S3 GC201307EN 28pp 14.01.20 updated - Dou Yee …...SMT Cube Temperature Treatment System • Hot...

Transcript of S3 GC201307EN 28pp 14.01.20 updated - Dou Yee …...SMT Cube Temperature Treatment System • Hot...

ADVANCED ASSEMBLYT E C H N O L O G Y

SMT Adhesive Dispense

Underfill Process

Reflow Oven Vaccum Reflow

Solder Paste Inspection

Automatic Optical Insp

Solder Paste Jet / Print

AOI & AXI

SMD Tower Storage

Stencil Cleaning PCB Cleaning

Cleaning Solution

Pick & Place

CONTENT

1 - 2

7 - 8

3 - 4

5 - 6

9

10

11

12

13 - 14

15 - 16

17 - 18

19 - 20

21

23

22

Automatic Calibration Station

Light Weight Z Height Touch Probe

Weight Scale

Red/Blue Light Illuminator

Precision Dispensing Systems

Applications:SMT AdhesivesSolder PasteUnderfillDam and Fill Globe TopConductive AdhesivesThermal GreasesTwo Part Materials. UV Glue

Max Series• Compact Foot Print

Rock Steady Unibody FrameAuto X,Y,Z CalibrationHeated/Non Heated Dispensing CapabilitiesAccuracy of ± 0.001” (0.025mm)Up to 38,000 dph Linear Speed 30”/sec (762mm/sec)Up to 2 Valve CapabilityRed/Blue Light IlluminatorHigh Speed GPD Cyclops™ VisionNeedle CleanerWork Area up to 14.1” x 12” (358 mm x 305 mm)

•••••••••••

MicroCell• Compact Foot Print

Rock Steady Unibody FrameAuto X,Y,Z CalibrationAccuracy of ± 0.001” (0.025mm)2 Valve CapabilityRed/Blue Light IlluminatorHigh Speed GPD Cyclops™ VisionNeedle CleanerWork Area 12” x 12” (305 mm x 305 mm)ClearVU™ Vision (programmable zoom & focus)Ergonomic, Side Mount Monitor ArmLive Process-Viewing Camera & Over Head Display

•••••••••••

DS Series• Inline, Standalone & Heated Models

Auto X,Y,Z CalibrationAccuracy of ± 0.0015” (0.0381mm)3 Valve CapabilityRed/Blue Light Illuminator28,000 dphNeedle CleanerWork Area up to 24” x 24” (609 mm x 609 mm)Automatic Vision

••••••••

1

HyFlow Valve• High Volume & Flow Rates

Mid to High Viscosity Abrasive FluidsEasy MaintenancesEncoder with 8,000 count per revolution

••••

PCD Valve (Positive Cavity Displacement)• Volumetric dispensing for low and high viscosity materials

High torque servo for accuracyAble to easily dispense heavily filled materialsWill not shatter or smash fillers

•••

Micro-Dot Valve• Encoder with 57,000 counts per revolution

Servo MotorHigh Torque transmissionQuick release cartridgePrecision machined auger and cartridge

••••

NCM Valve (Non Contact Metering)• High speed, No needle method of dispensing

Works with Flux, Underfill, SMT Adhesive,UV Curable Glues, Conductive AdhesiveNo board planarity issue, dispense at 1-3mmheight.

•

•

2

Inlet Condensation Trap

ABS Process Gas Cleaning

Modular Cooling ZoneDual Lane

Center Support

Intelligent Nitrogen Control

SMT Nozzle System with

All SMT reflow soldering systems guarantee optimum process reliability with it innovative technology and feature thefollowing advantages:1) Special Nozzle system for Optimum heat transfer

Sophisticated control concept for lowest possible energy and nitrogen consumption. Multi stage condensate filter for efficient cleaning. 15” touch screen with user-friendly operator interface.Process chamber in stainless steel design.Modular cooling stage concept with 1-5 cooling stages.

