consumption and CO2 emissions than current engines

Flight tests start

12,000

15 %

2013

silvercrest at a glance

servicing the Makila 2A engines on a Eurocopter EC 725 Caracal deployed in Afghanistan.

© F

rédé

ric

Lert

/ s

afra

n

© E

ric

Dro

uin

/ sne

cma

/ saf

ran

26 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 27

marchésMarkets

tion engines, we can anticipate demand by ana-lyzing wear. We still have to adjust a few things, but startup has gone very well, and I hope that this continues,” notes Didier Desnoyer. Long-term contracts and anticipating needs means that fluctuations in supply and demand can be smoothed out, and also enables Snecma to guarantee reduced costs and maximum dispatch reliability for its customer.

Another Group entity involved in this con-tract is Sagem’s Safran Electronics division, which is pleased with the new way of operating. “It guarantees constant workload over several years, which is a crucial factor in maintaining our skills,” says Michel Caunes, head of cus-tomer support. “Plus, we can now concentrate even more on our core business, since working on a fixed-rate basis streamlines administrative requirements.” Initial customer feedback has been very positive, since the dispatch reliability of the printed circuit boards and electronic con-trol units on these engines has improved, with

Safran committed to repair turnaround within a few weeks. Caunes adds, “Safran Electronics offers unique expertise in onboard electronic components, which have to offer reliability specs far more stringent than for consumer elec-tronics. And it’s thanks to this expertise that Safran can guarantee its contractual commit-ments.” For example, if one of the PC boards in the engine fails, the engine itself indicates the problem. The armed forces’ maintenance crew then identifies the damaged subassembly and returns it for repair. “Safran and the French gov-ernment pioneered this type of contract,” con-cludes Caunes. “It’s a clear sign of a relationship of mutual trust.”

Improved dispatch reliability plus reduced costs is a winning formula, and should continue to be the model for most maintenance contracts signed by Safran in the future. ■

* AIA: Atelier Industriel de l’Aéronautique, military aircraft maintenance workshops.

© é

ric

Dro

uin

- sne

cma

tually defined availability and responsiveness. In exchange, the government made a longer-term commitment, at least ten years in general. General Albanel continues: “Thanks to these kinds of arrangements, the armed forces know in advance what they’re going to spend, while Safran can forecast production, avoiding fluc-tuations, and has the visibility needed to invest and upgrade engines to enhance reliability. It’s a real win-win situation for everybody involved.”

rEsPOnsivEnEss And COst COntrOLThe largest and most emblematic of these con-tracts was signed by Turbomeca (Safran) and the French government in 2001. Renewed for ten years in September 2012, this contract involves a total support package for 1,400 helicopter engines, and covers a vast range of services: repair, technical assistance, training, technology intelligence, etc. According to Bruno Even, Vice President and General Manager, Operators, at Turbomeca, “Our main commitment is the obli-gation to reinstall any engine we remove within ten days. Over the last 30 months we have scored 100 percent, and the government tells us that their overall costs have dropped eight percent.” What this means is that the government can refocus on its heliborne missions, while keeping a close eye on its expenditures.

The same win-win approach is applied to two similar support contracts that Snecma (Safran) has signed with the French government, each covering about 100 engines. The first con-cerns the Tyne turboprop engines powering the Transall and Breguet Atlantique transport and maritime patrol aircraft, while the second concerns the supply of spare parts and repairs for the Rafale fighter’s M88 engine. The TP400 turboprops on the Airbus A400M will also be covered by this type of contract, as soon as this military airlifter enters service.

sAFrAn, A GOvErnMEnt PArtnEr On thE rAFALE FiGhtEr“The through-life contract that we signed for Rafale’s engines has some very ambitious objec-tives,” notes Didier Desnoyer, Vice President and General Manager of Snecma’s Military Engine division. “Safran has pledged to supply any part within three days, and to reduce overall mainte-nance costs per flight-hour by 25 percent by the end of the contract.”

Snecma can count on several advantages to meet this challenge, such as the new-generation M88 engine with the TCO (total cost of owner-ship) package, which has refined its maintenance

schedule based on more in-depth understand-ing of parts wear. Some components have also been redesigned, especially in the high-pressure turbine section, resulting in longer life. Having entered service in May 2012 on the latest Rafales to roll off the assembly line, the upgraded engine has already met and exceeded its objectives.

“The other key part of this contract is our tighter integration within a government supply chain,” continues Desnoyer. “We are a supplier to both the AIA* and air bases that deploy Rafales. To make sure this system operates smoothly, teams have to communicate, and that’s what guarantees quick reactions. Furthermore, the sup-port contract includes performance-based clauses: if we exceed our objectives, we split the profits! Yet another reason for working hand in hand.”