2)3)4)5)6)

Force Convection Nitrogen Reflow Oven

3

SMT Vacuum Soldering System

Without vacuum With vacuum

SMT Reflow Oven with Integrated Vacuum Soldering

HTT System (High Temperature Temper System)

SMT Cube SMT UV Curing System

SMT Vacuum Modulesystem for improvingquality of solderjoints. Voids in thesolder joints can bereduced to aminimum.• Vacuum Process

can be switchedon or off.Nitrogen or airsoldering possibleVacuum processparameterSettableNo increase innitrogenconsumption.Small foot print.

•

•

•

•

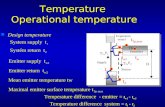

SMT Cube Temperature Treatment System • Hot Function Test for Temperature

ranging from 60°C to 140°C. Cooling to Room Temperature forless than 40°C and more than 25°CCold Function Test for Temperatureof -50°C to -10°C

•

•

SMT UV curing system, modular variable machine design for UV-curing of ready mounted control units or PCB with extended passthrough height.• complete process reliability over a long production period

lifetime of UV light source > 6,000 hoursStart-up-time < 1 minuteNo expenditure maintenance (no checking and readjusting of theUV light source)Fully integrated into SMT machine data system (management datasystem and MES)Significantly lower costs.

•••

•

•

HTT has been designed especially for drying,tempering, curing and heating for subsequenttesting.• Single and up to 5 lanes track concept

Maximum of 20 heating zones.Length from 1.5m up to 10m with steps of 0.5m Perfect heat transfer propertiesExcellent energy efficiency rating.

••••

4

MY100DXHigh mix at high volumes• Top speed up to 34,000 cph

IPC net throughput 27,500 cph24/7 reliabilityFuture proof accuracyUp to 160 feeder positions Flexibility and All-In-One

•••••

MY100SXHigh mix at medium volumes• Top speed up to 21,500 cph

IPC net throughput 17,800 cph24/7 reliabilityFuture proof accuracyUp to 176 feeder positions Flexibility and All-In-One

•••••

MY100LXHigh mix at low to medium volumes• Top speed up to 15,000 cph

IPC net throughput 13,500 cph24/7 reliabilityFuture proof accuracyUp to 176 feeder positions Flexibility and All-In-One

•••••

Agilis™ Flex feedersFeed anything on tape• Feed anything from small chip components to large ICs

and connectors.Unique electronic and barcode identificationSimple feeder snap-in mechanismAdd/remove feeder on-the-flyFits any position in magazine

••••

5

MY500 JET PRINTERJet Printing for faster response time• No stencils

No ordering, handling, storing or cleaning stencilsNo cleaning solvents or other consumablesLower operator costHigher equipment utilizationClosed system for solder pasteJet Printing uses less paste than screen printingClean handling - healthier working environmentSpeed: 30 000 cph equivalentDot volume: 5-15 nlDot diameter: 0.33 – 0.47 mm

••••••••••

SMD TowerAutomated & Intelligent Material Handling• No misplaced components in stock

No mix-up of componentsAll stock movements are recorded, components arealways booked in and out.Availability check for ensuring component availabilitybefore set- up or production start.Kit lists or single part numbers are providedsequentially for shorter set-up times.Controlled atmosphere with dry air unitMonitoring of storage atmosphere in SMD Tower,Temperature and relative humidityMonitoring of floor life (out of bag) for MSDsMSD classification according to IPC/JEDEC 033BWarning message for exceeded floor lifeNo repacking of MSDs

••

•

•

••

••••

6

we imaginecleanness like this…

Excellent cleaning solution for you

Super SWASHAutomatic Spray Cleaning System for Stencils,Misprints and de-fluxingAdvantages of Super SWASH• Very low consumption of cleaning agent thanks to

optimised nozzles and chamber shape!Short process times, programmable spray fieldwidth.Chamber hermetically closed during cleaning byautomatically controlled vent flaps.Integrated window and backlit wall to check process.Machine controlled with PC – WINDOWS 7 SWplatform.Graphical touch screen interface.All process parameters controlled and monitored byPC, adaptive control of process time.SPC – traceability, log file for machine activity.Compressed air knife for dewatering and dryingsaves energy and time.No additional facility for DI water needed.

•

•

••

••

••

•

STENCILCLEAN SIASpray Cleaning System for metal and plastic StencilsAdvantages of STENCILCLEAN SIA• Designed for solder paste cleaning q as well as cleaning

SMT glue from thick stencils (PumpPrint®, VARIDOT® etc.)– cleaning media heating in basic configuration.Uses self- rinsing cleaning agents – no waste waterproblems from rinse.Motor-driven spray-arms rotate simultaneously. Cleaningwithout risk of damage even to very thin and fine stencil.Safety clutch and rotation monitoring of spray manifoldsassures safe process and protection of stencil againstdamage from incorrectly placed stencils.Spray chamber equipped with special automaticallycontrolled exhaust/inlet air flaps. Hermetically closedduring spray.Efficient drying with hot air circulation and controlledventilation through exhaust/inlet air flaps.Compact design with very small floor space requirement.Easy transport even through 80 cm doors.

•

•

•

•

•

• .•

7

COMPACLEANAutomatic Spray Cleaning System for PCB de-fluxing,Misprints and Solder pallets

-

Advantages of COMPACLEAN• Very low consumption of cleaning agent!

Machine controlled with PC – WINDOWS 7 SW platform.Graphical touch screen interface.All process parameters controlled and monitored by PC,adaptive control of process time.SPC – traceability, log file for machine activity.DI water plant integrated, including measurement ofconductivity.Efficient hot air drying up to 110 °C.Cooling fan to cool down after drying.Machine can work as a fully closed loop system withoutany waste drain.

•••

••

•••

MODULECLEANFlexible Cleaning System for all tasks and high throughputAdvantages of MODULECLEAN system• Automatic parallel transport system or robotic one which

allows select specific sequence of processes.Completely new design of process chambers providehigh efficiency. Big capacity on small place.Highest possible flexibility of configuration depending oncapacity, customer’s process and waste waterlimitations.Can be built totally to customer specification.Can combine different cleaning techniques and differentprocesses in one system.Can provide full process data traceability up to single PCBlevel.Can handle extremely heavy assemblies with tallcomponents.Very robust system for harsh plant environment incontinuous production. Cart as a sliding buffer for easy loading and unloadingoperation.System has its own re-cycling plant integrated.Rinsing with several cascade of DI water system can beconfigured.Easy capacity balancing by doubling of modules.

•

••

••

•

•

•

•

••

•

8

OptiCon SPI-LINE 3DIn contrast to other solder paste inspection systemsfor mounted PCBs, the OptiCon SPI-Line 3D impresseswith the exact measurement of the applied solderpaste.The fringe projection based three-dimensional imagerecording is operated without moving parts. Coreelement is a specifically developed 3D camera head.It guarantees a reliable solder paste monitoring, keepinginline cycle times thanks to optimised speed. The user-friendly software is self-explanatory, up-to-date and can be operated per touchscreen.

OptiCon TurboLineInline AOI System for High-End Inspection in LargeScale ProductionThe OptiCon TurboLine AOI system’s special featuresare opportunities for double-sided inspection as wellas various camera and illumination configurations.

It is possible to inspect the PCB bottom side withoutassembly turning. This is a decisive advantage overcommon AOI systems as inline speed is guaranteed.The rotatable angled-view and the segmented bandmodule also help for faster inspection.

OptiCon X-Line 3D3D in-line X-ray inspection system for maximum faultcoverage using digital tomosynthesis with outstandinginspection speed.