CUstOMEr-FOCUsEd EXPErtisEThis contract has also led to a reorganization of teams to ensure maximum parts availability. “Thanks to our experience on the first-genera-

parts/month delivered in less than 3 days

parts in the inventory in 2012

8,500

1,025,000

This new type of contract is very innovative. It’s based on the presence of three snecma support correspondents at our Landivisiau, saint-Dizier and mont de marsan air bases, and another at the aIa center in Bordeaux. Thanks to excellent groundwork by snecma and sImmaD, their servicing operations could be totally

integrated in our logistics system without any modification.We were delighted to see that there were no complications or late deliveries in the process, quite to the contrary in fact. We also expect this through-life support contract to significantly reduce parts shipping times, which has been achieved during shipments between

sites. snecma correspondents are fully responsible for managing our stocks, and they have handled this flawlessly, using much simpler decision-making circuits than when we were in charge. There is one point that could be improved, however, namely integrating support issues further upstream when we have to process technical incidents or changes to publications.

* sImmaD (structure intégrée de maintien en condition opérationnelle des matériels aéronautiques de la défense): the integrated through-life support organization for aircraft deployed by French armed forces.

m88 group leader, Fleet 01/rafale, sImmaD*

w thiErry duPont

“Our correspondents are very responsive”

© s

necm

a

staff trained by turbomeca to provide total support services

repairs in ten years by turbomeca, along with 400 on-site assistance missions

2,500

1,800

28 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 29

marchésInsight

On November 10, 2012, an Ariane 5 rocket orbited the Eutelsat 21B and Star One C3 satellites, in the launcher’s 66th mission and 52th successful flight in a row. This was

a landmark for the European space industry, and also for Safran, which provides virtually all pro-pulsion systems for Europe’s launcher, along with other systems and equipment (see page 30).

“It all started with France’s determination to have its own nuclear deterrent force, including its own ballistic missiles, which demand in-depth knowledge of space technologies,” explains Jean-

can’t really talk about competition between the leading players in this sector,” notes Martin Sion. “But Europe is in a particular situation because we mainly count on commercial launches to ensure the financial health of our space industry, which means that we have to stay very competi-tive to ensure our long-term viability.”

This situation is reflected in successive upgrades to Ariane 5, Europe’s workhorse launch vehicle, and preparations for its succes-sor. There are two imperatives at play: inno-vation and cost reduction. “Both manufactur-ers and government agencies expect Safran to come up with concrete solutions, and help shape current thinking on these issues,” explains Jean-Lin Fournereaux.

One of the solutions being offered by Safran is the Vinci cryogenic engine, intended to replace the current HM7B on the upper stage of Ariane 5. Drawing on 15 years of intensive R&D, this new restartable engine will enable the launcher to

A successful maker of rocket engines has to be extremely meticulous and meet a constant stream of technological challenges. Safran is the uncontested rocket propulsion leader in Europe and No. 2 worldwide.

Safran: Shooting for the StarS

rOcKET PrOPULsION

Telescopes for satellitesanother safran space business line is the design and construction of high-performance optics for observation satellites. Group company sagem is now the world leader in this field, drawing on expertise developed by its reosc subsidiary since 1937, and the subsequent acquisition of matra’s optics department. The company’s exceptional expertise is also applied to optics for lasers, and large single-piece or multisegmented mirrors for earth-based observatories.

1947space propulsion activities start at snecma’s Vernon plant, west of Paris

1979First flight of Viking and hm7 engines on ariane 1

1998First Vulcain main stage engine enters service

2000100th ariane 4 launch

201250th successful launch in a row for ariane 5

Lin Fournereaux, Safran Vice President, Space. “Building from these foundations, the country subsequently developed an independent civilian space industry.”

Another key to this success was the creation of the national space agency CNES (Centre National d’Etudes Spatiales) in 1961. Acting as industrial prime contractor, this agency enabled France to develop a very consistent space policy within a European framework. The propulsion systems were developed by several specialized companies, now part of Safran, with experience in solid and liquid rocket propulsion, including cryogenics*, reaching back some 60 years.

CuTTing-edge TeChnOlOgiesOne of these companies is Herakles, Safran’s solid propulsion specialist for both space and mil-itary applications. “The advanced technologies we developed for nuclear deterrence contributed to independent access to space,” notes Thierry Francou, director of the space business unit at Herakles. Safran’s expertise in liquid rocket propulsion, a highly demanding field because these systems operate at temperatures ranging from -250°C to +3,000°C, is widely recognized. Group company Snecma rose to this challenge, and also leverages synergies with its military air-craft engines, which operate at very high tem-peratures as well. “People sometimes think solid propulsion and liquid cryogenic propulsion are total opposites, but in fact they are often com-plementary energy sources on large rockets like Ariane 5,” says Martin Sion, head of Snecma’s Space Engines division. “And it is precisely our mastery of these two technologies that under-pins Safran’s strength in rocket propulsion.”

lOng-TerM COMpeTiTivenessThe watchword in global markets is competi-tiveness. “The space industry is above all an expression of a country’s sovereignty, and you

Assembling the solid rocket motor nozzle.

© D

.r.

© F

ranç

ois

Lafo

rêt /

Equ

ivox

herakles, the solid propulsion specialistLong expected, the merger of snecma Propulsion solide and sNPE matériaux Energétiques (smE) is now a reality. Initiated by safran’s acquisition of smE in april 2011, it continued with the merger of the two entities in may 2012, to create a new company called herakles. “The founding of herakles allowed us to combine functions, rationalize our skills and create a powerful center of solid propulsion expertise in France,” explains Gilles Fonblanc, head of Pyroalliance, one of herakles’ subsidiaries.

herakles is now the leading solid propulsion company in europe and number 2 worldwide. It provides solid rocket motors (srm) for strategic and tactical missiles, as well as for launch vehicles through two subsidiaries based in Kourou, French Guiana: Europropulsion, which assembles the solid rocket motors for ariane 5’s boosters, and regulus, which makes the solid propellants used in these boosters. Both of these companies are jointly owned by safran and the Italian aerospace company avio.

“The solid propulsion industry is the first to undergo rationalization in Europe,” notes Thierry Francou, head of the space business unit at herakles. “It now has two main players, herakles and avio/space.”

30 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 31

marchésInsight

inject satellites into different orbits, and thus continue Arianespace’s policy of dual launches despite the increasing weight of new satellites. Four engines have already been ground tested, and the first qualification flight on the Ariane 5 ME (Midlife Evolution) version is expected in 2017. In addition to the Vinci engine, this upgraded launcher will incorporate a number of compo-nents also to be used on the future Ariane 6, for which the ESA Council meeting in November 2012 approved initial design studies.

The new Ariane 6 launcher, slated to enter service in 2021 and designed to carry a single payload at a time, aims to retain Arianespace’s 50% share of the commercial satellite launch market, despite increasingly fierce competition. To meet this objective, Ariane 6 would have to lower costs by 30 to 40% compared with Ariane 5.

plAsMA: sATelliTes gO eleCTriC! One of the more innovative developments in space is electric propulsion for satellites, and Snecma is the European leader here as well with its PPS 1350 plasma thruster. Back in 2005, a PPS 1350 propelled the Smart-1 lunar probe from Earth to Moon orbit, using only 80 kilograms of its propellant, xenon. A highly fuel-efficient system, electric propulsion will enable satellites to carry more payload and less propellant, while the orbital transfer phase will

hM7The hm7 cryogenic engine entered service in 1979 and powered the third stage of the ariane 1 to 4 launchers. During this time, it was upgraded to the hm7B configuration, now used on the ariane 5 upper stage. Developing 14,300 lb of thrust, it powers this stage for 15 minutes to inject the payload into geostationary transfer orbit.

plasma thrusters for satellitesPlasma thrusters, which eject a high-speed flow of plasma, using xenon as a fuel, offer much higher efficiency and lighter weight than conventional chemical propulsion, although at very low levels of thrust. snecma has invested in this technology since the 1990s.

Critical equipmentsafran provides pressure transducers for launcher and satellite guidance, along with wiring and pyromechanisms used to separate stages and release satellites from the launcher.

vulcain The cryogenic engine for ariane 5’s main stage. The current Vulcain 2 model delivers almost 300,000 lb of vacuum thrust, the equivalent of about a dozen cFm56 jet engines. It’s 20% more powerful than the first-generation Vulcain, which it replaced in February 2005.

solid boosters25 meters high (82ft), 270 metric tons, 1,188,000 lb of thrust at liftoff: each of the two ariane 5 solid boosters is made of three segments, in which the solid propellants are cast. The boosters deliver 90% of ariane 5’s total liftoff thrust.

What exactly does your job entail?You could say that I’m the conductor, in charge of all launch operations. I work directly with all operating teams, including those from

safran group companies, or about 250 to 300 people in all. my role is to federate all staff and create a real team spirit so that each launch proceeds as smoothly as possible.

Each company has its own technical culture, and in Kourou we really appreciate the contribution of safran’s engineers and technicians.