Benefits of the 3D X-Ray Inspection:• Safe inspection of double-sided assembled PCBs

Reconstruction of any layersSpatial allocation of detected faultsFast and user friendly test program generation byusing a single unified library

•••

9

FINEPLACER matrix maFlexible Asembly Platform• Placement accuracy better

than 3 μmComponent sizes from 0.125mmSupported substrate size up to12”Closed loop force controlLow maintenance, easy serviceaccessFast conversion from assemblyplatform to hot air solderingstation

•

•

••

•

FINEPLACER femtoAutomated Sub-micron Bonder• Placement accuracy 0.5

μmComponent sizes up to100² mm² Working area up to 450 x150 mm²Supports wafer up to 12” Bonding forces up to 500 NSmall footprint andcompact design

•

•

•••

Micro Assembly System

FINEPLACER lambda maSub- Micron Bonding Platform• Placement accuracy up to 0.5 μm

Component from 0.07 mm - 60 mmSupported substrate size up to 6”Closed loop force controlVery small footprint Compact and modular designHigh quality optics

••••••

Micro Assembly Processes• Thermocompression

ThermosonicUltrasonicSoldering (In, AuSn, C4, eutectic)Adhesive technologies (ACP, Curing)Mechanical assembly Curing (UV, thermal) Single Laser / Laser bar bondingVCSEL, photo diode assemblyLED bonding

•••••••••

Advanced Rework System

FINEPLACER coreIndustry leading cost effective rework• Automated soldering processes

Compact and robust designVision alignment system with Fixedbeam splitterIntelligent thermal managementReal time process observation cameraReproducible placement accuracyCoordinated control of all processparameters: temperature, flow, time,process environmentFast process development

••

••••

•

FINEPLACER pico rsHigh density rework• Automated soldering processes

Modular designVision alignment system with fixedbeam splitterIntegrated Process Management(IPM)Real time process observationcameraProcess transfer from system tosystemHigh level of application flexibilityHighest placement accuracy

••

•

•

•

••

Advanced ReworkApplications• BGA, µBGA, CSP, QFN,

PoP, QFP, PGA, Small Passives (0201,01005)RF shields, RF framesConnectors, socketsC4 Flip ChipReworkable Underfill,conformal coatingSingle Ball Rework

•

••••

•

10

PCB HANDLING EQUIPMENT

Automatic Loader/Unloader• Sturdy and stable design

User friendly ‘soft touch’ LED membrane control panelPneumatic clamps provided for magazine alignment Pneumatic pusher’s pressure regulatedHigh throughput with short magazine change-over timeSMEMMA compatible

•••••

Advance Platform Loader/Unloader• Touch screen panel enables swift adjustment for various types

of magazines in operationMulti-magazine type manual loading (quantity depends ondimension of magazine)Stores up to 10 different types of magazine dimensions.Suitable for ‘high-mix’, ‘low-volume’ operations.Servo motor drive for precise indexingPneumatic pusher’s pressure regulatedSMEMA compatible

•

•••••

Laser Marking Cell• 10 watt CO2 (Class 4)

Class 1 Laser Protected housingAir Cooling SystemFume Extraction SystemUser friendly softwareDigitally controlled linear axis for X & Y movementsSlectable by-pass operationAutomatic width adjustment conveyorPCB side clamping PCB lifting system for constant focal pointShort product chang-over timeBarcode scanner or camera for readability checkIndustrial PC & 17” LCD monitorSMEMA compatible

•••••••••••

•

11

Customer Evaluation Results

NIX 3D PCB Cleaner

POWER CYCLONE 3D• Inline, quickly and efficiently removes dust and particulates

from PCB surface before solder application Reduce defects with Power Cyclone's high removal rate •

The NIX Power Cyclone 3D provides unprecedenteddust and particle removal performance to dramaticallyreduce bleeding, bridges, missing solder, insufficientsolder, and other defects caused by particulates.

12

MuCOM CM MuCOM CM∑

Micro-Dispensing at ITS BEST!

Throw Out the Hassle ofCleaning and Costly Wastage!

The PATENTED Sigma Functions of SUPER CMII:

Automatic Fluid Drip Prevention The automatic vacuum control system prevents fluid drips and aeration

Automatic Correction of Water Head Variation The function eliminates variations in dispensing volume that are causedby water head differences, giving incredible accuracy especially for largesyringe sizes.

Automatic Level Alarm Accurate detection of remaining quantity of fluid in syringe

The PATENTED Sigma Functions of SUPER CMII:

INCREDIBLE HIGH SPEED NON-CONTACT DISPENSING

SUPER CMII HIGH PERFORMANCE PRECISION DISPENSER

SUPER CMII∑

Wide Range of Dispensers for Every Application

13

Mapping Function / Camera Teaching Dispensing / Measuring / Observing

Create DispensePatterns via ourTouch Screen

One CommandDeviationCorrection

14

UV LED TECHNOLOGY

LINE SHAPE IRRADIATION

EXECURE-H-1VC II

H-1VH

STANDARD UV LED Spot UV LED • Multi-drive of up to 8X head units

Match with various HOYA UV LED LensIndividual control of intensity and time for each channelLong life time of head unitLow power consumptionSmall footprintHigh intensity multi-chip typeSpecial elliptical irradiation shape

•• •••••

H-1VH4-V1 + YA4-G1

H-1VH4-V1 + H04-D12L

MULTI-CHIP UV LED

H-1VH4-V1 + H04-W16L

MULTI-CHIP UV LED (ELLIPTICAL)

Large Area UV LED • Multi-drive of high intensity LED chip

Customized irradiation shape to suitdifferent applicationsProgrammable irradiation intensity andtimeLong life time of head unitCertified CE markingStandard fan cooling or high intensitywater cooling models availableExternal controller for machineinterfacing

•

•

• • •

•

SQUARE SHAPE IRRADIATION

15

UV LAMP LIGHT SOURCE EXECURE 4000

• Flexible layout – vertically or horizontallyLarge reduction in apparent power, compatible with worldvoltagesConvenient and easy filter settingAdaptable to wide variety of light guides such as multi-branch,special shape and fusion type are possibleComes with standard 200W Mercury Xenon lamp, guaranteedlamp life of 3,000 hours Easily connected to PC through RS485 port for aperturesettings, program patterns, etc

•

•

•

•

•

UL 750 • Balanced high power and long life at its class

Comes with high output 750W Super High Pressure Mercurylamp, guaranteed lamp life of 2,000 hoursSuitable for high power UV applicationsAdaptable to light guides or direct irradiation lens unit

•

• •

UV Accessories • Custom fiber optic light guide for various UV applications.

Multi-branches to maximize throughputCustom lens to achieve required intensity profileCustom UV filters to cut unwanted wavelengthSimple UV power meter for intensity measurementUV protective goggles

• • • •

EXECURE 4000

UL 750

Major UV Applications • Assembly of image sensor, lens unit and LCD panel for digital camera

Assembly of HDD for personal computerAssembly of camera module, touch panel and image sensor for smart phoneAssembly of injection needles, catheter and optical fiber for medical industryAssembly of optical pick-up lenses unit for CD, DVD and Blu-raySealing, printing and coating for electronics industry

• • • • •

16

PREEFLOW Series

EcoPEN / EcoDUO

ViscoDuo-V

ViscoMT-XS

ViscoTreat-Inline

ViscoDuoV-4/4ViscoTreat-lm

Unique Low FluidCharge PressureDosing

Very High ToLow Viscosity

2-Part FluidsPrecise Mix andDispense

17

ViscoMT-CCartridge emptying

ViscoMT-DPail emptying

ViscoMT-XSBucket emptying

ViscoMT-LBarrel emptying

ViscoTreat-InlineInline degassing

ViscoTreat-RMixingand circulating

ViscoTreat-HHydraulic accumulator

ViscoPro1-componentdispenser

ViscoDuo-V2-componentdispenser

ViscoDuo-V 4/42-componentdispenser for thesmallest volumes

Just Imagine a piston.

Or even better, several pistonsbehind each other.

Now we’ll make the wall thicknessof the piston zero...

and change the piston shapeslightly.

Volla - the endless piston principle!