Are there any special challenges in your job? There are about a half-dozen launch complex operations managers at arianespace, and we deal with a broad spectrum of specialists. To do our job, we need experience at every rung of the operational

ladder. That means 15 to 20 years working in operations, covering both the launchers themselves and the associated ground facilities. It all equates to a tremendous personal investment.

how do you prepare for an Ariane 5 launch? Each manager participates in three main phases. The first, under the responsibility of astrium, is where the different parts of the launcher are

integrated. Then we move to final assembly, which includes the installation of the satellite(s) and all systems which may be hazardous or time-limited, as well as the final preparation of the engines and launcher configuration. The last phase is the launch itself, including transfer of the launcher to the launch zone the day before the launch. an entire “launch campaign”, as we call it, takes about two months.

arianespace Launch complex Operations manager

w Patrick Lucet

“each company has its own technical culture”

safran-built engines have powered Ariane since the first launch in 1979

safran’s consolidated sales in the space market

safran employees involved in the space business

1,338

€900M

4,000

be longer. With just 9 grams of thrust from a plasma thruster, we’re not in the same league as conventional solid or liquid rocket engines. But the goal for Safran is still the same: optimize performance, increase simplicity and reliabil-ity, while meeting increasingly demanding cost restrictions. ■

* Cryogenic refers to systems or materials operating at very low temperatures, usually under -150°C. The most common cryogenic propellants are liquid oxygen (Lox) and liquid hydrogen (LH2).

The vinci upper-stage engine on the test stand.

© D

.r.

© a

ntoi

ne D

agan

Ariane 5: safran from top to bottom

© P

asca

l cad

iou

/ aria

nesp

ace

32 _ December 2012 _ safran Magazine safran Magazine _ December 2012 _ 33

marchésInsight

in less than two decades, the Internet has changed the world. According to certain experts, like the American author and “visionary” Jeremy Rifkin, president of the Foundation on Economic Trends, this

is only the beginning. Didier-François Godart, Director of the Safran Innovation department, explains: “According to Mr. Rifkin, the fusion

of new communications technologies, as chan-nels for exchanges and knowledge sharing, and new energy sources which are increasingly dis-tributed and renewable, such as smart grids, will create a new period of long-term growth and a new industrial revolution. This will be accompanied by a flowering of innovation across the board.”

prOfessiOnAlizing innOvATiOnSafran, as a recognized specialist in high tech-nology and innovation, fully shares this view and believes that it must adapt to this new and fast-evolving environment. That’s what led to the creation of the Safran Innovation department in June 2011, headed by Didier-François Godart. “Our goal is to organize

Safran has created a new entity to nurture the development of tomorrow’s products and services, helping the Group maintain its leadership and expand its market reach.

SPearheading innovation

FUTUrE the innovation supply chain for products and services within the Group, and place it on a more professional basis, by capitalizing on the technological innovations developed through our Research & Technology investments,” says Godart. It may seem paradoxical to associate the down-to-earth “supply chain” with high-flying “innovation”. But contrary to the old comic book cliché of an idea springing up like a light bulb over the head of a solitary genius in his lab, innovation today, especially in markets characterized by high added-value, is increas-ingly the result of a collective, cross-functional thinking process, demanding a rigorous meth-odology.

iMAgine, invenT, deMOnsTrATeThis brainpower chain comprises several links. To imagine tomorrow’s aerospace products and services, Safran must first have a feasible scenario of air transport 20 or 30 years from now. Following an initial analysis, directed by the Strategy department, the Safran Innova-tion department formed a think tank includ-ing not only representatives of the Group, but also a number of outside contributors (from Aéroports de Paris, Renault, RATP, Orange, Michelin, etc.) to solidify this vision by inte-grating the multimodal character of tomor-

row’s transportation systems. To innovate, you have to stimulate the crea-

tion of new ideas, and that’s why the Inno-vation department seeks to foster knowledge sharing both inside and outside the Group. Safran has set up several specialized task forces, bringing together employees of its own compa-nies and others working in similar fields, such as EDF or Alstom, to address issues including onboard energy management and the inter-faces between aircraft and airports.

Once new ideas have sprung forth and the best of them selected, their technical feasibility and economic value for the customer still have to be demonstrated. This phase entails the construction of actual demonstrators, along with the identification of market openings for the subsequent products or services. Reflect-ing this thinking, Safran has acquired its own Airbus A320 flying testbed. It will be used for several projects already under way, including the electric green taxiing system, hybrid ther-mal-electric propulsion systems, distributed onboard electric networks and the replacement of hydraulic actuators by electric units. By sys-tematically advancing in phases from the ini-tial vision to designs to demonstrators, Safran plans to contribute its own building blocks to tomorrow’s air transport system. ■

an “adjacent innovation”: that’s how axelle Gigou, program manager at safran Engineering services, describes her team’s work for Bombardier. “We transposed the concept of the ‘iron bird’ to railroads. This is a test rig that is usually used to test the interactions between all electrical systems on an aircraft under development by mixing real components, such as a door, with simulated