The working Principle of Viscotec corresponds to an Endless PistonDeviceThis allows an endless, precise Pulse-free dispensing flow unlikeother conventional methods of dosing.

All manner of fluids, whether with Fillers, high/low viscosities arehandled efficiently with

• High Precision, Low Shear Stresses•

and importantly,

• Very Low Fluid Charge Pressures

Applied Industries:

Automotive, Electronics, Photovoltaic, Aviation, Cosmetics, Food and Beverage, Pharmaceuticals (Sterile)

Emptying systems + Preparation systems + Dosing systems

18

19

20

Anaerobic AdhesivesUV Curing Anaerobic Structure Bonding AdhesivesHeat Curing Impregnation MaterialsUV Curing AdhesivesActivator Curing/ 2-parts Modified Acrylic AdhesivesSolvent type AdhesivesOne Part Heat Curing Epoxy AdhesivesActivator/ PrimerOther Adhesives (Customised to Requirements)

For wide area UVhardening and surfacetreatment.

Large Xenon Short Arc Lamp

SSD Lamp For inspection processsuch as liquid crystal andsemiconductor

Compact Xenon Short Arc Lamp For wafer inspection andchemical analyticalinstrument in semiconductorindustry

Compact Xenon Short Arc LampFor wafer inspection andchemical analytical

Compact Short Arc Lamp For UV Spot-Cure Systems.

Widely used in entertainmentindustry, from studio lighting,imaging projector, solarsimulator, lamplight device,fish luring etc.

Large Short Arc Lamp Widely used in PCB, LCD andPDP industry.

21

LONG ARC LAMPS

THE WORLD’S FIRST CLEAN-ROOM CLASS 10

COMPLIANT PRESS MACHINE!

• Automatic screw feedingHandles various screw typesEasily replaceable Rails for screw changesHigh productivityImproved flexibility

• • • •

ELECTRO PRESS JP Series

QUICHER AUTOMATIC SCREW FEEDER

NS - Series NJ - Series

NEJIKURA - Series

Examples of Screws which can be fed

• Driven By AC Servo Motor. Clean, Quiet and Efficient.• Stand Alone, Head, Unit Types with 5kN to 80kN Pressing Capacity• High Accuracy, Capability and Multi-functional• Various Modes of Press Conditions Selectable• Low Impact, High Yield and Productivity• Complete Quality Control, Production and Process Traceability with complete process records.• Touch Panel Display and Large LCD screen• Self-Diagnosis function or Errors

22

SPECIFICATIONS at a GlanceForce Measuring Range 0 - 250 grams

Speed 100 - 600 + 5mm/minute in 50mm increments Angle 160-180 degrees

Accuracy + 3% Tape Widths 8, 12, 16, 24, 32, 44, 56mm (optional 8 to 120mm)

Dimensions 318mm H x 368mm W x 737mm D x 29.5kgAC Input 100 – 240 VAC PC/Laptop Control Windows based proprietary FORCEWare™ Software, Data capture, SPC Analysis

23

DOU YEE ENTERPRISES

PRODUCTS & SERVICES

Our manufacturing plants, located in Singapore, Malaysia (Seremban), China (Suzhou) and France are governed by consistent quality systems with ISO 9001:2015 and ISO 14001:2015 certifications.

Electrostatic Discharge ControlMicro Contamination ControlDry Packaging / Electronic Packaging MaterialsElectronic Equipment and ToolsBio MedicalChemical for Electronics IndustryPersonal Protective EquipmentNano Composite Materials

SINGAPORE (HQ) MALAYSIA CHINA (Suzhou) FRANCE

A premier total industrial solutions provider in the Asia Pacific region, serving with distinction the semiconductor, data storage, electronics and biomedical industry since 1982.

We have 42 international branch o�ces strategically located around the world to give customers the fastest and most accessible products and services.

www.douyee.com>

S3_GC

201307EN_28pp_

.01.20_updated

HEAD OFFICE Singapore2304 Bedok Reservoir Road, Bedok Industrial Park C, Singapore 479223Tel : (65) 6444 2678 • Fax : (65) 6743 7172 • Website : www.douyee.com • Email : [email protected]

DOU YEE ENTERPRISES GLOBAL NETWORK

More than 42 offices

Sales Agent:

scan QR code for E-catalogue

HEAD OFFICE

More than 42 offices42 offices42 Across 23 countries23 countries countries23

MALAYSIAJohor BahruTel : +607 556 6284 / 558 6285 Email : [email protected]

MalaccaTel : +606 231 5060/61/62/64 Email : [email protected]

Kuala LumpurTel : +603 5121 1613 / 14 Email : [email protected]

PenangTel : +604 390 4824 Email : [email protected]

IpohTel : +605 2911853 Email : [email protected]

SarawakTel : +082 262518Email : [email protected]

PHILIPPINESManilaTel : +63 2 8807 4683 / 84 / 85 Email : [email protected]

CebuTel : +63 32 341 1577 Email : [email protected]

INDONESIAJakarta Tel : +6221 8990 1153 Email : [email protected]

BatamTel : +0117 7061 2490 Email : [email protected]

Hong Kong SARTel : +852-2480 6337 Email : [email protected]

THAILANDPathum ThaniTel : +662 529 0979 Email : [email protected]

VIETNAMHo Chi MinhTel : +848 3910 4420 Email : [email protected]

HanoiTel : +844 6275 4337 Email : [email protected]

JAPANYokohamaTel : +8145 312 9906 Email : [email protected]

SOUTH KOREAIncheon Tel : +82 10 26984161 Email : [email protected]

UNITED STATESTruckeeTel : +530 320 1313 Email : [email protected]

Murphys Tel : +209-822-0121Email : [email protected]

UNITED KINGDOM - ENGLANDExeterTel : +44 (0) 139 235 7548Email : [email protected]

FRANCEToulouseTel : +33 5 61 16 20 50Email : [email protected]

Pont de PoitteTel : +33 (0) 3 84 87 02 39Email : [email protected]

NETHERLANDS - BENELUX GeldropTel : +31 (0) 886 363 555 Email : [email protected]

NORWAYHortenTel : + 47 93829207Email : [email protected]

AUSTRIAWienTel : +43 6601414926Email : [email protected]

SWEDEN - NORDICSHandenTel : +46 (0) 10 690 06 20Email : [email protected]

LATVIARigaTel : +371 200 188 37Email : [email protected]

POLANDDlugolekaTel : + 48 71 750 04 80Email : [email protected]

CZECH REPUBLICBrnoTel : +420 724 317 455Email : [email protected]

SLOVAKIABratislavaTel : +421 908 581 747Email : [email protected]

HUNGARY - ROMANIABudapestTel : +36 70 609 4216Email : [email protected]

CHINAShanghaiTel : +86-21-5899 4619Email : [email protected]

SuzhouTel : +86-512-6258 5066Email : [email protected]

BeijingTel : +86-10-8368 6931Email : [email protected]

DalianTel : +86-411-8377 9193 Email : [email protected]

ChengduTel : +86-28-8501 7691 Email : [email protected]

Xi’anTel : +86-29-8824 7085Email : [email protected]

ShenzhenTel : +86-755-8389 0255Email : [email protected]

NanJingTel : +86 025-58826689Email : [email protected]

XiamenTel : +86 180-20737052Email : [email protected]

Taiwan, TaipeiTel : +886-2-27151156 Email : [email protected]

Taiwan, HsinChu Tel : +886-3-5670698 Email : [email protected]

21

![SLM n.o.slm.sk/wp-content/uploads/Skus_1.pdfAnnex is an integral part of Certificate of Accreditation. evidence Of to the activity by Of the Accreditation granted on 14.01.20]9 is](https://static.fdocuments.in/doc/165x107/5f793f5cbbb229203c2108eb/slm-noslmskwp-contentuploadsskus1pdf-annex-is-an-integral-part-of-certificate.jpg)